Full-automatic finish machining device for air cylinder cover

A cylinder head, fully automatic technology, used in positioning devices, metal processing, metal processing equipment and other directions, can solve the problems affecting the processing accuracy of cylinder heads, poor clamping and positioning accuracy, low processing efficiency, etc., and achieve accurate and firm clamping and positioning. , Reduce the influence of inertial impact, and ensure the effect of clamping position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

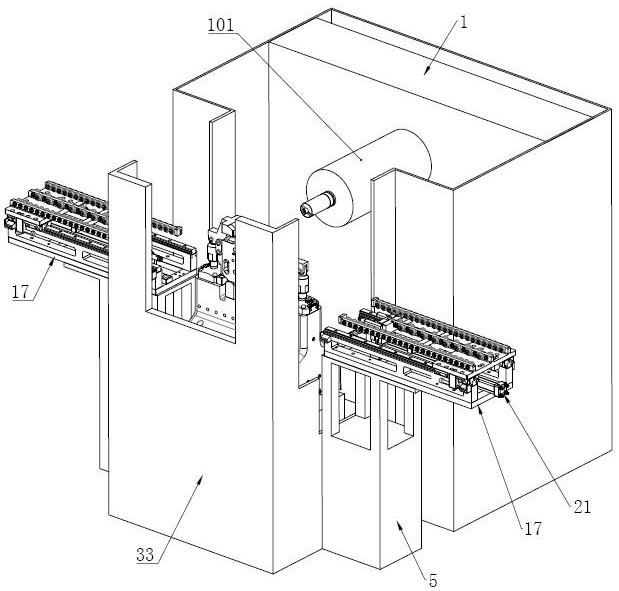

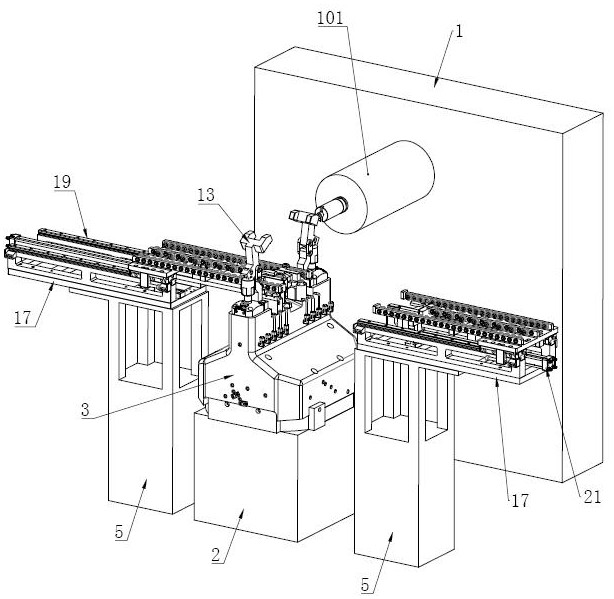

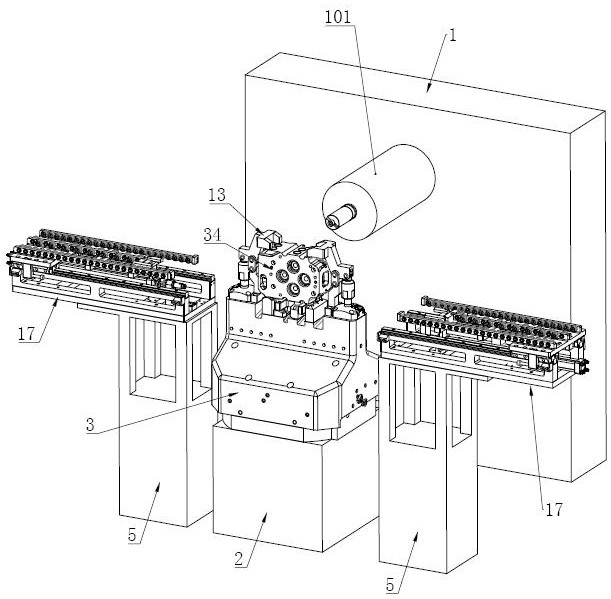

[0052] Such as Figure 1 to Figure 12 As shown, this embodiment provides a cylinder head automatic finishing device, including a machine tool 1, a mounting base 2 is provided on one side of the machine tool 1 having a spindle 101, and a tooling driven by a first driving device is installed on the mounting base 2 in rotation. Seat 3, the both sides of installation base 2 are respectively provided with feeding seat 5, and feeding seat 5 is respectively provided with in order to realize the conveying device of cylinder head 34 loading and unloading, and two sets of conveying devices are arranged correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com