Patents

Literature

57results about How to "Accurate clamping position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Connector product test device

ActiveCN103018608ANot easy to damageReduce manufacturing costElectrical testingMeasurement instrument housingTest efficiencyElectricity

The invention discloses a test device, in particular to a connector product test device which is high in test accuracy, reduces test cost and improves test efficiency. According to the connector product test device, a test pin is adopted to replace the test connector in the prior art for product testing, is arranged on a movable carrier and is electrically connected with a test terminal. During testing, the carrier moves by aid of manual operation or through a power device and drives the test pin to move in the direction of a connector to be tested, and finally the tail end of the test pin is contacted with a metal sheet of the connector to be tested to achieve testing. The connector product test device is widely applied to the connector test field.

Owner:珠海市运泰利自动化设备有限公司

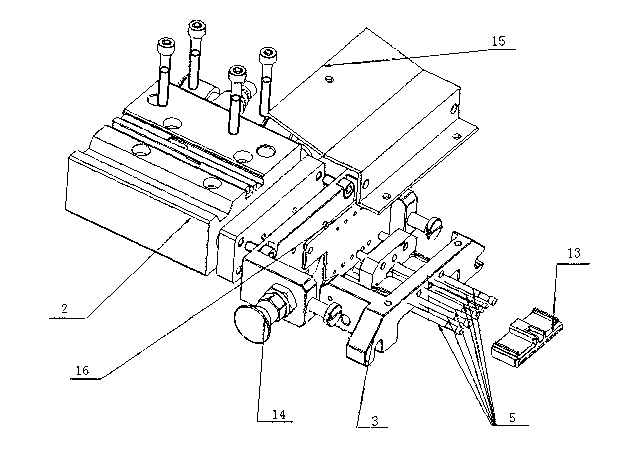

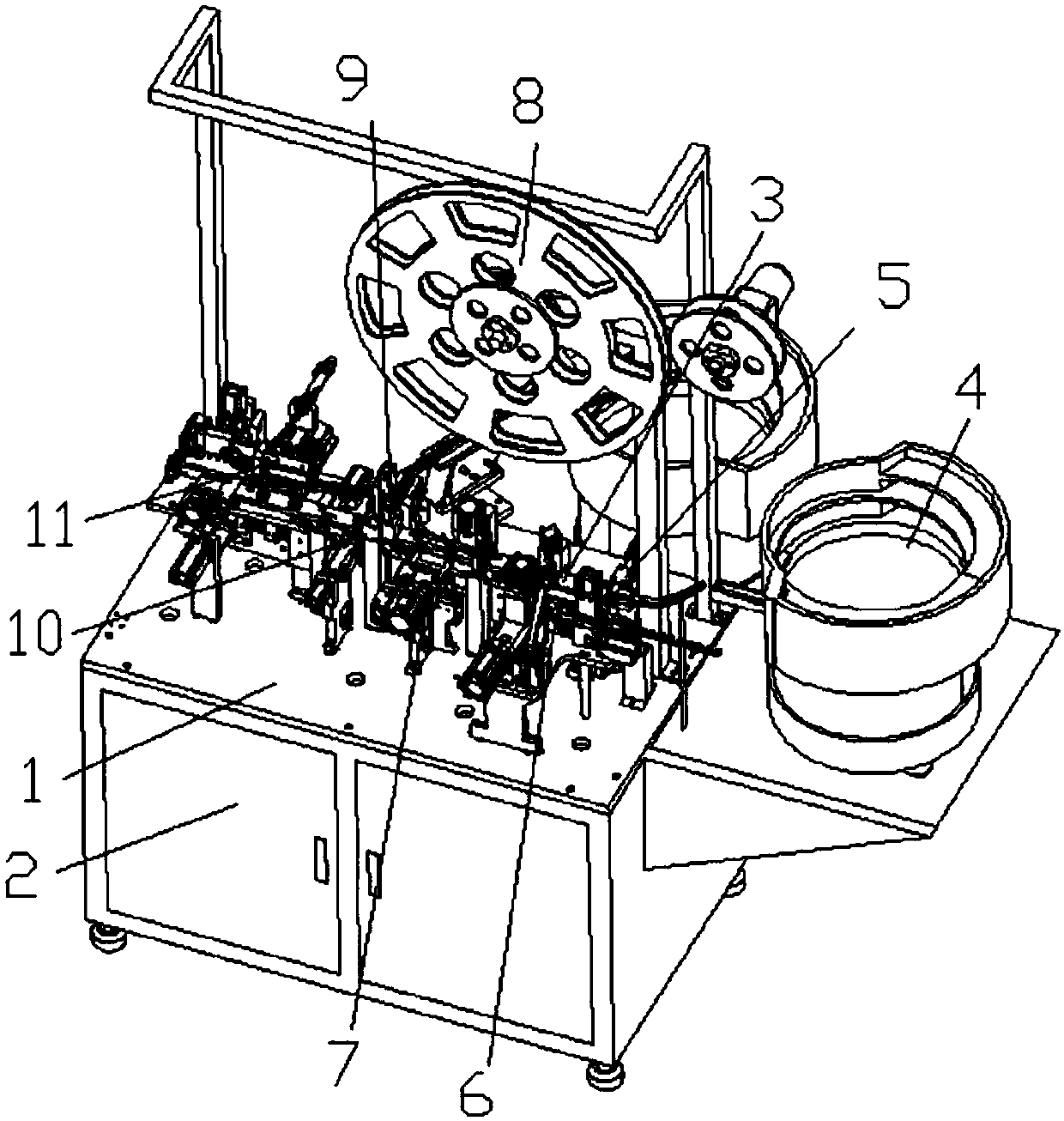

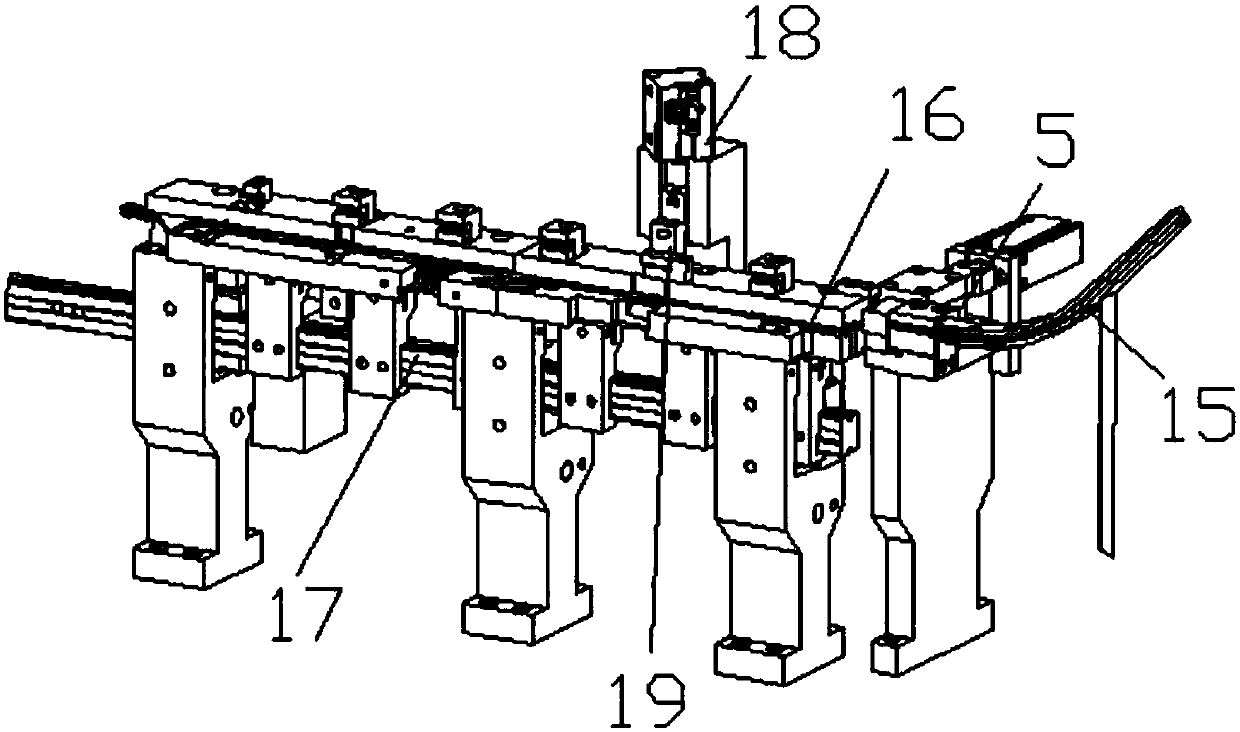

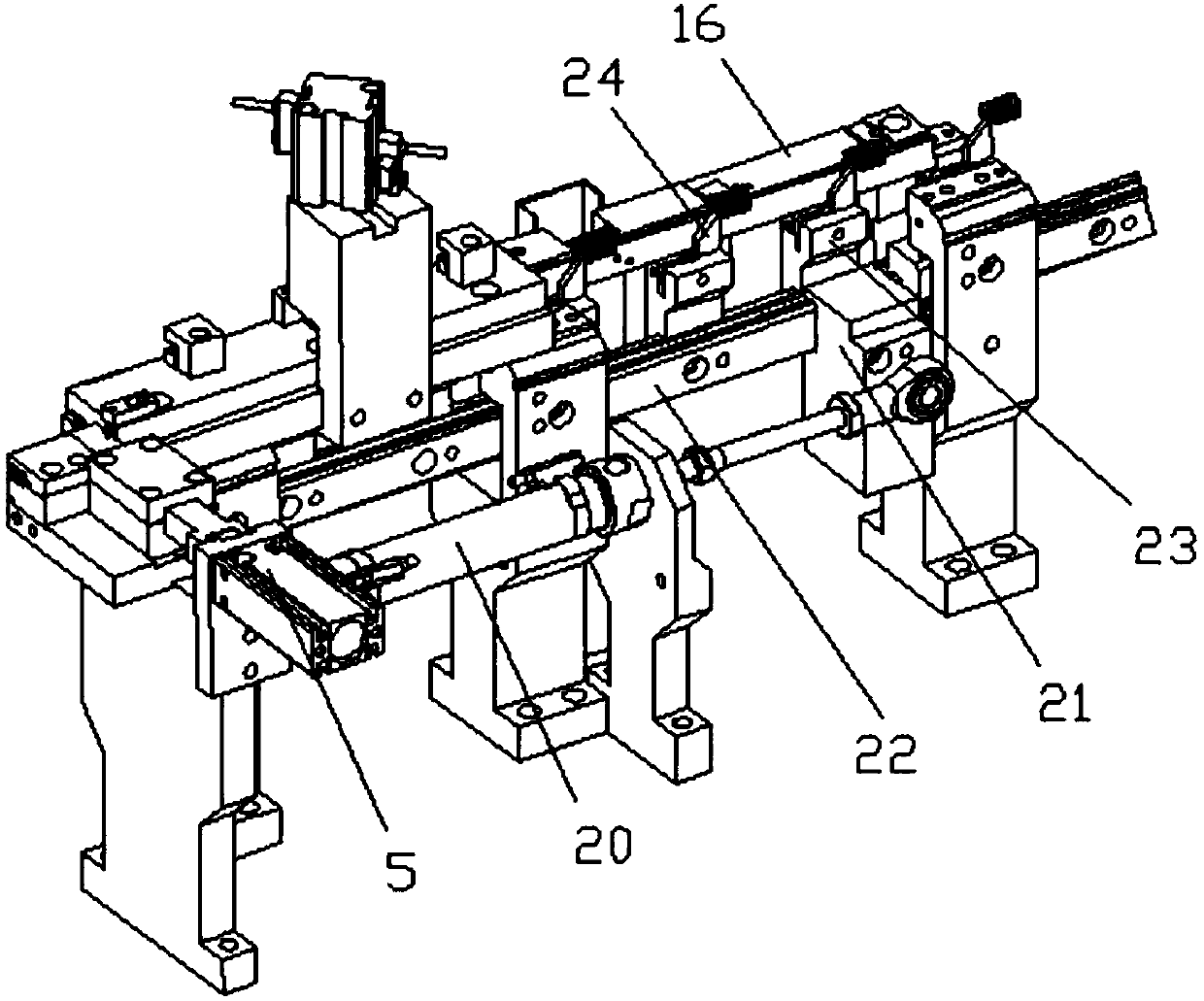

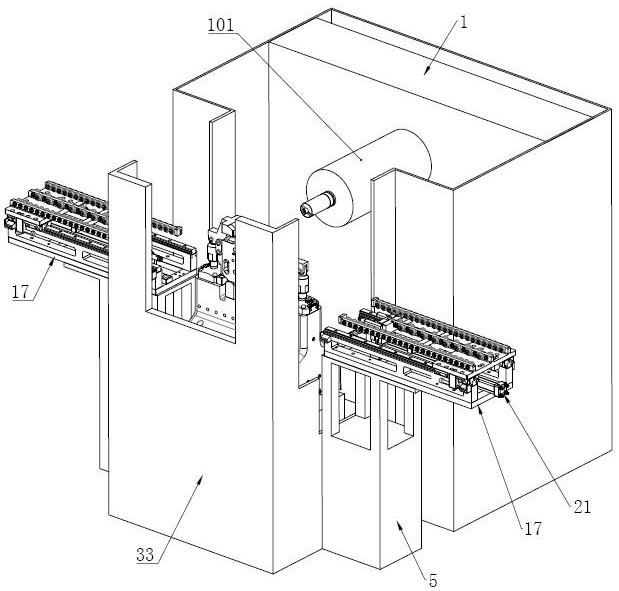

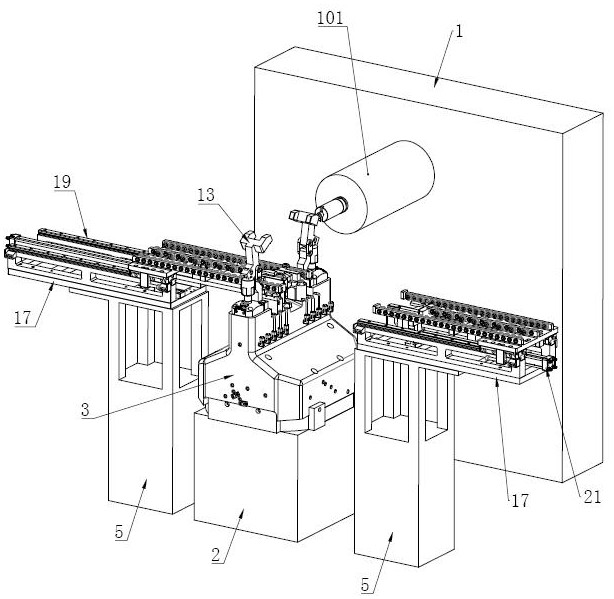

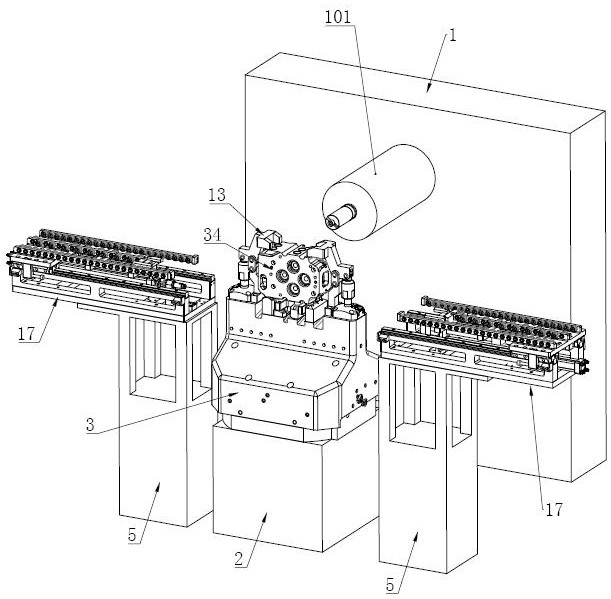

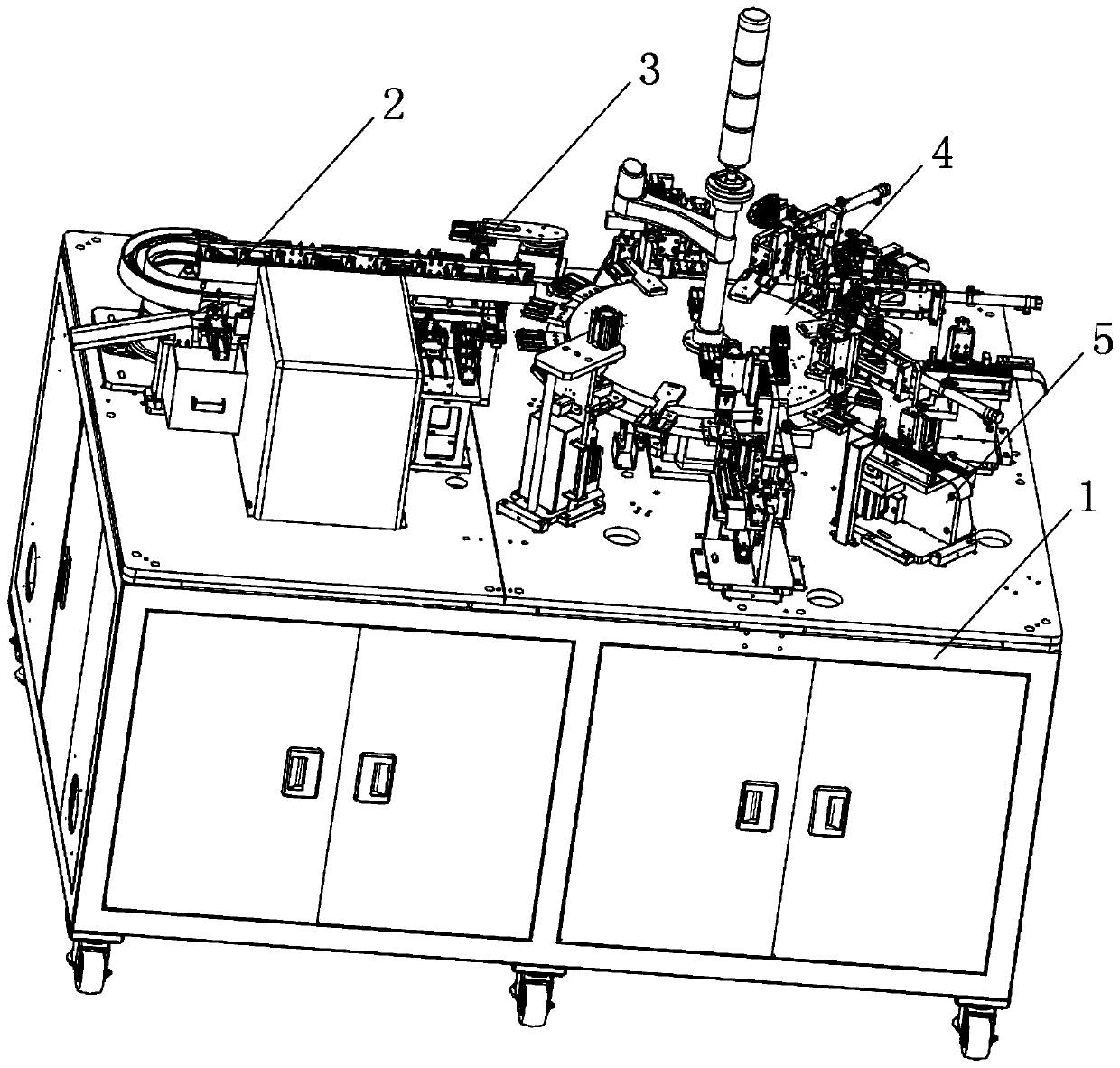

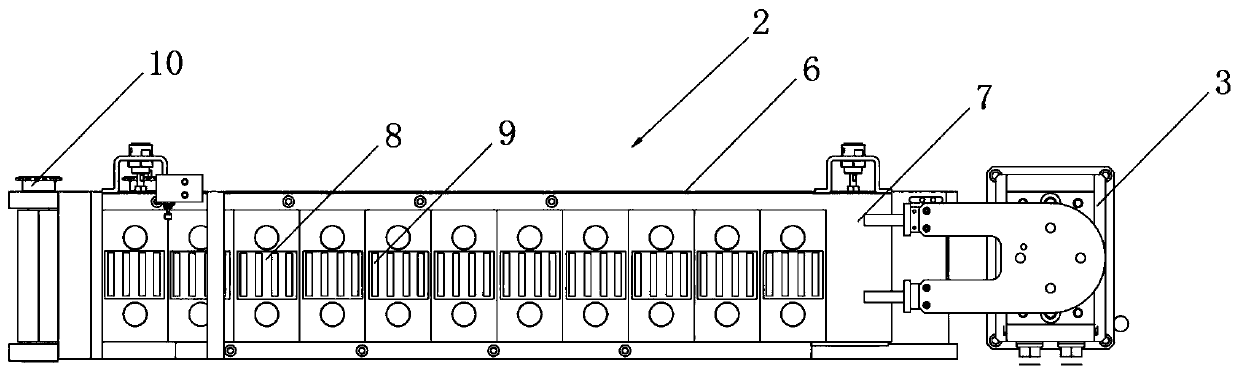

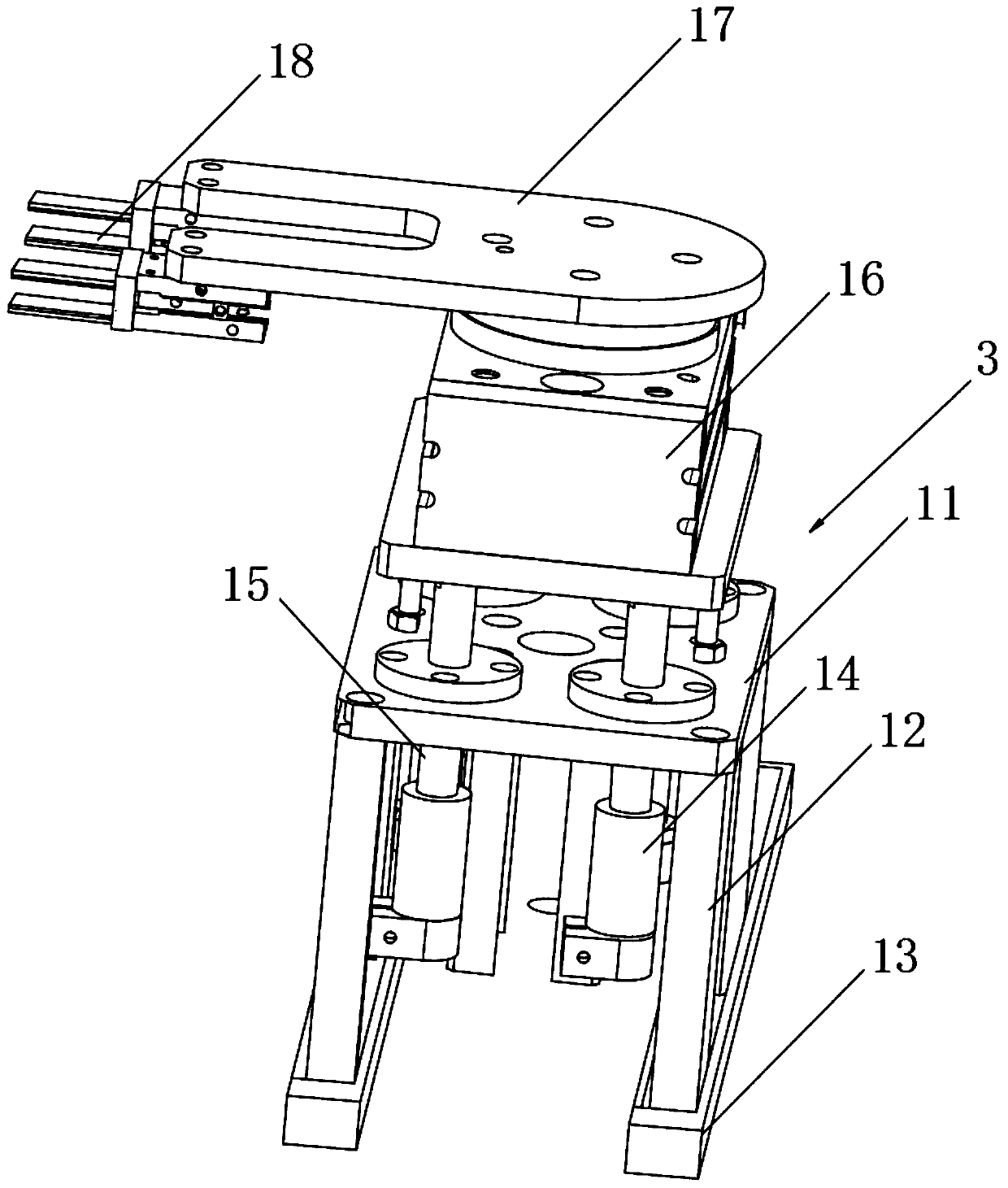

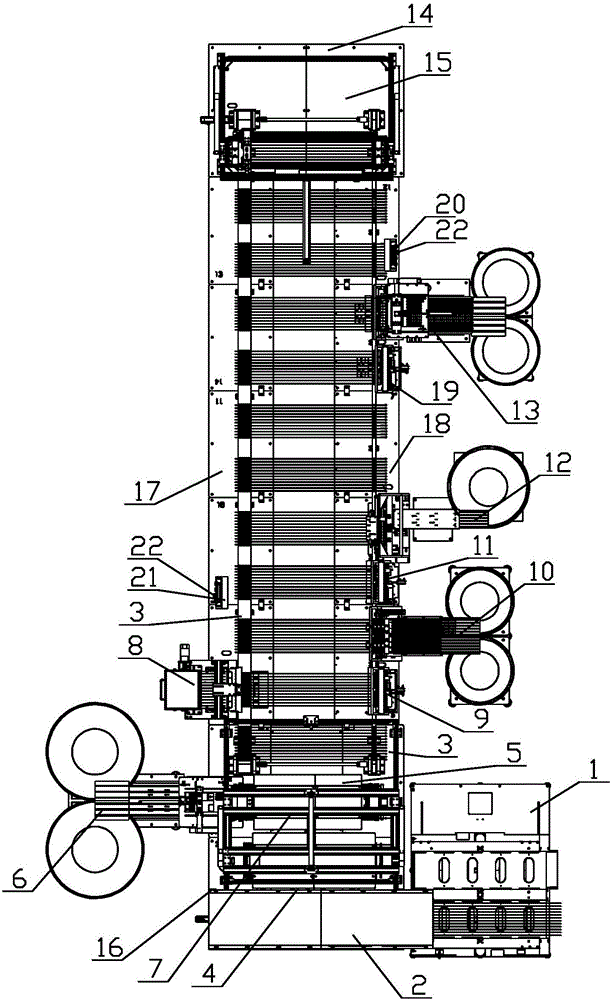

Automatic assembling machine for connector

ActiveCN107553085AAccurate jackingRealize automated assemblyOther manufacturing equipments/toolsMetal working apparatusMechanical engineering

The invention relates to an automatic assembling machine for a connector. A rack is provided with a rubber core conveying device and a shell conveying groove; a shell feeding device is arranged on theupper portion of the shell conveying groove, a shell material feeding device is matched with the right side of the shell conveying groove, and a rubber core ejecting-in port is formed in the front side of the shell conveying groove and is matched with a rubber core ejecting-in device; the shell material feeding device is connected with a shell vibration material feeding disk through a shell material feeding groove; the shell feeding device comprises a shell feeding lifting cylinder which is connected with a shell reciprocating feeding pull rod; the shell reciprocating feeding pull rod is connected with a shell feeding block; and feeding grooves matched with the left and right length of the shell are uniformly formed in the lower portion of the shell feeding block. According to the automatic assembling machine for the connector, by means of the shell feeding device in fixed distance feeding guarantees the fixed distance feeding of a shell, the fixed rubber core ejecting-in port is formed in the shell conveying groove, it is guaranteed that a rubber core is accurately ejected in from the rubber core ejecting-in port, automatic assembling of the connector rubber core and the shell isachieved, meanwhile the positioning and assembling structure is simplified, and the work efficiency is improved.

Owner:TONGXIANG YAORUN ELECTRONICS

Automatic tube feeding device for hose assembly machine

ActiveCN102152104AIncrease productivityReduce labor intensityMetal working apparatusMicro computerManipulator

The invention discloses an automatic tube feeding device for a hose assembly machine. The automatic tube feeding device comprises a tube pushing cylinder, a hose array rack, a tube pushing rack, a mechanical finger, a mechanical hand rack, a manipulator opening and closing cylinder, a manipulator lifting cylinder, a tube clamping cylinder, a tube clamping fixing die and a tube clamping moving die; the tube pushing rack fixed on a mandrel of the tube pushing cylinder pushes the arrayed hoses downwards to the bottom; and the mechanical finger and the mechanical hand rack continuously clamp the bottommost hose, push the bottommost hose forwards, and descend simultaneously after leaving the tube picking position to delivery the hose to an assembly position. A micro computer instructs a tube clamping moving seat and a tube reducing moving die to fold transversely towards a tube clamping fixing seat and a tube reducing fixing die, the mechanical finger draws back, the two dies hold the hose simultaneously, and the tube clamping seat clamps the hose firmly, and loosens the hose to be reset until the next assembly procedure is completed. When the manipulator picks up all the hoses on the hose array rack, the tube pushing cylinder lifts the tube pushing seat, slides the tube pushing seat through the whole row of hoses, and drags the tube pushing seat to a gap at the upper end; and the tube pushing rack resets, and pushes the hose downwards while jacking the hose.

