Dissimilar metal rivet welding connecting device, notch rivet and control method

A technology of riveting and welding joints and dissimilar metals, applied in rivets, welding equipment, metal processing equipment, etc., can solve problems such as excessive deformation of connectors and notch rivets, inability to suppress brittle metal riveting cracks, lack of mold-assisted deformation, etc. , to achieve the effect of increasing the contact boundary of riveting and welding, improving the condition of welding interface and improving the stability of riveting and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

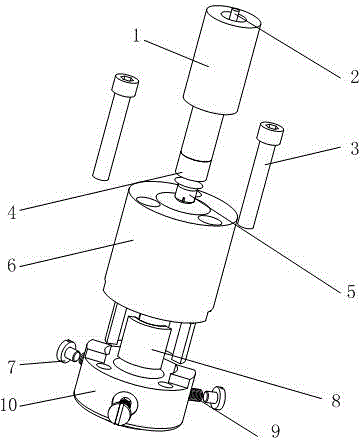

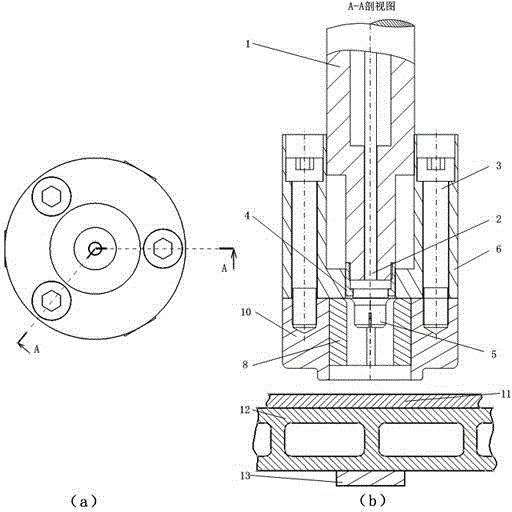

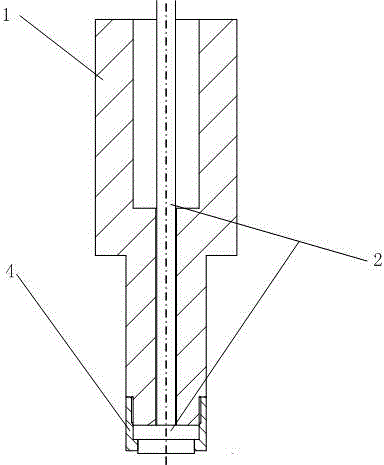

[0031] Such as figure 1 with figure 2 As shown, the dissimilar metal rivet welding connection device of the present invention includes an impact electrode, a guide member 6, a spring press block mechanism, a binder ring 10, a notch rivet, and a deflector 13, wherein the impact electrode, the guide member 6, and the binder ring 10 , the plate parts 11 to be connected, the structural parts 12 to be connected, and the deflectors 13 are arranged from top to bottom. The impact electrode, the guide 6 and the blank holder 10 are coaxially arranged, the guide 6 is a hollow columnar structure, the impact electrode is matched with the inner hole of the guide 6, and the notch rivet is positioned by the spring pressing mechanism in the binder 10 , the impact electrode is connected to the positive pole of the power supply through a wire, the impact electrode can slide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com