Plastic knitting cloth water jet loom

A technology of plastic woven cloth and water-jet loom, which is applied in the direction of looms, textiles, mechanical equipment, etc., to achieve the effects of high weft flying speed, compact structure, and fast water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

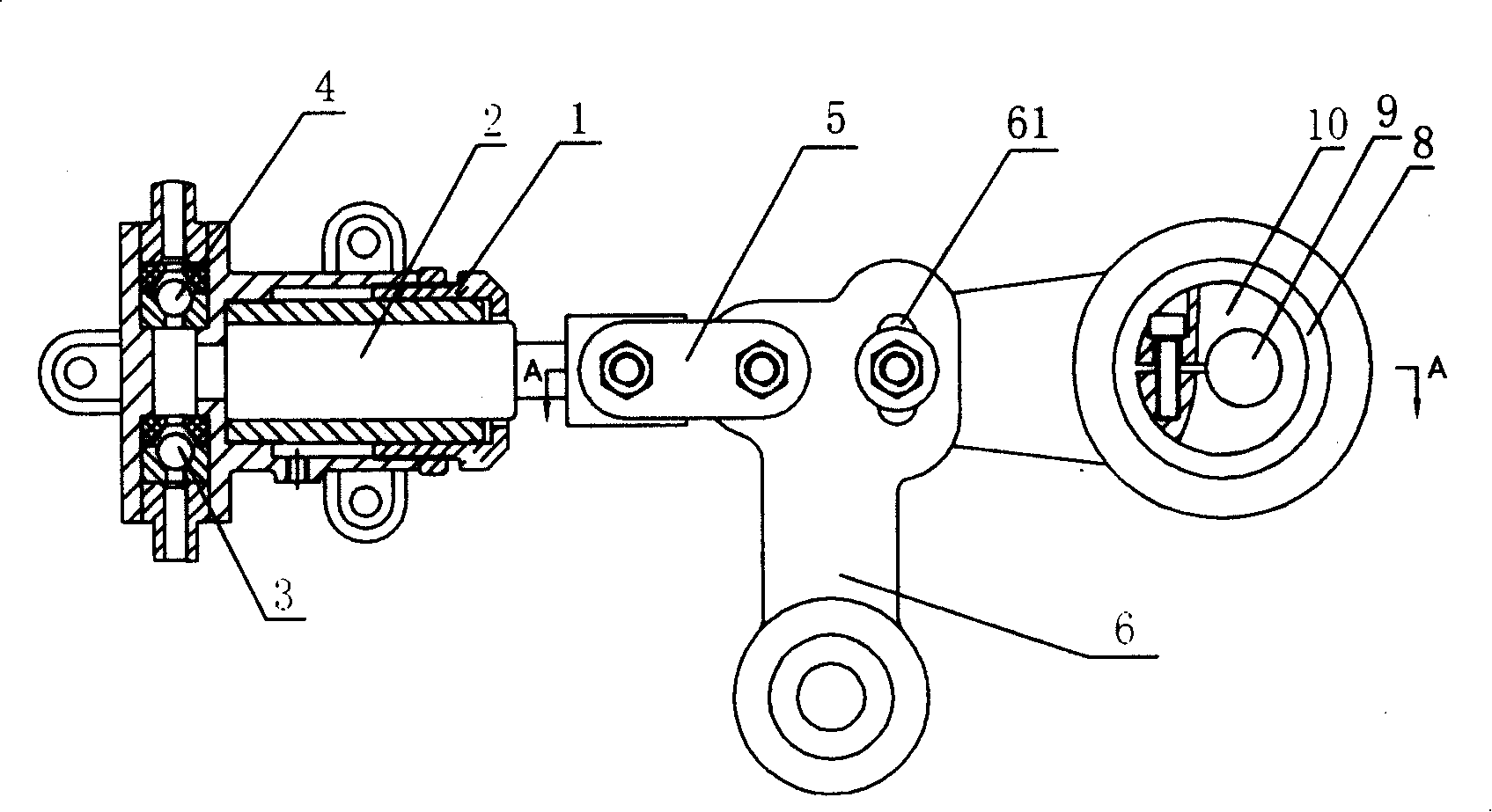

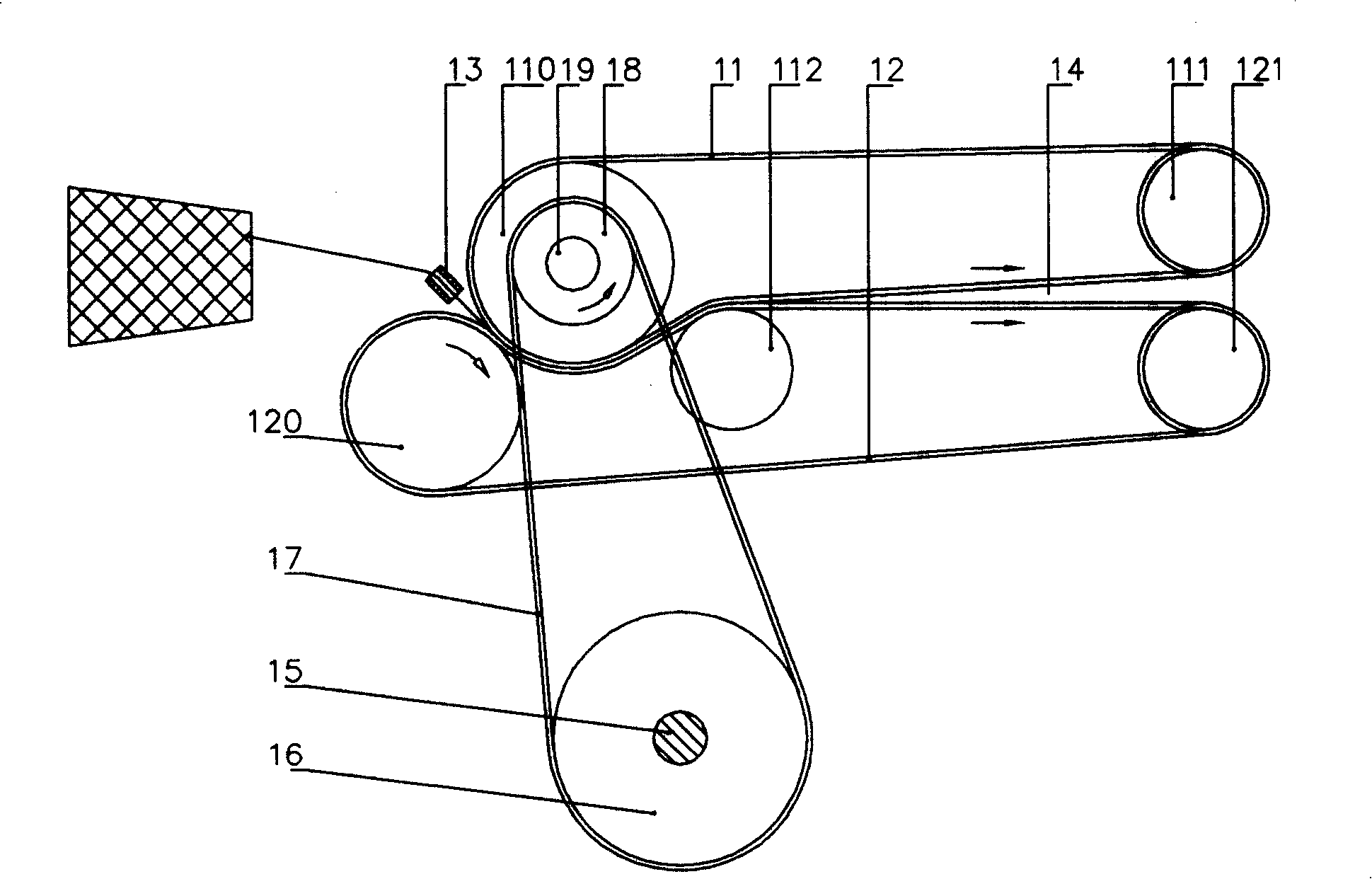

[0020] The plastic weaving water-jet loom of the present invention, its opening mechanism, weft insertion mechanism, weft beating mechanism, let-off mechanism, coiling mechanism and other auxiliary mechanisms, etc., except the following technical content, all can adopt the prior art. The technical characterictic that the present invention contributes to prior art is explained emphatically below:

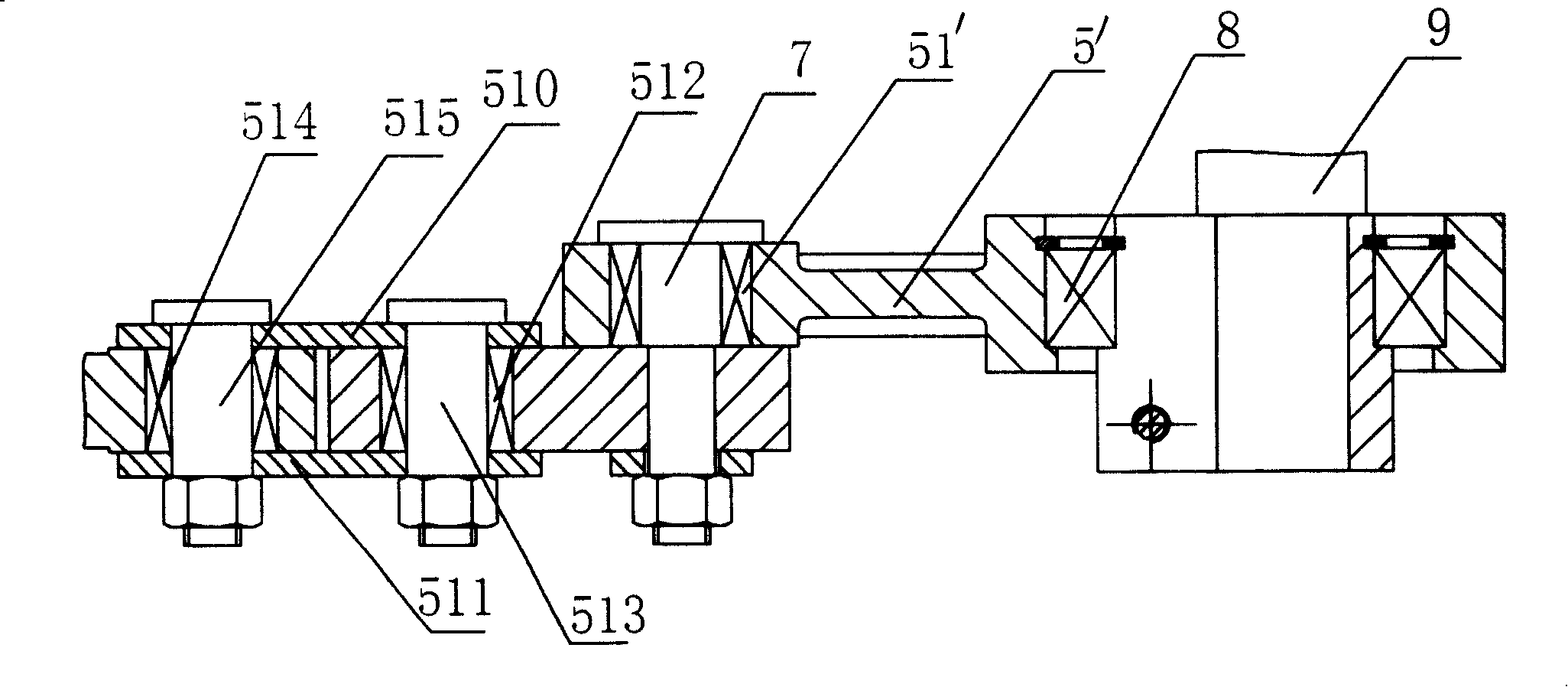

[0021] combined reference figure 1 , 2 , The jet water pump in the weft insertion mechanism includes a pump body 1, a plunger 2, a water inlet valve 3, and a water outlet valve 4. The plunger 2 is equipped with a direct-acting push rod 5, which is a clamping structure formed by two side wall plates 510, 511, and a rolling bearing 512 is arranged at the junction of the supporting swing rod 6, and the rolling bearing 512 is located on the two side wall plates Between the two side wall plates 510, 511, a connecting shaft hole is set at the corresponding place, and the shaft column 513...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com