Owner:浙江本发科技有限公司

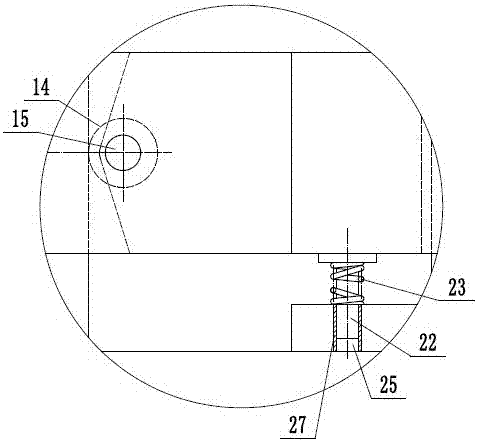

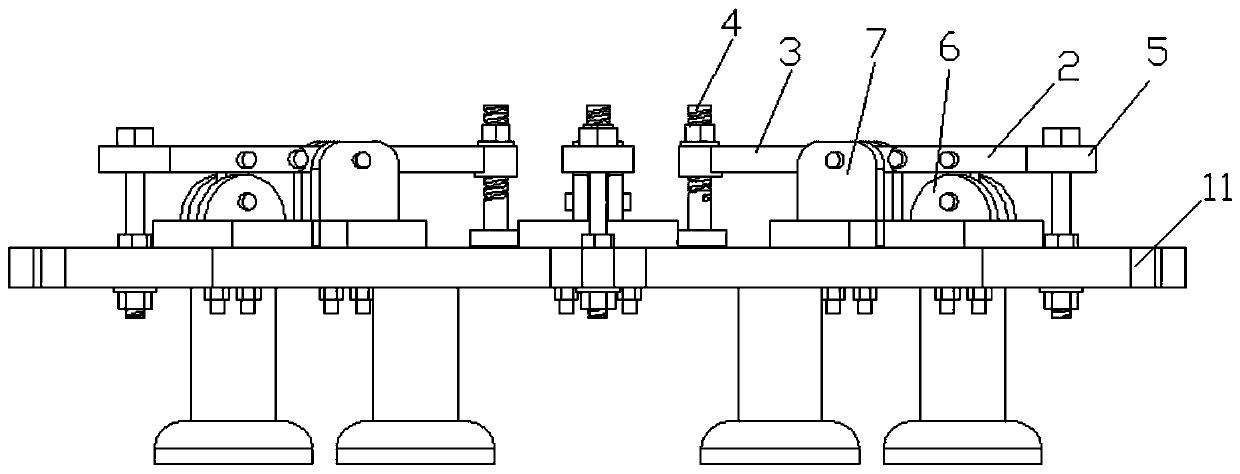

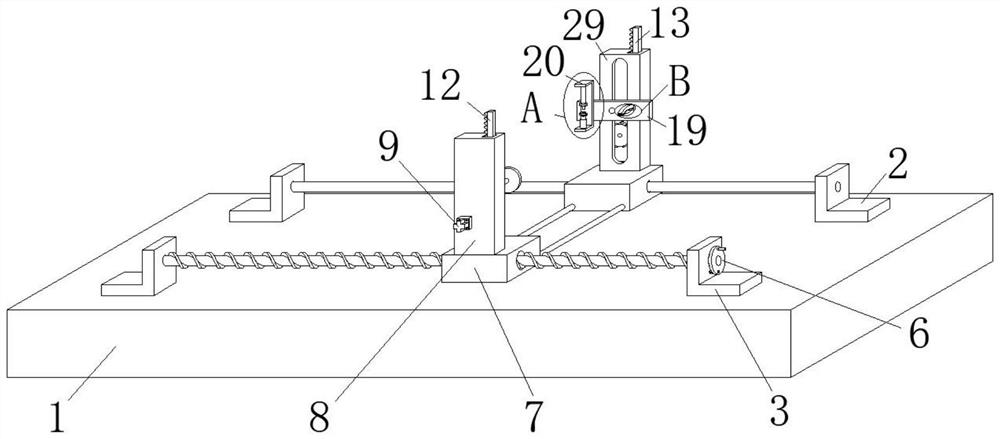

Jaw type clamp

InactiveCN107150235AAchieve replacementExtended service lifePositioning apparatusMetal-working holdersEngineeringMachining

The invention provides a jaw type clamp, which belongs to the technical field of mechanical processing. It includes a fixed jaw, a movable jaw, and a Y-shaped lever. The fixed jaw is fixed on the supporting base, the lower end of the movable jaw is hinged on the jaw support through the supporting pin, and the left end of the Y-shaped lever is passed through the Y-shaped lever pin. The shaft is hinged on the fixed jaw, and the driving roller can be rolled on the fork of the Y-shaped lever through the roller support rod. The fixed screw passes through the pin hole at the right end of the Y-shaped lever, and the upper end of the fixed screw is threaded with a pressure sleeve. There is a grip handle on the pressure sleeve, and a pressure pad is arranged between the pressure sleeve and the Y-shaped lever. The middle end of the supporting swing rod is hinged on the optical axis section at the lower end of the fixed screw rod. The other end of the swing rod is provided with a push rod groove, and the push rod can slide up and down to be arranged on the push rod groove. The invention adopts the structure of one fixed jaw and one movable jaw, so as to realize fast clamping of the workpiece, and the clamping position is accurate.

Owner:张帼威

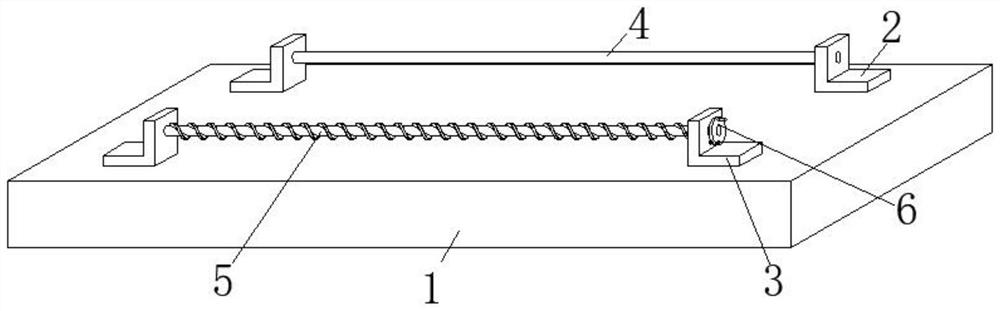

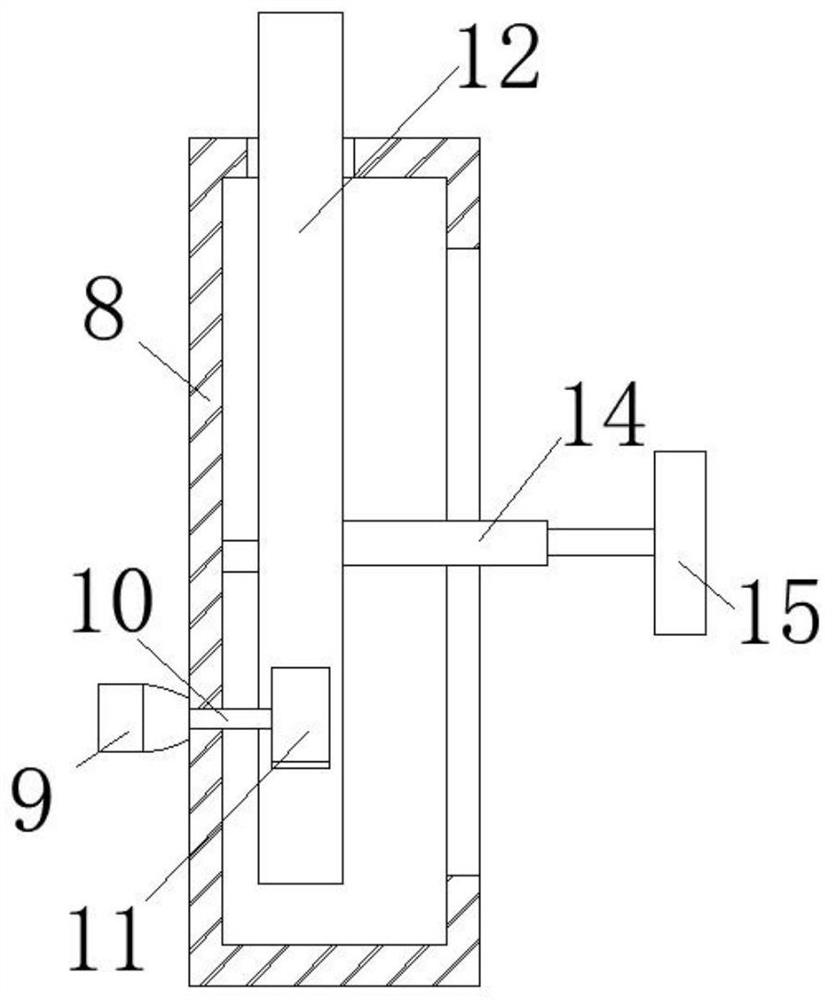

Valve body clamp for vertical machine tool

ActiveCN105108529ASimple structureLow costPositioning apparatusMetal-working holdersMachine toolAxis of symmetry

The invention discloses a valve body clamp for a vertical machine tool. The valve body clamp comprises a clamp body, a V-shaped clamp, a directional clamp and two side clamps. The clamp body is provided with a first T-shaped channel, a second T-shaped channel and a third T-shaped channel. The second T-shaped channel and the third T-shaped channel are symmetrically arranged at the two sides of the first T-shaped channel with the first T-shaped channel serving as the axis of symmetry. A reverse thread lead screw is arranged in the first T-shaped channel, the V-shaped clamp is arranged at one end of the first T-shaped channel in a sliding mode, the directional clamp is arranged at the other end of the first T-shaped channel in a sliding mode, and the two side clamps are arranged in the second T-shaped channel and the third T-shaped channel in a sliding mode respectively. The valve body clamp is simple in structure and low in cost, a valve is accurately positioned, and the product quality is improved.

Owner:南通高中压阀门有限公司

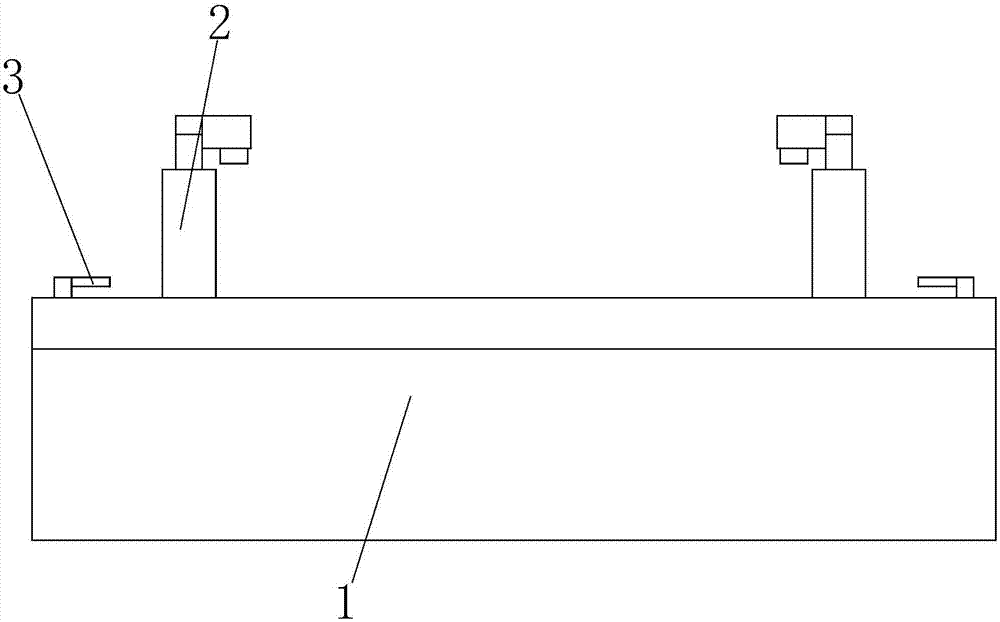

Clamp for machining of pipe type part

InactiveCN106985066AEasy to useEasy to grindRevolution surface grinding machinesGrinding work supportsPulp and paper industryMachining

The invention relates to a fixture used for processing pipe parts, which includes a workbench, on which two positioning blocks and two pipeline fastening devices are respectively installed in a left-right symmetrical manner; each positioning block is provided with a Arc surface. The invention is easy to use, and can automatically fix and clamp the left and right ends of the pipe parts in a left and right symmetrical manner on the basis of realizing preliminary positioning, and ensures accurate clamping positions, thereby achieving the effect of facilitating subsequent grinding and processing.

Owner:ANHUI REMFG ENG DESIGN CENT

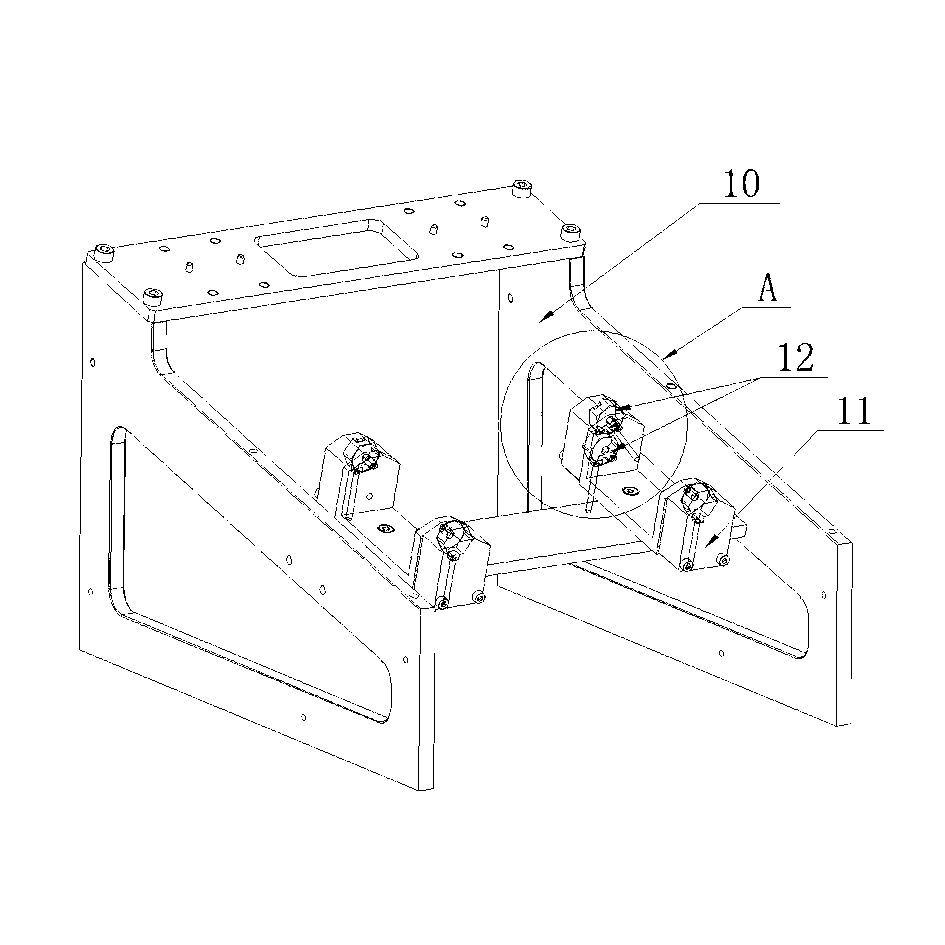

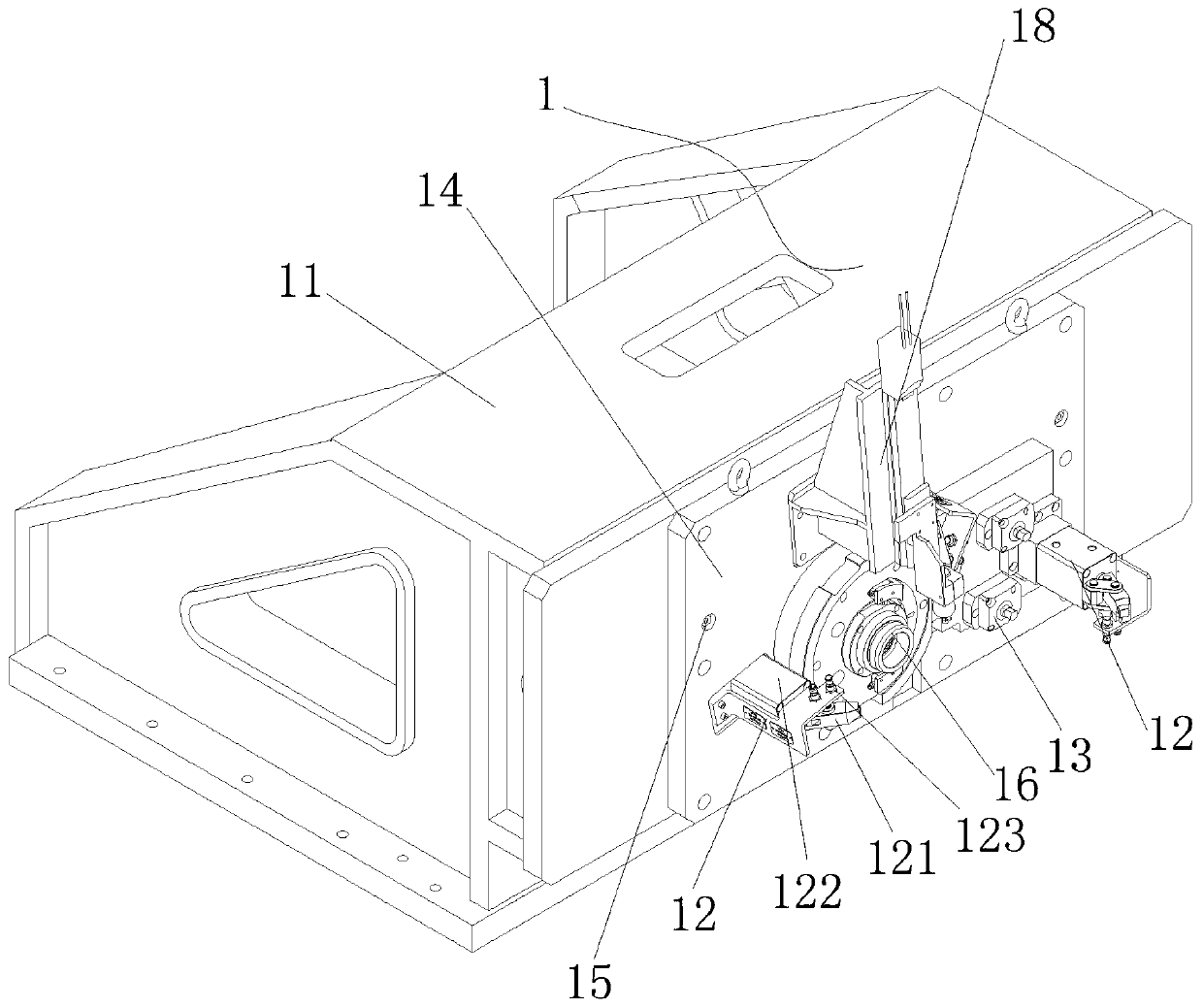

Automatic welding equipment

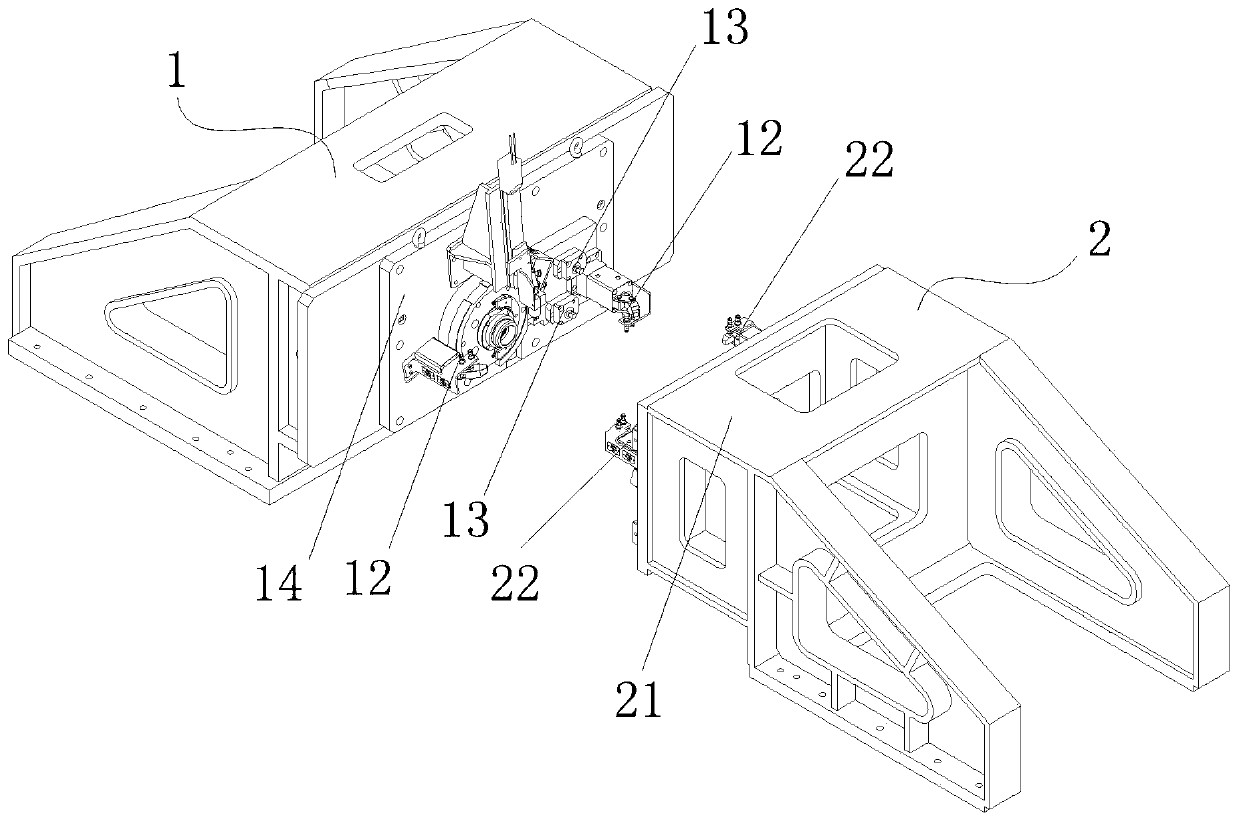

InactiveCN112296556AHigh degree of automationImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

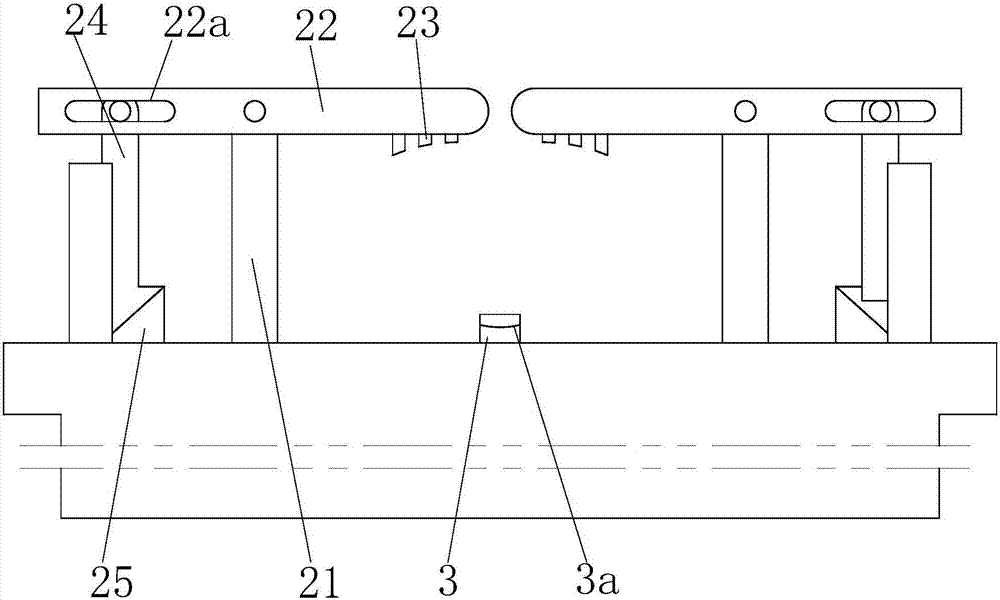

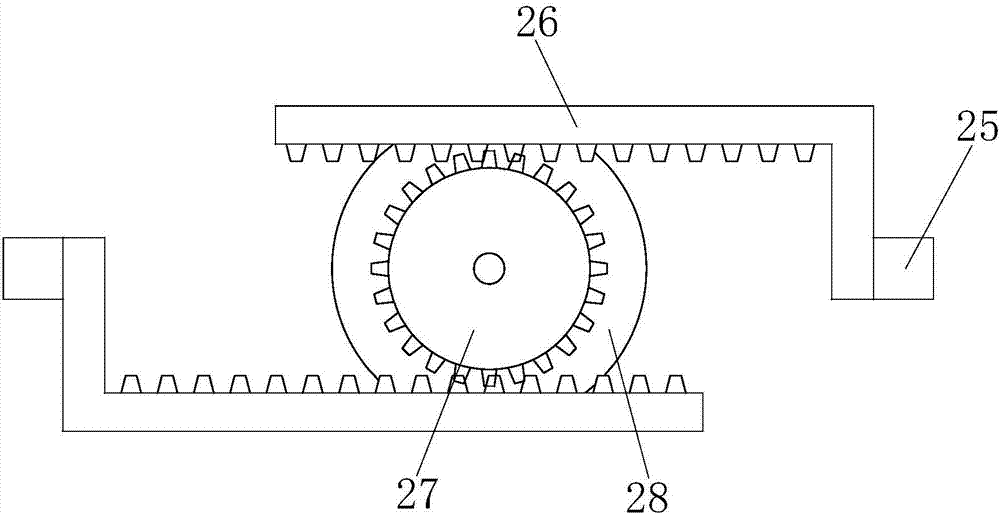

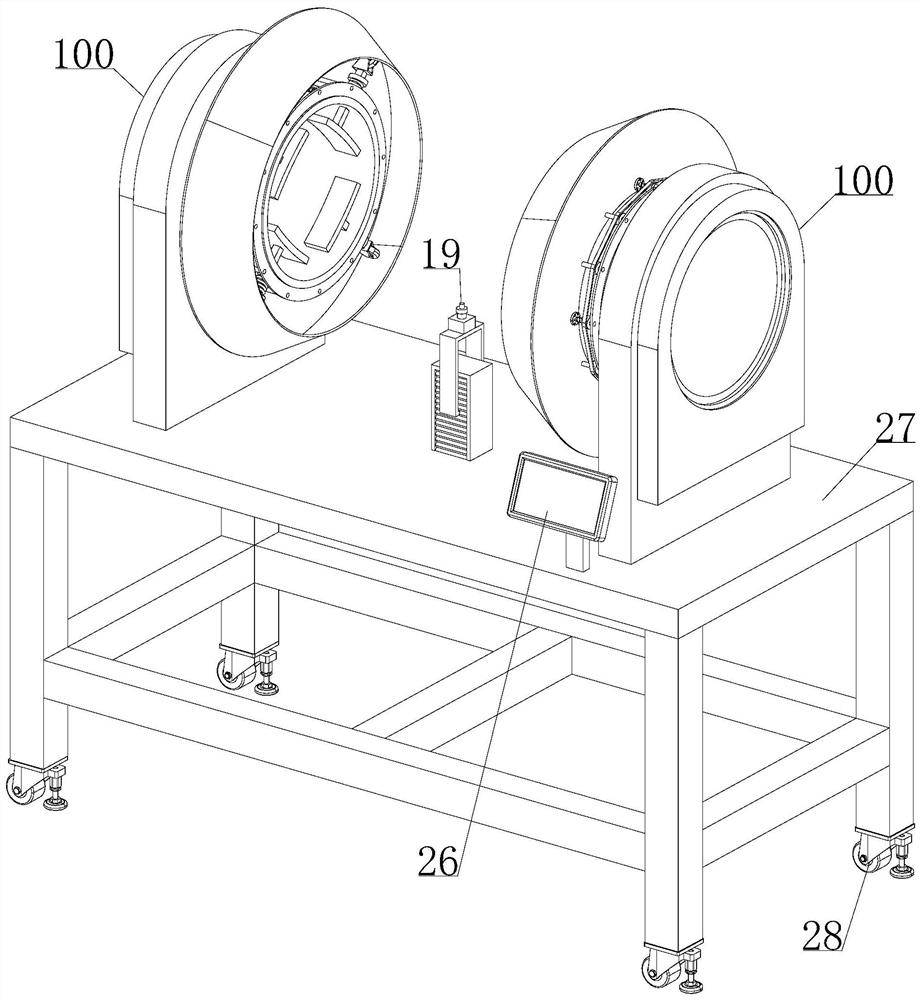

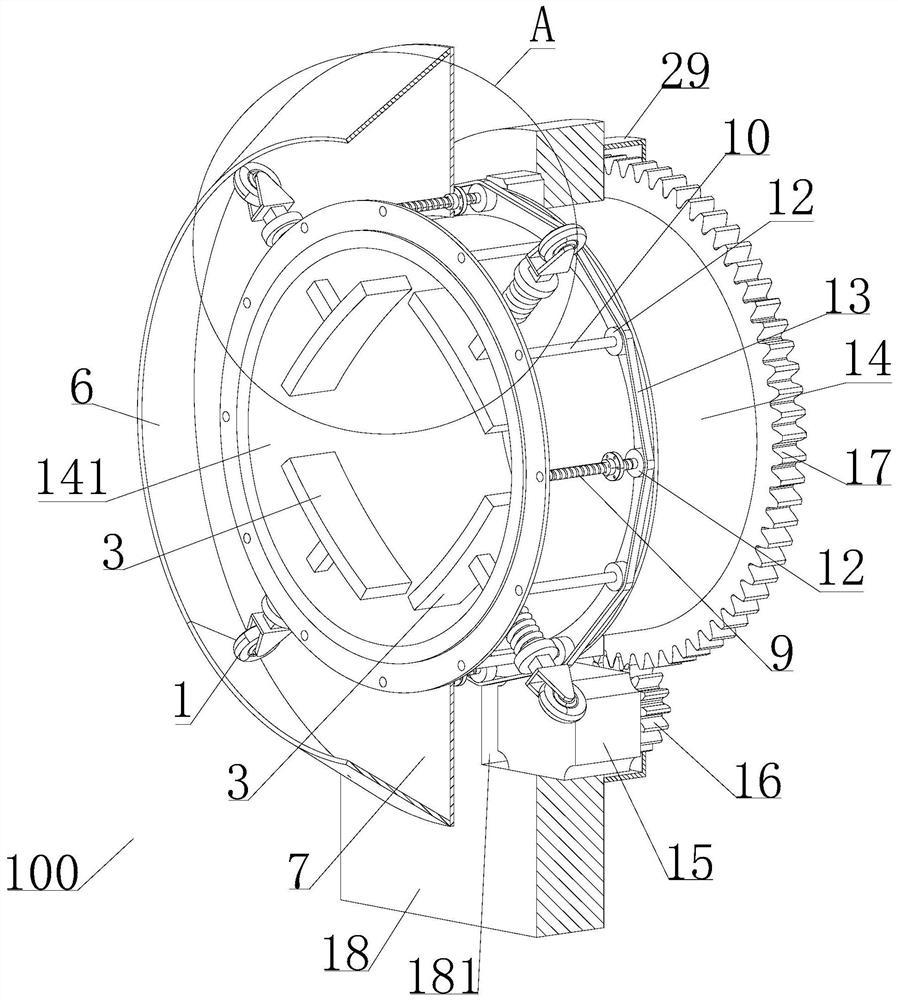

The invention discloses automatic welding equipment. The automatic welding equipment comprises clamp rotation mechanisms, a welding head, a control panel and a machine frame, wherein two groups of clamp rotation mechanisms are arranged abreast in the horizontal direction; each group of clamp rotation mechanisms comprises a clamping assembly, a push plate, a connecting plate, a rotary drum, a mounting table, a movable driving mechanism for driving the connecting plate to be moved in the horizontal direction and a rotation driving mechanism for driving the rotary drum to be rotated, wherein a lifting mechanism for driving the welding head to be lifted is arranged on the machine frame; a central shaft of the corresponding rotary drum is horizontally arranged; a clamp channel is coaxially arranged on the corresponding rotary drum; the rotary drum is rotatably arranged on the corresponding mounting table; the rotation driving mechanism is arranged on the corresponding mounting table; and the control panel is separately connected with the corresponding welding head, the corresponding movable driving mechanism, the corresponding rotation driving mechanism and the corresponding lifting mechanism. According to the automatic welding equipment disclosed by the invention, metal tube can be stably clamped and can be driven to be rotated, and in a rotation process of the metal tubes, the twometal tubes can be automatically welded through the welding head, and thus, the automation degree is high, the welding accuracy is high, and the welding quality is high.

