Clamping device for off-line detection of motor gearbox of new energy vehicle

A new energy vehicle, clamping device technology, applied in the direction of machine gear/transmission mechanism testing, chuck, manipulator, etc., can solve the problem of poor clamping of the motor gearbox, and achieve accurate clamping position, stable clamping, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

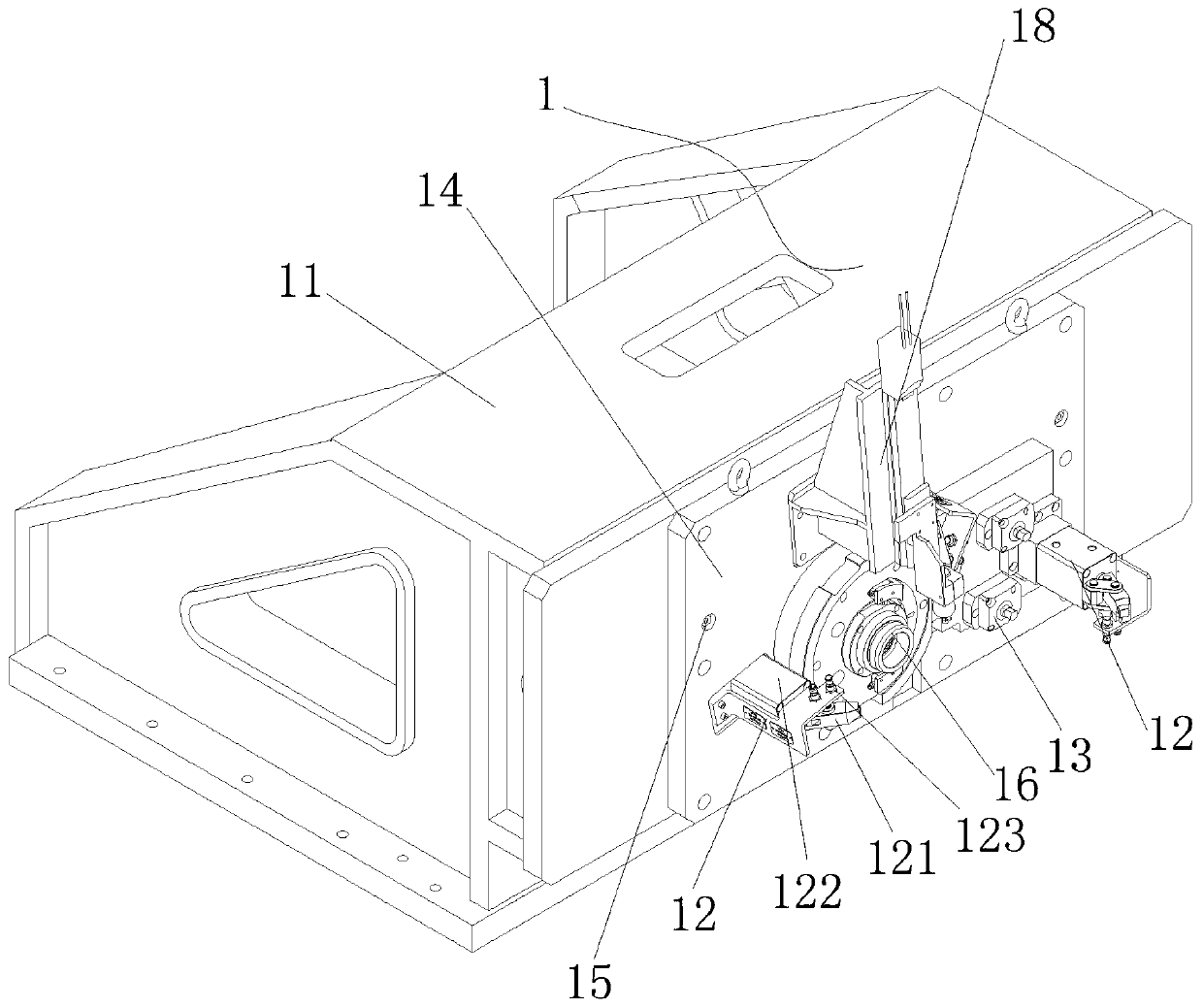

