Combined type roller for rolling wave form corrugated composite boards

A composite plate and combined technology, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of low bonding strength of composite plate, easy cracking of composite plate, long production cycle, etc., to avoid plate run Offset problem, shortening roll processing and assembly cycle, and improving the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

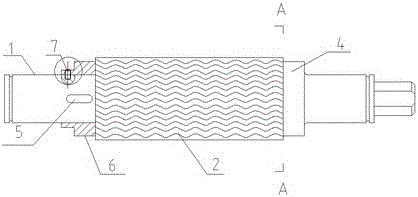

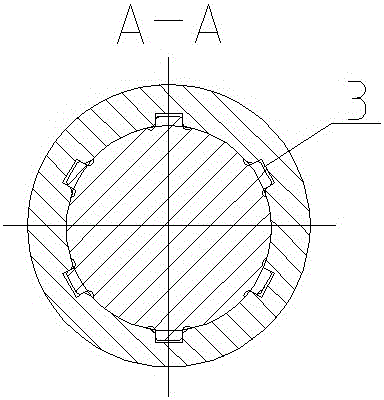

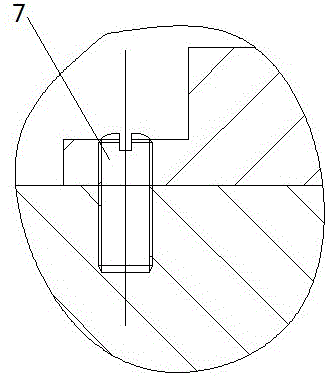

[0017] Such as figure 1 As shown, it can be seen from the figure that a new type of combined roll for rolling wave-shaped corrugated composite plates according to the present invention is used for rolling metal composite strips with wave-shaped corrugations, and its structural features include roll shafts (1) , composed of a roller sleeve (2) with an internal spline groove, a flat key (5), a locking retaining ring (6) and a screw (7) matched by a spline (3); it is used for rolling corrugated Metal composite strip, the outer peripheral surface of the 65Mn roller shaft (1) is continuously cut and processed by a high-precision CNC spline milling machine to have wave-shaped corrugations perpendicular to the roll axis and continuously distributed on the outer surface of the roll shaft. Continuous grinding on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com