Owner:深圳市励东科技发展有限公司

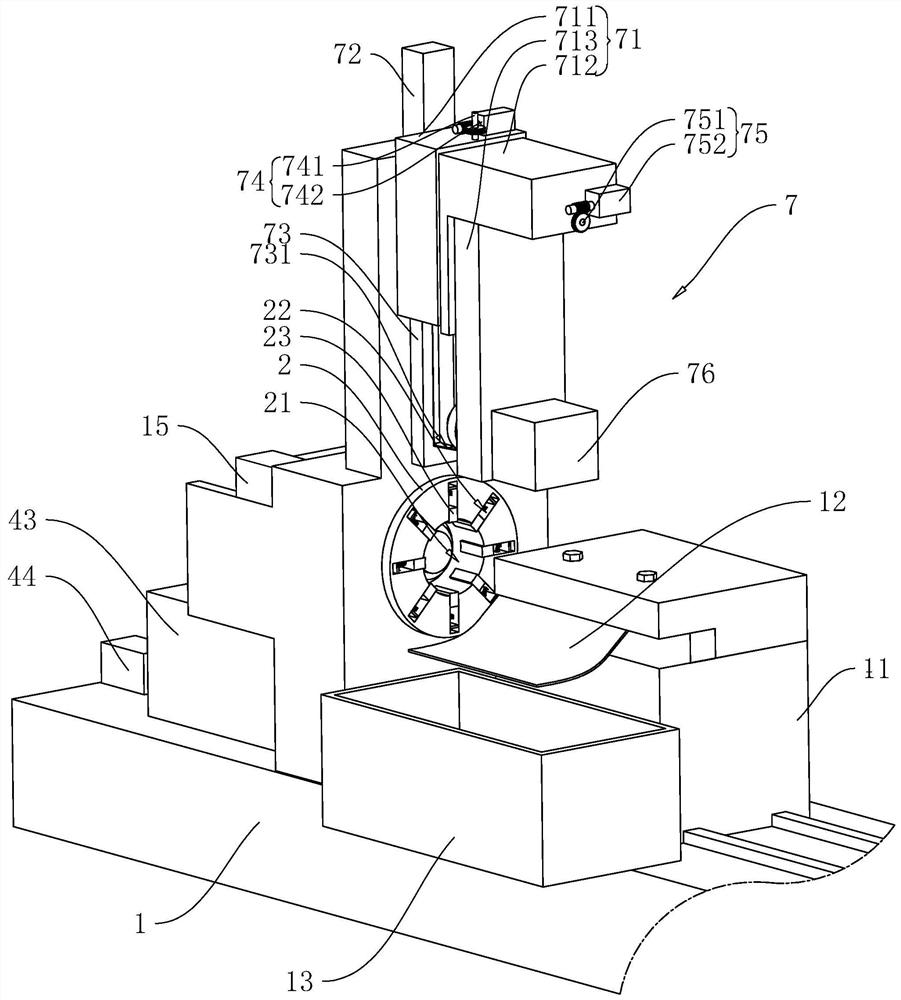

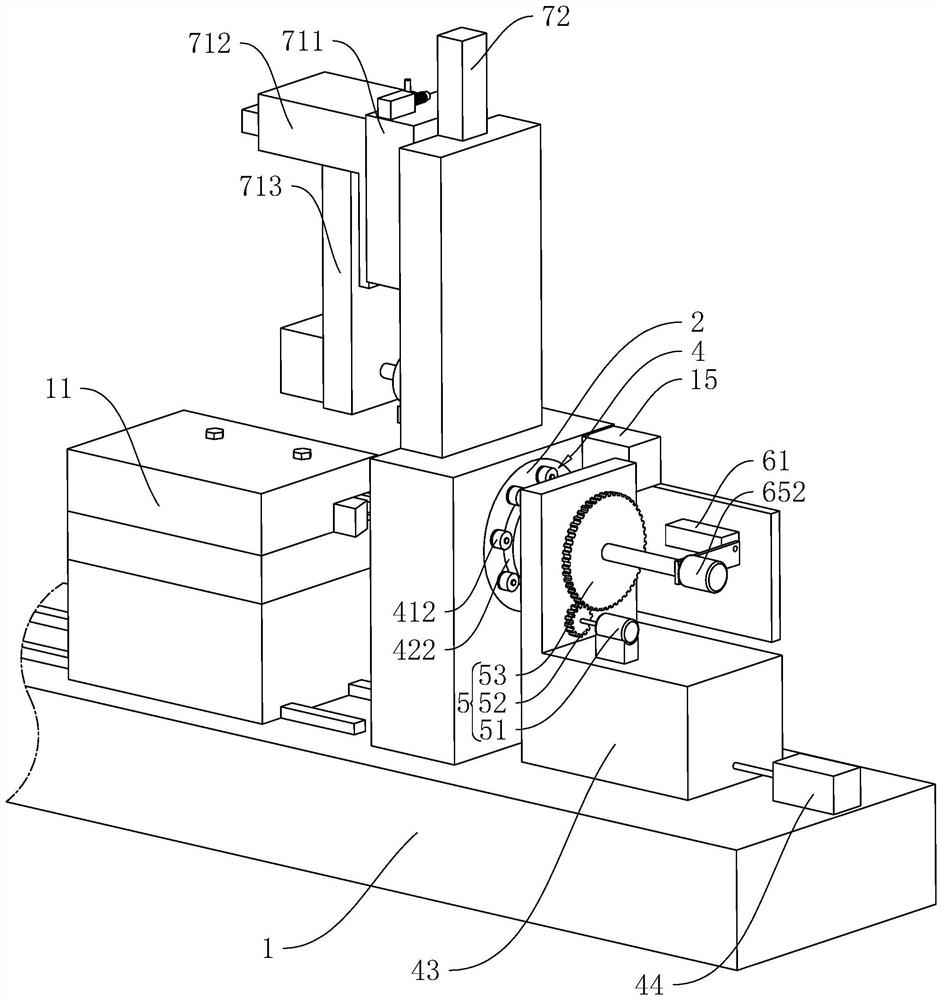

Full-automatic finish machining device for air cylinder cover

ActiveCN112091705AReduce the impact of inertial impactEnsure accuracy in placeMeasurement/indication equipmentsMetal working apparatusEngineeringMachine tool

The invention belongs to the technical field of air cylinder cover machining equipment, and provides a full-automatic finish machining device for an air cylinder cover. The full-automatic finish machining device comprises a machine tool, a mounting base is arranged on the side, provided with a main shaft, of the machine tool, a tool base driven by a first driving device is rotationally mounted onthe mounting base, a workpiece supporting plate driven by a second driving device is arranged on the tool base, a lifting positioning pin used for achieving pre-positioning of the air cylinder cover is arranged on the bearing face of the workpiece supporting plate, and a clamping positioning pin used for achieving clamping of the air cylinder cover, a supporting table and a clamping mechanism arefurther arranged on the tool base; and feeding bases are arranged on the two sides of the mounting base respectively, conveying devices used for achieving feeding and discharging of the air cylinder cover are arranged on the feeding bases respectively, and the two conveying devices are arranged correspondingly. Compared with traditional air cylinder cover machining equipment, full-automatic finishmachining of the air cylinder cover is achieved, conveying, positioning and clamping of the air cylinder cover are accurate and reliable, and the machining efficiency and the finish machining qualityof the air cylinder cover are greatly improved.

Owner:潍坊思博精工科技有限公司

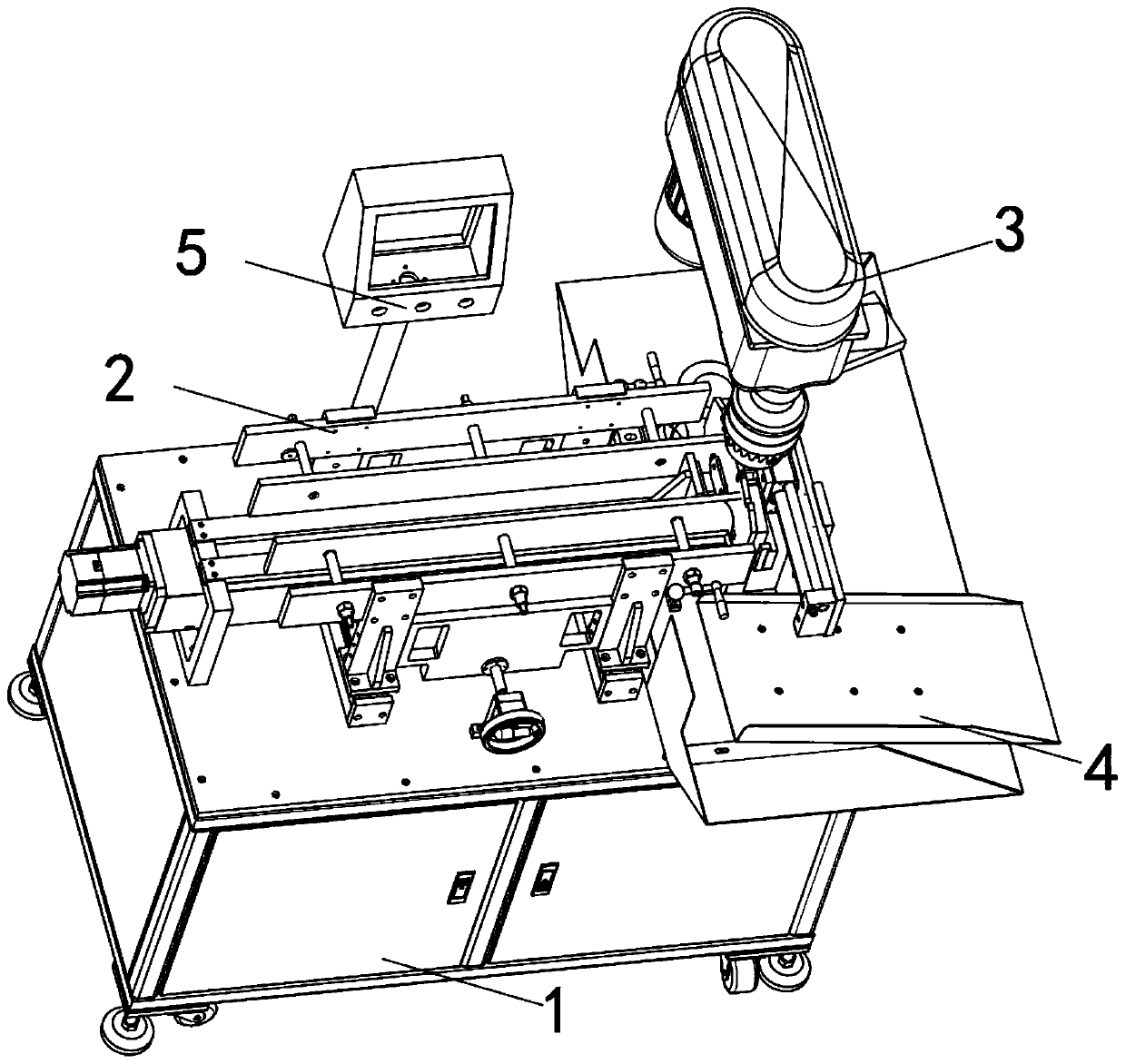

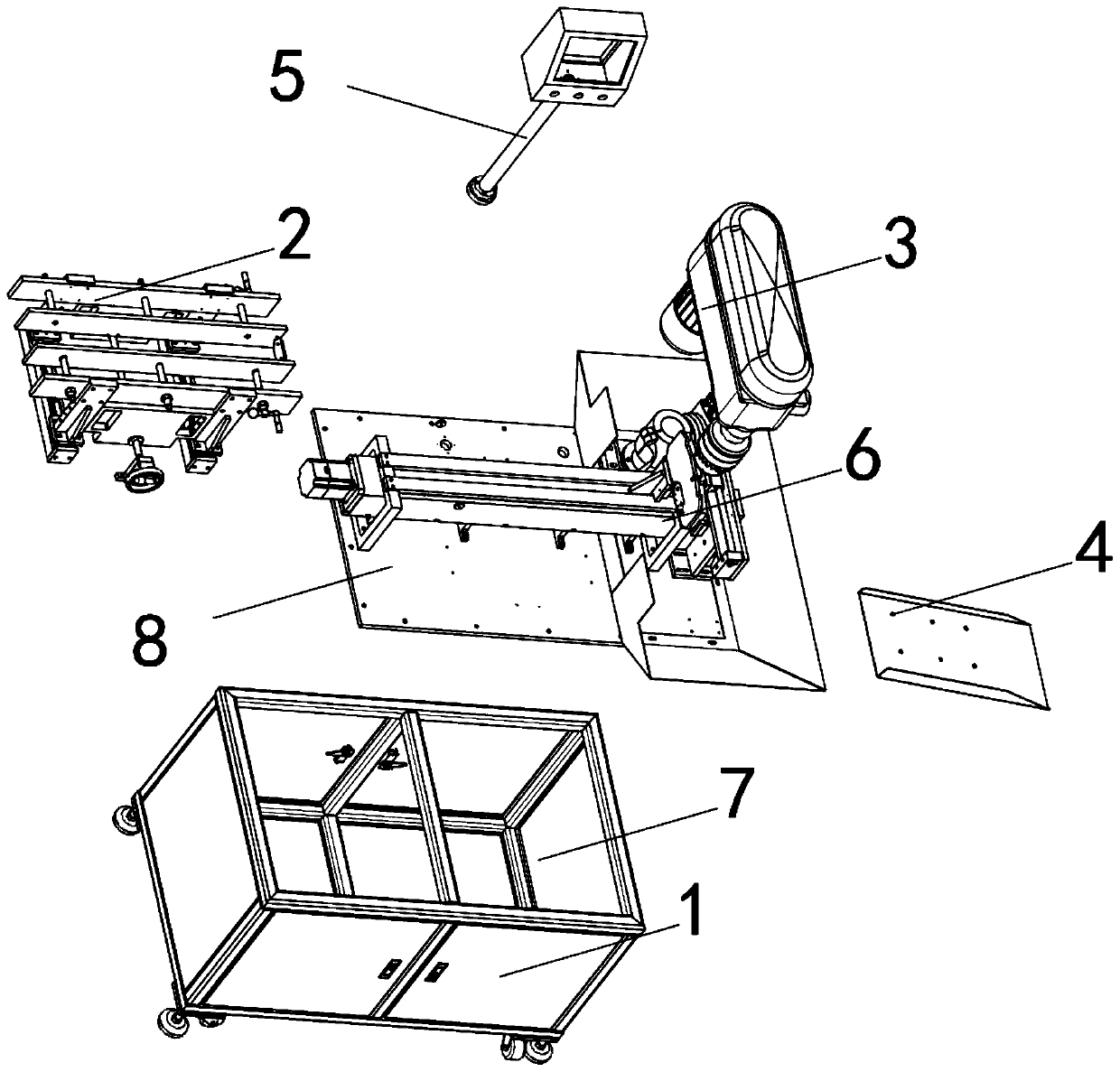

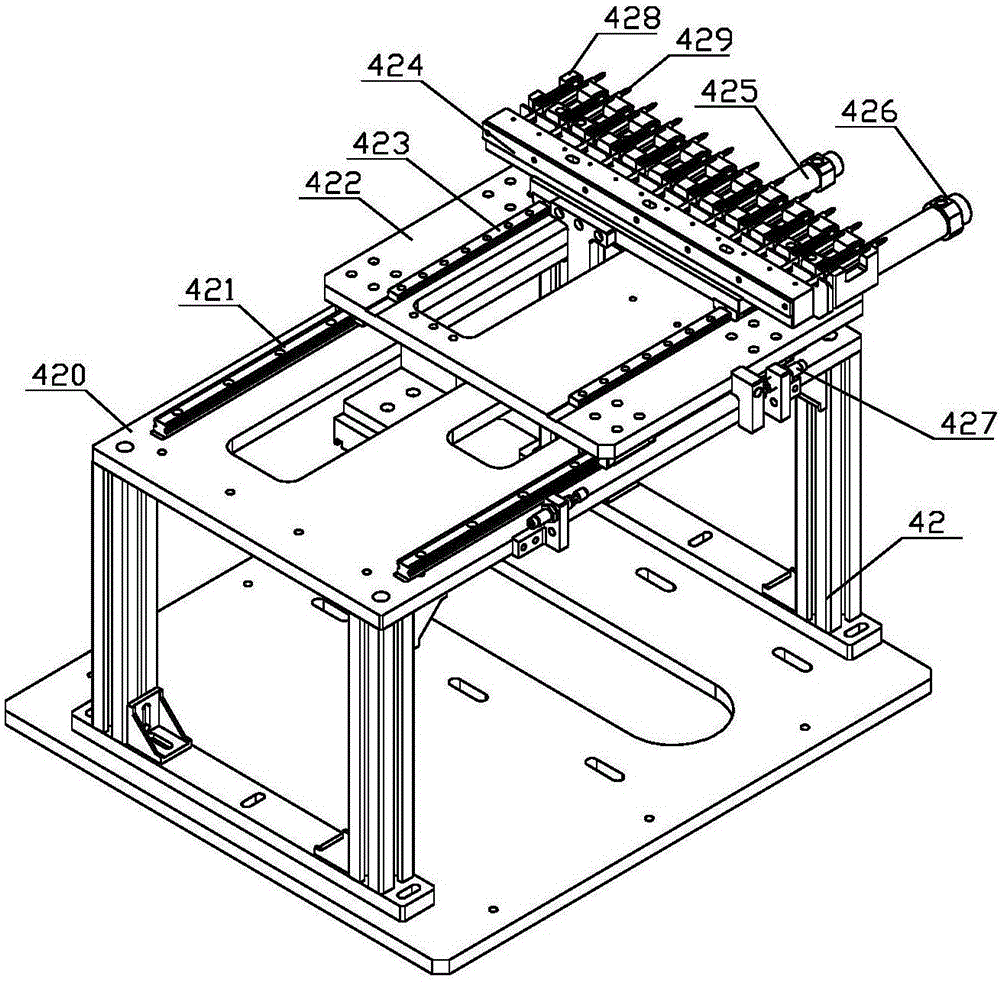

Integrated device for rapid dispensing of chips on printed circuit board (PCB) and dispensing method of integrated device

InactiveCN110449314AAvoid damageImprove delivery efficiencyLiquid surface applicatorsCoatingsMotor driveEngineering

The invention discloses an integrated device for rapid dispensing of chips on a printed circuit board (PCB) and a dispensing method of the integrated device. The integrated device includes a workbench, a plate feeding disc, a transferring frame, a rotating disc and dispensing frames, the plate feeding disc is arranged at one end of the upper part of the workbench, the transferring frame is arranged at one end of the plate feeding disc, the annular rotating disc is arranged at one end of the transferring frame, and the six dispensing frames are arranged at the edge of the rotating disc with equal radian. The integrated device has the beneficial effects that after the PCB is clamped between two clamping jaws, a seventh motor drives the two clamping jaws to rotate to clamp and fix the PCB through a swing shaft, two supporting clamping blocks on the clamping jaws are arranged symmetrically and obliquely in a concave groove, the side wall of the PCB is attached and clamped through a plurality of second rubber strips arranged on the side wall of one end of the supporting clamping blocks at equal intervals, it is ensured that the clamping jaws clamp the PBC more firmly, rubbing damage ofthe PBC by the clamping jaws is prevented, six clamping discs are arranged on the rotating disc with equal radian, and the intake capacity and the work efficiency of the integrated device for synchronous dispensing of the PCB are improved.

Owner:张云飞

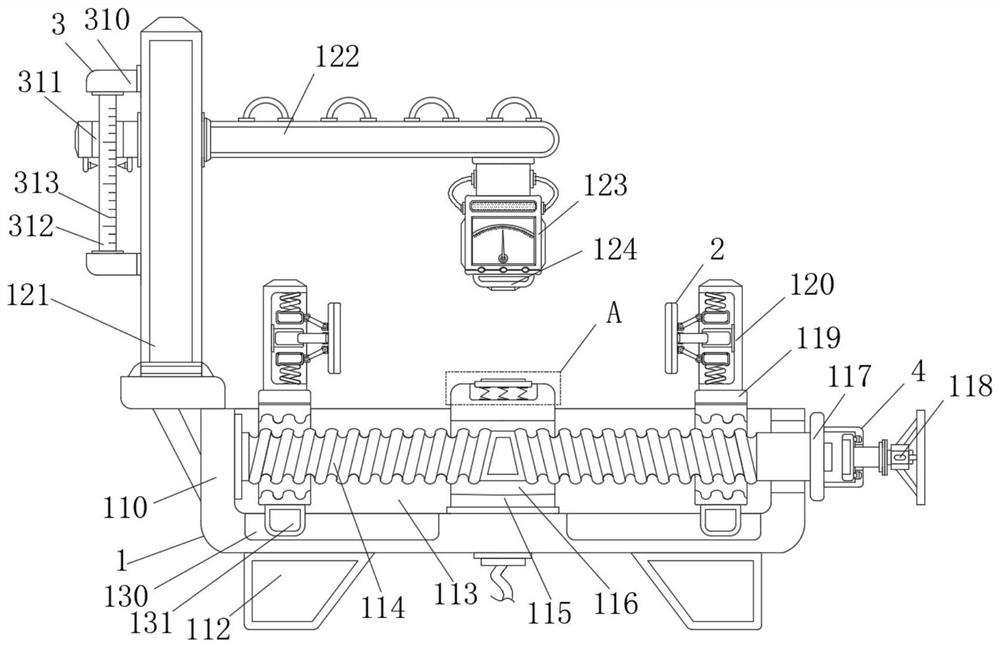

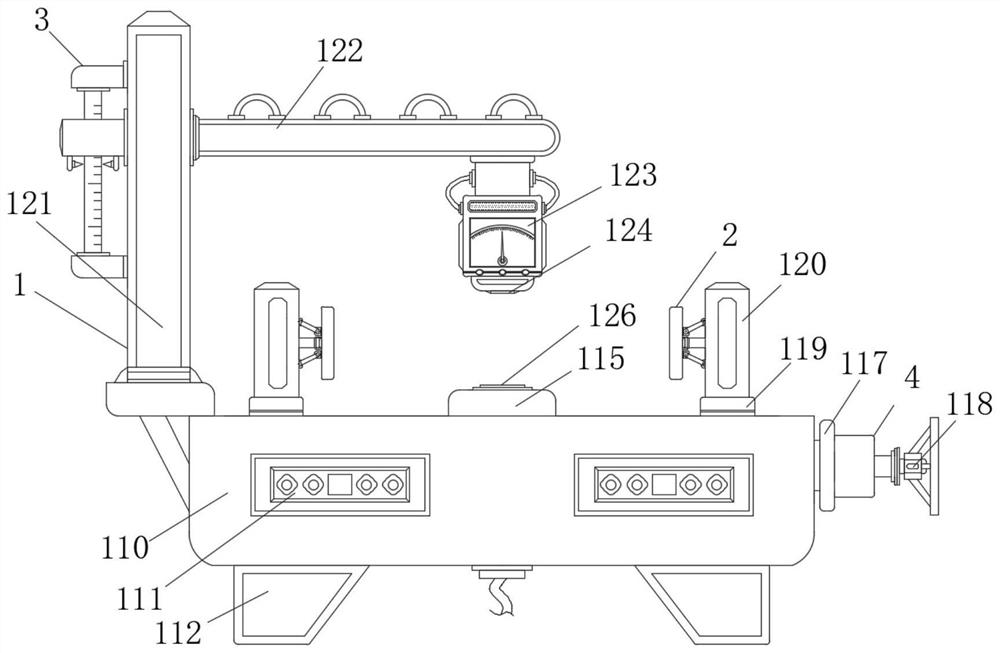

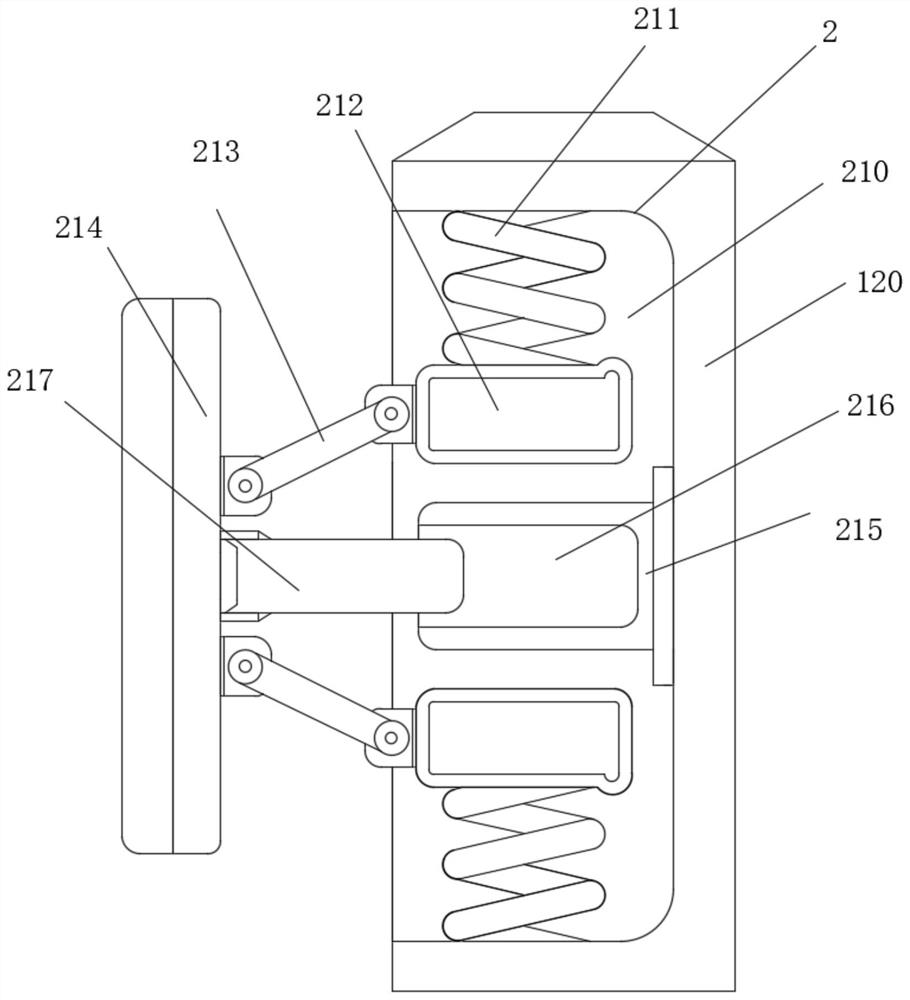

Lithium ion battery processing clamping device with electric quantity detection function

InactiveCN112305270AImprove stabilityLift can be approachedElectrical testingMeasurement instrument housingElectrical batteryElectrically conductive

The invention relates to the technical field of battery processing, in particular to a lithium ion battery processing clamping device with an electric quantity detection function, which comprises a device body, and the device body comprises a mounting plate. By arranging a voltameter, a first conducting strip, a mounting groove, a second conducting strip, a screw rod, a threaded sleeve and a auxiliary limiting plate, the voltameter can be used for measuring the electric quantity of the battery while clamping the battery, so that the battery with the electric quantity is prevented from being wasted; and meanwhile, the situation that a battery with electric quantity is directly crushed to possibly generate danger is prevented, the device can be safer, the device can utilize two auxiliary limiting plates to conduct auxiliary clamping on the battery, the situation that the battery is only vertically and unidirectionally clamped and is not stable is avoided, the stability and the approaching ability of the device are improved to a certain extent, and the practicability of the device is improved. And meanwhile, the device is easy to operate and more convenient for workers to use.