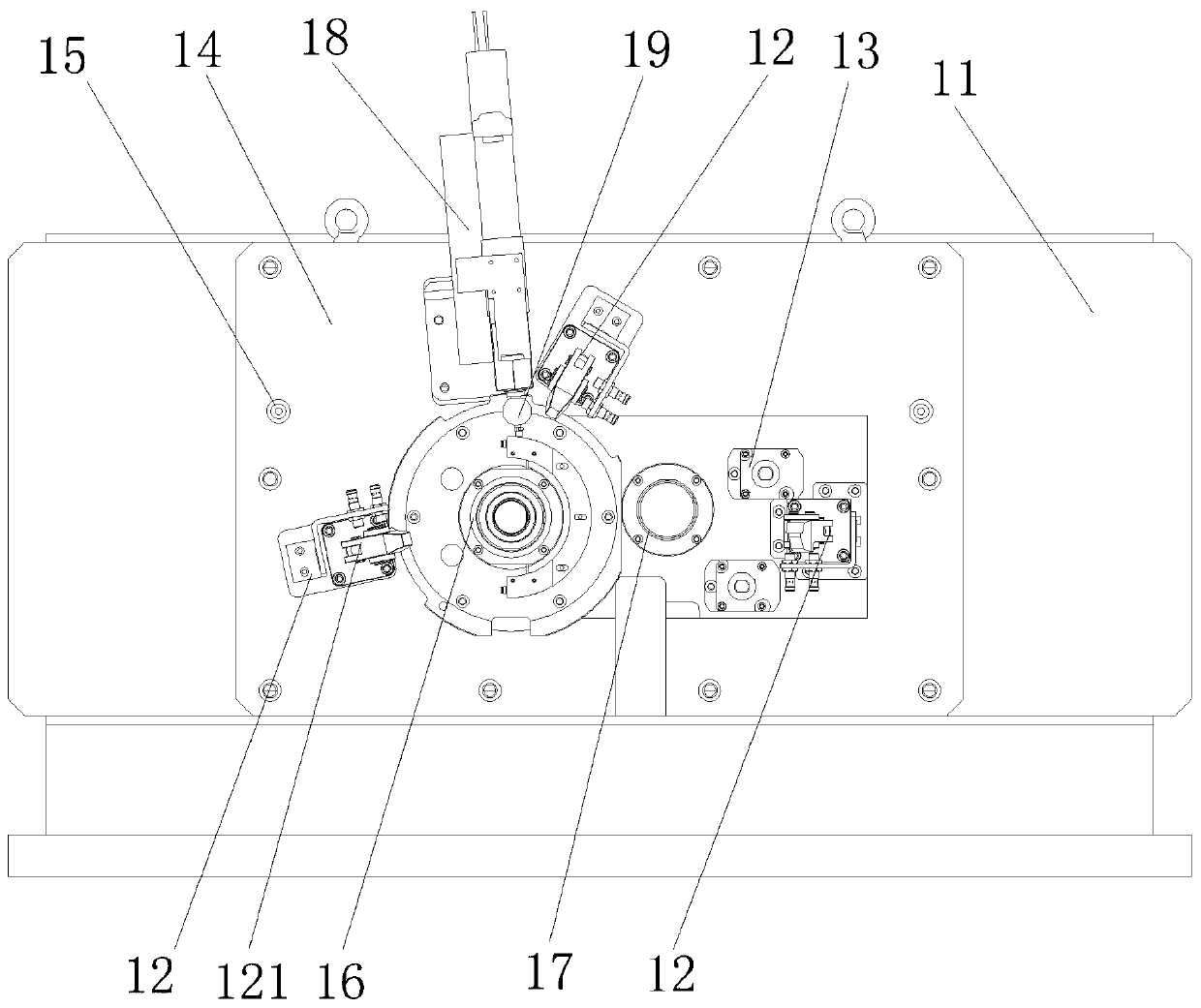

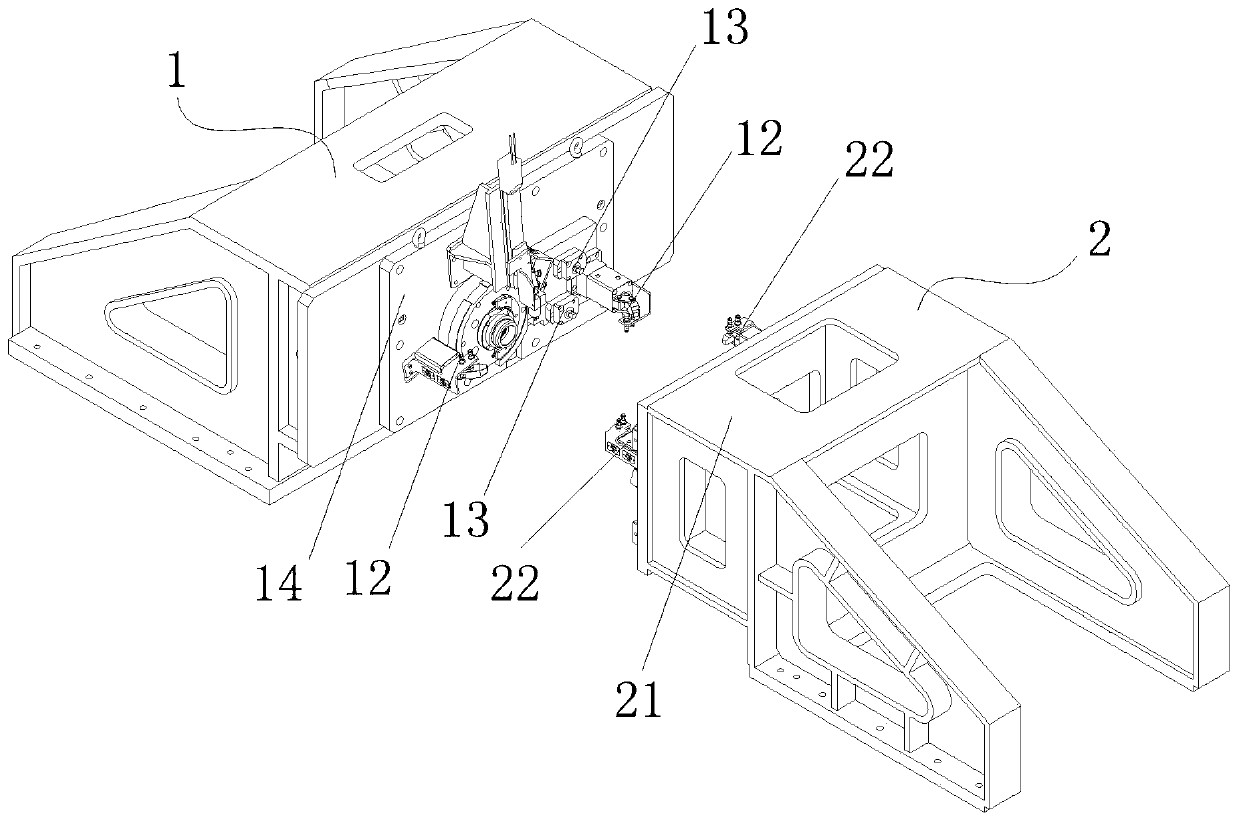

[0040] Such as Figures 1 to 5 As shown, the clamping device of the present invention for off-line detection of a new energy vehicle motor gearbox includes a fixed end part 1 of the clamp body and a movable end part 2 of the clamp body.

[0041] Wherein, the fixed end part 1 of the clamp body includes a fixed seat 11, a plurality of fixed end clamping units 12, and a support unit 13, and the moving end part 2 of the clamp body includes a moving seat 21, a plurality of movable end clamping units 22 , and a plurality of positioning pin seats 23.

[0042] The moving base 21 can move back and forth horizontally. There are three clamping units 22 at the moving end. The shell is clamped at the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com