Round material mechanical grabbing system

A technology for mechanical grasping and materials, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unreliable clamping, fixed clamping range, and uncompact structure, etc., to achieve stable and reliable clamping, avoid jamming, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

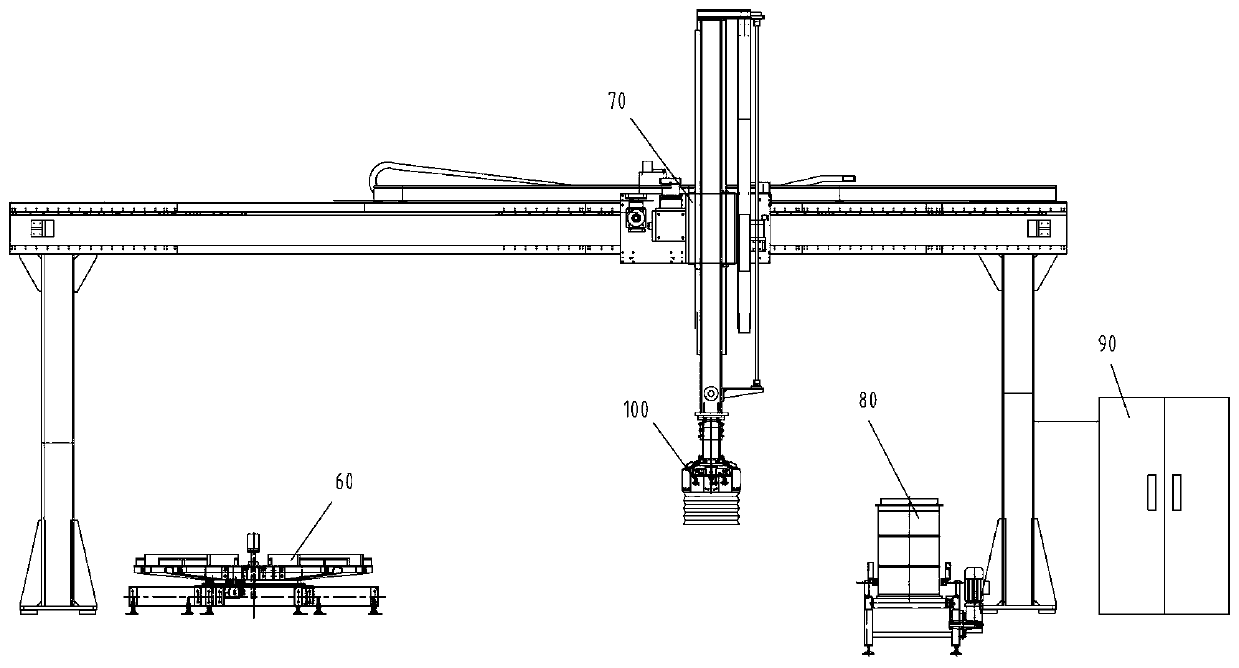

[0026] The circular material mechanical grasping system of this embodiment is as follows: figure 1 As shown, the system includes a steel drum conveying roller table 80 and a material storage table 60 spaced apart from each other. Above the conveying roller table 80 and the material storage table 60, a truss composed of guide rail beams supported on columns at both ends is installed. The truss is equipped with A manipulator 70 that can move horizontally, the manipulator 70 has a lifting arm with a circular material mechanical grasping device 100 at the lower end.