Owner:师肖飞

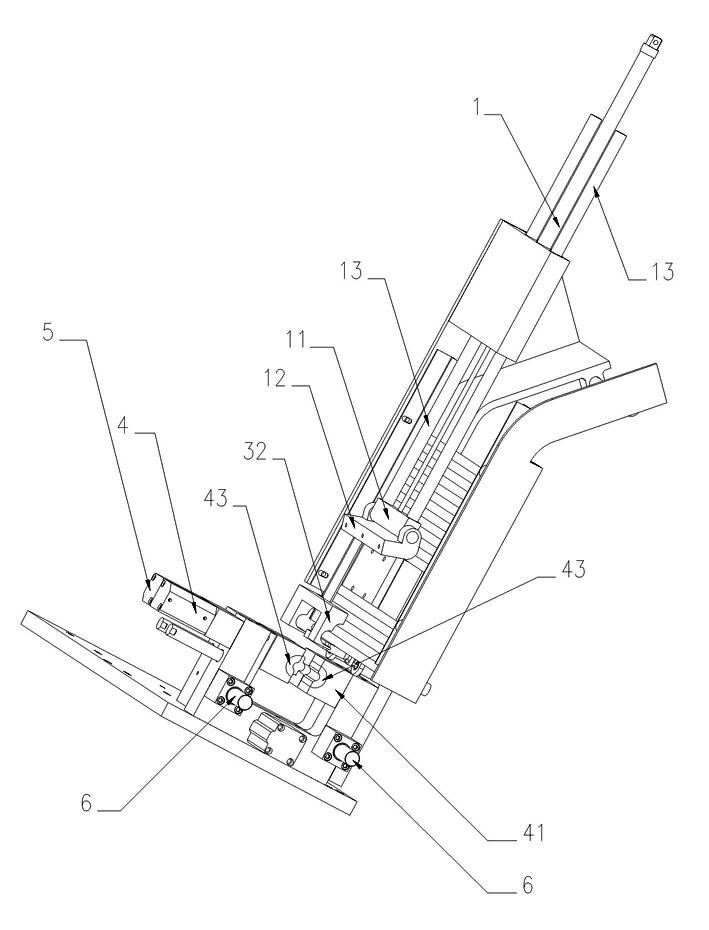

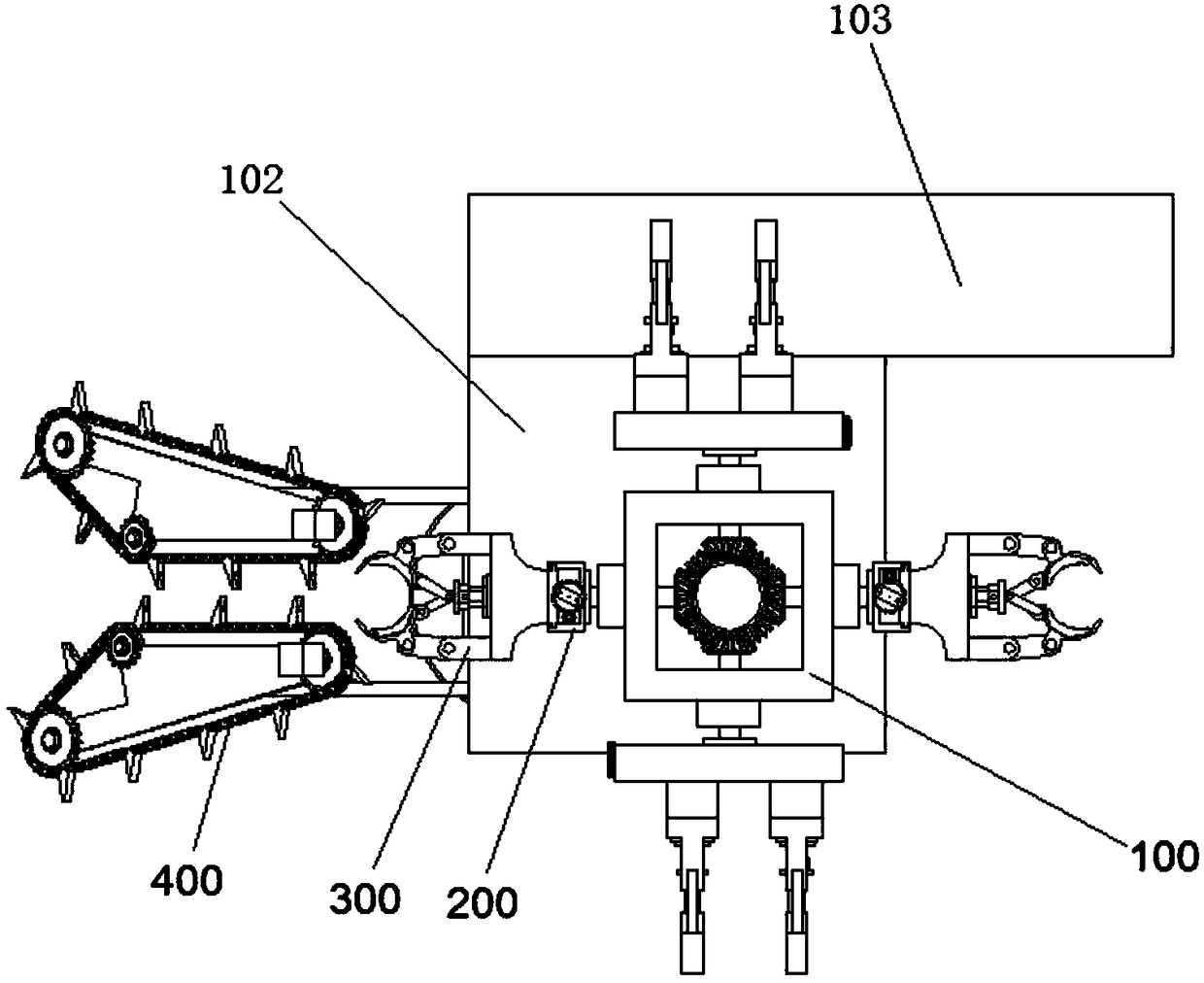

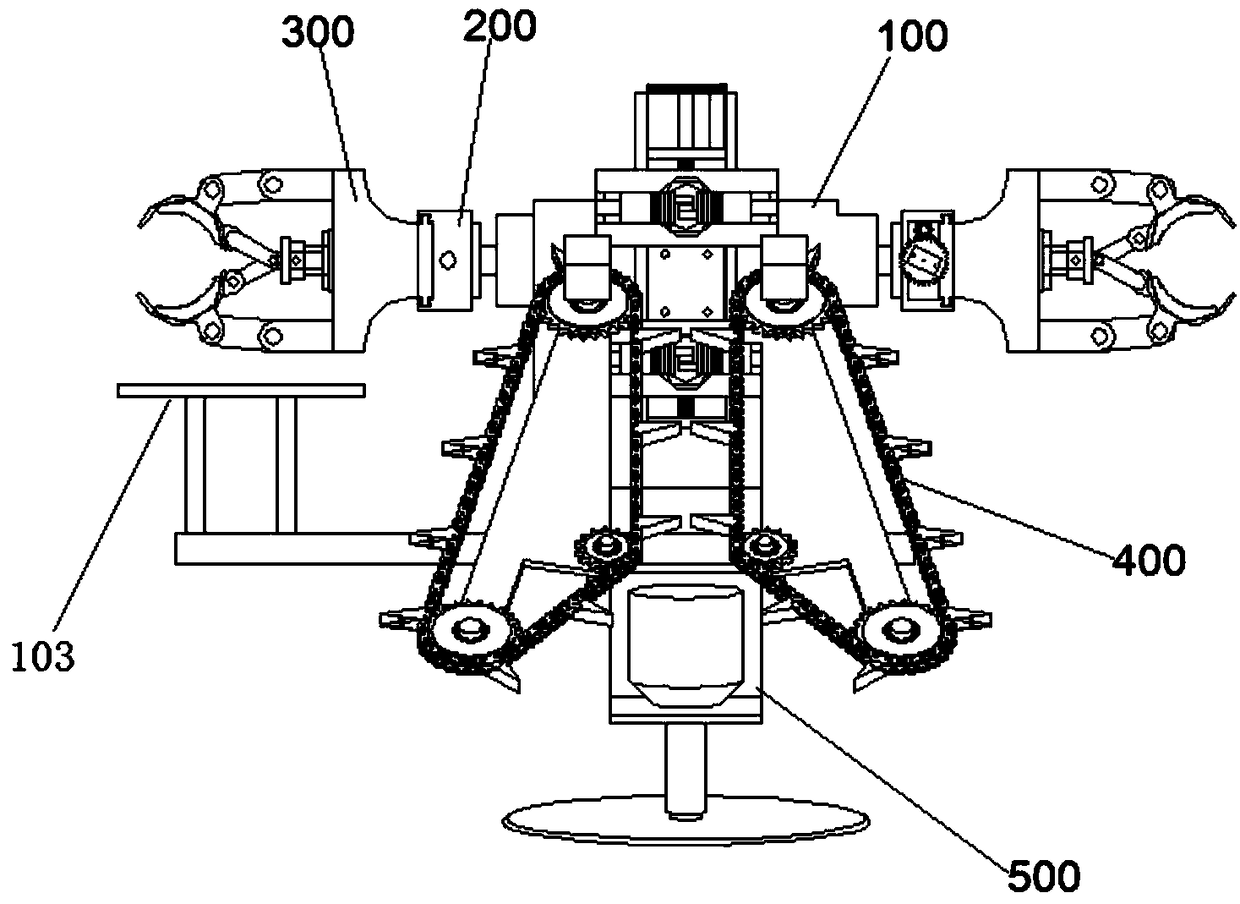

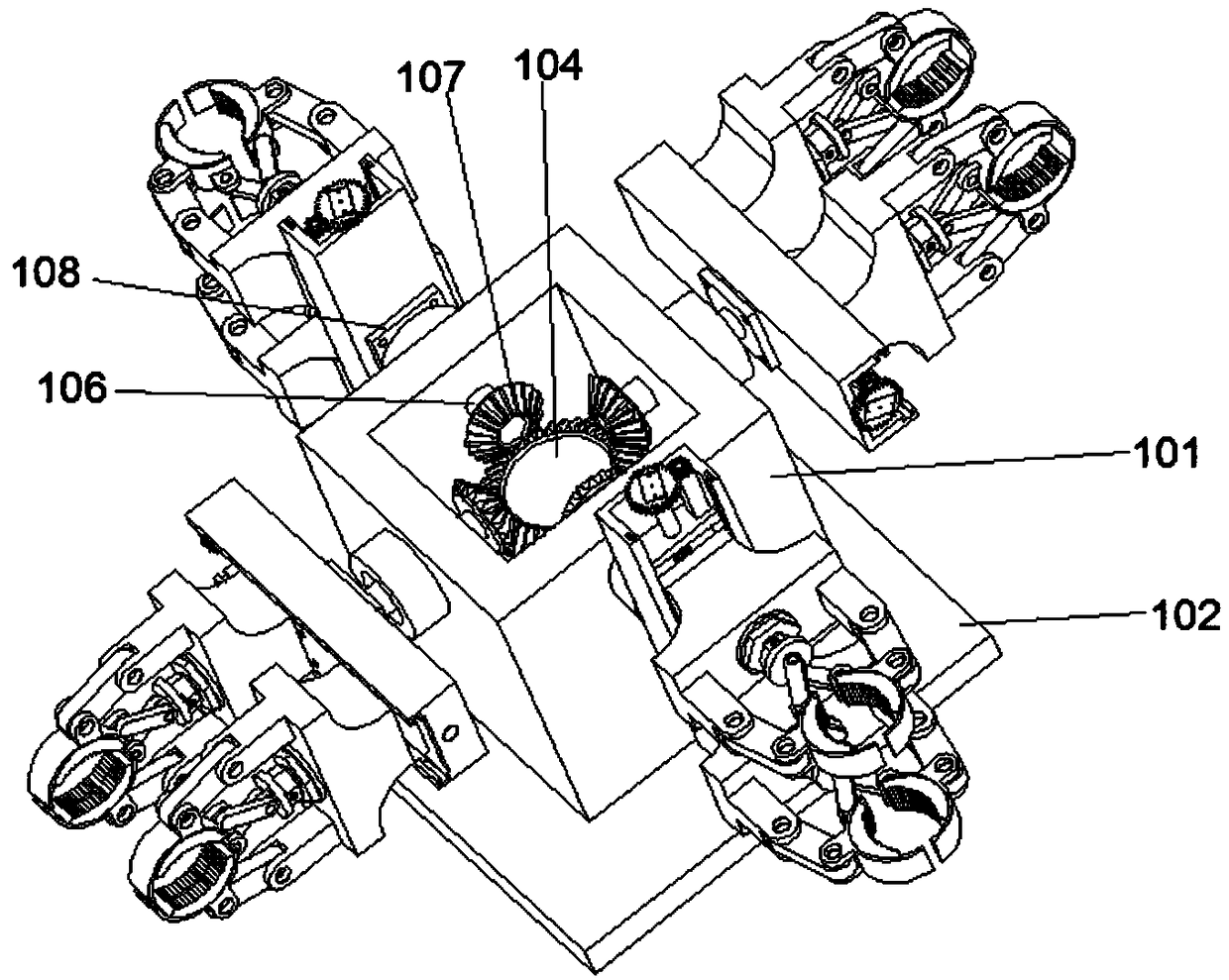

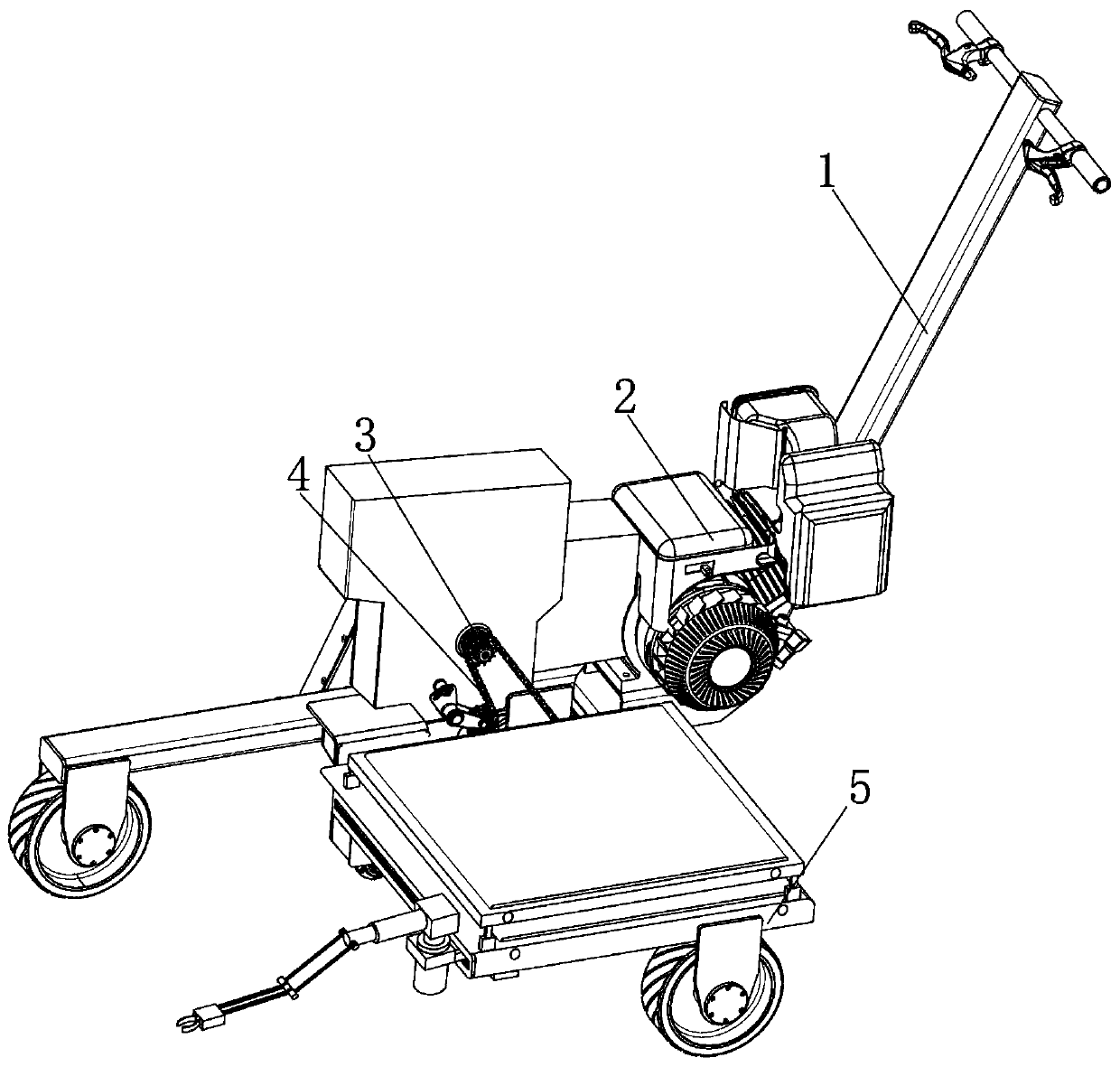

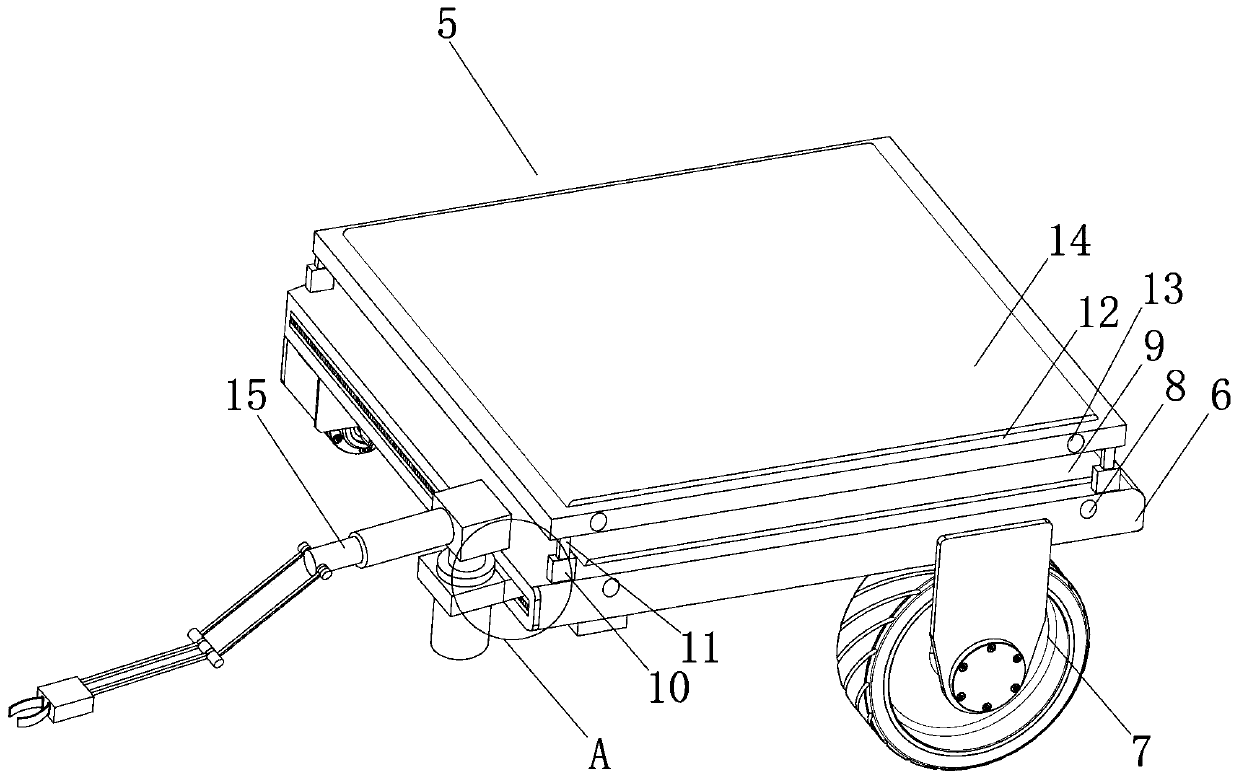

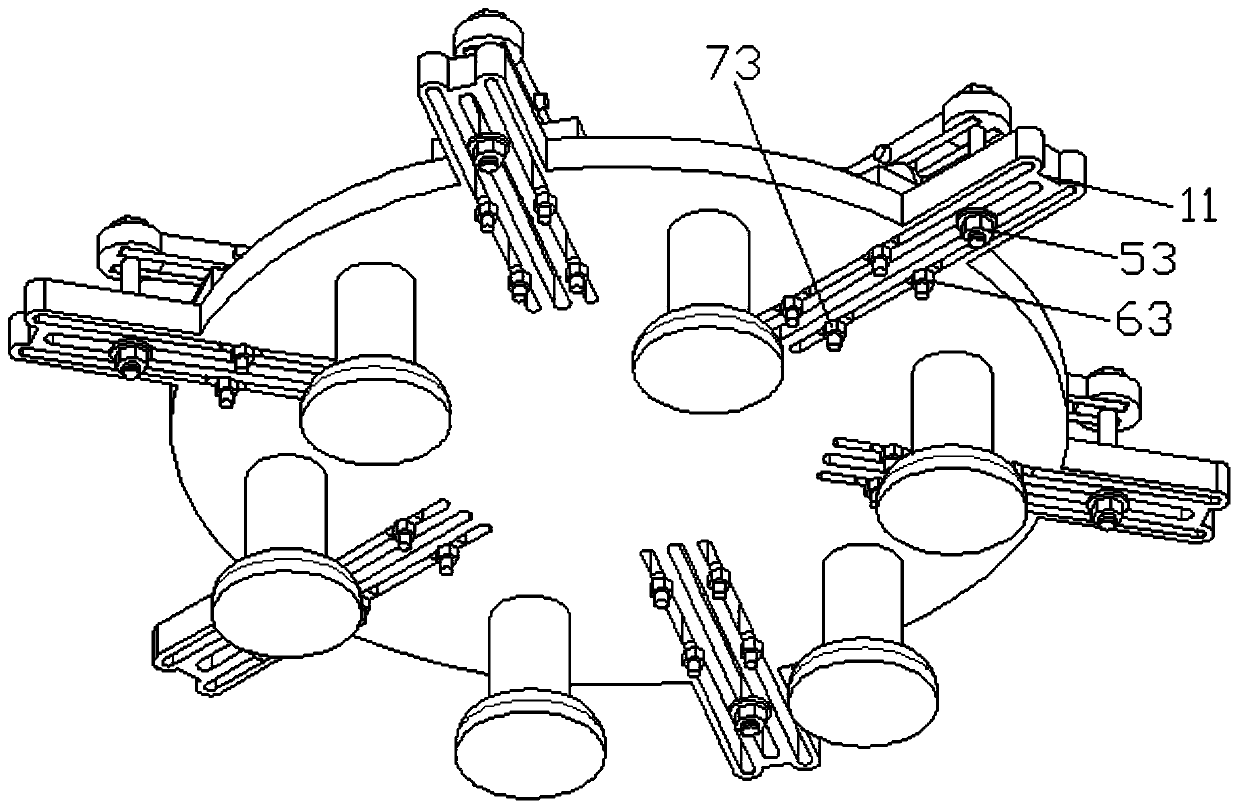

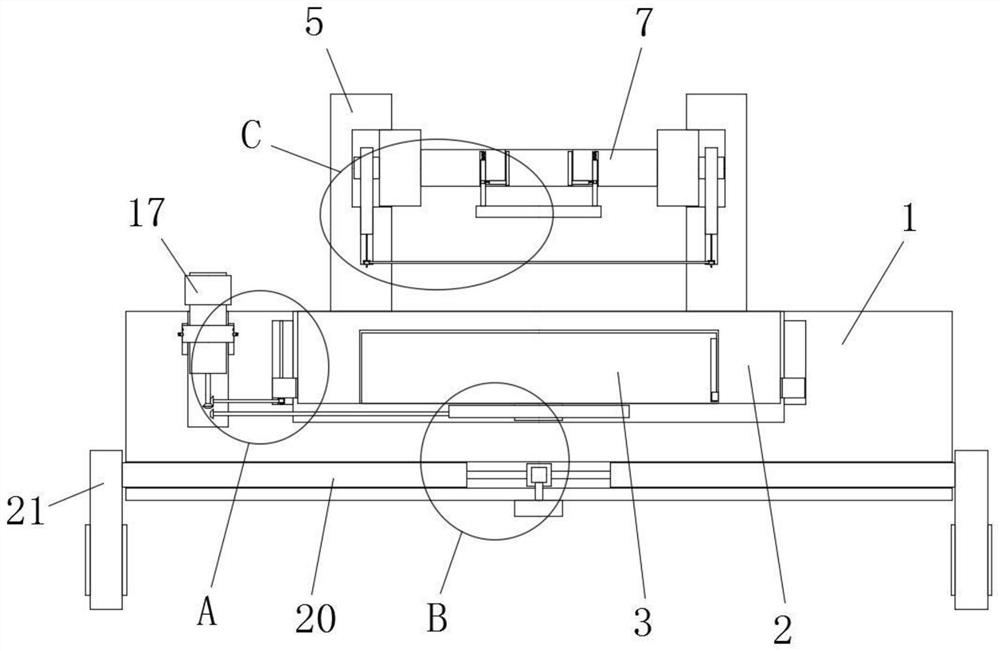

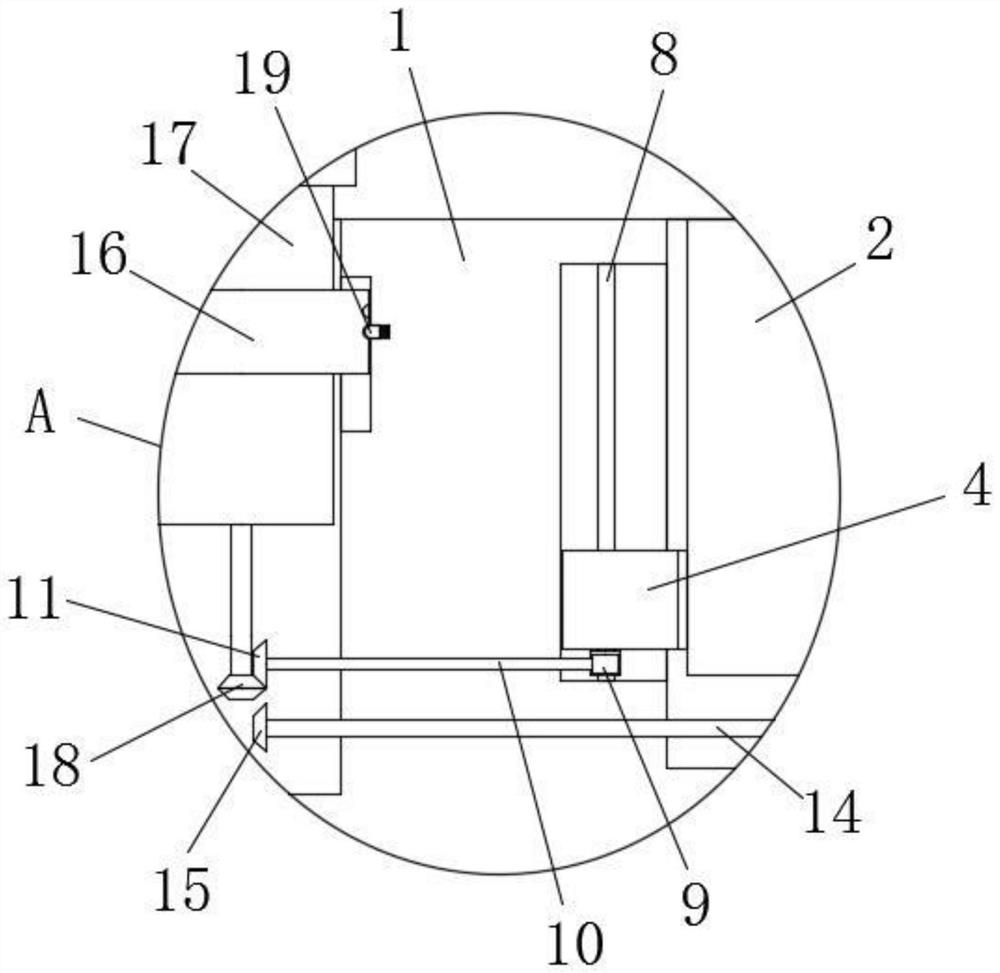

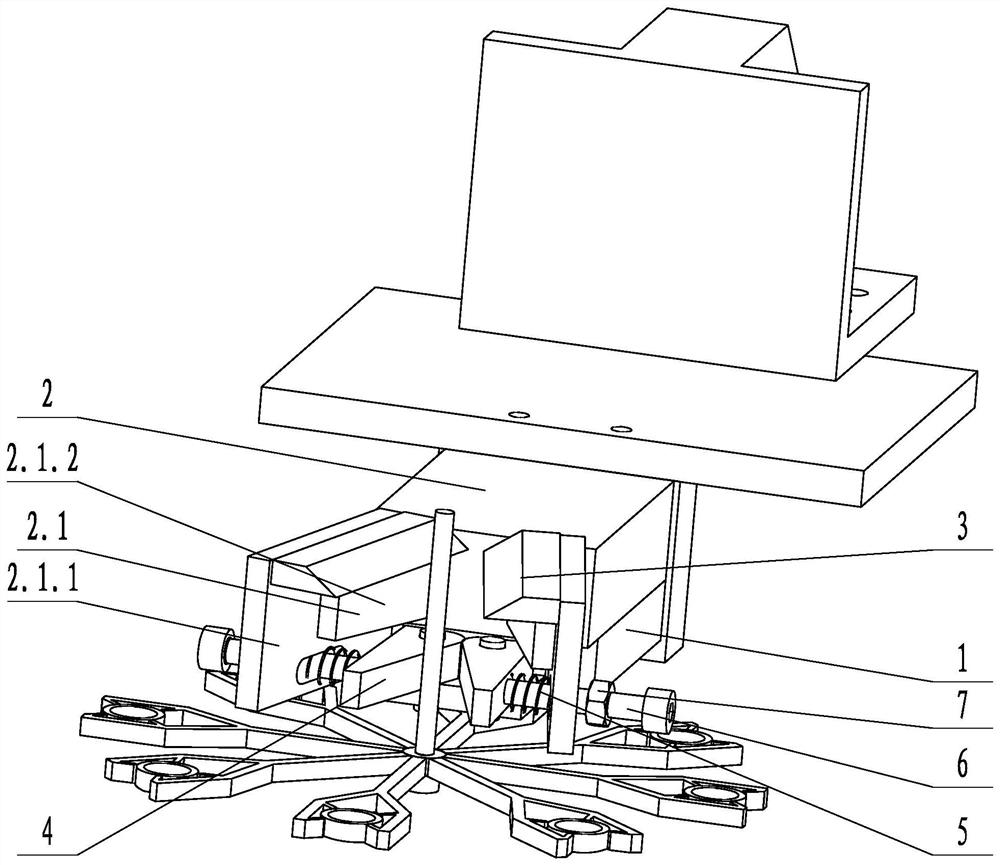

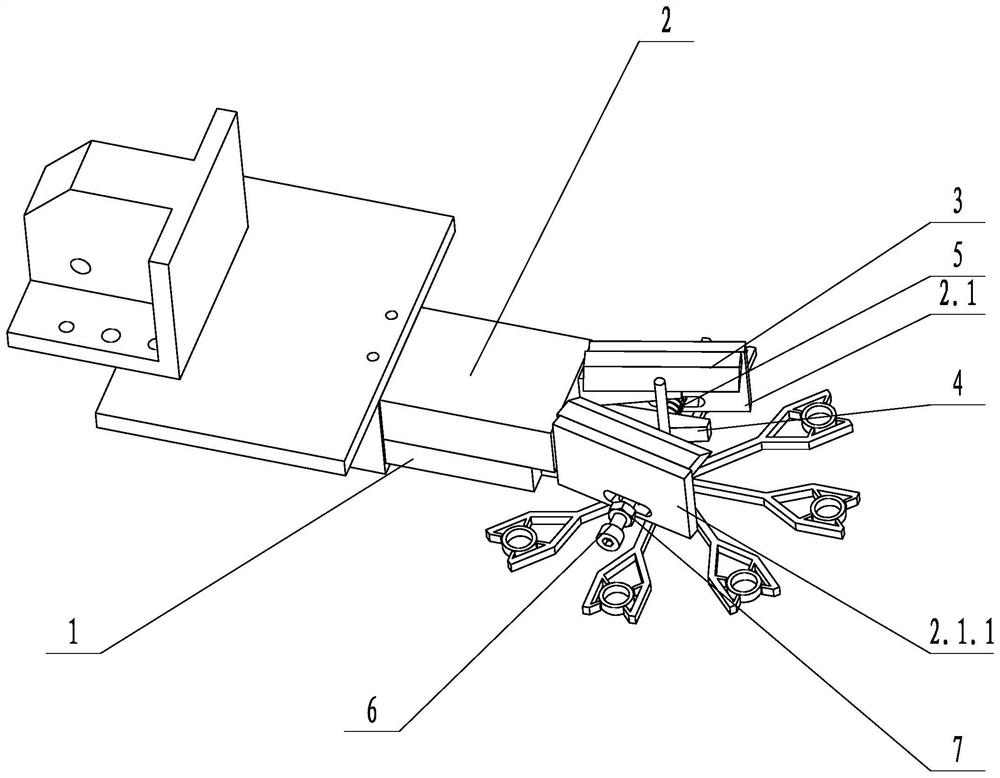

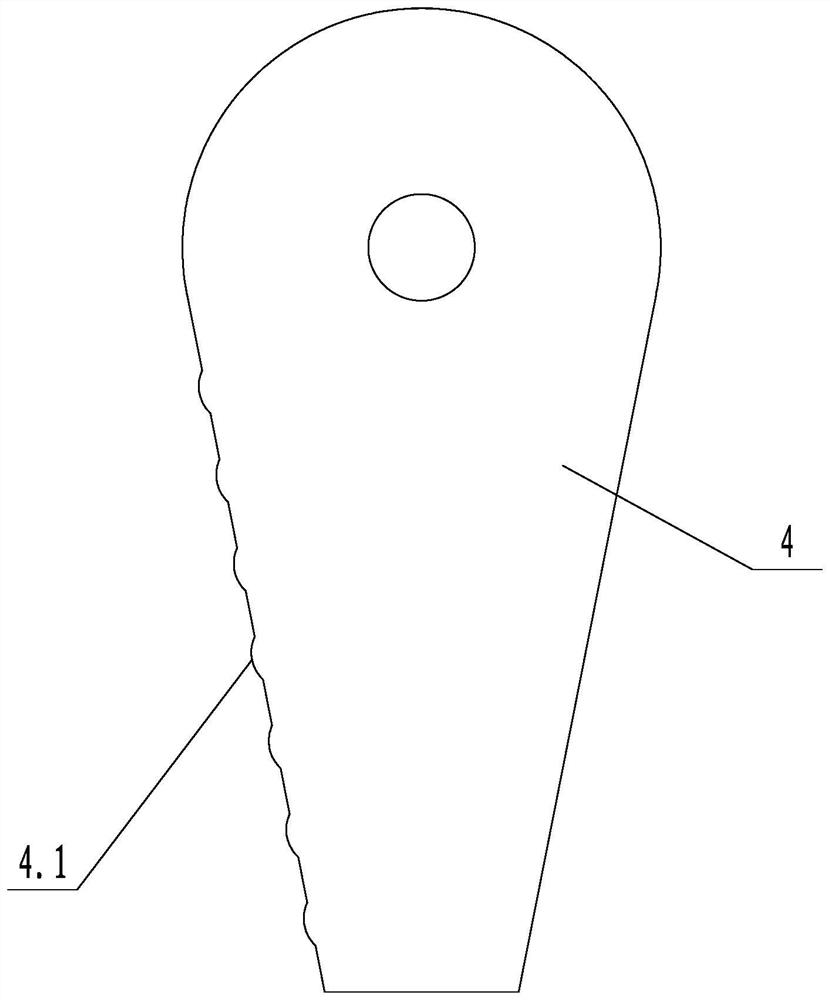

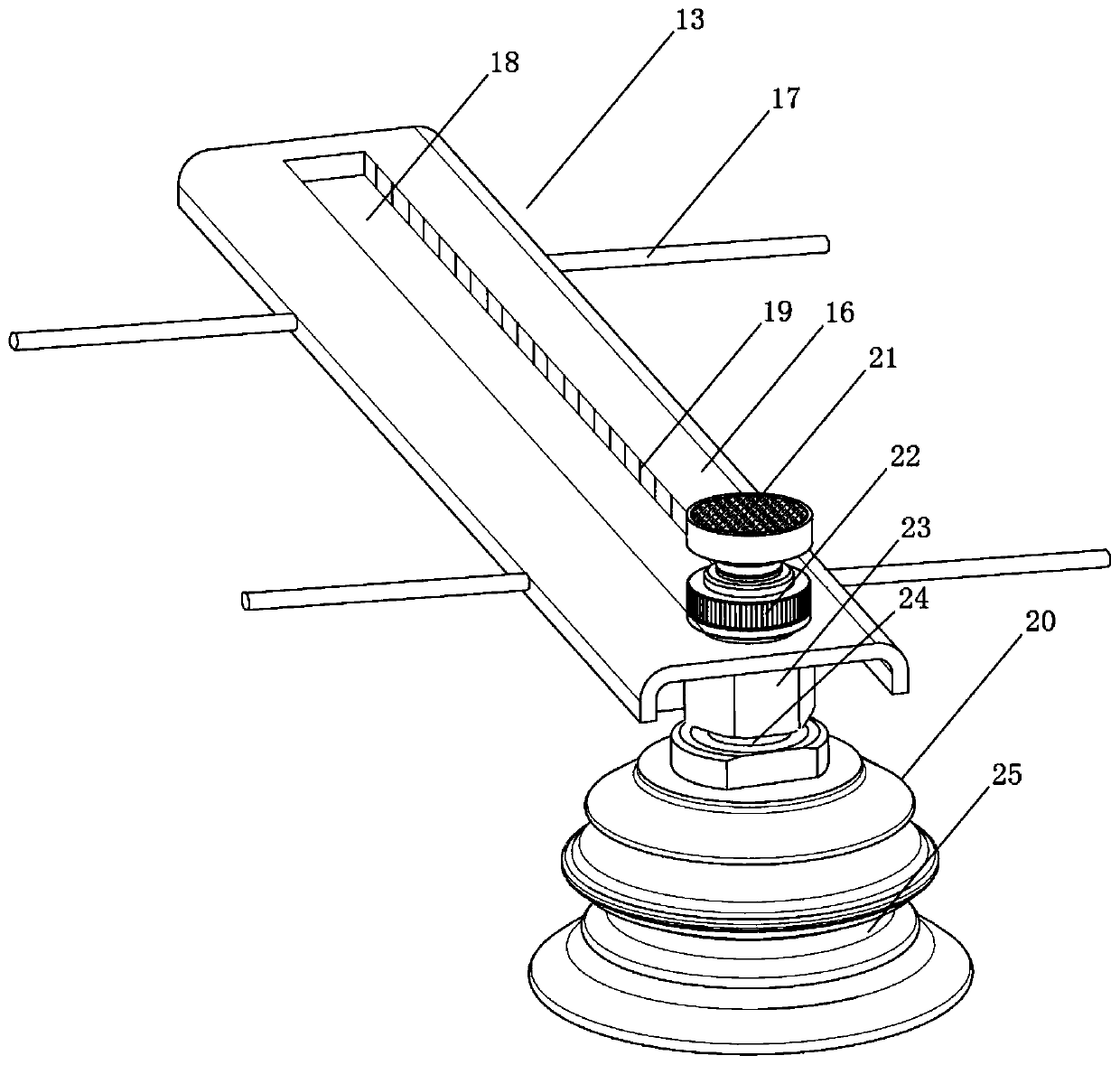

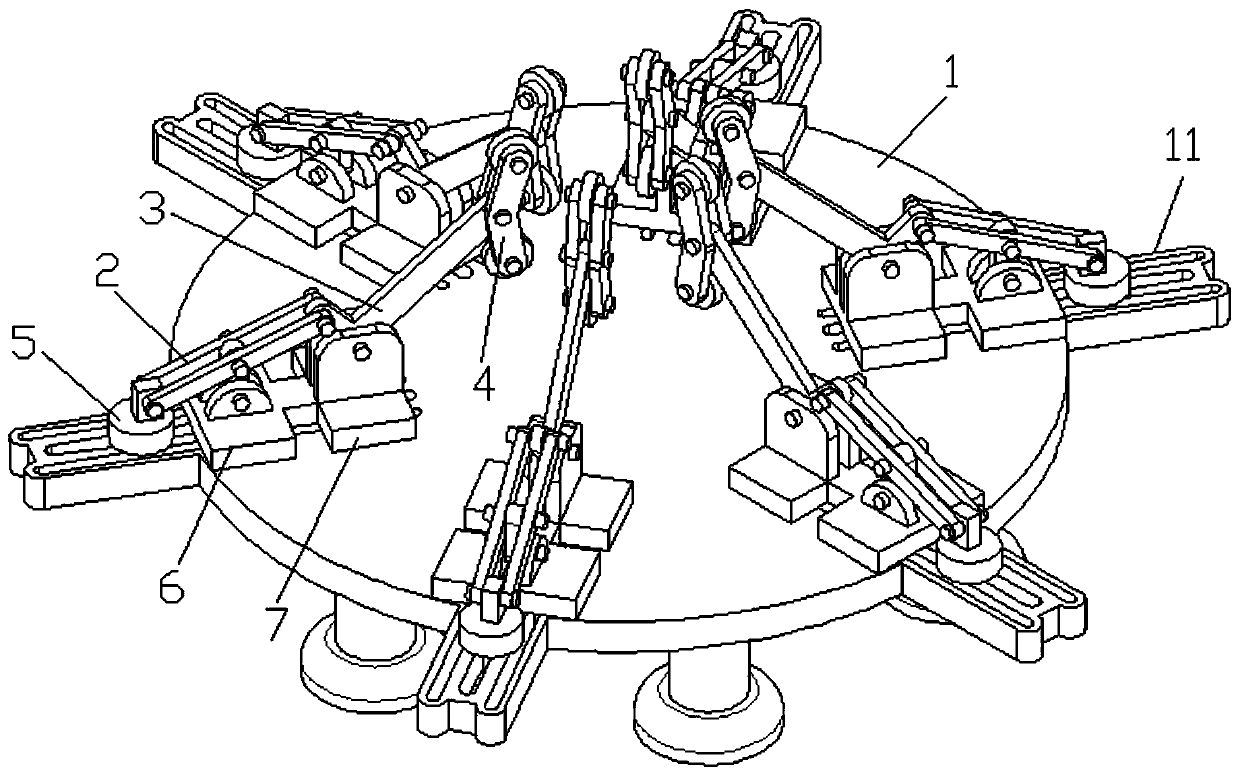

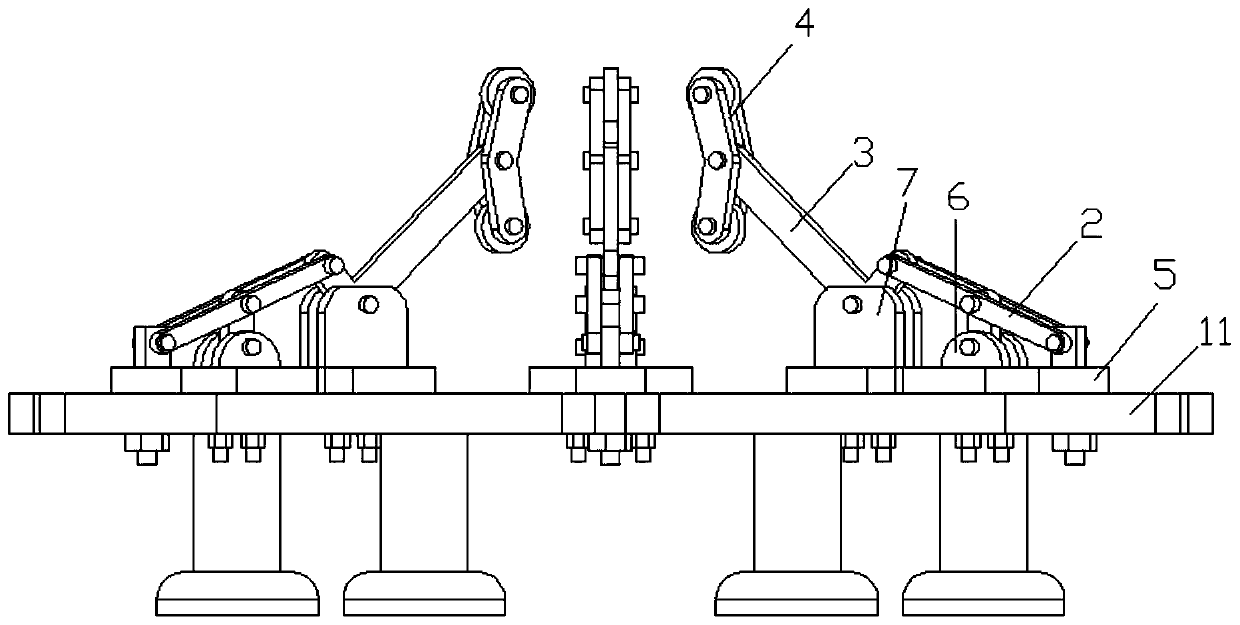

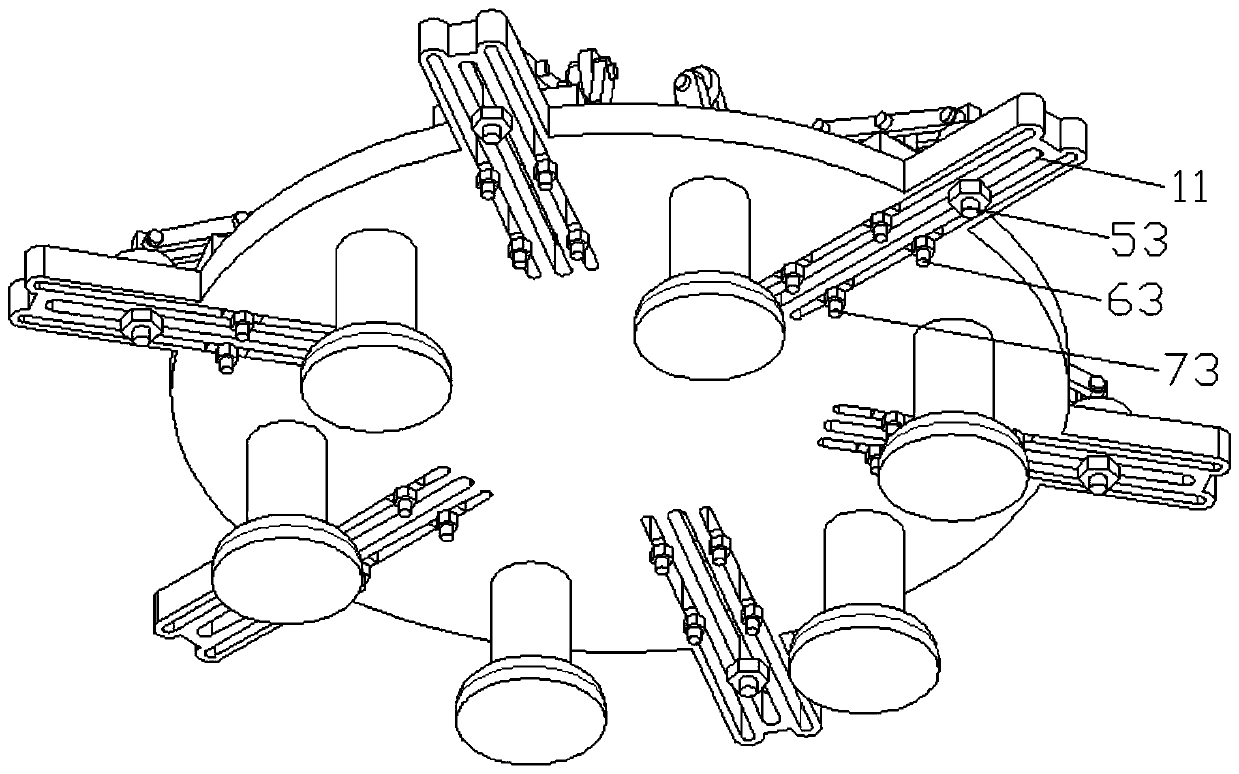

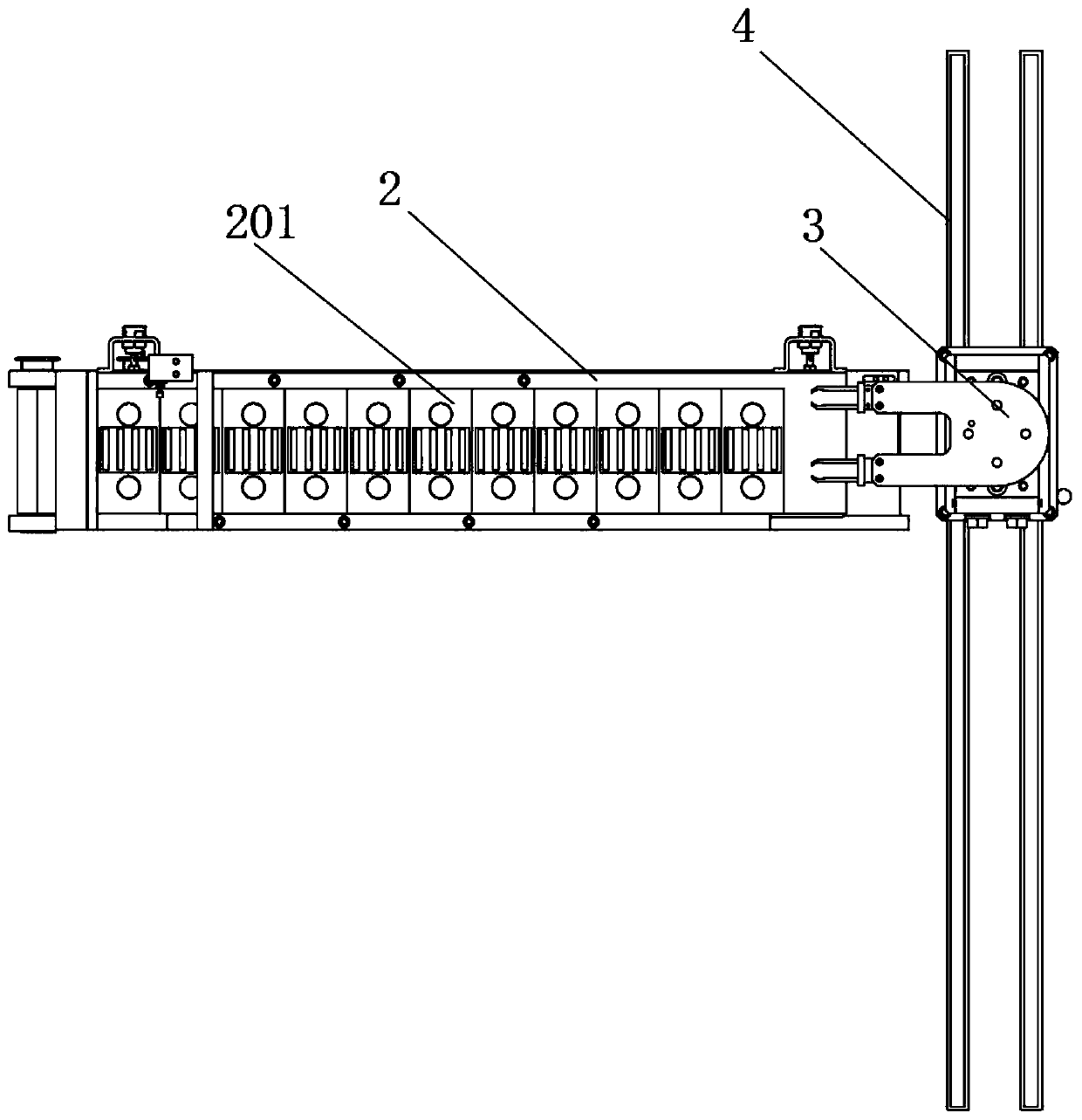

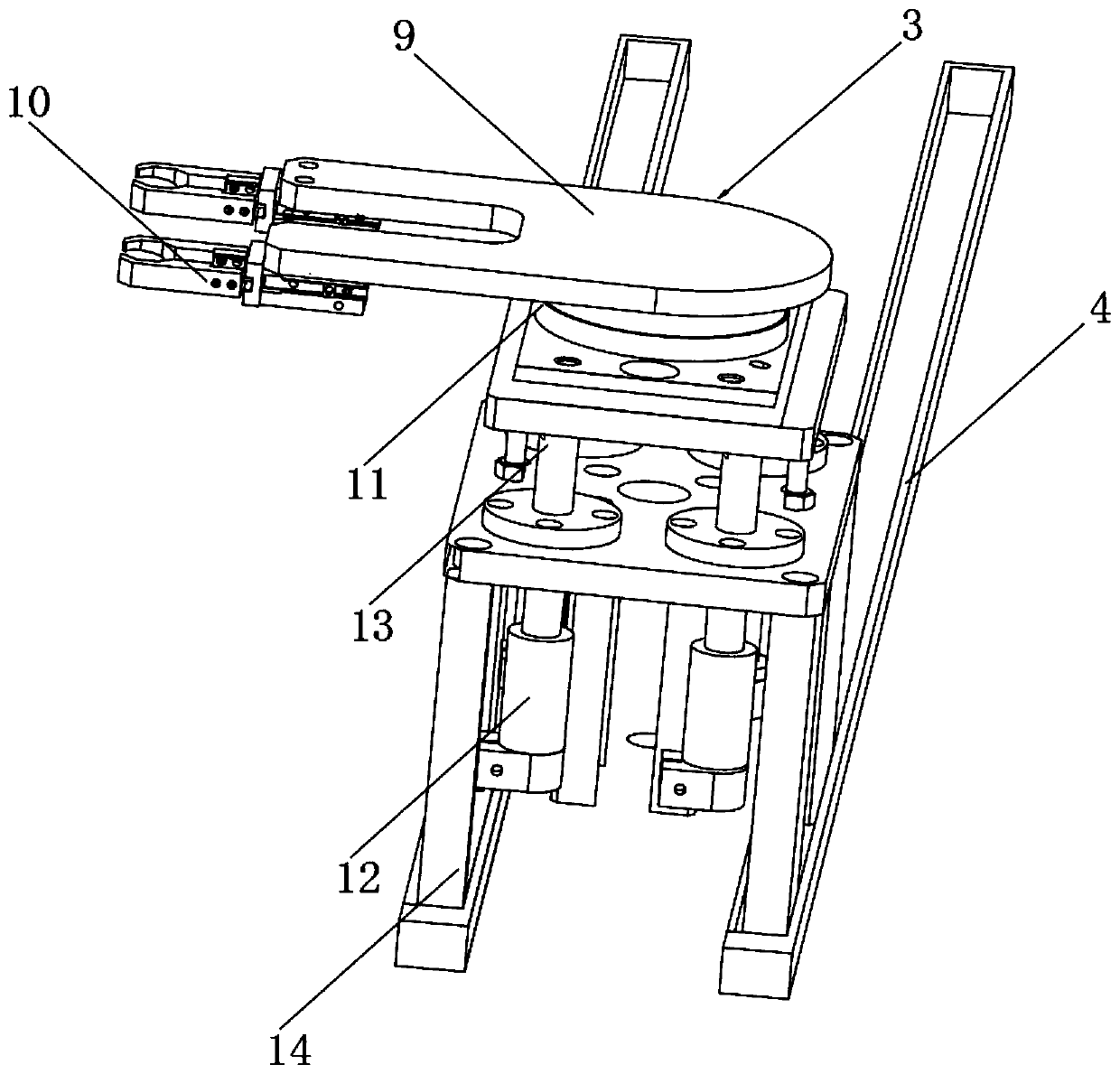

Intelligent fetching harvesting device for sugarcane harvester and using method of intelligent fetching harvesting device

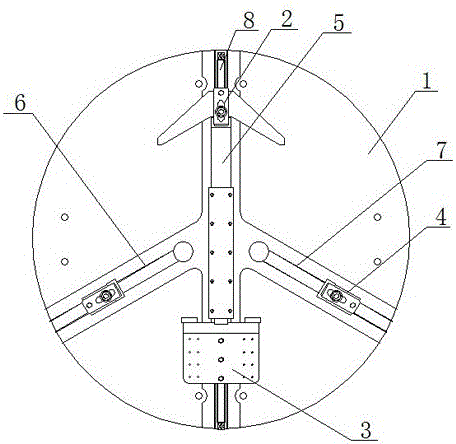

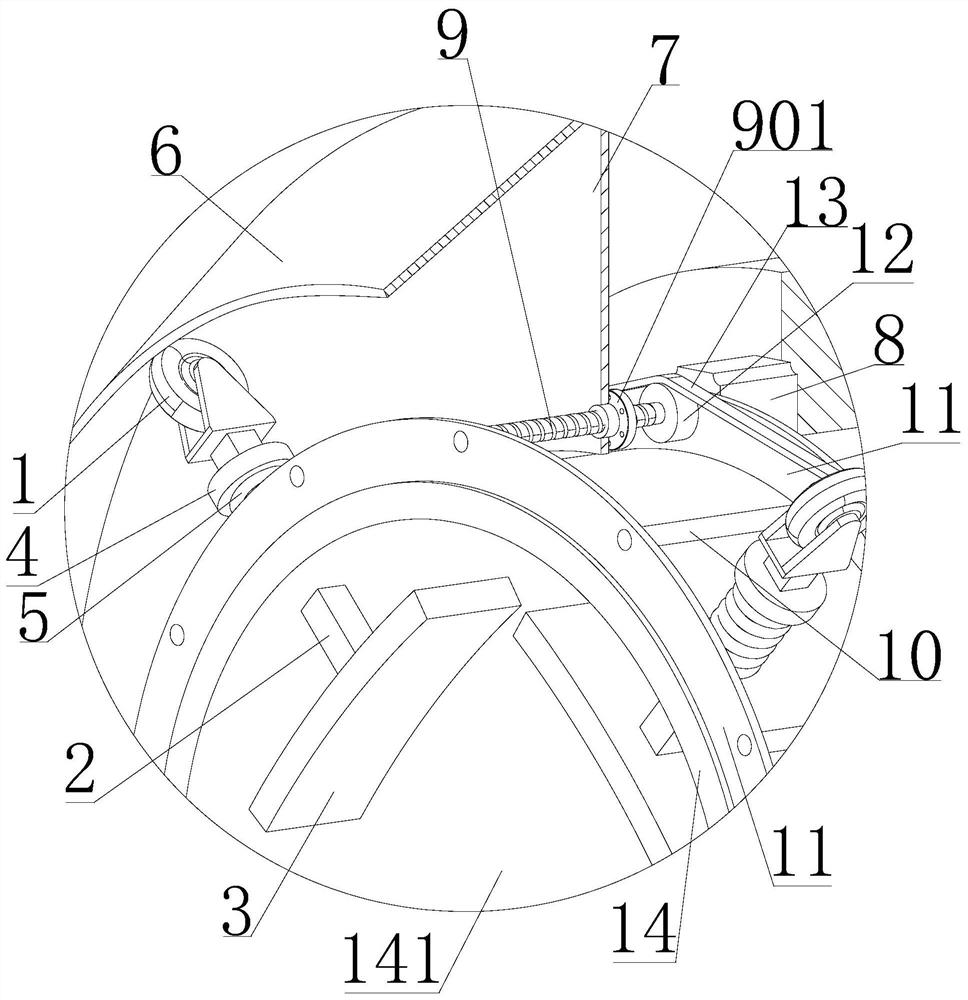

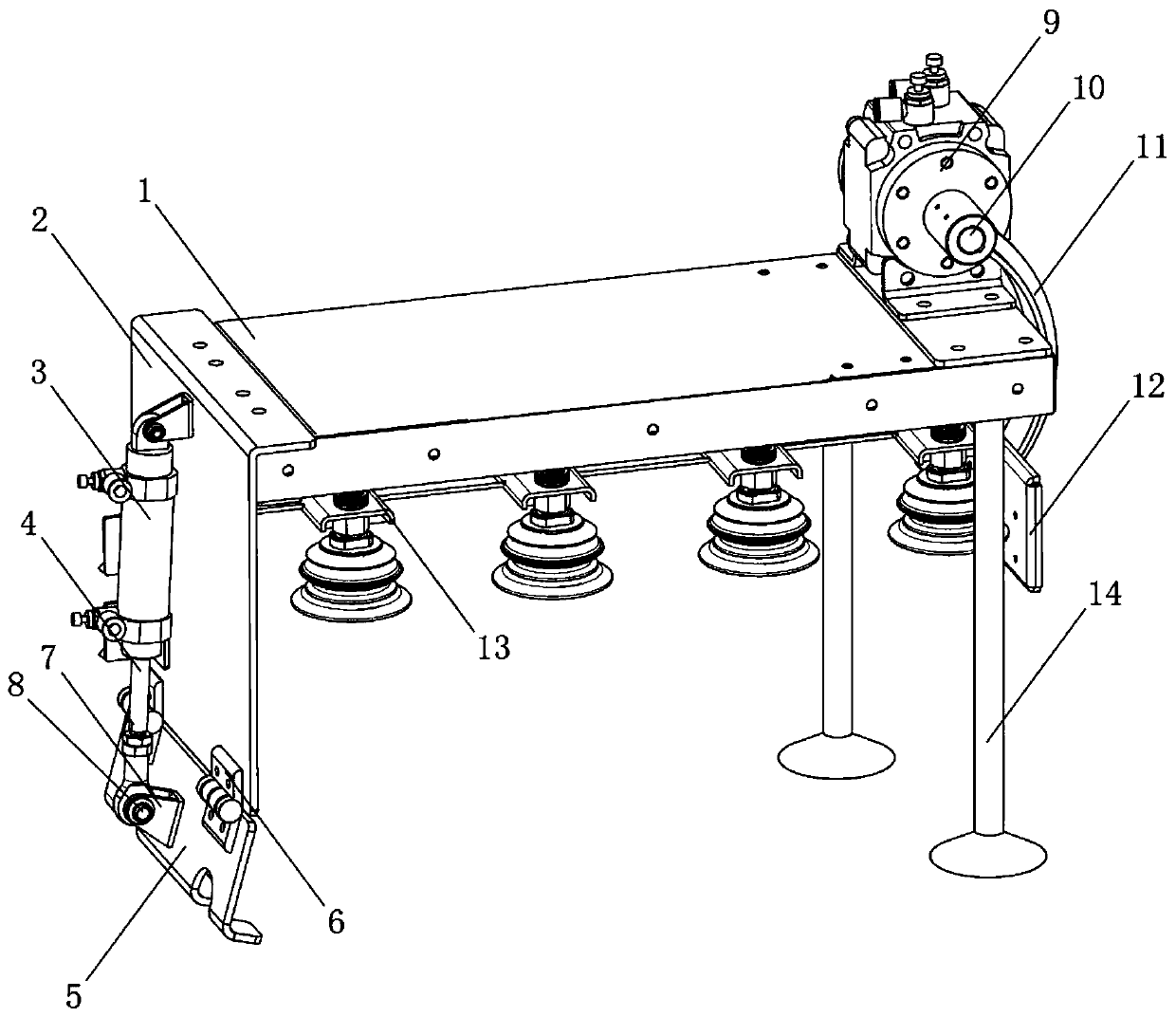

ActiveCN109429701AAccurate clamping positionImprove efficiencyHarvestersAgricultural lifting devicesEngineeringSecondary growth

The invention discloses an intelligent fetching harvesting device for a sugarcane harvester and a using method of the intelligent fetching harvesting device. The intelligent fetching harvesting devicecomprises a hollow rotary mechanism, arm lifting mechanisms, fetching arms, sugarcane supporting devices and a cutting device, wherein the sugarcane supporting devices convey sugarcane into the cutting area, the sugarcane is cut and separated, then the sugarcane is lifted by the arm lifting mechanisms, the hollow rotary mechanism rotates to make the sugarcane conveyed into a collection area, andfinally, the sugarcane is put down by the fetching arms. Compared with the prior art, in the intelligent fetching harvesting device for the sugarcane harvester and the using