Plastic-coated pipeline carrying hanger

A technology of pipes and spreaders, which is applied in the field of spreaders, can solve the problems of inconvenient picking and handling, and achieve the effect of stable and reliable clamping and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

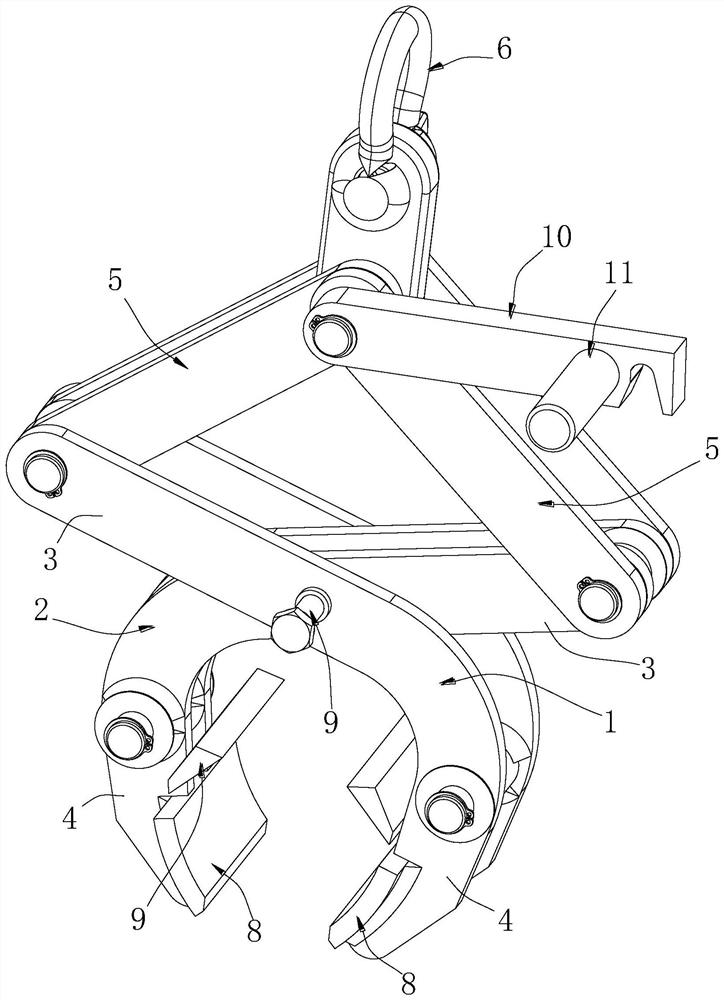

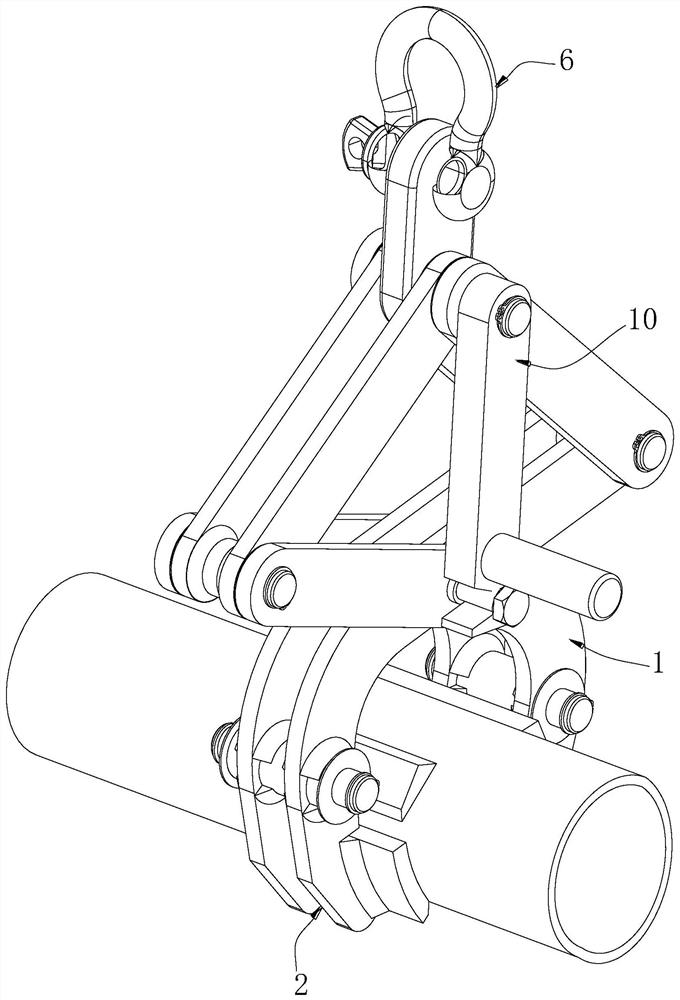

[0022] refer to Figure 1-2 , a plastic-coated pipeline handling sling, including a first clamping arm 1 and a second clamping arm 2 that are both L-shaped, and each of the first clamping arm 1 and the second clamping arm 2 has a connecting arm 3 and a clamping arm 4. The connecting arms 3 of the first clamping arm 1 and the second clamping arm 2 cross each other and are hinged together, the end of the clamping arm 4 is downward, and the L of the first clamping arm 1 and the second clamping arm 2 The curved opening of the type is arranged obliquely downward, and the outer ends of the connecting arms 3 of the first clamping arm 1 and the second clamping arm 2 are respectively hinged with a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com