Special workpiece fixing equipment for boring

A technology for fixing equipment and workpieces, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of too many types of fixtures, slow clamping speed, low processing efficiency, etc., and achieve stable and reliable clamping, structure Simplicity and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

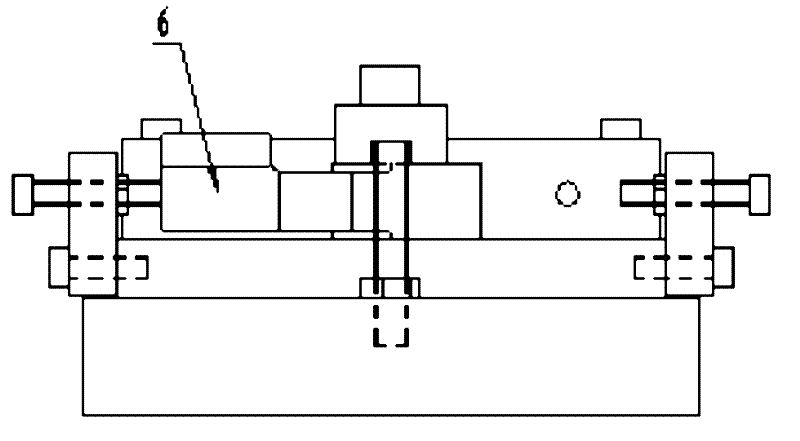

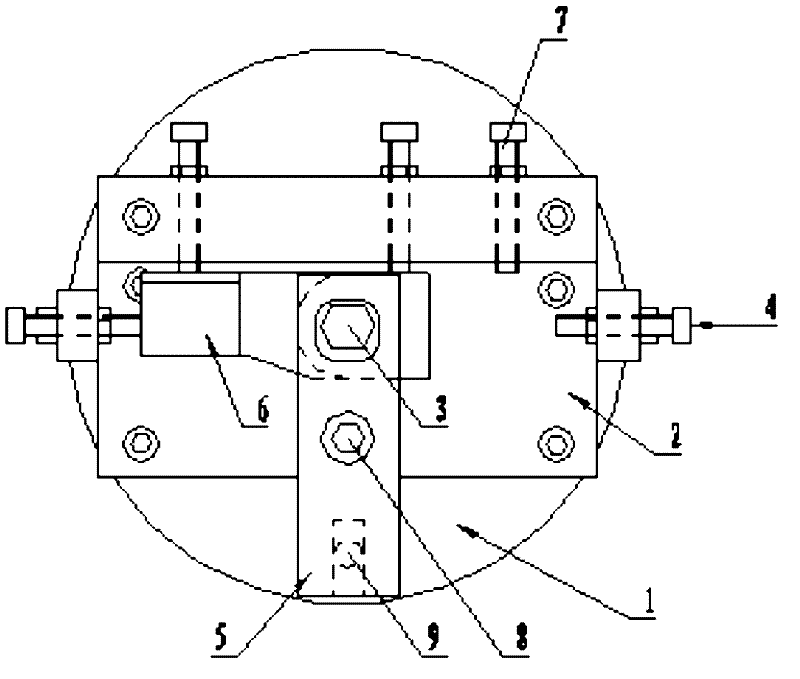

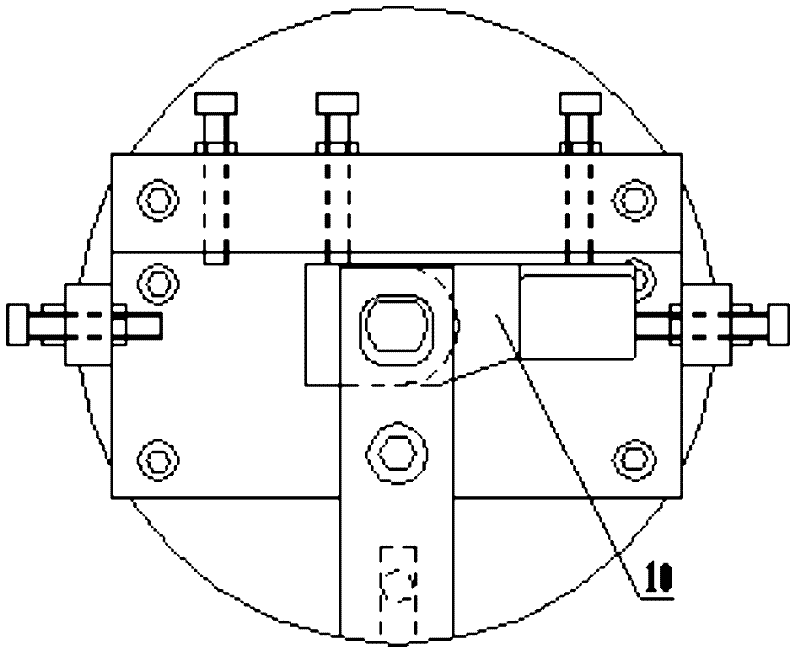

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0016] A special workpiece fixing device for boring, including a workbench, the workbench is composed of a flange 1 and a bottom plate 2 fixed on it, a horizontal positioning screw 4 is installed on the left and right sides of the workbench, and the workbench One group of vertical positioning screws 7 is installed on the front side, and the vertical positioning screws are usually 2 to 5 evenly arranged, and in this embodiment, there are three.

[0017] A workpiece processing area is formed on the worktable between the horizontal positioning screw and the vertical positioning screw, and a pressing plate 5 located above the workpiece processing area is installed on the rear side of the working table, and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com