method of the intelligentfetching harvesting device, the fetching arms synchronously work, and the work efficiency is high. During cutting, the sugarcane is in a fixed state, the cuts of the sugarcane are regular, secondary growth of the sugarcane is not affected, the work efficiency is improved, and the labor force is liberated.

Owner:YANCHENG INST OF TECH

Dendrobium nobile indoor planting device and planting method thereof

PendingCN111296010AEasy plantingIncrease capacityTransplantingFurrow making/coveringHydraulic cylinderGear wheel

The present invention discloses a dendrobium nobile indoor planting device and a planting method thereof. The dendrobium nobile indoor planting device comprises a T-shaped grab rail, an engine and a planting frame, the grab rail is obliquely arranged, besides, the engine is positioned below the grab rail, one end of the engine is rotatably connected with a first gear, besides, an annular chain sleeves the first gear, and one end of a bottom part of the engine is connected with a planting frame through a fixed rod. Beneficial effects are as follows: a turning-over clamping claw is in a circulararc structure, ensures more tight and firm clamping of mud blocks under dendrobium nobile seedling below, it is firm, and put kind of platform and to the stem of dendrobium nobile seedlings, besides,a placing table clamps the dendrobium nobile seedlings on a first crawler belt, besides, after planting is completed, then a second hydraulic cylinder drives a rotating block to move upwards througha second hydraulic rod to adjust height, besides, the placing table clamps the dendrobium nobile seedlings loaded on a second crawler belt and carries to planting grooves, and the first crawler belt and second crawler belt respectively load the dendrobium nobile seedlings and greatly improve holding capacity for supporting and carrying the dendrobium nobile seedlings.

