Hydraulic and pneumatic combined clamping device for machining shell

A clamping device, liquid and gas technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large workpiece shape and position errors, difficult quality control, etc., achieve uniform force on the workpiece, and improve production efficiency , Interchangeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

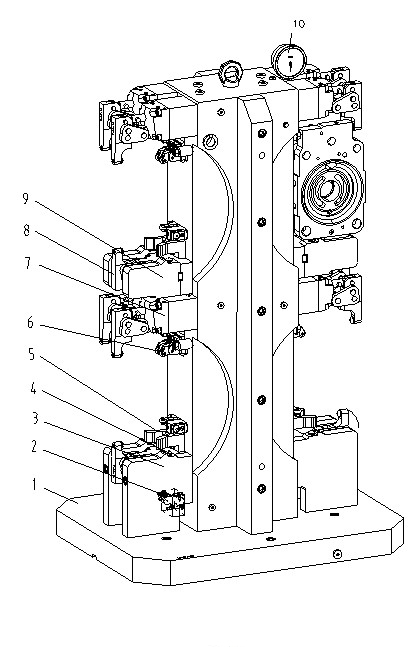

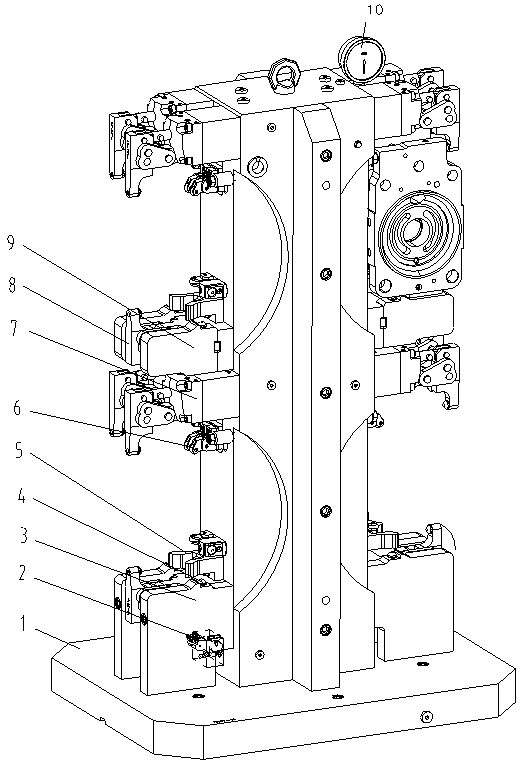

[0015] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0016] Please refer to the figure, a hydraulic-gas combined clamping device for shell processing, including: a base 1, which is an inverted T-shaped structure, that is, composed of a bottom horizontal chassis and a longitudinal support column located on the chassis; the lower part of the base The horizontal chassis cooperates with the loading platform and is centered by the middle taper pin, and fits with the four taper pins with a gap of 0.005mm-0.008mm. Four pairs of hydraulic cylinders 7 are symmetrically arranged on the left and right sides of the support column; two pairs of hydraulic cylinders are located at the top of the support column, and the other two pairs of hydraulic cylinders are located in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com