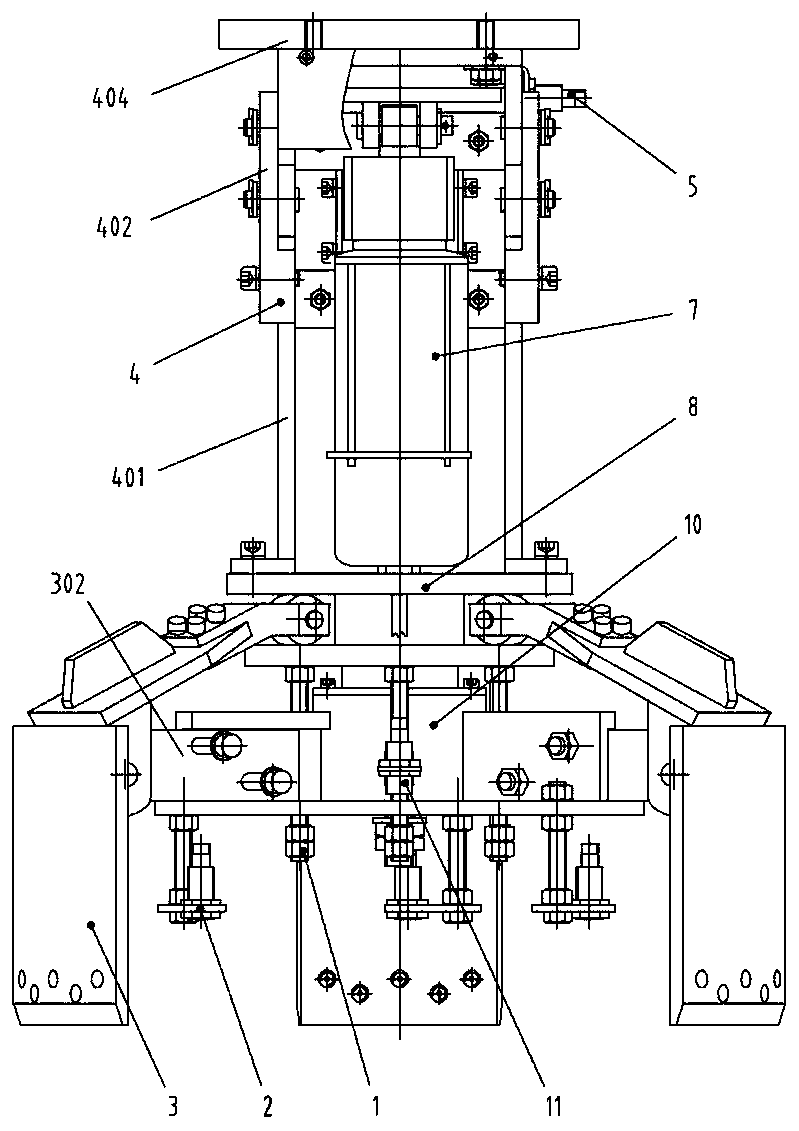

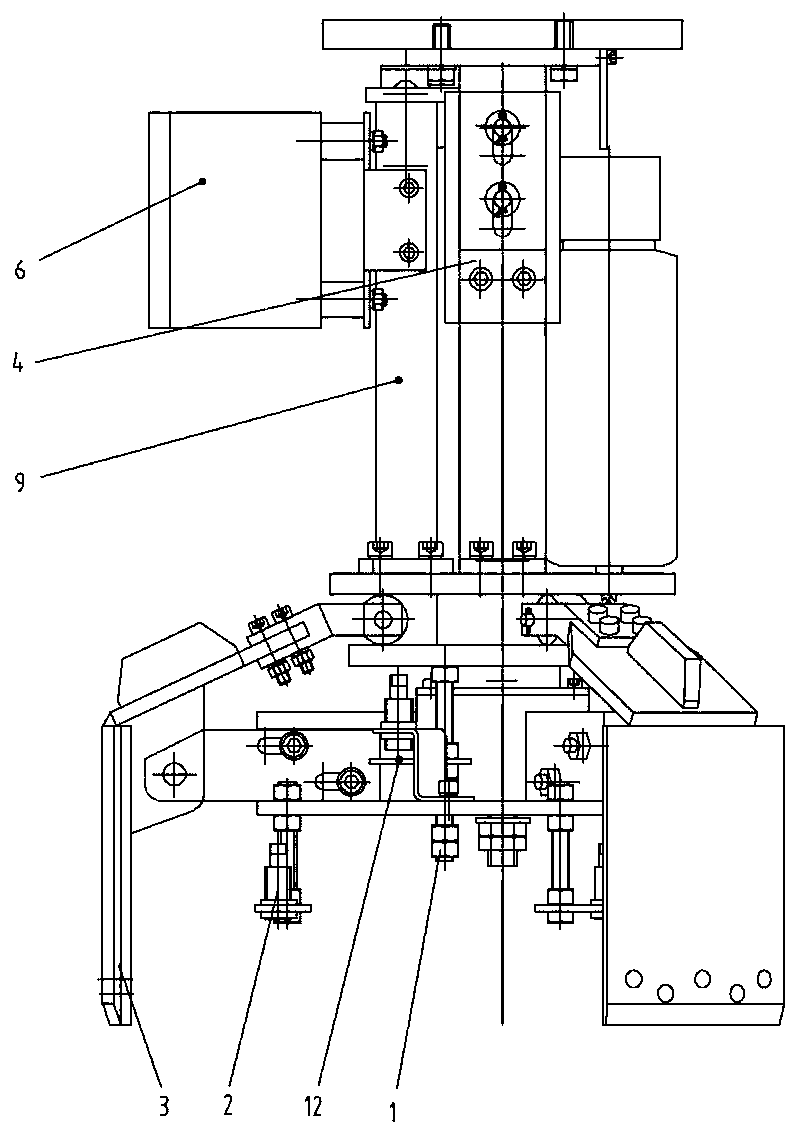

[0027] The specific structure of the circular material mechanical grasping device 100 is as follows: Figure 2 to Figure 6 As shown, it includes a telescopic support 4 whose upper end is fixedly connected to the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com