Special clamp suitable for assembling and welding of multiple specifications of vertical plates and multiple round pipes

A special fixture, multi-specification technology, applied in the field of tooling fixtures, can solve the problems of complex procedures, low efficiency, labor-intensive, etc., and achieve the effects of ensuring processing quality, reducing production costs, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention will be further described below in conjunction with the accompanying drawings, so as to help understand the content of the present invention.

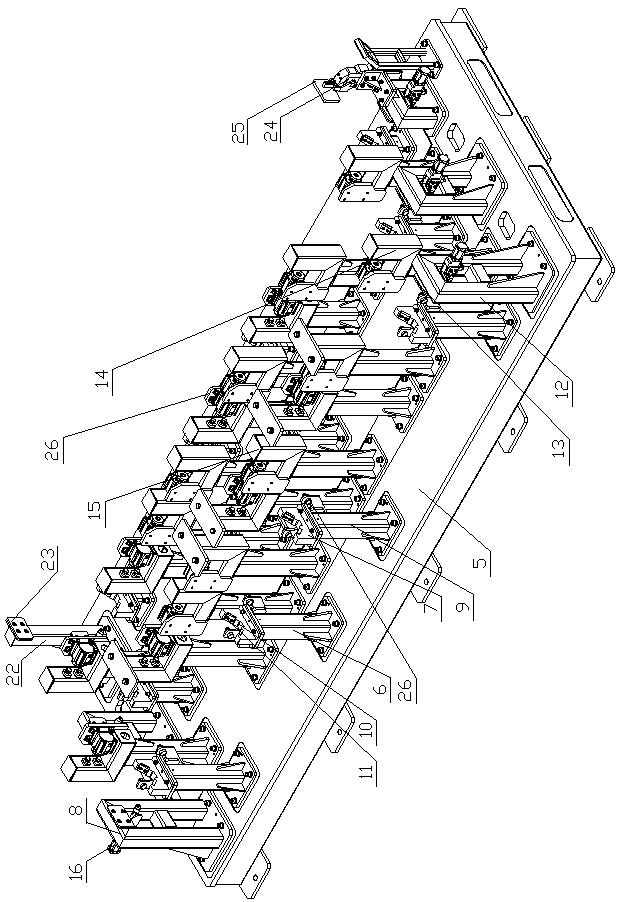

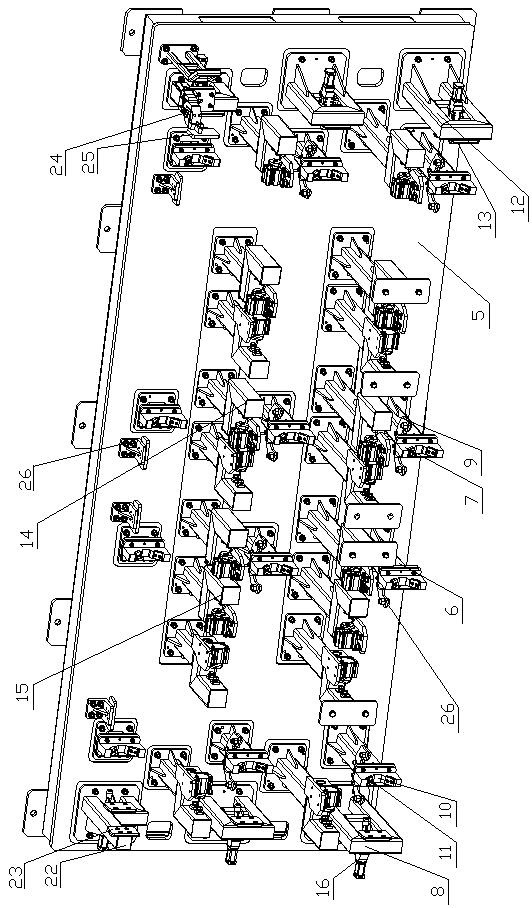

[0020] Such as Figure 1-4 As shown, a special fixture suitable for tailor welding of multi-standard vertical plates and multi-round tube groups is used for three first round tubes 1 with ear plates 3, a second round tube 30 without ear plates and nine The clamping and positioning of the first vertical plate 2, the first round tube 1 is arranged in steps from front to back, and the ear plate 3 on the first round tube 1 is provided with an ear hole 4.

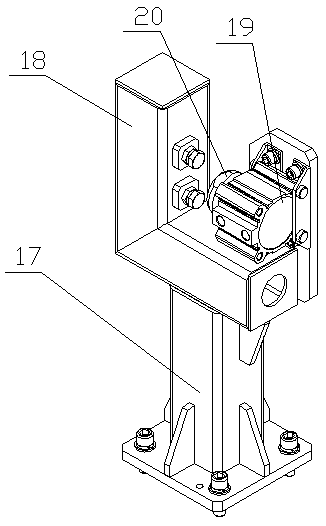

[0021] The special fixture includes a support platform 5, on which three sets of hosting assemblies 6 are arranged in parallel and at intervals, the hosting assemblies 6 are used to support the round pipe 1, and the ear plate 3 of the first round pipe 1 supported on the hosting assembly 6 is arranged downwards The hosting assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com