Automatic tube feeding device for hose assembly machine

An assembly machine, automatic feeding technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy work injury and failure, affecting production efficiency, etc., to improve assembly quality, improve production efficiency, clamping position precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

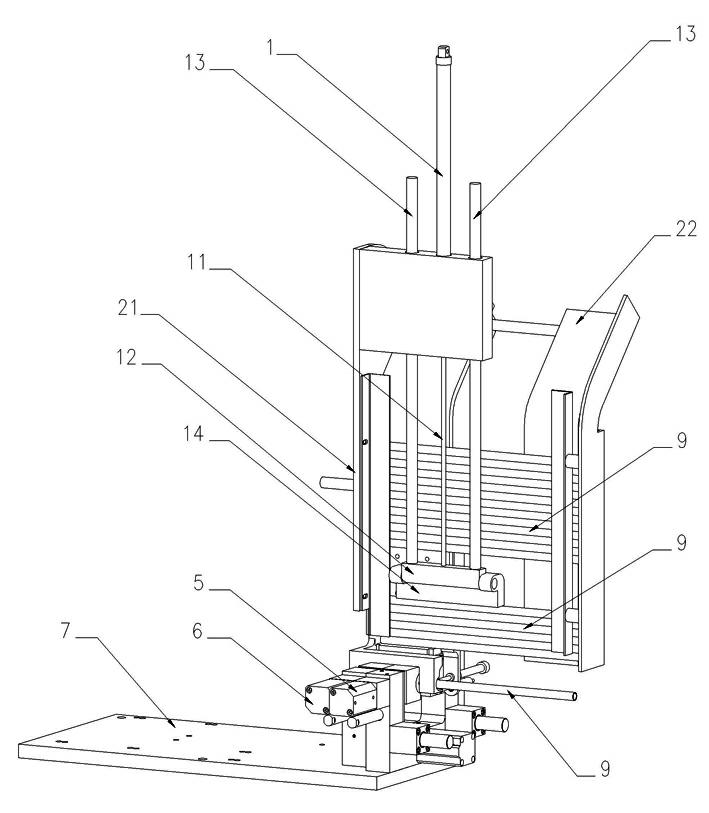

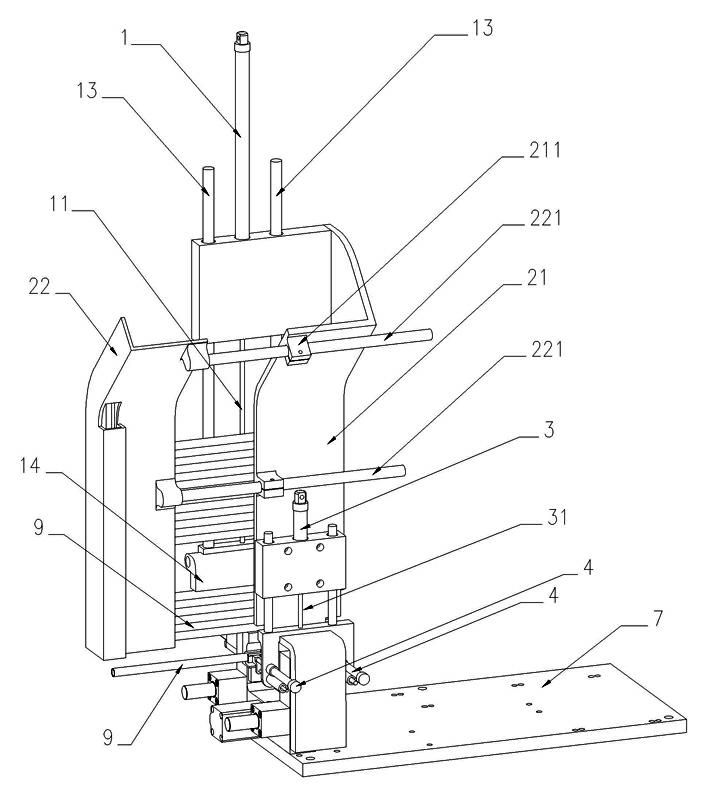

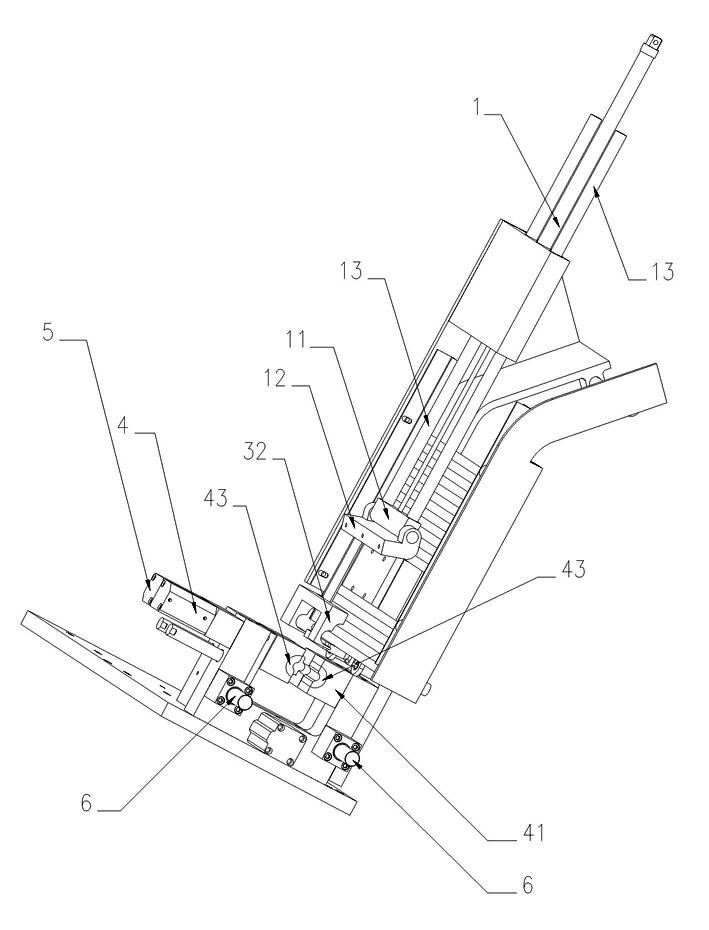

[0028] Further elaborate the present invention below in conjunction with embodiment and accompanying drawing:

[0029] Such as Figure 1 to Figure 5 The working process of the automatic tube feeding device of the hose assembly machine shown is as follows: the operator arranges the fixed-length hose 9 on the fixed backing 21 of the hose arrangement frame 2, and arranges the ferrules on the ferrule chute Inside, set the nut and core together and arrange them on the vertical nut core slideway; select the process parameters on the microcomputer touch screen according to the model specification of the hose, and then start the machine.

[0030] The push rod of the push tube cylinder 1 stretches out, and the push tube seat 11 fixed on the front end of the push rod drives the pin-connected push tube rack 12 to push down the entire row of hoses 9 arranged on the fixed backing 21 with a constant air pressure. , so that the lowermost hose is accurately positioned on the pipe-taking posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com