Owner:ANHUI TONGCHUANG MODERN AGRI INVESTMENT DEV

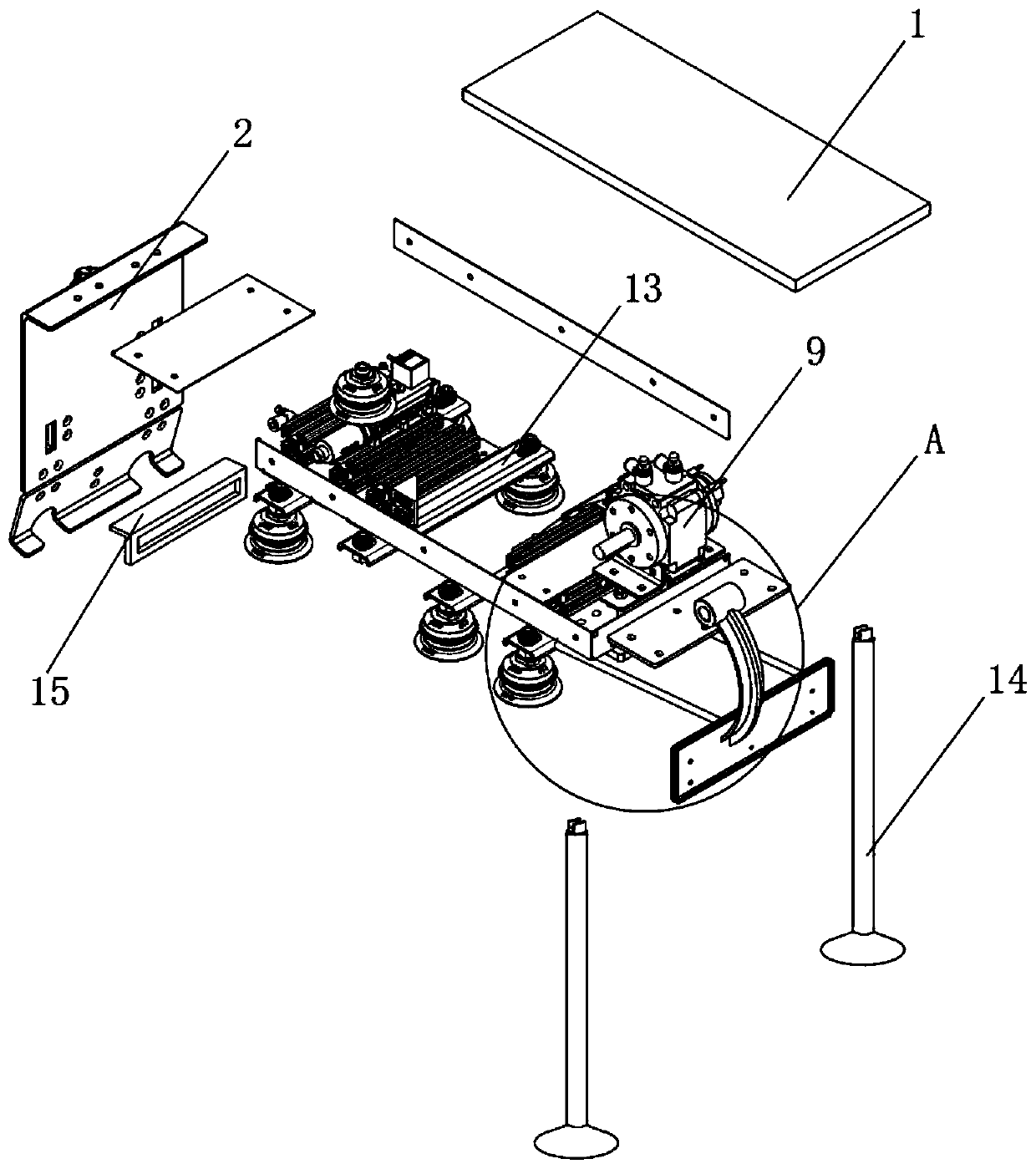

Cable appearance defect on-line detection equipment

PendingCN114527144APromote repairEasy to operateMaterial analysis by optical meansDisplay deviceStructural engineering

The invention relates to cable appearance defect online detection equipment which comprises a main counter, and a main detection device, an auxiliary positioning installation device and two three-jaw chucks are installed on the main counter. The two three-jaw chucks are located on the left side and the right side of the main counter respectively. The auxiliary positioning and mounting device comprises two semicircular ring sleeves, and the central axes of the two semicircular ring sleeves are collinear with the central axes of the two three-jaw chucks; the main detection device comprises an auxiliary cabinet frame installed on the rear portion of the main cabinet table, and a detection displayer and a detection main drive assembly which are both installed on the auxiliary cabinet frame. According to the invention, coaxial positioning is carried out on the cable during installation through the semi-circular ring sleeve, and the clamping position is ensured to be accurate, so that the detection accuracy is improved. The detection probe head can be controlled to make full contact with the whole outer surface of the cable, feedback is conducted through the jumping value, the defect position is found in time, and repairing is convenient. The whole detection process is completed through automatic instruments except for clamping, and operation is relatively convenient.

Owner:ANHUI STAR CABLE

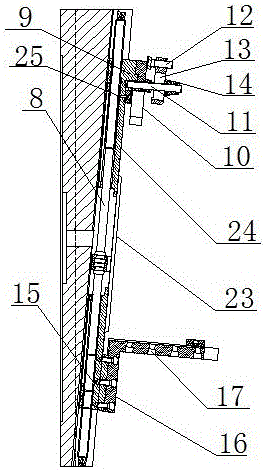

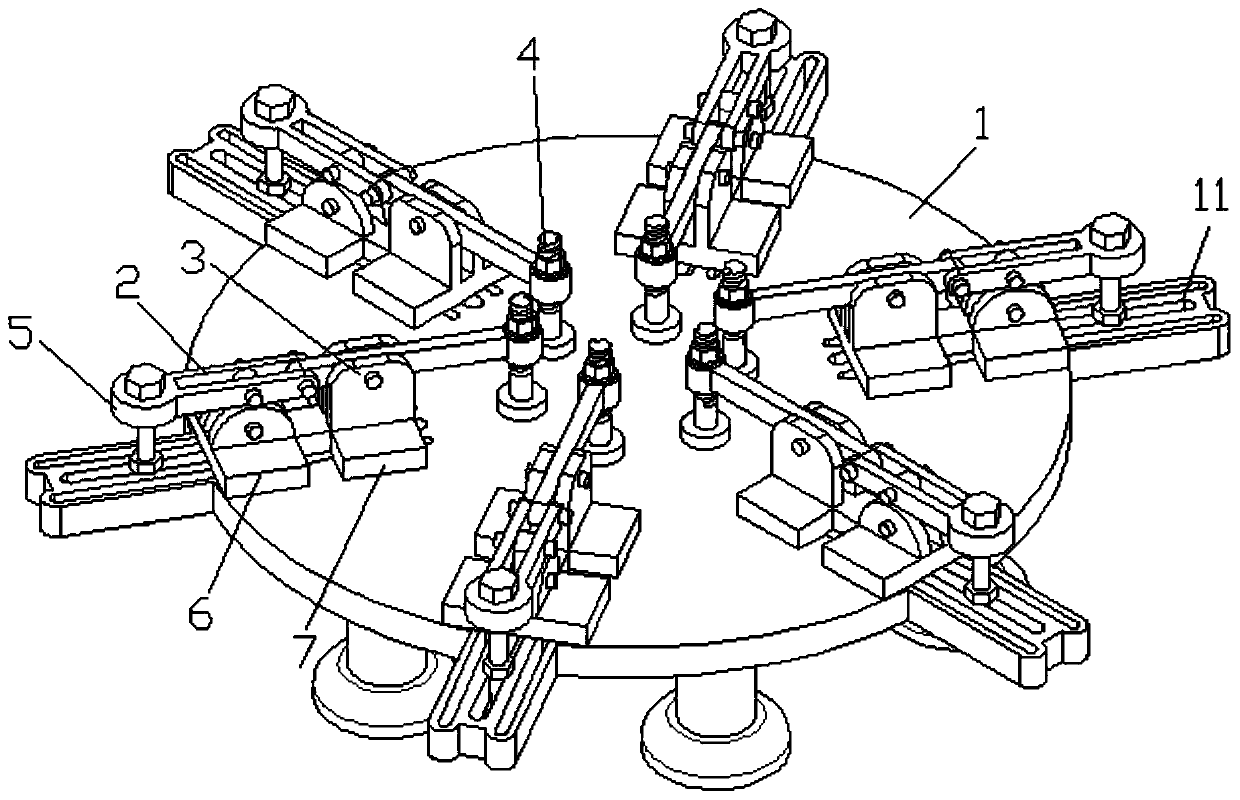

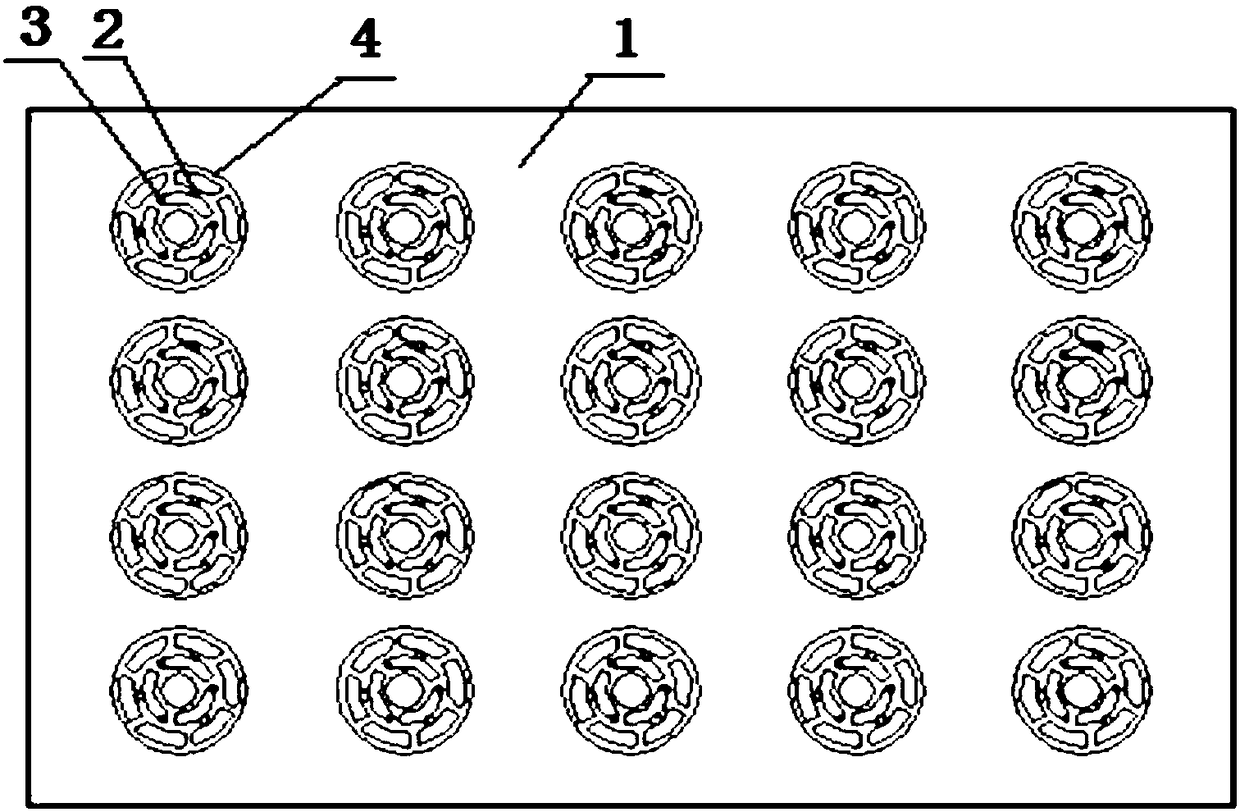

Fairing clamp

PendingCN110216604AVersatileAccurate clamping positionWork holdersWind energy generationEngineeringCowling

The invention provides a fairing clamp. The clamp comprises a base plate and a plurality of clamping units uniformly distributed on the base plate, each clamping unit comprises a clamping part which is driven by a connecting rod assembly to move and locate; a sleeve part is arranged at the free end of the connecting rod assembly, and inner threads are arranged on the sleeve part; and the clampingpart comprises a clamping bolt and a pressing block which are arranged up and down and fixed by welding, the clamping bolt is in threaded fit with the sleeve part and is fixed by fastening a nut, andthe pressing block abuts against the lower edge of the fairing. The clamp is provided with the plurality of clamping units, the plurality of clamping units are matched to realize the clamping and fixation of the lower edge of the fairing, the plurality of clamping units are independent to one another and have a same structure, each clamping unit can realize the clamping with different or identicalstrength of the lower edge of the fairing through the cooperation of the connecting rod assembly and the clamping part, the clamping units can be applied to clamping fairings with different specifications and sizes, and the universality is high.

Owner:EULIKIND TIANJIN TECH

Slotting mechanism for hull plate processing and application method thereof

ActiveCN109865861AAccurate locationQuality improvementLarge fixed membersMetal working apparatusHydraulic pumpEngineering

The invention discloses a slotting mechanism for hull plate processing and an application method thereof. The slotting mechanism comprises a cabinet body, a clamp-put table, a slotting seat and a piece discharging hopper, wherein the clamp-put table is horizontally arranged above the cabinet body, the slotting seat is longitudinally formed in one end of the clamp-put table, and the piece discharging hopper is obliquely arranged under one side of the slotting seat. The slotting mechanism has the beneficial effects that a motor I drives a push plate through a rolling belt to movably regulate theclamping and blocking position of a plate, so that the mechanism can clamp and block the plates with different lengths and slot and drill the plates; clamping frames on the two sides of a piece placing slot are matched to clamp and block the two sides of the plate, so that the plate is more stable and firm when being slotted, and the slotted position of the plate is more accurate and has higher quality; and a hydraulic pump II pushes the plate through a push block into the piece discharging hopper to be discharged, so that a worker can conveniently transfer and arrange the slotted plate, thehigh automation of work of the mechanism is ensured, and the mechanism saves time and labor during use.

Owner:天长市平安船舶设备有限公司

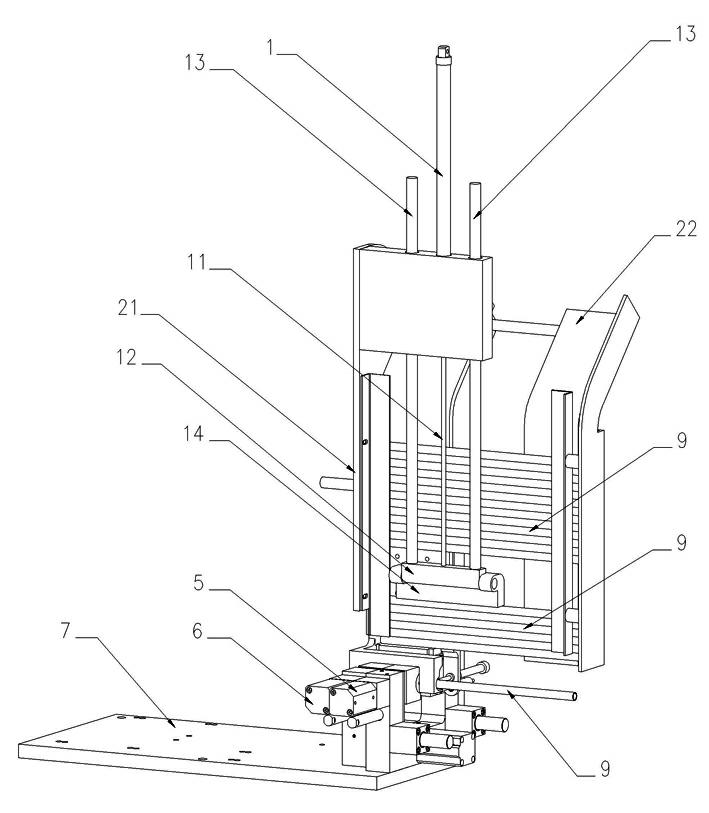

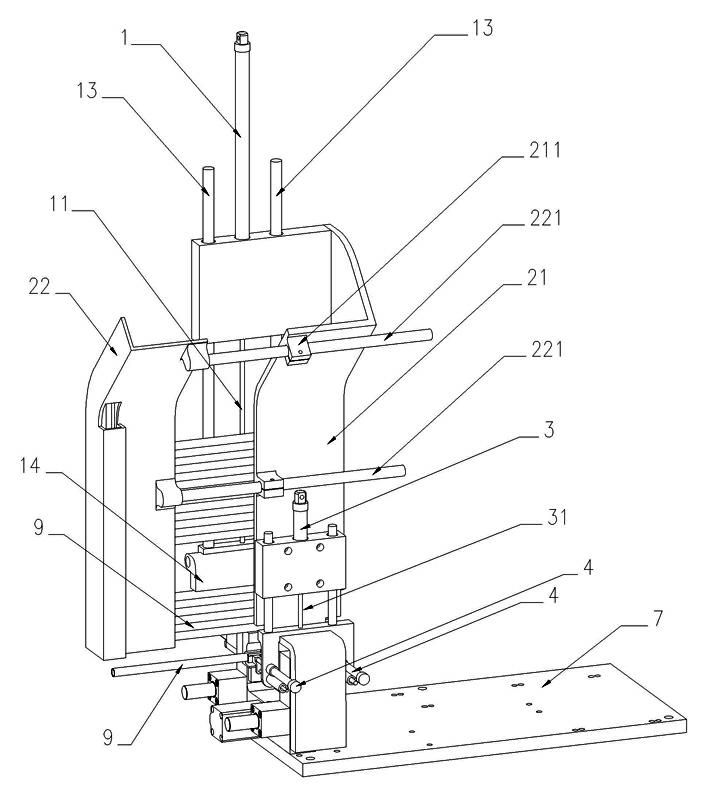

Automatic side wing stretcher

PendingCN111289366AReduce work intensityEasy to operateMaterial strength using tensile/compressive forcesControl systemClassical mechanics

The invention discloses an automatic side wing stretcher, which comprises a rack and a control system, wherein an upper clamp and a lower clamp which correspond to each other up and down are arrangedon the rack; the upper clamp is fixed to the rack, and an upper driving device capable of driving the upper clamp to be clamped or opened is arranged on the rack; the lower clamp is connected to the rack in a sliding mode, and a lower driving device capable of driving the lower clamp to be clamped or opened is arranged on the rack; a stretching driving device drives the lower clamp to slide up anddown; a hanging plate close to the bottom of the upper clamp is fixed below the upper clamp on the rack; the hanging plate is provided with a hanging seam which is used for laterally clamping the side wing so as to limit s back buckle from falling from top to bottom and is through up and down; the rack is provided with a pushing out device for pushing a side wing clamped in the hanging seam frombelow the hanging plate out and enabling the side wing to be separated from the hanging plate; and a receiving device for receiving an underwear falling from above is arranged below the lower clamp. By means of the combined design, automatic positioning, clamping, stretching, discharging and receiving of the side wing are achieved, operation is easy and convenient, and the stretching efficiency ishigh.

Owner:YINGSHANG MATIAN TEXTILE PROD CHINA ZHONGSHAN

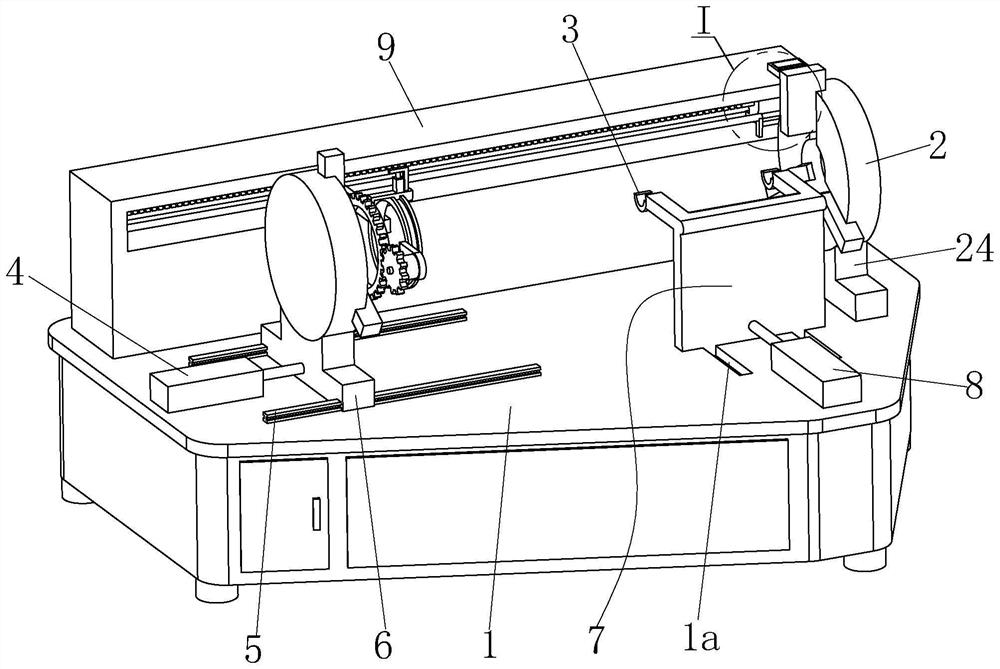

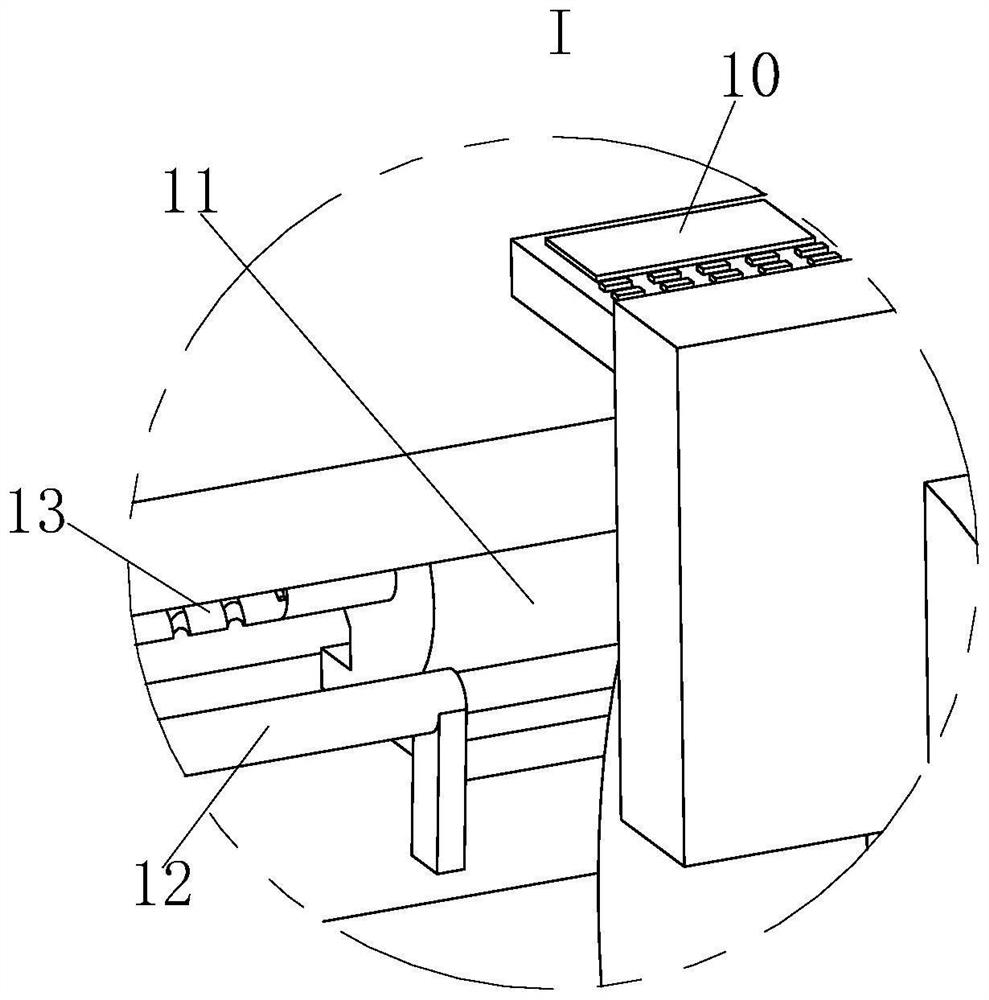

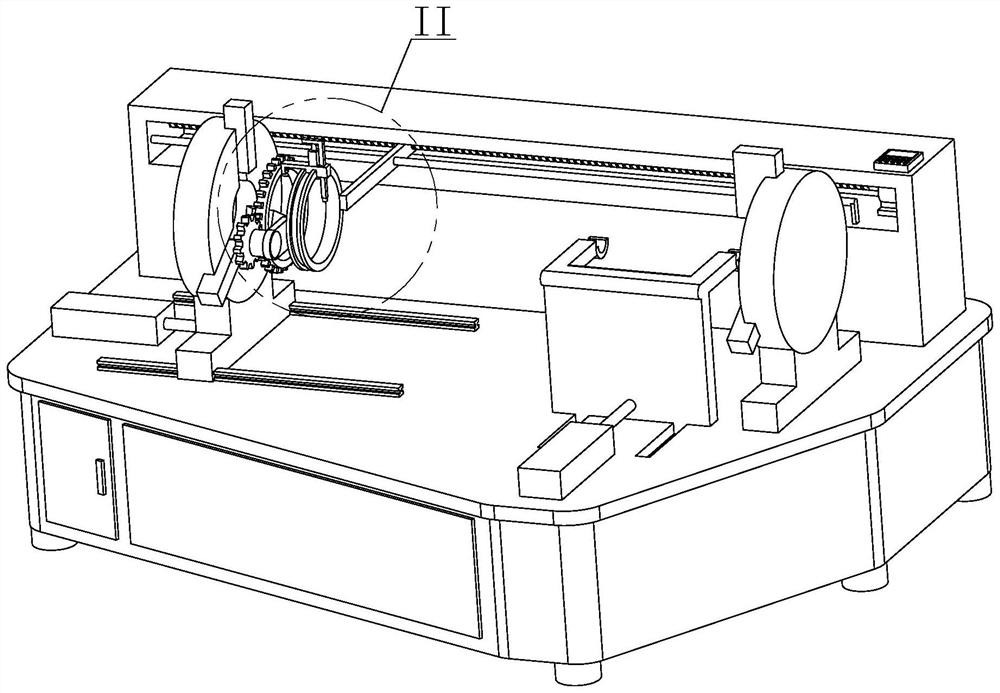

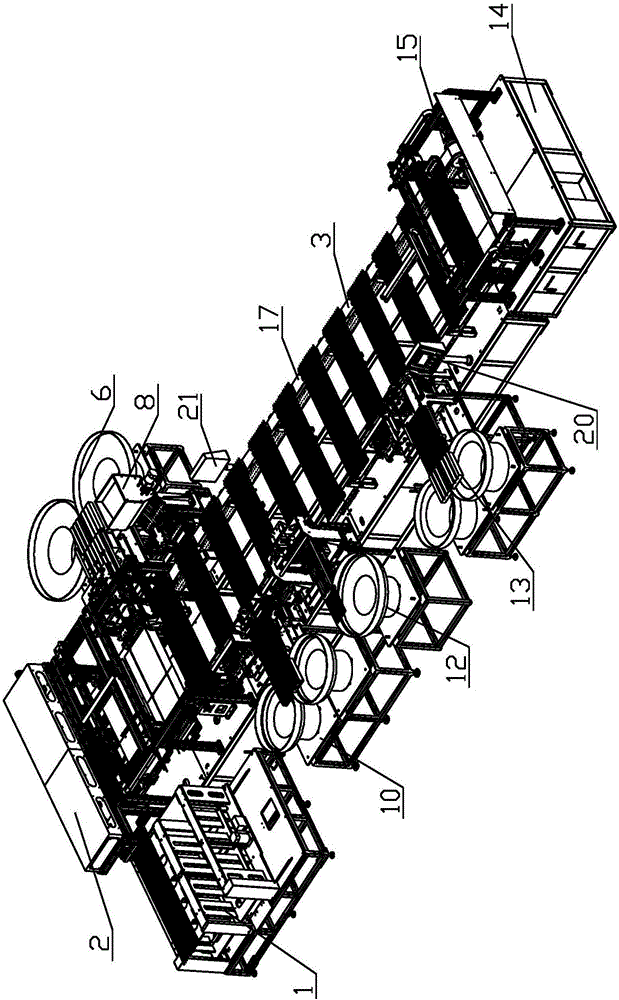

Straight long tube machine

The invention relates to a straight long tube machine. The straight long tube machine is characterized by comprising a front end rack used for installing a catheter feeding device, and a finished product blanking rack used for installing a finished product blanking device, wherein a left side rack and a right side rack which are used for erecting a conveyer device are fixedly installed between the front end rack and the finished product blanking rack; the catheter feeding device is connected with a catheter storage device; the catheter feeding device is connected with a catheter translation device, the catheter translation device is connected with a catheter cache positioning device, and the catheter cache positioning device is connected with a regulating box feeding device; a catheter moving device is erected above the catheter cache positioning device; the conveyer device is also sequentially and fixedly connected with a regulating wheel feeding device used for putting a regulating wheel into a regulating box, a catheter gluing device used for gluing catheters, a two-pass feeding device used for taking out a two-pass, a two-pass gluing device used for gluing the outer ring of the two-pass, a latex tube feeding device used for taking out latex tubes, a latex tube gluing device used for gluing the inner rings of the latex tubes, and a filter feeding device used for taking out a filter.

Owner:梁启明

A stable clamping device for finishing the steering knuckle of forklift accessories

ActiveCN112108912BAvoid damageFull gripPositioning apparatusMetal-working holdersControl engineeringStructural engineering

The invention discloses a stable clamping device for finishing the steering knuckle of a forklift accessory, which includes a base, and the top surface of the base is respectively equipped with a bracket one and a bracket two, and the bracket one is provided with two, and the two brackets one A guide rod is installed between them, a screw rod is rotatably sleeved on the second bracket, one end of the screw rod is fixedly connected with a turntable, and a moving block is respectively installed on the other end of the screw rod and the guide rod, and the moving block Connecting rods are fixedly connected between the blocks, and the top surface of the moving block is fixedly connected with the first casing and the second casing, and the side walls of the first casing and the second casing are respectively equipped with electric motors; the invention can turn and turn joint, so that the steering knuckle can be transposed, no need to clamp and fix the steering knuckle twice, save time and effort, reduce labor costs, facilitate surface change processing, and can fully clamp and stabilize the steering knuckle, which is beneficial to the finishing use of the steering knuckle, making The clamping is simple, the clamping installation time is reduced, and the working efficiency is improved.

