Cable appearance defect on-line detection equipment

A technology for appearance defects and cables, which is applied in the field of online detection equipment for cable appearance defects, can solve the problems of complicated operation, inability to perform secondary judgment, and low work efficiency in switching back and forth, and achieves the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

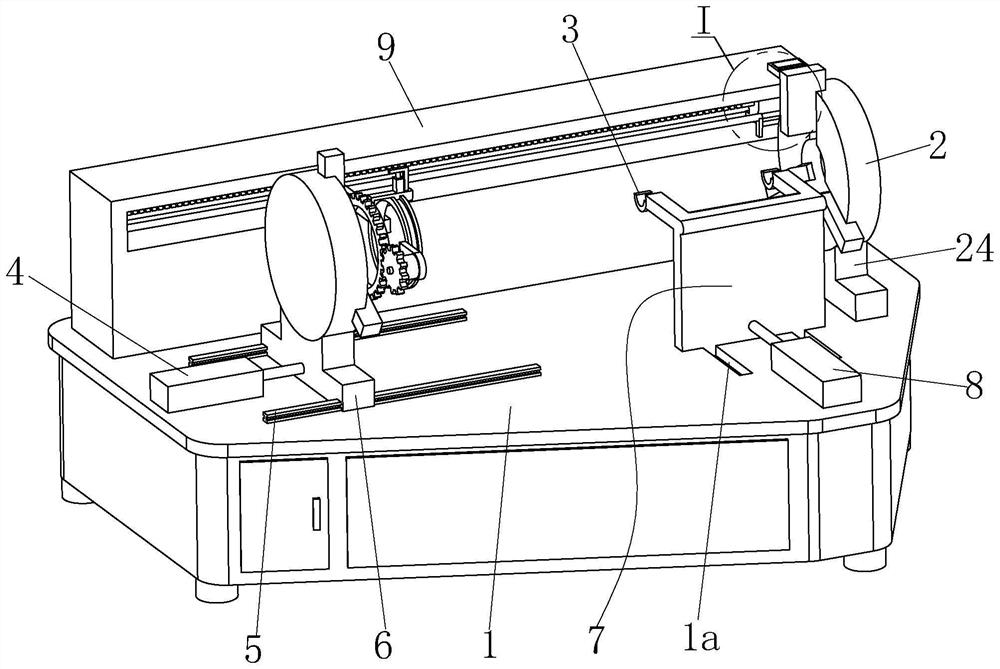

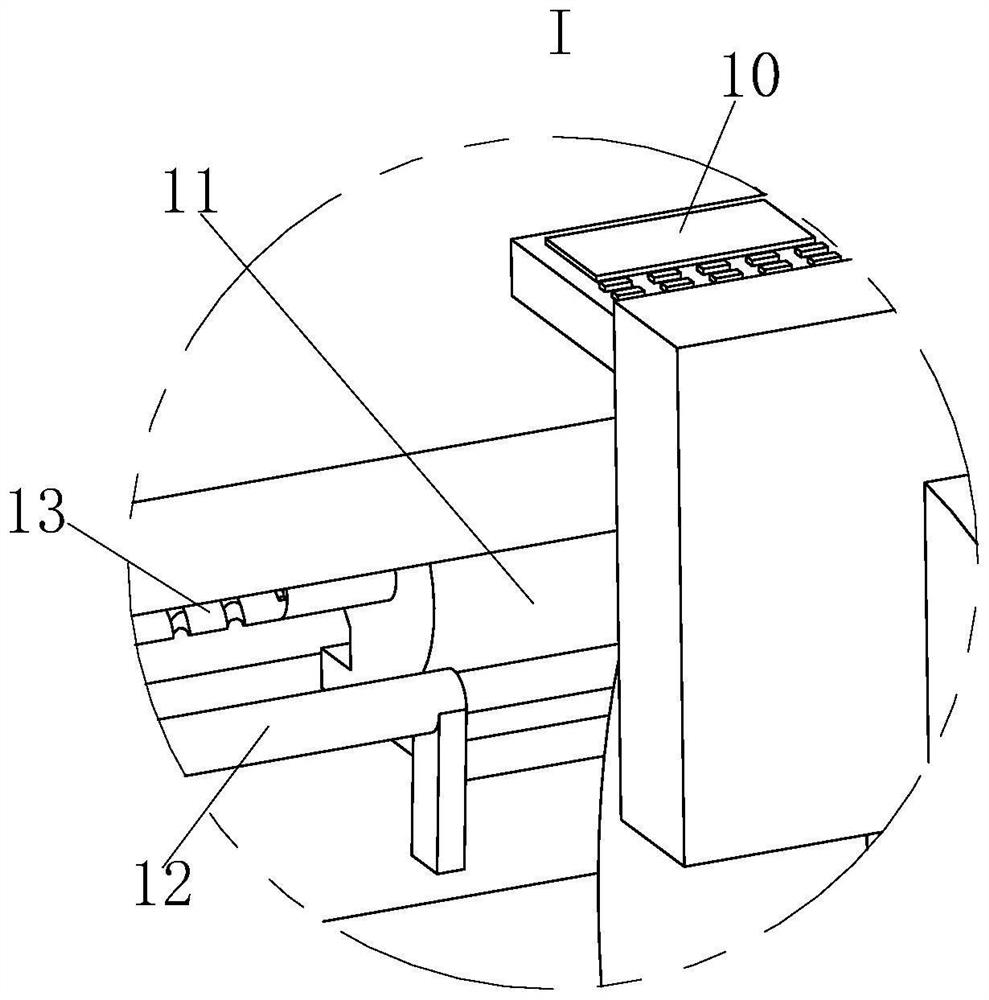

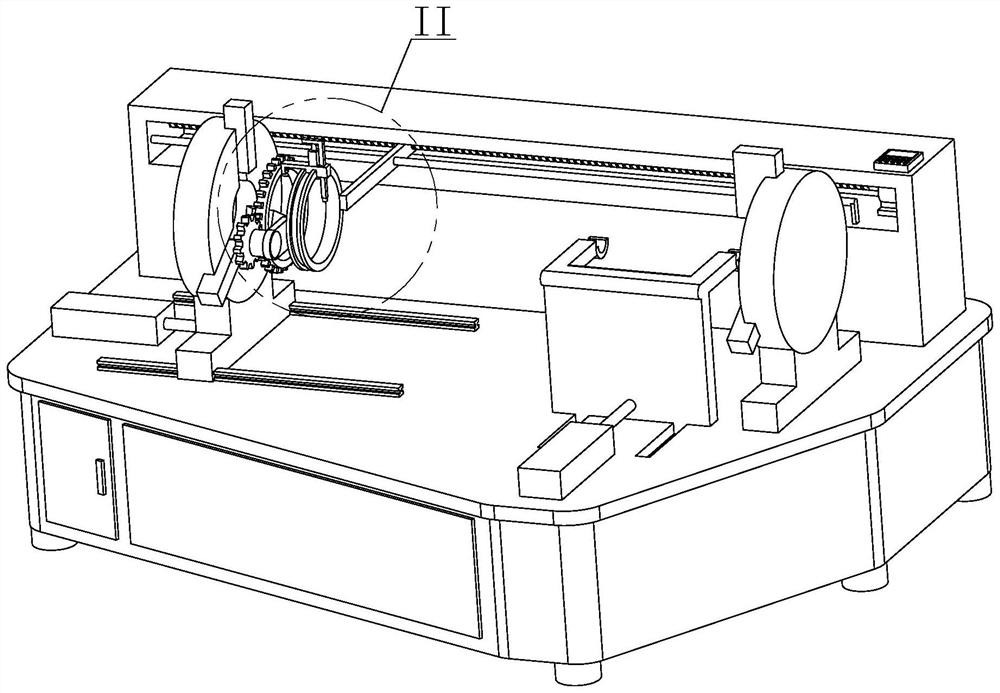

[0032] like Figure 1 to Figure 6 As shown, an on-line detection equipment for cable appearance defects includes a main counter 1, on which a main detection device, an auxiliary positioning installation device and two three-jaw chucks 2 are respectively installed; the two three-jaw chucks 2 are respectively Located on the left and right sides of the main counter 1; the auxiliary positioning and installation device includes two semi-circular ring sleeves 3, the central axes of the two semi-circular ring sleeves 3 are collinear with the central axes of the two three-jaw chucks 2; the main detection device Then it includes an auxiliary cabinet frame 9 installed at the rear of the main counter 1 , a detection display 10 and a detection main drive assembly all installed on the auxiliary cabinet frame 9 . The main detection device is used to detect whether there are defects on the outer surface of the cable, the auxiliary positioning and installation device is used to assist manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com