Tension control device of hot mill and control method

A technology of tension control and hot rolling mill, applied in the direction of tension/pressure control, etc., which can solve the problems of plate width variation and insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

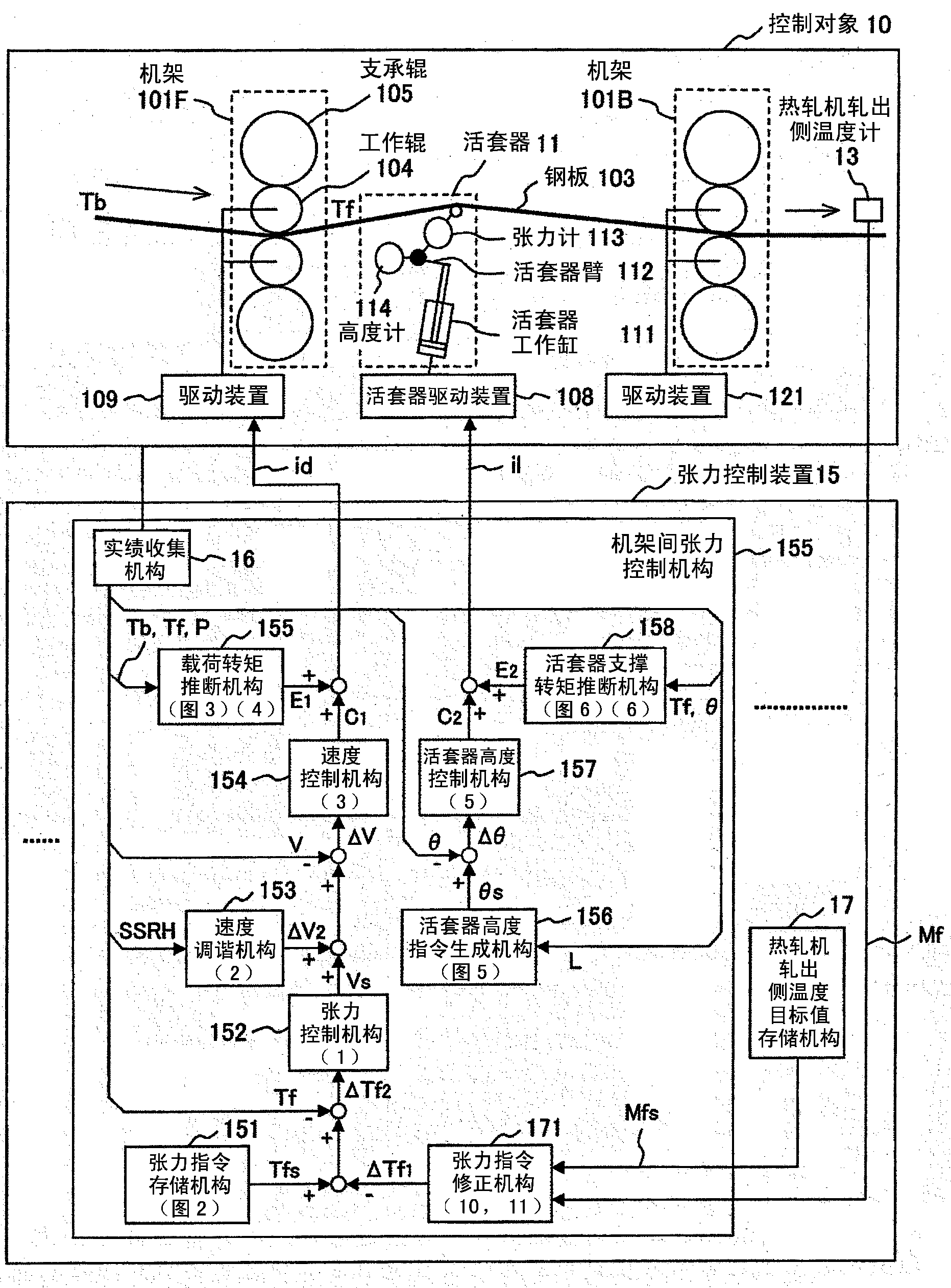

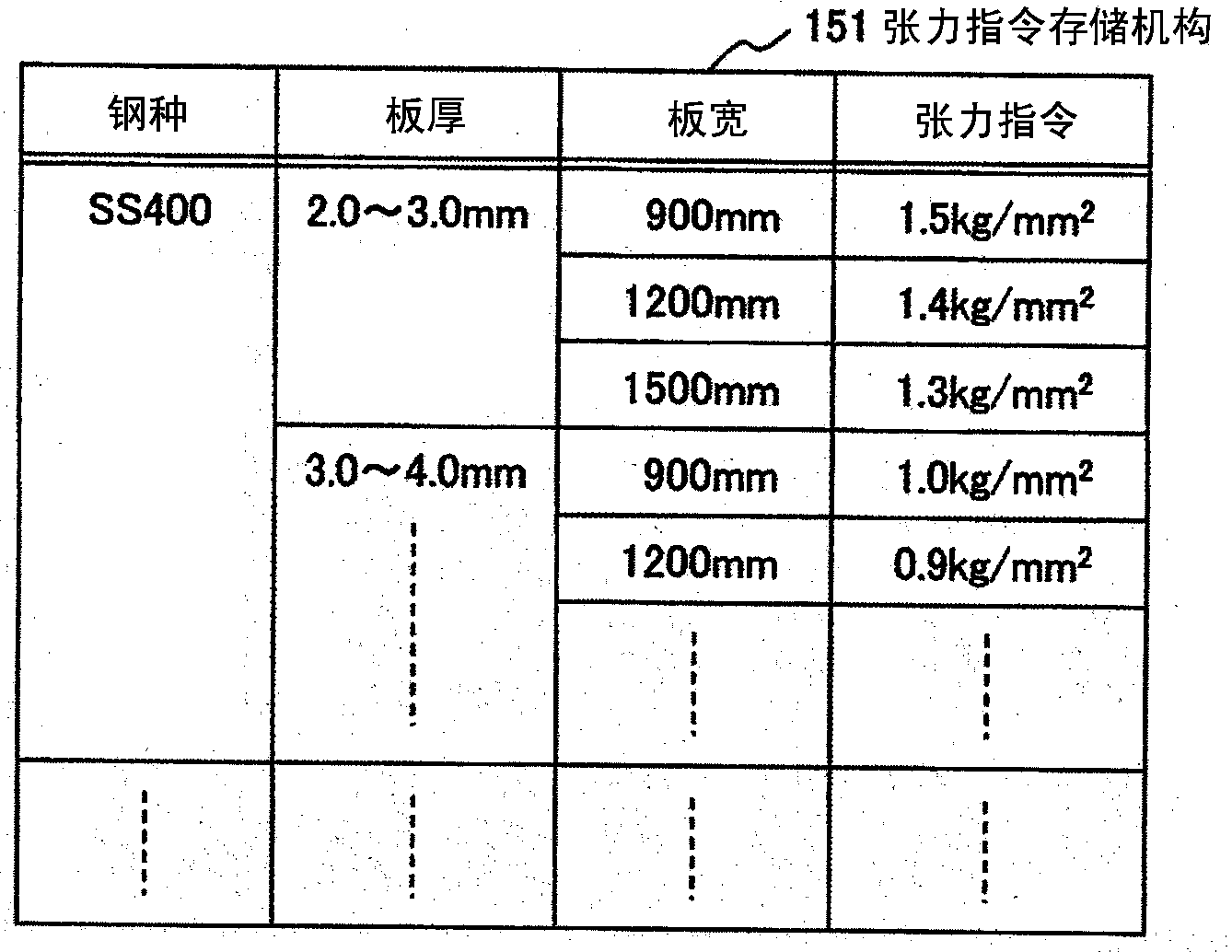

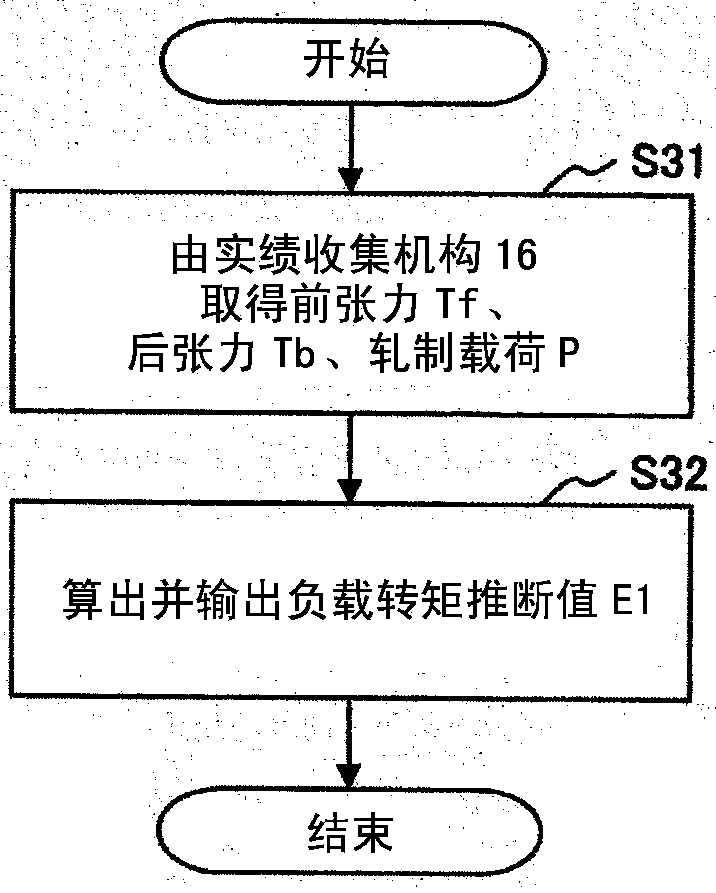

[0070] figure 1 This shows the first embodiment of the present invention. In the tension control of the hot rolling mill of the first embodiment, it is characterized in that correction is made in accordance with the temperature of the rolling side of the hot rolling mill to drive the drive device of the stand. in figure 1 Here, the tension control device 15 receives various signals from the control target 10 (hot rolling mill), and outputs the control signal to the control target 10.

[0071] First, the configuration of the control target 10 will be described. In this embodiment, the control target 10 is a tandem mill that continuously rolls the steel plate 103 with a plurality of stands 101. The steel plate 103 moves from the left side