Connecting structure of shaft-mounted brake disc and disc hub of railway vehicle

A rail vehicle and brake disc technology, applied in the direction of brake discs, brake components, brake types, etc., can solve problems such as reducing service life and affecting the safety of brake discs in service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

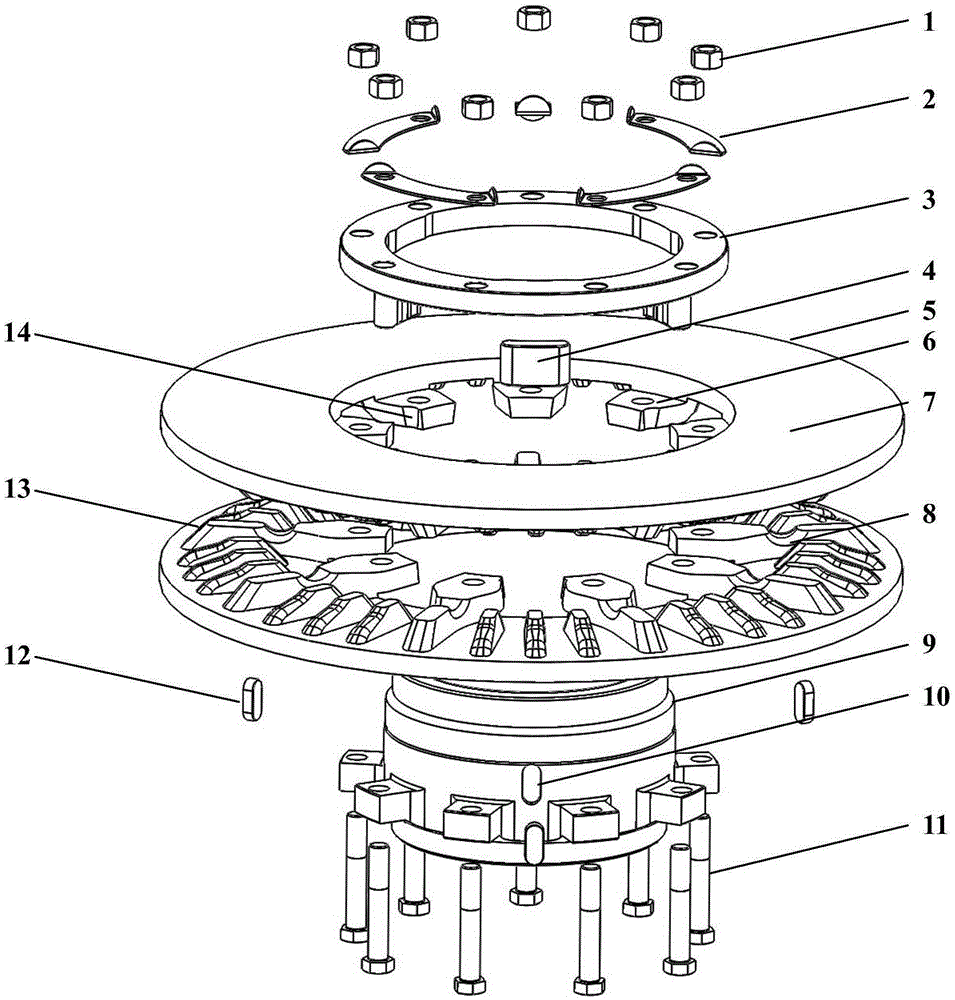

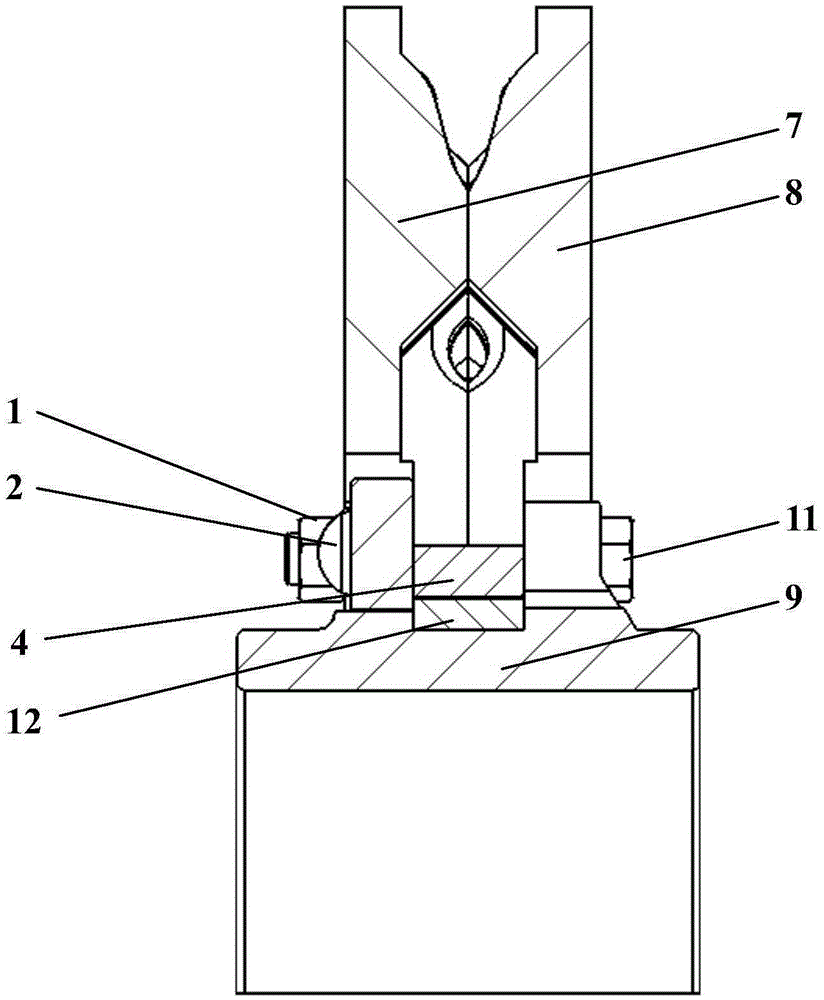

[0018] The connection between a rail vehicle shaft-mounted brake disc and the disc hub is shown in the appendix figure 1 , a rail vehicle shaft-mounted brake disc, comprising a hub (9), a disc body (7) and a disc body (8), the disc body is composed of a flange (6), a friction ring (5), a cooling rib (13) Form a whole.

