Special clamp for welding thin-walled conical body

A special fixture and cone technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult welding, poor welding quality, difficult positioning of elasticity and shape, etc., and achieve reliable clamping effect , flexible and convenient operation, and the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

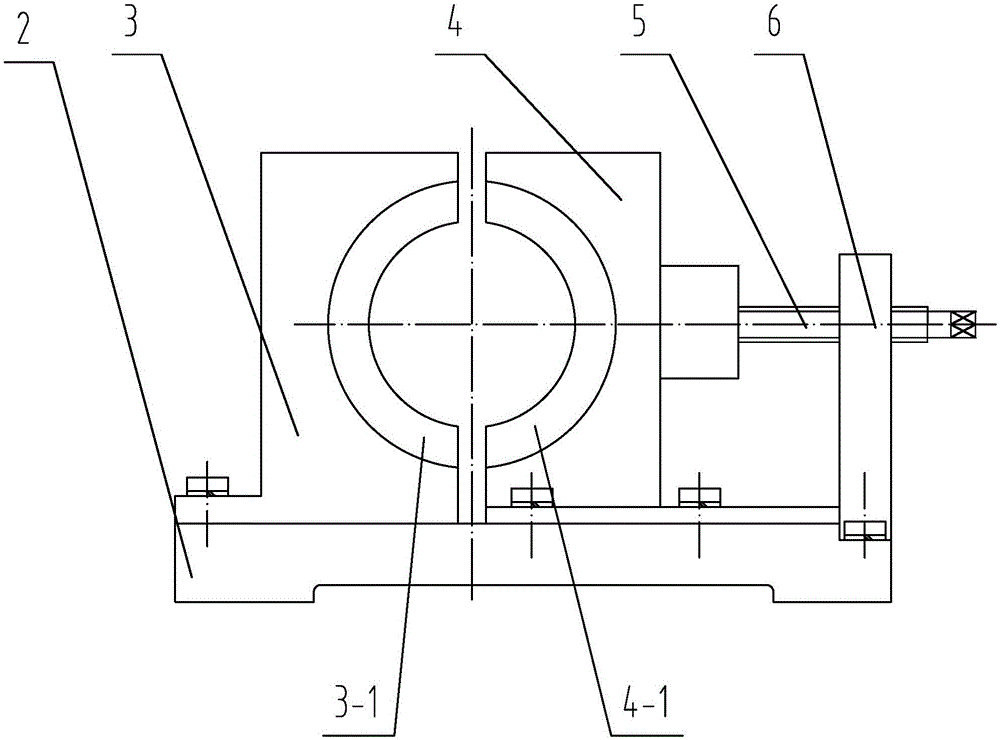

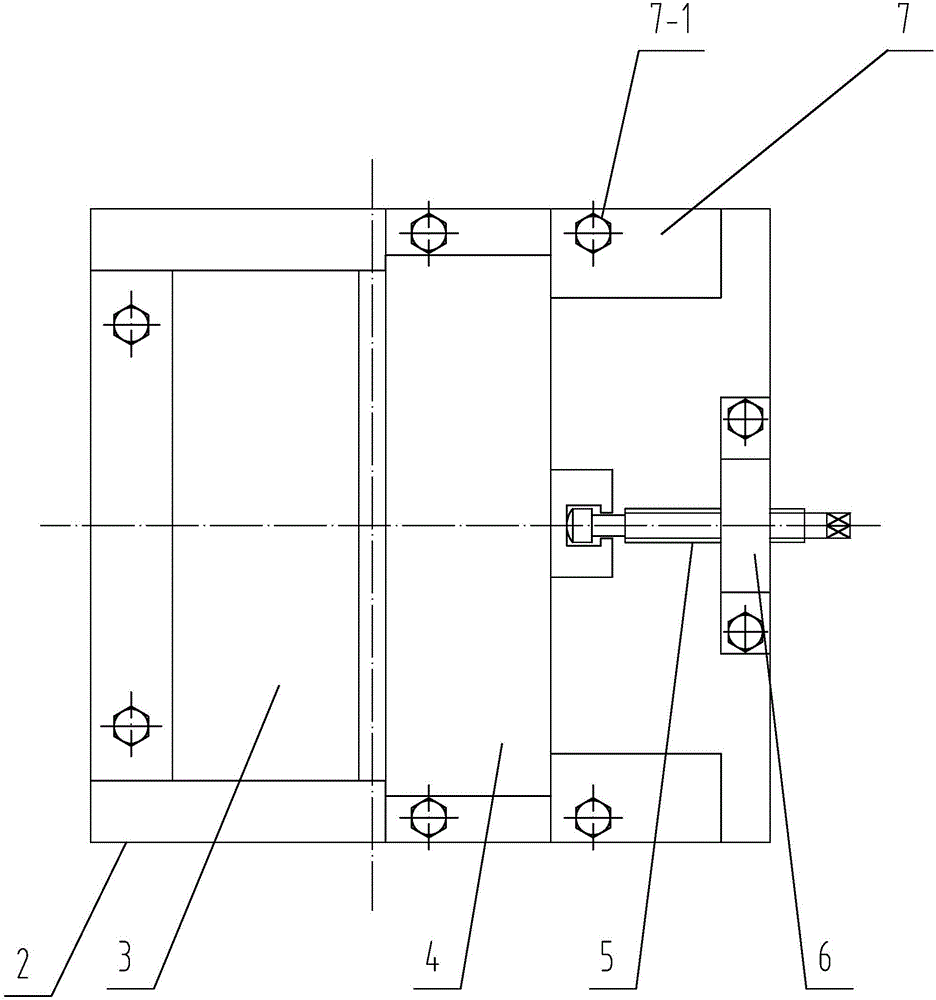

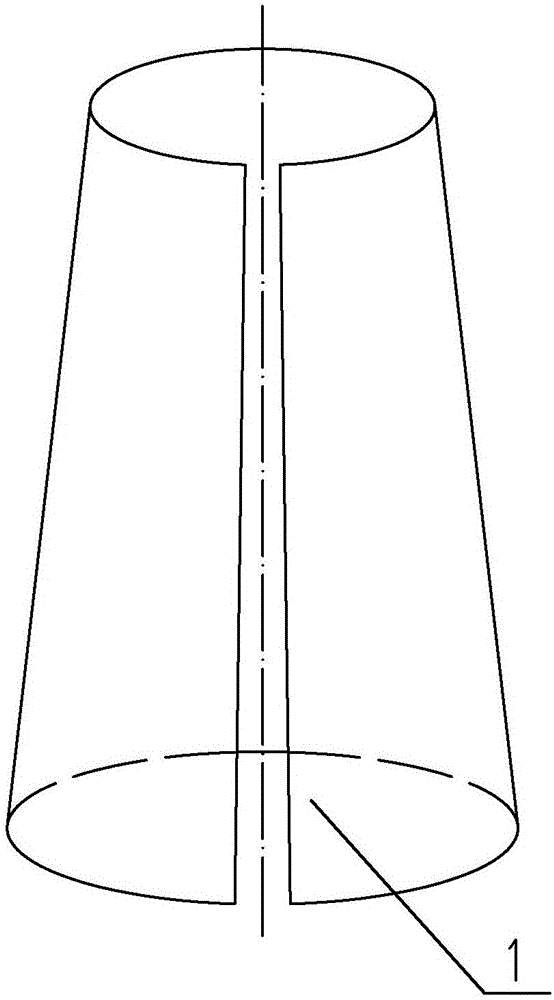

[0024] Specific implementation mode one: combine Figure 1 to Figure 15 Describe this embodiment, this embodiment comprises a base 2, a fixed block 3, a movable block 4, a screw 5, a support 6 and two pressure plates 7, the base 2 is horizontally arranged, and the two ends of the top surface of the base 2 are respectively processed There is a boss 2-2, and the fixed block 3 is fixedly connected between the two bosses 2-2. One end surface of the fixed block 3 is processed with a first tapered groove 3-1, and the movable block 4 is set Between the two bosses 2-2 and sliding fit with the base 2, the end surface of the movable block 4 facing the fixed block 3 is processed with a second tapered groove 4-1, and the first tapered groove 3-1 Set opposite to the second tapered groove 4-1, the support 6 is set on the base 2, the screw 5 passes through the support 6 to connect with the movable block 4, and the pressure plate 7 corresponds to the boss 2-2 one by one It is provided that b...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination figure 1 , figure 2 , Figure 4 to Figure 11 This embodiment is described. In this embodiment, the end of the fixed block 3 far away from the movable block 4 is processed with a plurality of first connection holes 3-3, and the base 2 is processed with holes corresponding to the first connection holes 3-3. A plurality of second connection holes 2-5, the fixed block 3 is fixedly connected with the plurality of second connection holes 2-5 of the base 2 through the plurality of first connection holes 3-3. The structures and connections not mentioned in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 2 , Figure 9 , Figure 10 and Figure 11 Describe the present embodiment, the two ends of the movable block 4 in the present embodiment are each processed with a slot 4-2, the slot 4-2 is set in one-to-one correspondence with the pressing plate 7, and one end of each pressing plate 7 is inserted into it. Corresponding slot 4-2. The structures and connections not mentioned in this embodiment are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com