Owner:HEFEI DONGLU MACHINERY MFG

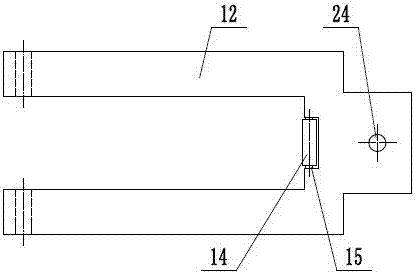

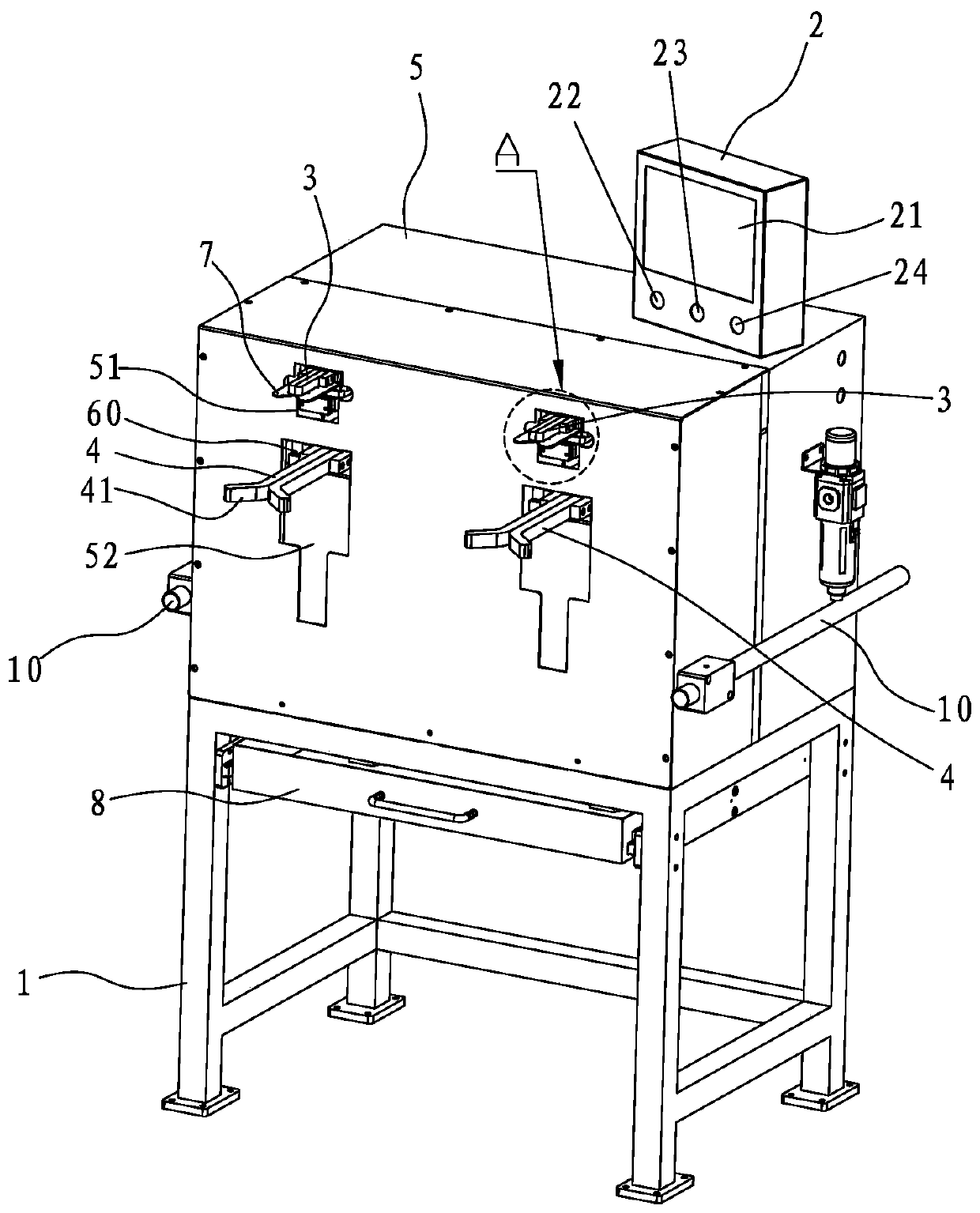

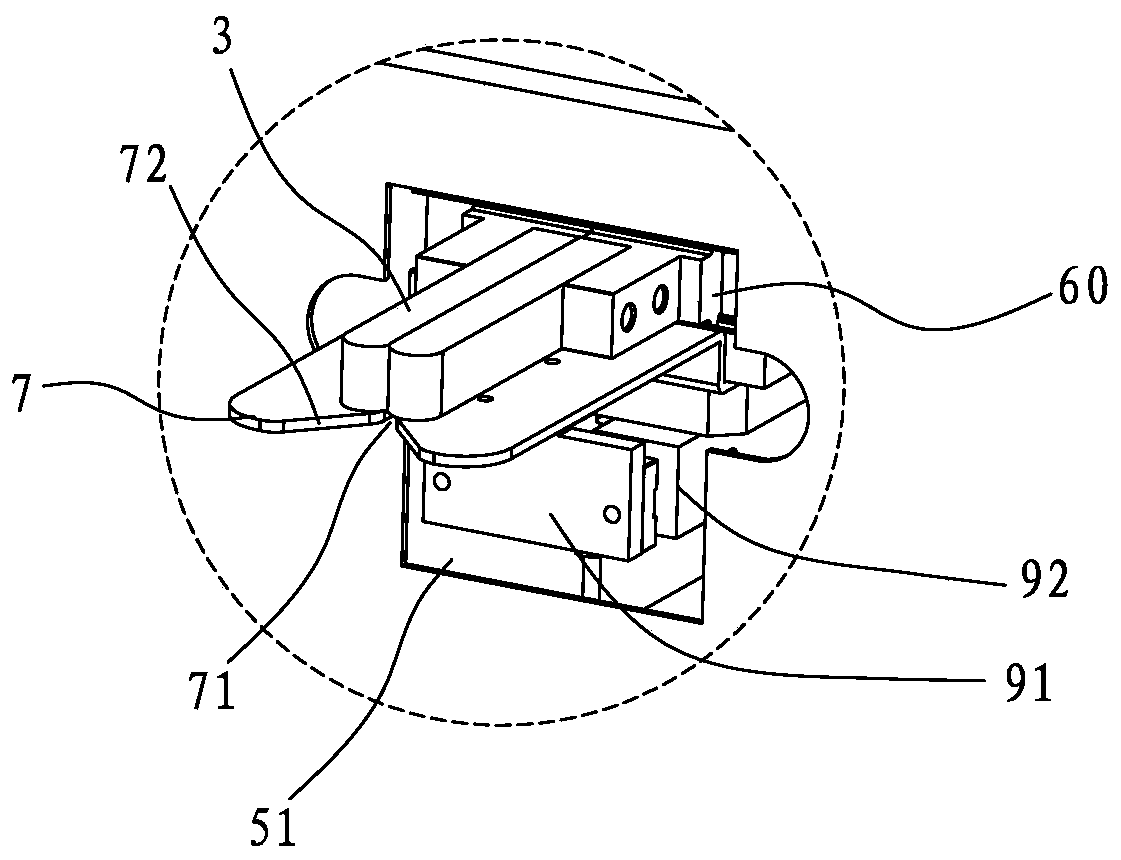

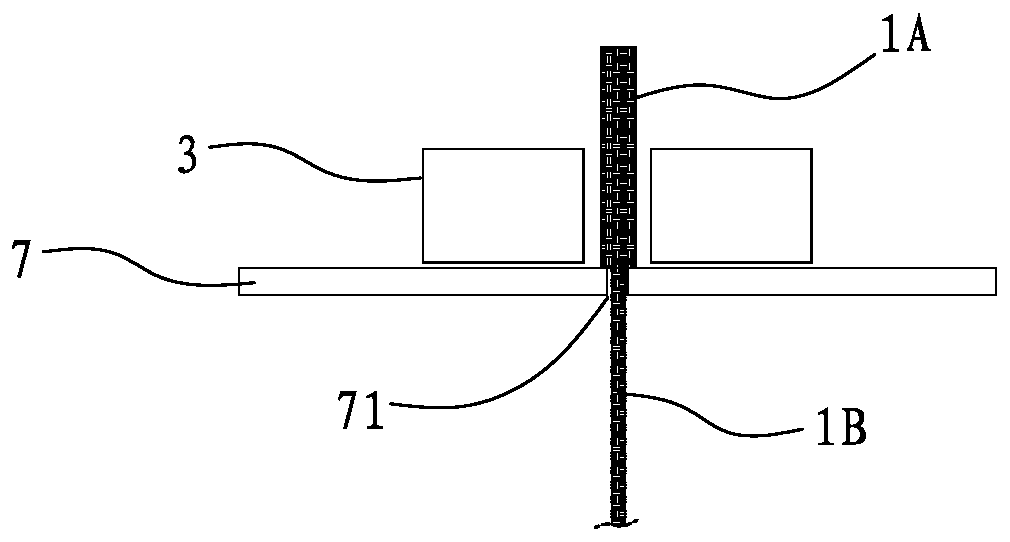

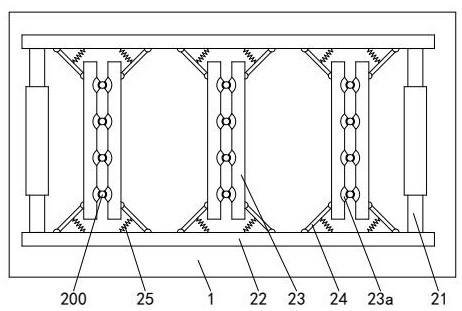

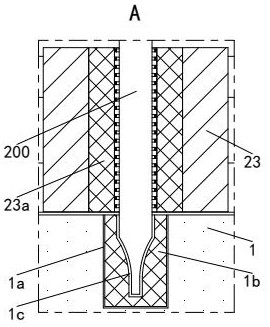

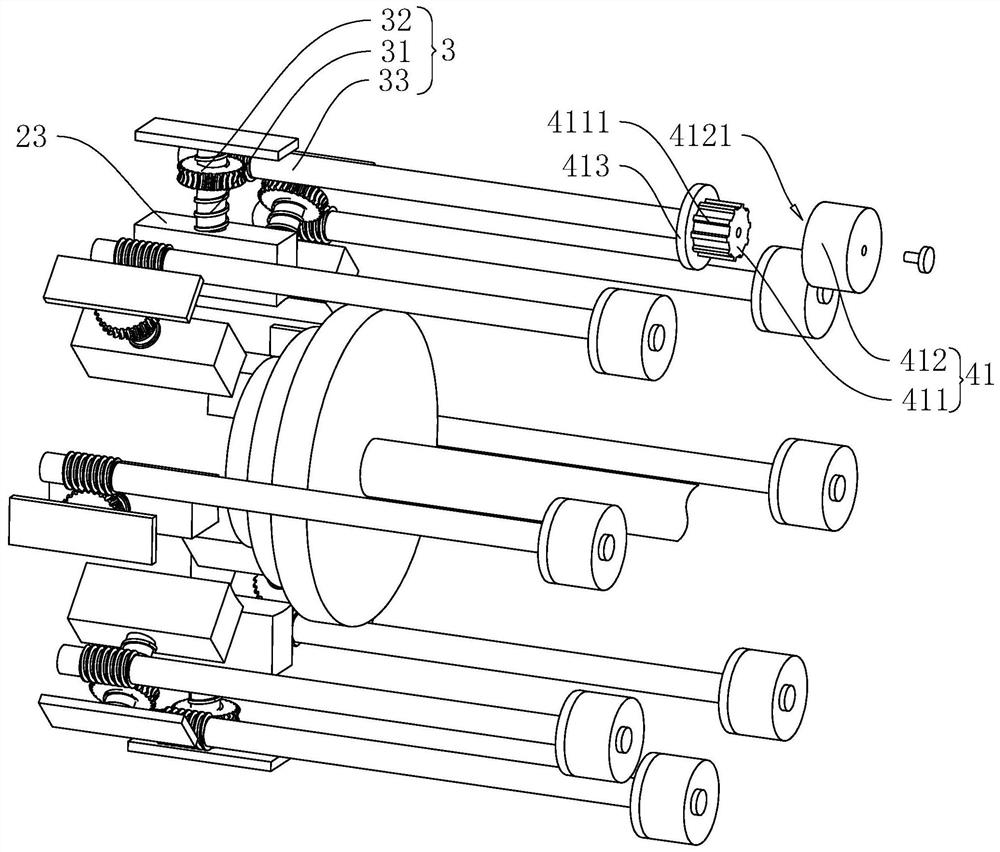

A hardware tool assembly fixed alignment fixture

ActiveCN113370120BAccurate clamping positionAvoid plugging misalignmentWork holdersMetal-working hand toolsSoftware engineeringHardware tool

The invention relates to the technical field of hardware fixtures, in particular to a fixture for assembling and fixing alignment of hardware tools, which includes a workbench, a tool bar clamping device and a handle clamping device. The present invention can solve the following problems still existing in the assembly process of the existing screwdriver assembly jig: a. When the existing screwdriver assembly jig clamps and inserts the plastic handle and the screwdriver shaft, the plastic handle and the screwdriver often appear The misalignment of the rod insertion leads to assembly failure, so that the existing tooling fixture can only realize the plastic handle and the screwdriver rod one by one, and cannot realize batch assembly; b. During clamping and plugging assembly, the plastic handle and the screwdriver shaft tend to slide relative to each other, resulting in loose assembly of the plastic handle and the screwdriver shaft, resulting in the plastic handle being easily detached from the screwdriver shaft.

Owner:江苏优霸五金工具有限公司

Urinary calculus crushing device for urinary surgery

InactiveCN114271897AEasy to adjust the use positionSave energySurgeryUrinary calculusUrological surgery

The invention belongs to the field of medical apparatus and instruments, particularly relates to a urinary calculus crushing device for urinary surgery, and aims to solve the problems that an existing calculus crushing device needs to be held by a medical worker during operation, so that the operation accuracy is reduced, the workload of the medical worker is increased, and once the operation time is too long, the medical worker cannot use the calculus crushing device. In order to solve the problem that medical workers feel uncomfortable due to the fact that the medical workers need to be placed on the medical workers, the following scheme is provided that the device comprises an operation control base, an installation assembly, a lifting adjusting base, a rotary driving base, a movable adjusting annular plate, an adjusting assembly and two installation bases, the installation assembly is arranged on the operation control base, and a control groove is formed in the top of the operation control base. According to the stone breaking device, the position of the operator can be stabilized, handheld use of medical staff is replaced, the operation accuracy is improved, the workload of the medical staff is relieved, and convenience is provided for the medical staff.

Owner:THE FIRST AFFILIATED HOSPITAL OF XINXIANG MEDICAL UNIV

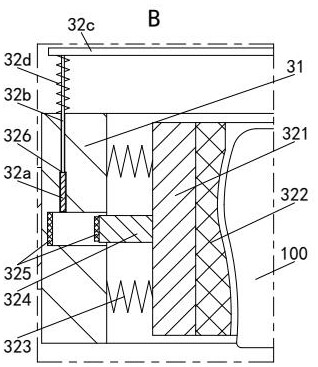

Single-acting clamping jig with shearing function

The invention discloses a single-acting clamping jig with a shearing function. The single-acting clamping comprises a connecting plate, a clamping jaw air cylinder, a shearing blade, a clamping plate and a stretchable spring, the shearing blade is arranged above the clamping plate, the clamping jaw air cylinder is fixed to the connecting plate, the clamping jaw air cylinder comprises a clamping jaw moving piece, the shearing blade is fixed to the clamping jaw moving piece, the clamping plate is rotationally connected with the connecting plate, one end of the stretchable spring is connected with the clamping jaw moving piece, and the other end of the stretchable spring is connected with the clamping plate. According to the single-acting clamping jig with the shearing function, a material rod of an injection molding product is cut to be short, so that possible interference between the material rod and a punch of a punching machine caused by deformation of the material rod is avoided, and further shortening of the injection molding period becomes reality; and two actions of clamping and shearing of the product can be completed through one clamping jaw air cylinder, the structure is more compact, the cost is lower, and clamping and shearing are more reliable.

Owner:NINGBO BEILONG PRECISION MOLDING

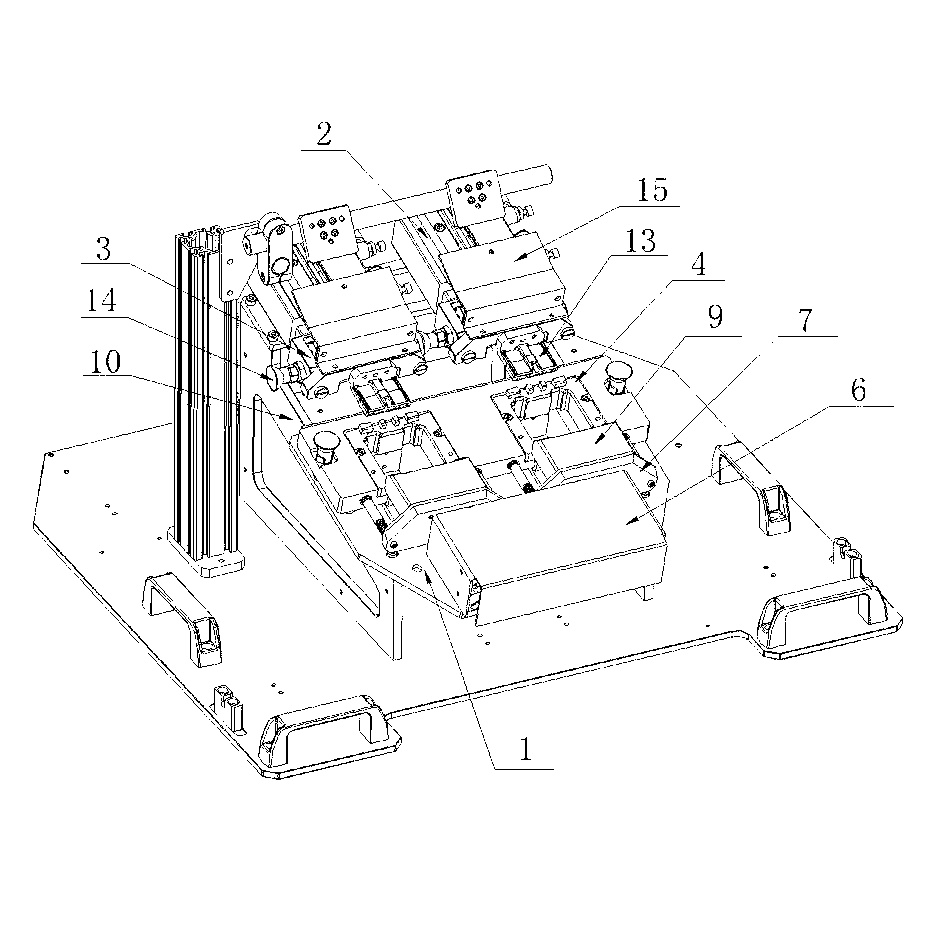

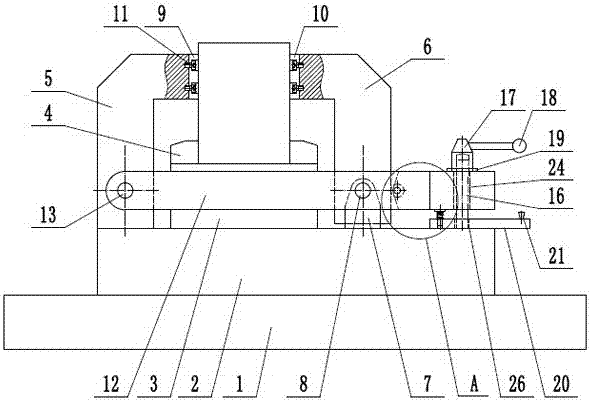

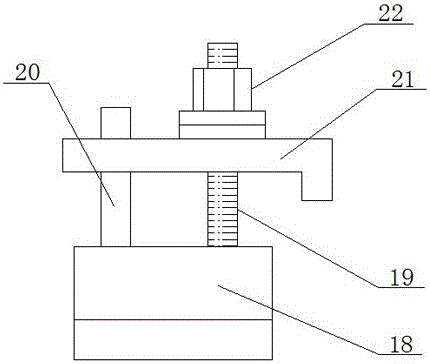

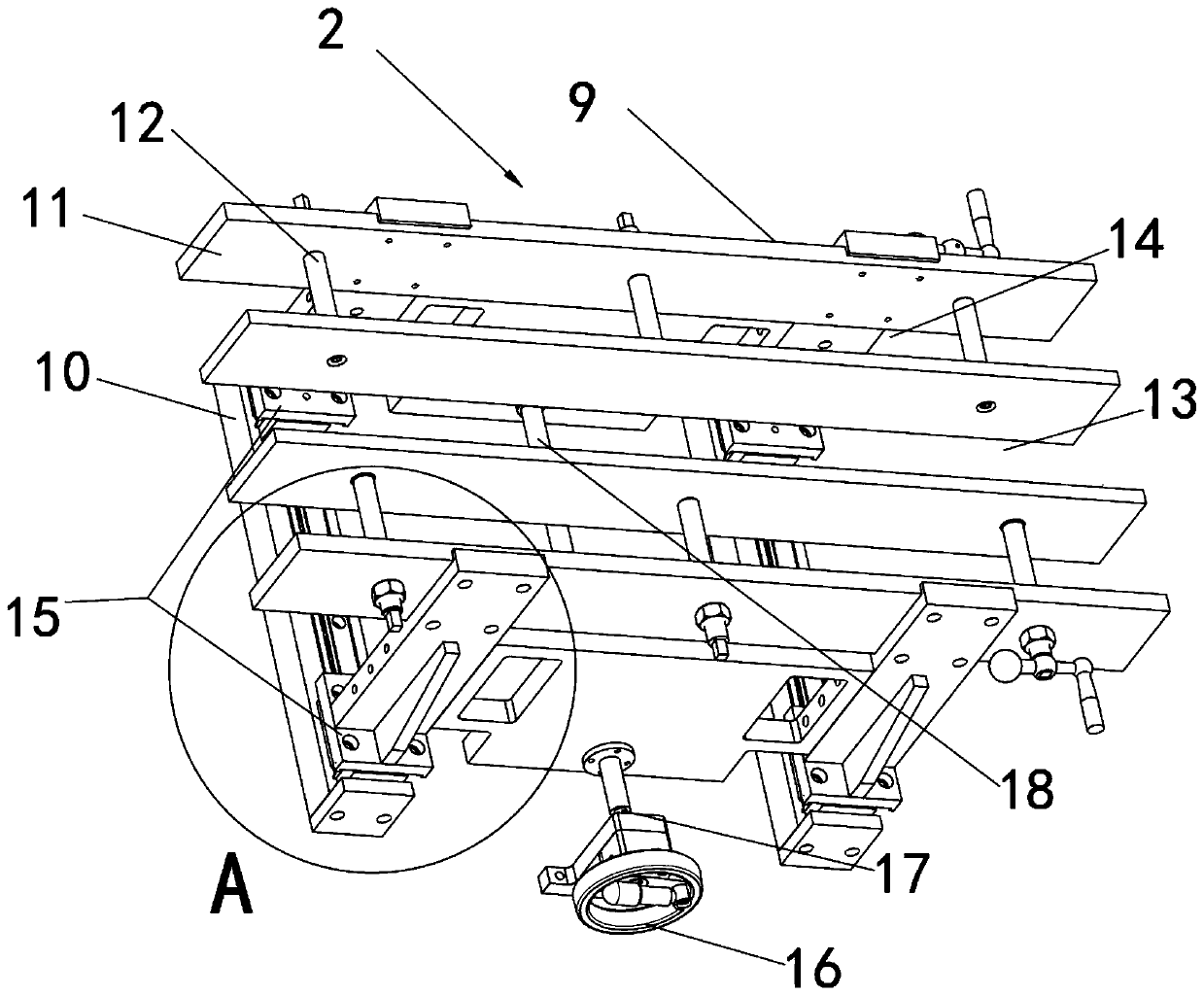

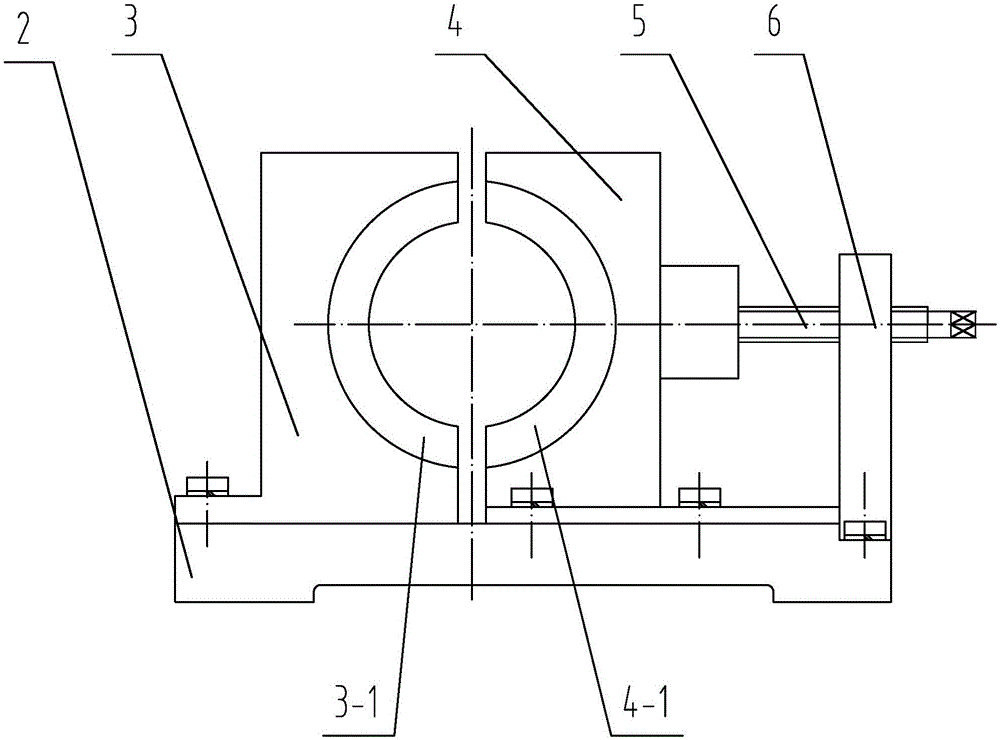

Clamping device for off-line detection of motor gearbox of new energy vehicle

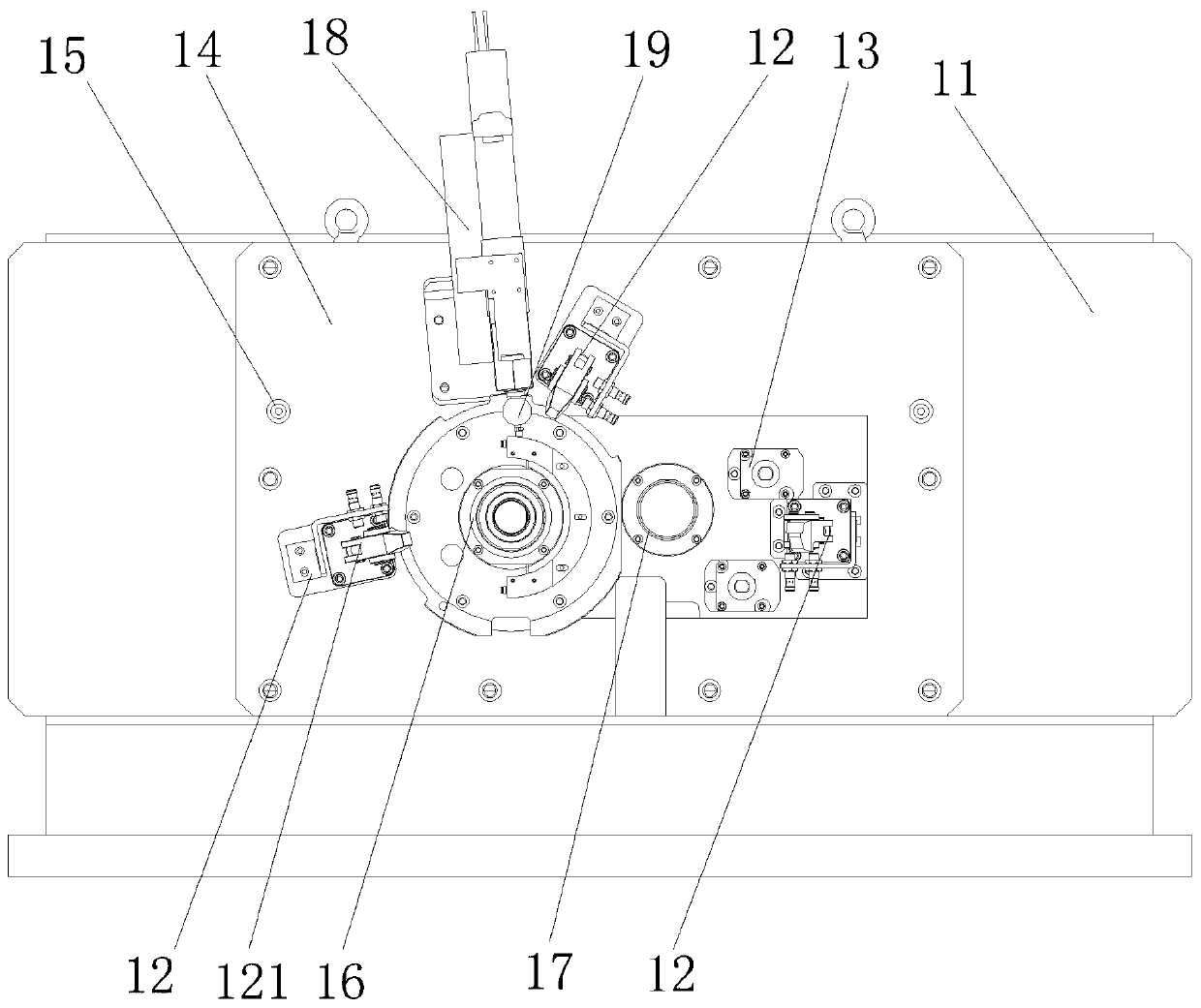

ActiveCN110000805AClamp firmlyAccurate clamping positionMachine gearing/transmission testingGripping headsNew energyEngineering

The invention discloses a clamping device for off-line detection of a motor gearbox of a new energy vehicle. The clamping device comprises a clamping body fixed end part and a clamping body movable end part; the clamping body movable end part comprises a movable seat, movable end clamping units which are arranged on the movable seat, and positioning pin seats which are arranged on the movable seat; positioning pins which are in location fit with technology holes in the gearbox are arranged in the positioning pin seats; the fixed end clamping body part comprises a fixed seat, fixed end clampingunits which are arranged on the fixed seat, and a supporting unit which is arranged on the fixed seat and used for abutting against and supporting the gearbox; after the gearbox is subjected to primary clamping by the movable end clamping units, the clamping body movable end part moves towards the clamping body fixed end part, the gearbox is subjected to secondary clamping by the fixed end clamping units; and after the secondary clamping, the clamping body movable end part returns. Split design is adopted to realize two-stage split clamping, so that a clamping position of the motor gearbox isaccurate and the clamping is more stable.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Clearing device for internal thread residue impurities during European-style dress manufacturing process

InactiveCN110983707AGood clean upClean up thoroughlyMechanical cleaningPressure cleaningElectric machineryKnife blades

The invention discloses a clearing device for internal thread residue impurities during a European-style dress manufacturing process. The clearing device comprises a horizontally arranged top carry plate, an L-shaped side support frame, a first motor and swing adjustment mechanisms, wherein the top carry plate is of a cube structure; the side support frame is vertically arranged at one end of thetop carry plate; the first motor is arranged on the other end of the top carry plate. The clearing device has the beneficial effects that thread residue impurities on European-style dress are sucked into a storage barrel via a plurality of suction holes arranged with equal radian, and a fourth motor is matched to drive blades arranged with equal radian to scrap and clear thread residues, so that the condition that the thread residue impurities on European-style dress are more completely sucked into the storage barrel; a second motor drives a gear to roll in a rolling slot, to drive a clear plate to move front and back repeatedly; and the plurality of swing adjustment mechanisms arranged at an equal interval work synchronously, so that the condition that the device clears the thread residues on the European-style dress more efficiently is ensured, the condition that the thread residues on the European-style dress are more thoroughly cleared is also ensured, and larger area of work coverage of the device is also ensured.

