Wrapping machine for cable production line

A production line and wrapping machine technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high equipment management costs and high technical requirements for maintenance personnel, and achieve the effects of low management costs, accurate control, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

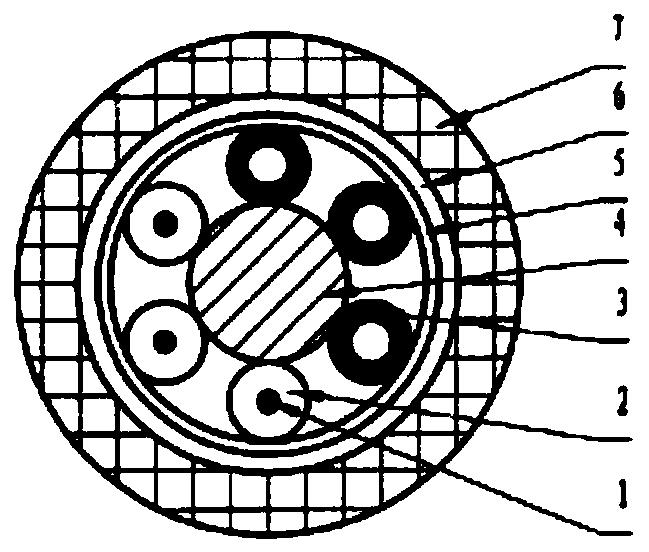

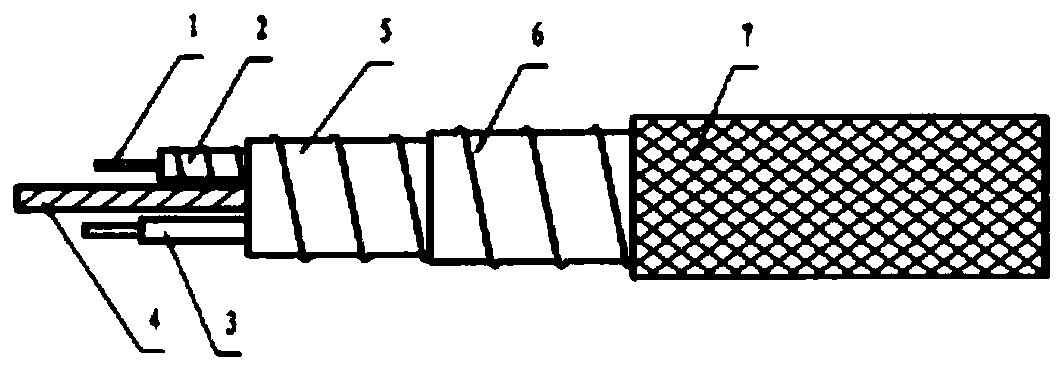

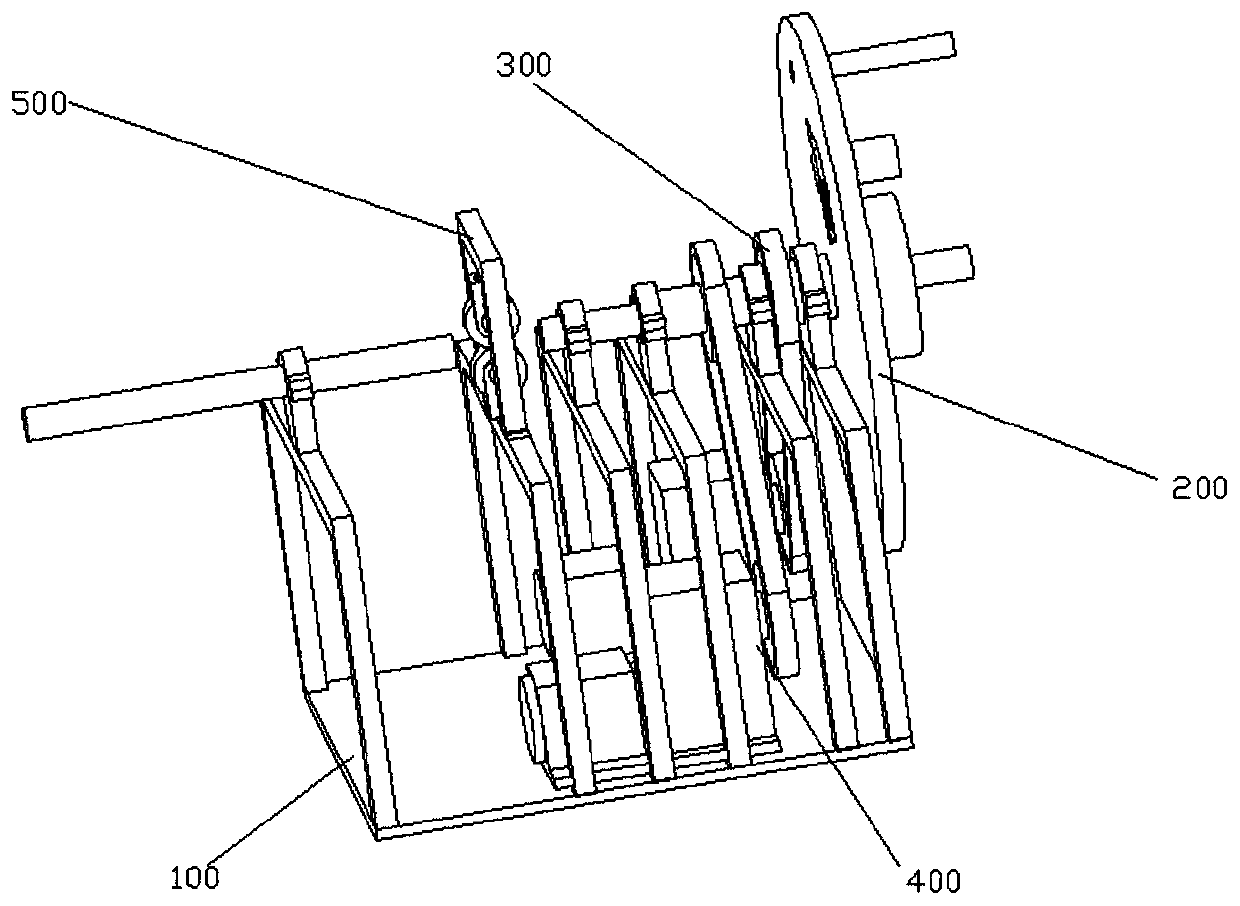

[0028] Such as Figure 3 to Figure 8 As shown, a winding machine for a cable production line includes a frame 100, a winding device 200, a belt unwinding transmission mechanism 300, a winding transmission mechanism 400 and a speed measuring device 500. The wrapping machine can be used for the optical fiber preparation in step S1 and the outer sheath wrapping process in steps S3 and S4 in the manufacturing method of the above-mentioned super-strong, super-flexible, and high-temperature resistant photoelectric hybrid cable.

[0029] The frame 100 includes a bottom plate 101. A number of brackets 102 are fixedly provided on the bottom plate 101, and a wrapping bearing seat 103, a tape releasing bearing seat 104 and a bearing 105 are respectively fixedly provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com