[0019] A rail vehicle shaft-mounted brake disc, which adopts a spliced disc structure, and a complete set of brake discs includes identical disc bodies (7) and disc bodies (8), all of which are made of low-alloy forged steel materials and formed into The way is forging. The height of the disc body after assembly is 80mm.

[0020] The friction ring (5) of the disc body (7, 8) has a thickness of 22 mm, an outer diameter of 640 mm, and an inner diameter of 350 mm.

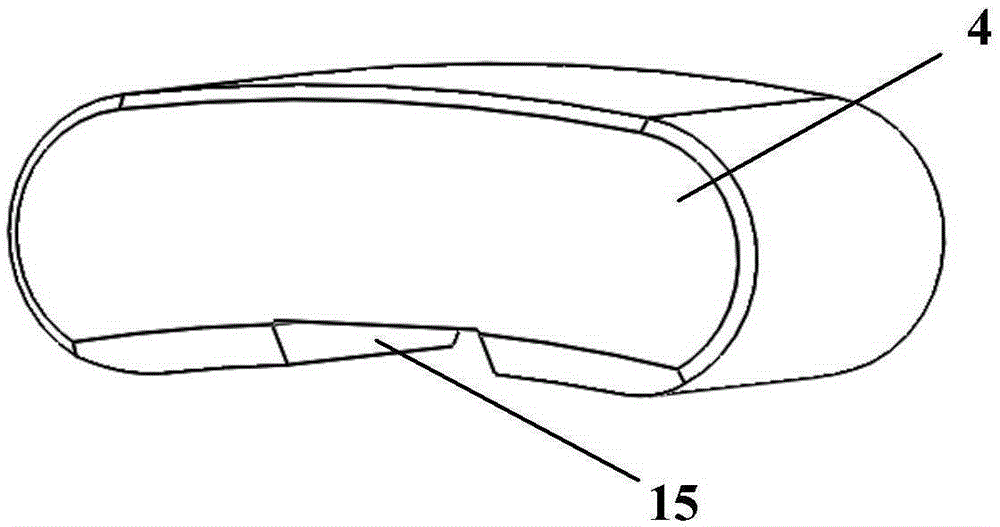

[0021] The flange (6) has 10 Φ28mm through-holes evenly distributed in the circumferential direction, and 3 pairs of U-shaped grooves (14) are evenly distributed in the circumferential direction b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com