Owner:界首市永顺服饰有限公司

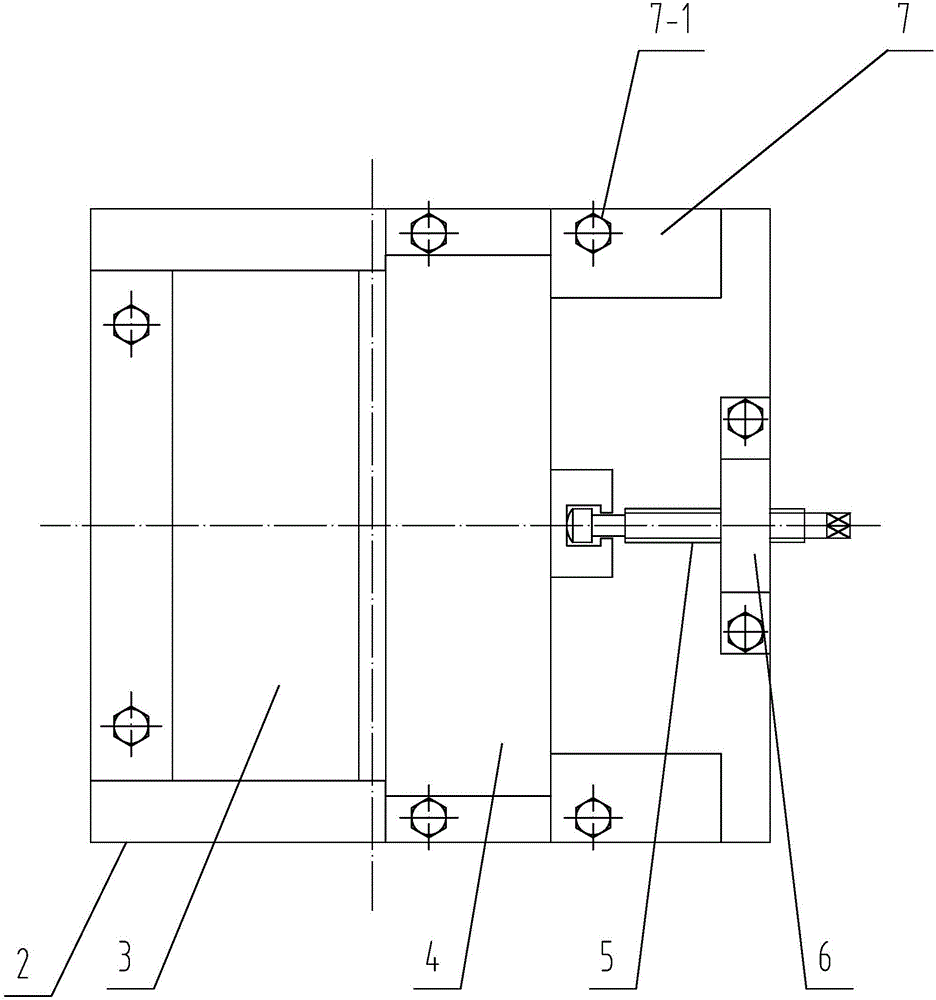

Special clamp for welding thin-walled conical body

InactiveCN106346180AImprove clamping effectClamping effect realizedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a special clamp for welding a thin-walled conical body, relates to a special welding clamp, and aims at solving the problems that the welding difficulty is larger and the welding quality is poor caused by difficult positioning due to the self elasticity and shape of the thin-walled conical body when a gap, generated by the self elasticity, of the thin-walled conical body is eliminated through a welding manner. Bosses are processed on the two ends of the top surface of a base respectively; a fixed block is fixedly connected between the two bosses; a first conical groove is processed in one end surface of the fixed block; a movable block is arranged between the two bosses and is ;in sliding fit with the base; a second conical groove is formed in one end surface, facing the fixed block, of the movable block; the first conical groove is opposite to the second conical groove; a supporting seat is arranged on the base; a screw rod penetrates through the supporting seat and is connected with the movable block; pressure plates are arranged corresponding to the bosses one by one; the two ends of the movable block are compressed on the base through the corresponding pressure plates; and each pressure plate is detachably connected to the corresponding boss. The special clamp for welding the thin-walled conical body is used for positioning the thin-walled conical body.

Owner:HARBIN JIANCHENG GRP

Clamping device applied to flow guiding hood

PendingCN110314785AAccurate clamping positionConvenient follow-up operationSpraying apparatusAerodynamics improvementEngineeringChassis

The invention discloses a clamping device applied to a flow guiding hood. The clamping device applied to the flow guiding hood comprises a chassis and a plurality of clamping units evenly distributedon the chassis. E ach clamping unit comprises a clamping part driven by a connecting rod assembly to move and conduct positioning, and comprises two obtuse-angle plates, wherein three vertexes of thetwo obtuse-angle plates are fixedly connected through connecting shafts, the connecting shafts located on the two sides are each provided with a rolling wheel, the connecting shaft located in the middle is rotatably connected with the free end of the connecting rod assembly, and the rolling wheels are connected with the outer side face of the flow guiding hood in an abutting manner. The clamping device is provided with the multiple clamping units, the outer side face of the flow guiding hood can be clamped and fixed through cooperation of the multiple clamping units, the multiple clamping units are independent and have the same structure, and each clamping unit can clamp the outer side face of the flow guiding hood with the different or same force through cooperation of the corresponding connecting rod assembly and the corresponding clamping part; and in addition, the clamping device can be suitable for clamping flow guiding hoods with different types and sizes, and the universality ishigh.

Owner:EULIKIND TIANJIN TECH

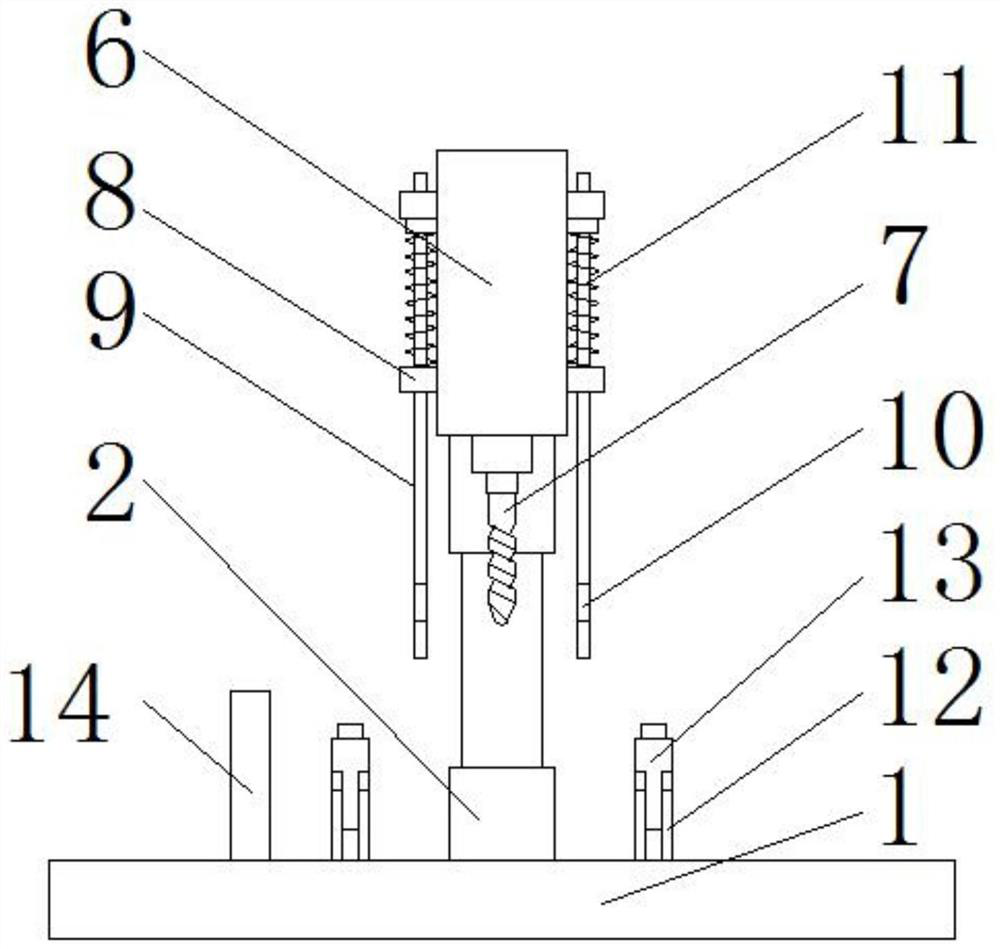

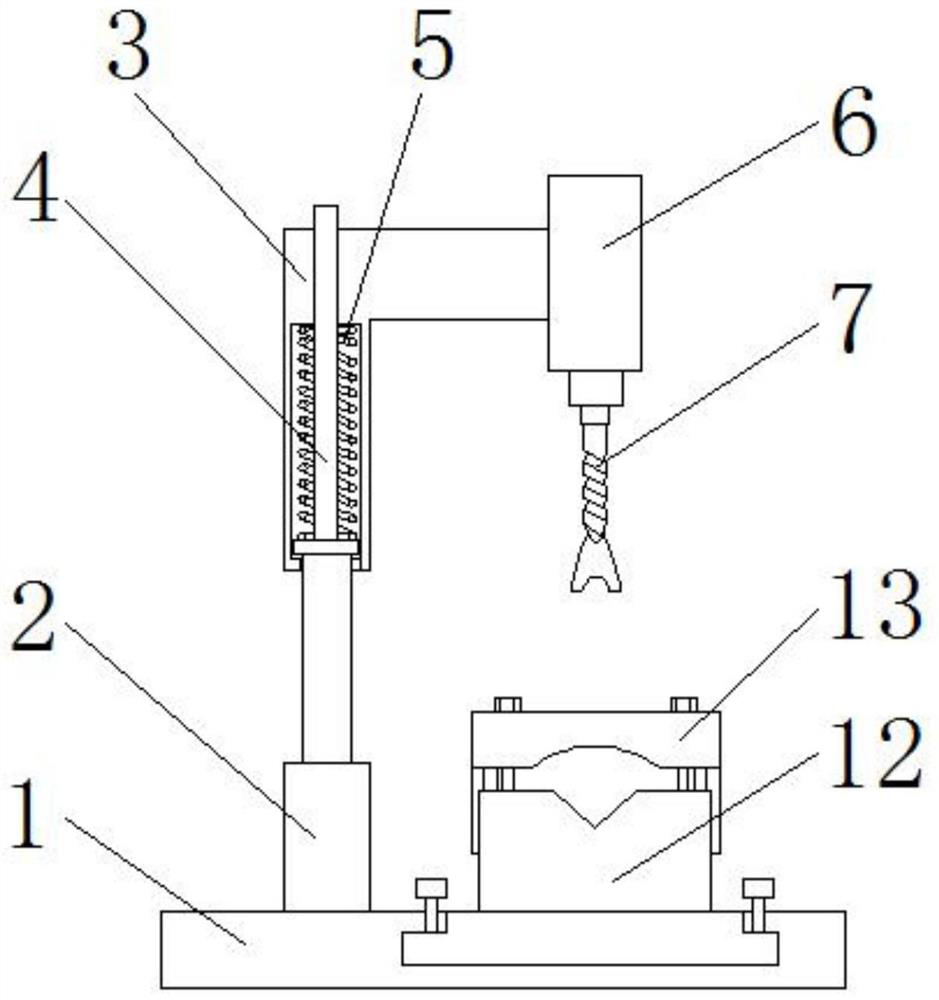

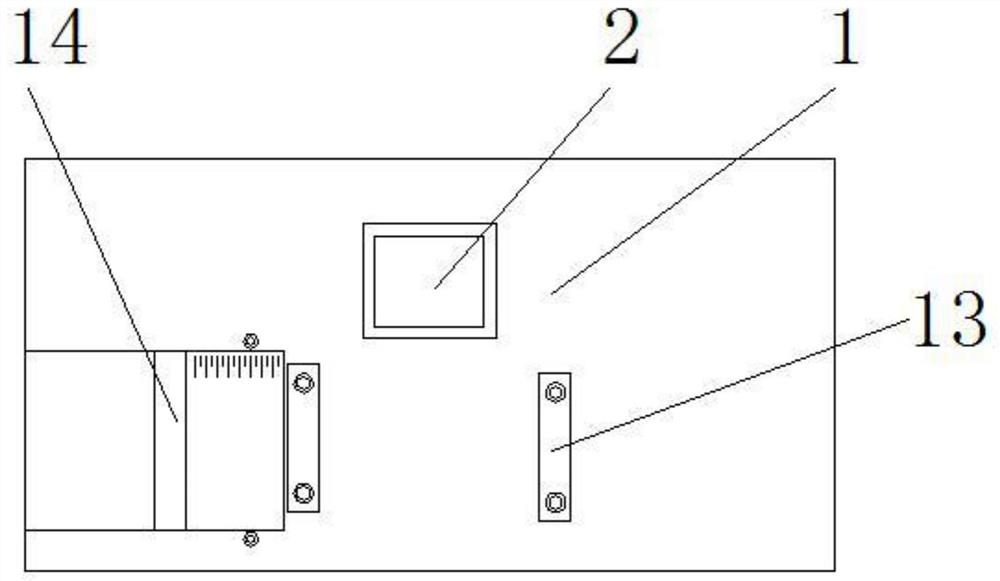

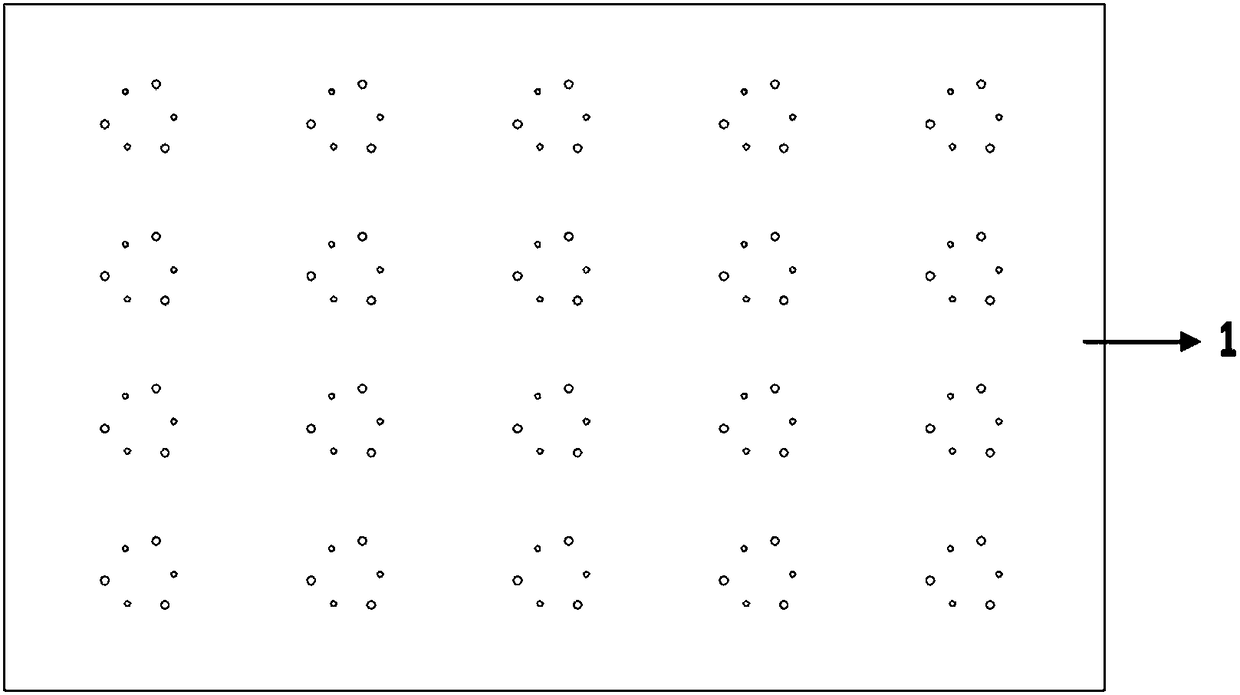

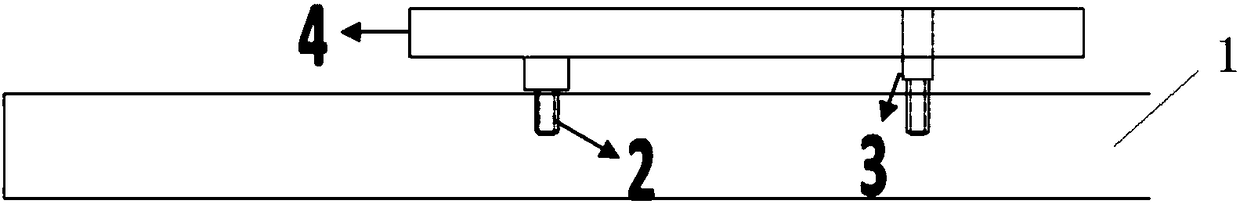

Drilling device for hot-rolled alloy steel HRB500E machining

PendingCN113020649AEffectively fixedAccurate clamping positionPositioning apparatusBoring/drilling componentsRebarMechanics

The invention relates to the technical field of hot-rolled alloy steel drilling devices, in particular to a drilling device for hot-rolled alloy steel HRB500E machining. The defects that during steel bar drilling, fixing is not firm, hole position deviation is caused by fixing deviation, and the drilling position cannot be rapidly designated are solved. The drilling device comprises a base, a stand column and mounting seats are welded to the upper surface of the base, the upper end of the stand column is sleeved with a mounting frame, a first guide rod is welded to the upper surface of the stand column, the surface of the first guide rod is sleeved with a first spring, a drill floor is mounted at one end of the mounting frame, a drill bit is clamped to the bottom of the drill floor, connecting plates are welded to the two sides of the drill floor, second guide rods are clamped in the connecting plates, the surface of each second guide rod is sleeved with a second spring, a clamping plate is welded to the bottom of each second guide rod, a cover plate is clamped to the upper surface of each mounting seat, and a limiting plate is clamped to one side of the base. According to the device, steel bars needing to be machined can be effectively fixed, a center judging device is additionally arranged to guarantee that the clamping position is accurate, and punching deviation is effectively avoided.

Owner:JINGYE STEEL CO LTD

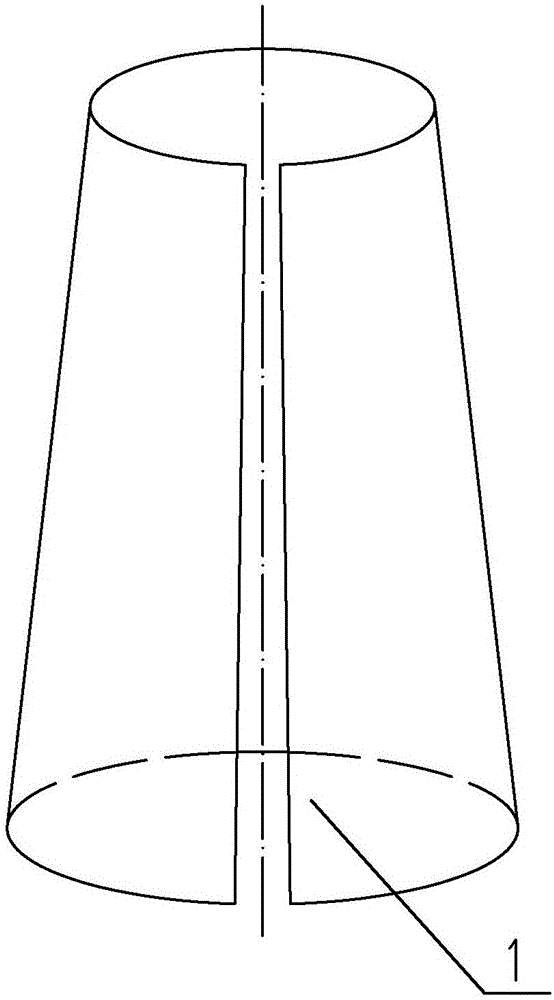

Heavy water reactor component end plate detection tool

InactiveCN108180828ARapid Batch DetectionPrevent Uncertainty from DeviationUsing optical meansTransmittanceEngineering

The invention relates to a heavy water reactor component end plate detection tool comprising a base reference plate, support pins and positioning pins. Two symmetric groups of pin holes are distributed on the base reference plate and each group includes three pin holes which are arranged at equal intervals of 120 degrees. Support pins are installed in one group of pin holes and are used for accurately supporting the end plate and reducing wear of the base reference plate by the end plate. The positioning pins are installed in the other group of pin holes and are used for positioning the end plate. The base reference plate is made of a material with good light transmittance. The both sides of the detection tool are provided with three thread positioning holes for mounting an image detectorfor detecting the size of the end plate in order to ensure that the consistency that the detection tool install or uninstall the end plate multiple times. The heavy water reactor component end plate detection tool can achieve the following effects of 1) stably clamping twenty heavy water end plates to achieve rapid batch size detection; 2) positioning the part arc of the end plate and achieving accurate clamping position and good consistency.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

A processing device for a bearing outer ring

ActiveCN112893882BEffective clampingAccurate clamping positionWork clamping meansTurning machinesEngineeringManufacturing line

The application relates to a processing device for the outer ring of a bearing, which includes a frame, the frame is rotated and equipped with a base, the frame is equipped with a first driving part connected to the base, and the base is coaxial with its rotating shaft and has a mounting hole for installation. The inner wall of the hole is provided with a plurality of fixing holes, and a fixing rod is installed for sliding in the fixing hole. The material mechanism, the frame sliding is equipped with a tool holder, and the turning tool is installed on the tool holder. The application has the ability to adjust the length of each fixing rod protruding from the fixing hole to match steel rings of different diameters, and fix the fixing rods to the base through a fixing mechanism, so that steel rings of different diameters can be formed between multiple fixing rods The interference fit is used for fixing, so that steel rings with different diameters can be processed on the same turning production line.

Owner:浙江品诺机械有限公司

A fast connection fixture for led aluminum substrate and its working method

ActiveCN110640653BQuick clampingEasy to separateWork holdersAluminum substrateMechanical engineering

A LED aluminum substrate quick connection fixture and its working method include a base structure, a first clamping structure and a second clamping structure, and the first clamping structure and the second clamping structure are arranged side by side on the base structure. Place the two LED aluminum substrates to be connected on the base structure, and connect them through the first clamping structure and the second clamping structure. The various structures work together to complete the quick connection of the LED aluminum substrate.

Owner:TAICANG HE S CIRCUIT BOARD CO LTD

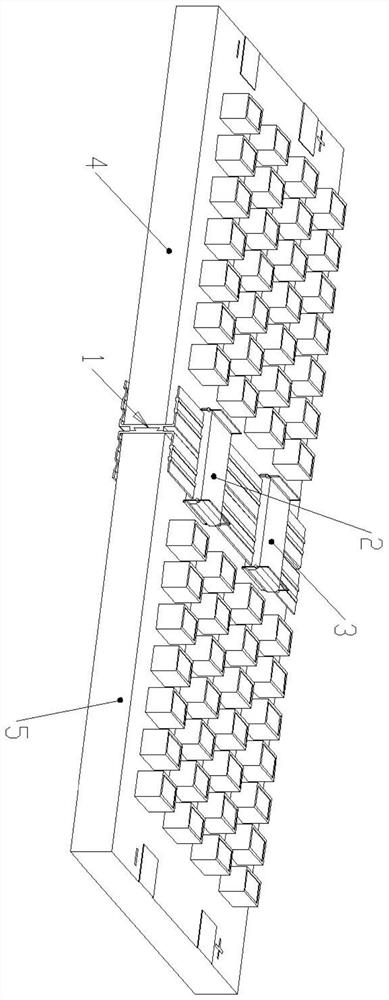

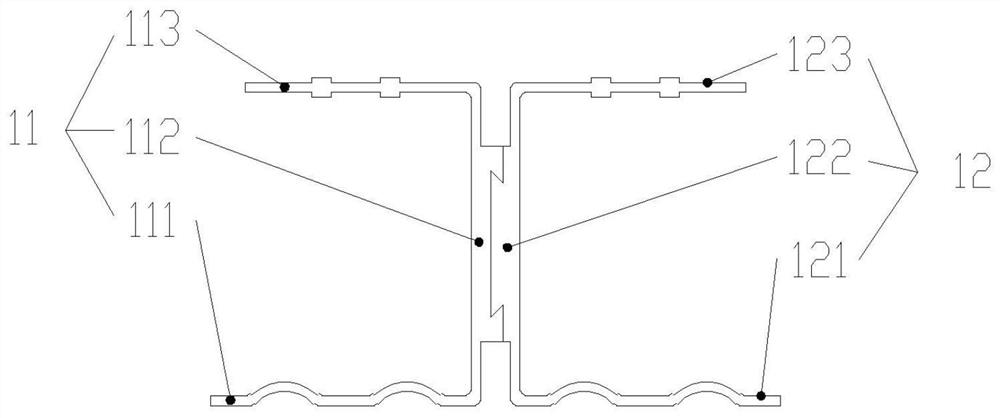

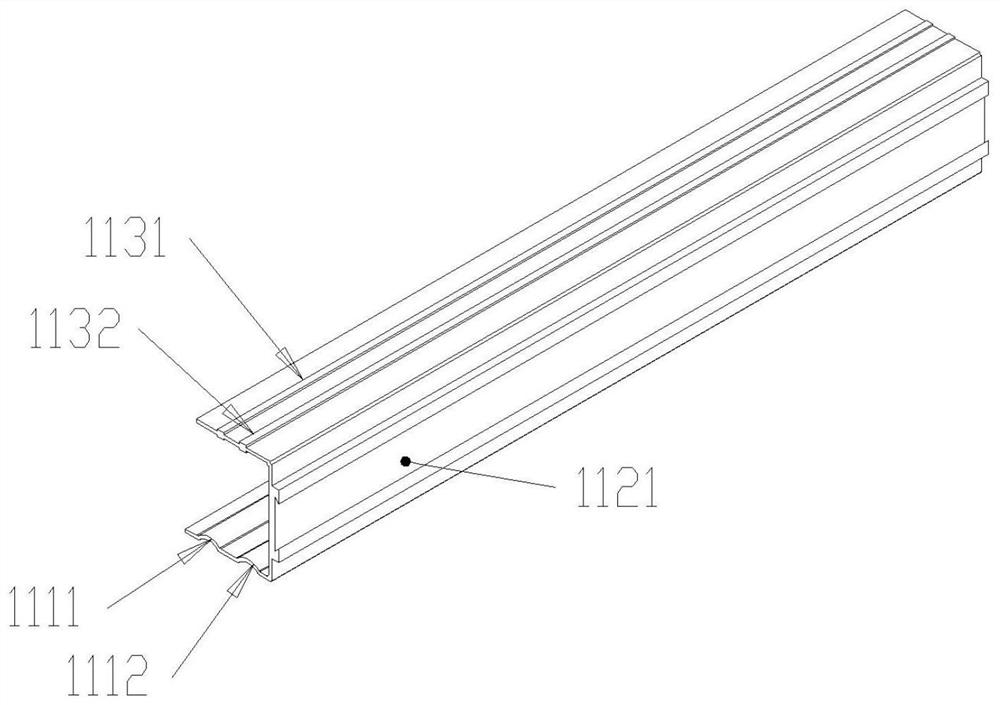

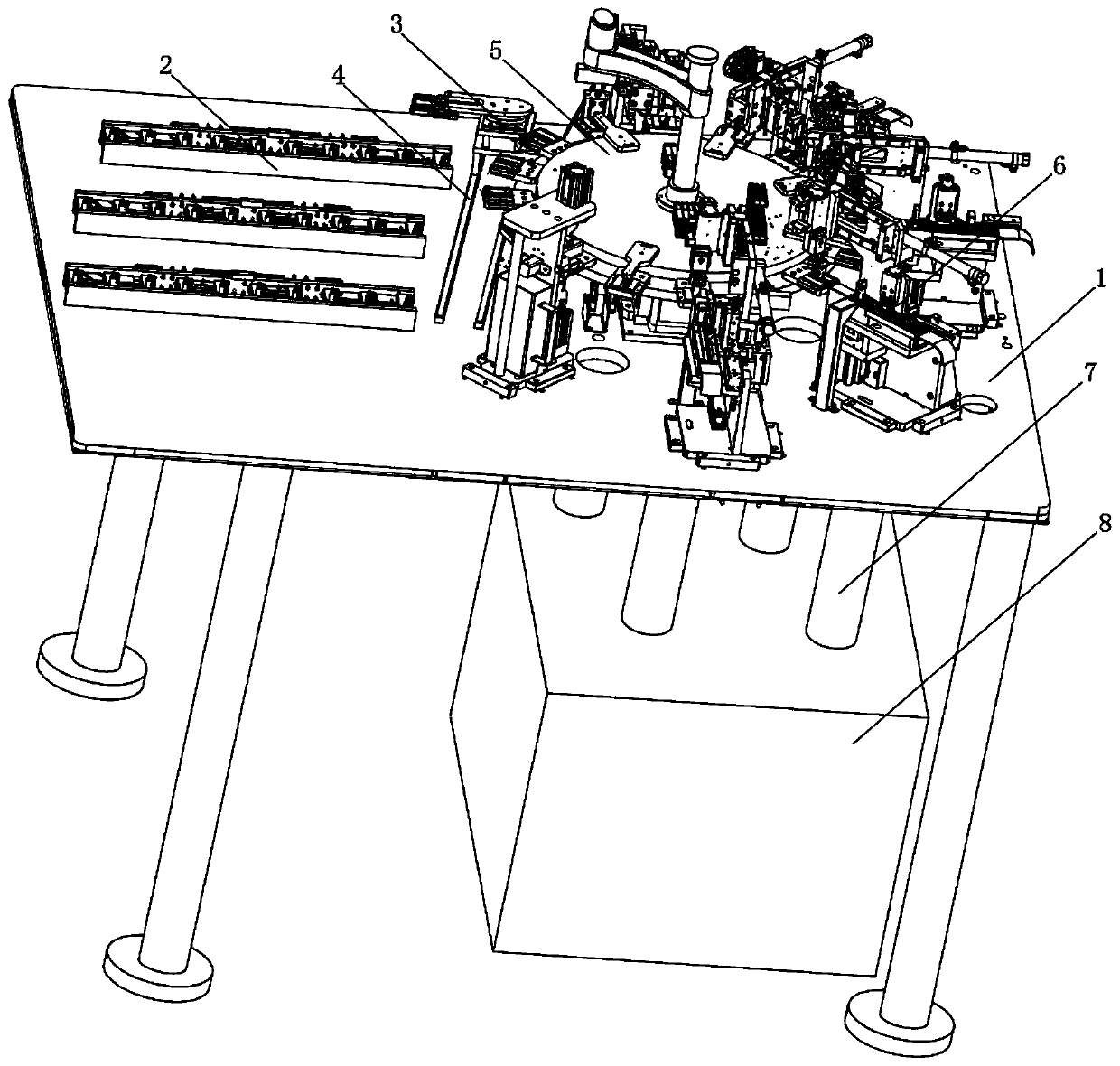

Full-automatic encapsulating device for inductor production and encapsulating method thereof

PendingCN110310819AHigh degree of automationSave time and effortEncapsulation/impregnationHydraulic cylinderInductor

The invention discloses a full-automatic encapsulating device for inductor production. The full-automatic encapsulating device comprises a worktable, conveyor tables, a shifter base, a rotary disk andan encapsulating frame. Three conveyor tables are arranged in parallel on one side of the upper end surface of the worktable in equal spacing. The full-automatic encapsulating device has the advantages that then the motor 4 drives the inductor to move directly below the encapsulating frame through the rotary disk, a hydraulic oil cylinder 2 drives an encapsulating separating cylinder to move downward through a hydraulic shaft 2, the encapsulating separating cylinder inserts the bottom of the adhesive tape into the groove at the connection between the inductor and the grip groove 2, then the motor 7 drive the rotating shaft and the inductor to rotate and wrap the adhesive tape, and the hydraulic oil cylinder 2 drives the encapsulating separating cylinder to move upwards at a uniform speedthrough the hydraulic shaft 2 so that the encapsulating work is performed on the inductor. The device has high automation degree of work and saves time and labor, the motor 3 drives the clamp 1 to swing to clamp the inductor, and the device can clamp and move the inductor of different width and sizes and thus the universality of the working adaptability of the device can be guaranteed.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com