to the right side as shown in the figure, and as it travels from the first stand 101F on the upstream side to the second stand 101B on the downstream side, the steel plate 103 is gradually thinned. In addition, there are actually multiple stands...

Embodiment 2

[0138] Picture 9 This shows the second embodiment of the present invention. in Picture 9 Here, instead of the rolling-out side temperature Mf of the hot rolling mill, the hot rolling-in side temperature Mb is used to calculate the correction value of the tension command, and the driving device as the operating end is driven. Picture 9 In addition to this point, the composition and function of figure 1 Exactly the same.

[0139] Picture 10 The processing performed by the tension command correction mechanism 901 is shown. The tension command correction mechanism 901 first obtains the target value Mb of the temperature on the delivery side of the hot rolling mill from the target temperature storage mechanism 903 on the delivery side of the hot rolling mill in step S101. Although the target value Mbs of the temperature on the feeding side of the hot rolling mill may be fixed, it may be set to a different value depending on the location of the steel sheet.

[0140] Next, in step S1...

Embodiment 3

[0155] Picture 11 This shows the third embodiment of the present invention. in Picture 11 In this method, the correction value of the tension command is calculated using the temperature of the feeding side of the rolling mill and the temperature of the rolling side of the rolling mill, and the driving device as the operating end is driven. Picture 11 The composition and function of the figure 1 Exactly the same.

[0156] Picture 12 The processing performed by the tension command correction mechanism 1101 is shown. The tension command correction mechanism 1101 first, in step S101, acquires the target value Mbs of the temperature on the delivery side of the hot rolling mill from the target temperature storage mechanism 903 on the delivery side of the hot rolling mill. Next, in step S102, the target value Mbf of the hot rolling mill rolling side temperature is acquired from the hot rolling mill rolling side temperature target value storage means 170. Although the target value M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com