Robot clamping device

A clamping device and robot technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of clamping device action and joint rotation not flexible enough, application level is difficult to play, and manufacturing cost is high, so as to achieve easy operation and Maintenance, easy processing, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment takes the clamping arm as an example with a two-layer structure to describe the following.

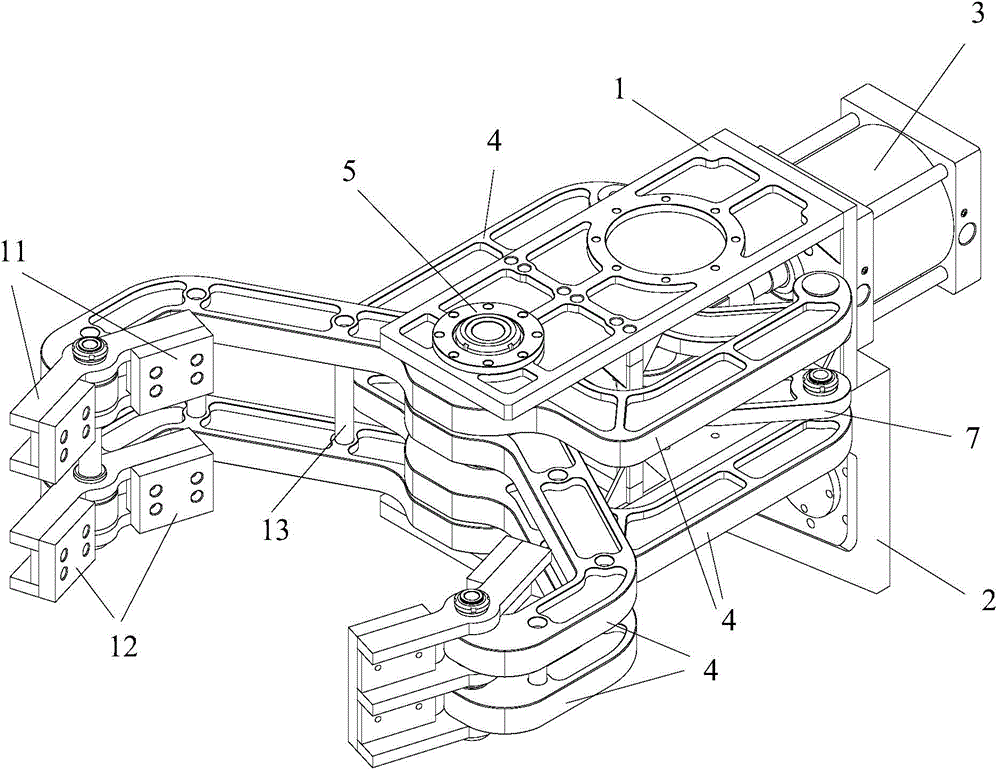

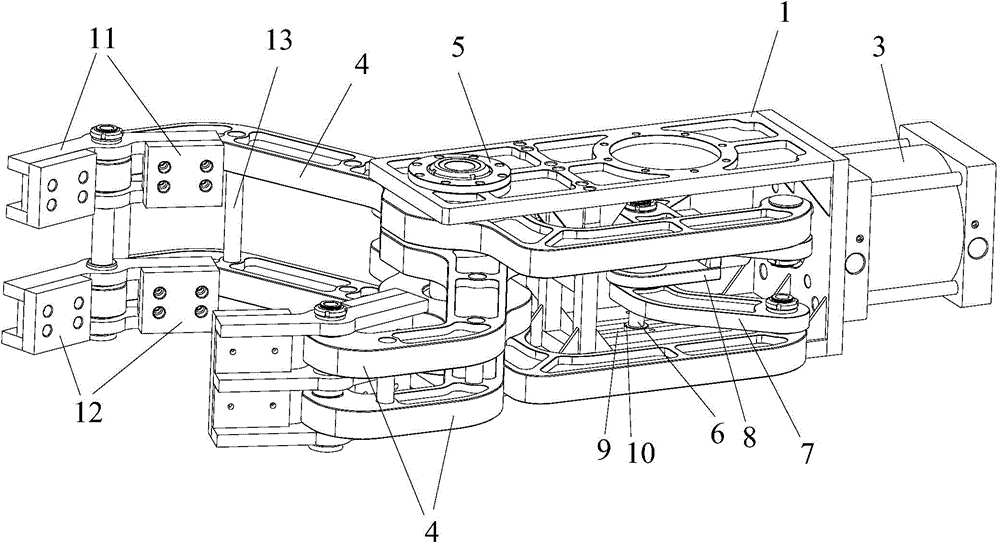

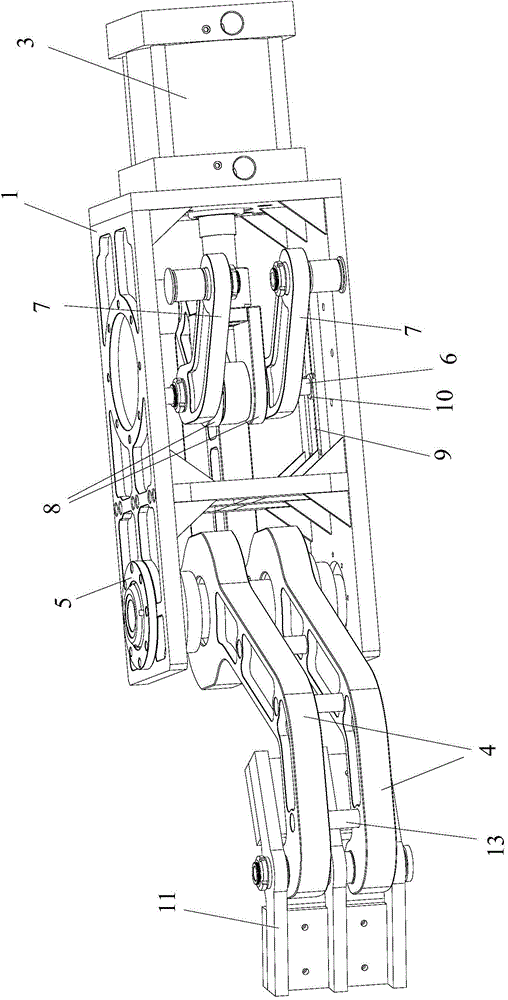

[0027] like figure 1 , figure 2 and image 3 As shown, the robot clamping device of the present invention is installed on the front end of the mechanical arm of the robot for clamping the workpiece; the clamping device includes a main frame 1, a connecting seat 2 for connecting with the front end of the mechanical arm, and The connection mechanism inside the frame 1, the driving mechanism 3 for driving the movement of the connection mechanism, the control mechanism and the clamping arm 4; wherein, the connecting seat 2 is arranged on the main frame 1, and the two clamping arms 4 are arranged on the main frame in a cross form. Both sides of the frame 1, and one end is hinged with the connecting mechanism. The intersection is the connecting shaft 5 arranged at the front end of the main frame 1, and the two clamping arms 4 are rotatably connected to the connecti...

Embodiment 2

[0034]The only difference between this embodiment and Embodiment 1 is that the two clamping arms can be set to a single-layer structure, a three-layer structure or a structure with more than three layers, and in the clamping arms with a three-layer structure or a structure with more than three layers , each structure is connected by connecting rods. The design of the multi-layer structure of the clamping arm can increase the contact area between the clamping arm and the workpiece, thereby further improving the clamping force of the clamping device.

[0035] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com