Connector product test device

A technology for product testing and testing devices, applied in the direction of measuring devices, measuring device casings, instruments, etc., can solve the problems of cumbersome testing process, increase testing cost, low work efficiency, etc., reduce testing cost, improve clamping accuracy, test Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

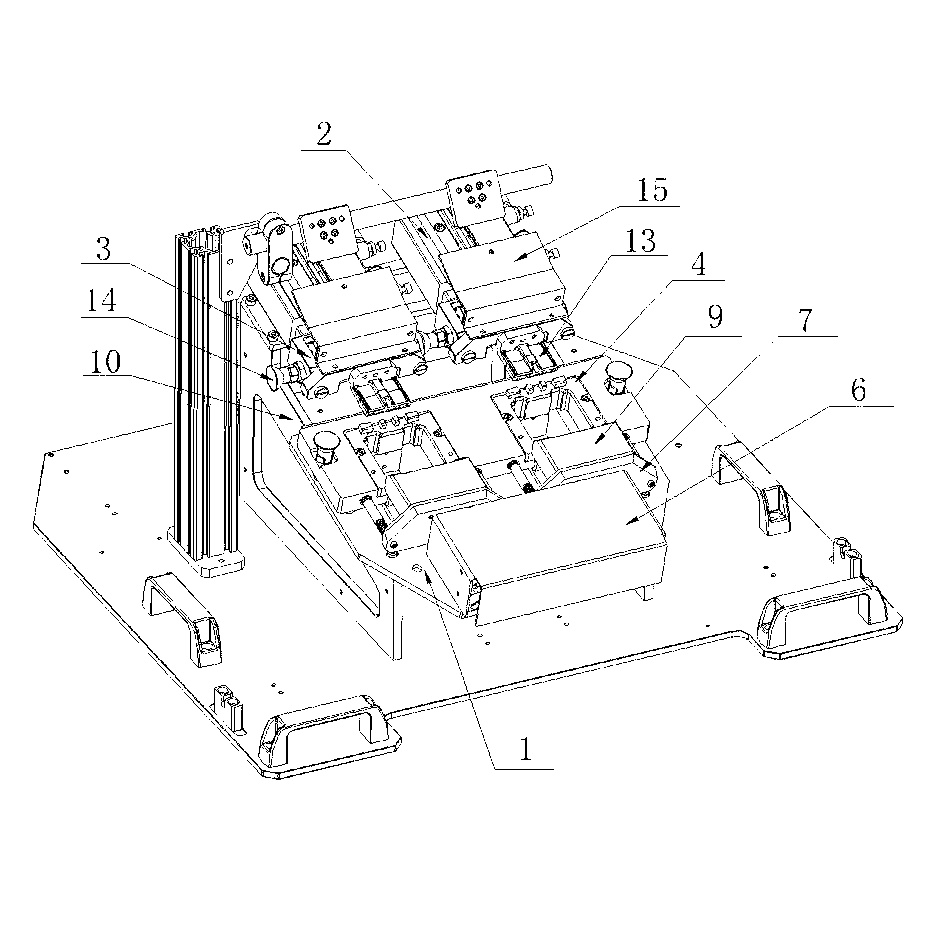

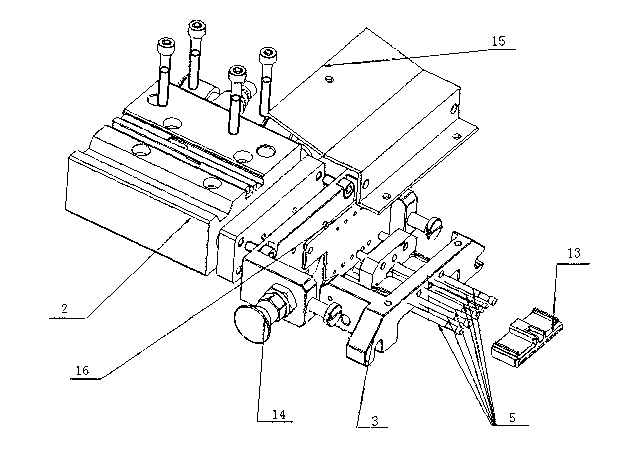

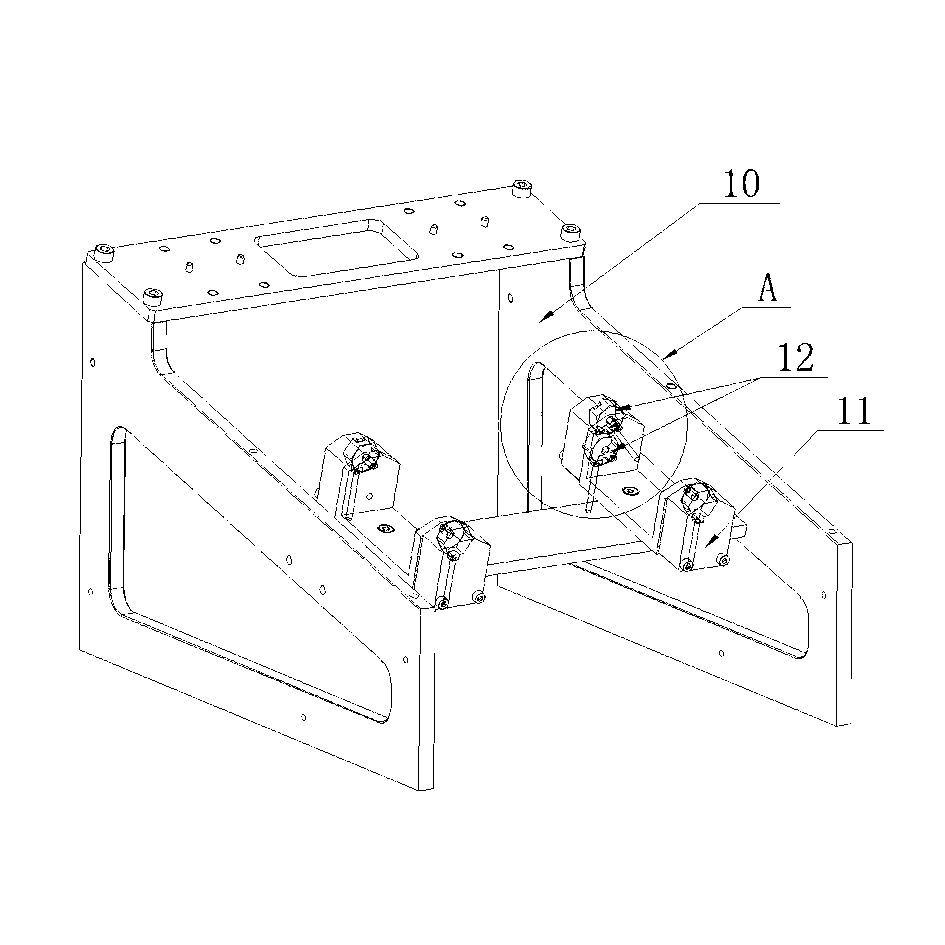

[0029] like Figure 1 to Figure 6 As shown, the present invention uses test pins to replace the test connectors of the prior art for testing operations, which includes a test terminal, a test device, a control circuit and a control button electrically connected to the control circuit, and the test terminal stores test data It is also used to record measurement data, and the control circuit and control buttons are used to control the specific actions and strokes of the relevant components of the present invention. The test device includes a support board 1 , a power unit I2 arranged on the support board 1 and a fixture seat 4 adapted to the connector to be tested. The power device I2 provides a power source, which can be a pneumatic device or a hydraulic transmission device or a hydraulic-pneumatic combination device. The power device I2 is electrically connected to the control circuit, so that the power device can be directly controlled by the control button Ⅰ2 specific actio...

Embodiment 2

[0037] This embodiment is the second technical solution of the present invention, and the design concept is the same as that of the first embodiment, which uses test pins instead of the prior art test connectors to test the product connectors, while this embodiment uses manual control.

[0038] like Figure 7 to Figure 10 As shown, the test machine of the present invention includes a test terminal 32 and a test device, the test device includes a base 20 and an upper cover 21 that is movably connected to the base 20, and the base 20 is provided with a Fixture seat 22, the side of the upper cover 21 facing the fixture seat 22 is provided with a test needle board 23, the outer side of the upper cover 21 is provided with an adapter plate 33 electrically connected to the test terminal 32, the transfer The connecting plate 33 has the same function as that in the first embodiment. The test needle plate 23 is provided with a suitable test needle 24, and the test needle 24 is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com