A pvc diaphragm cutting machine

A technology of slitter and diaphragm, which is applied in the direction of winding strips, sending objects, thin material processing, etc., which can solve the problems of cumbersome operation steps, increase the labor intensity of operators, and low work efficiency, so as to reduce the occupied area of equipment , Improve the cutting quality and reduce the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

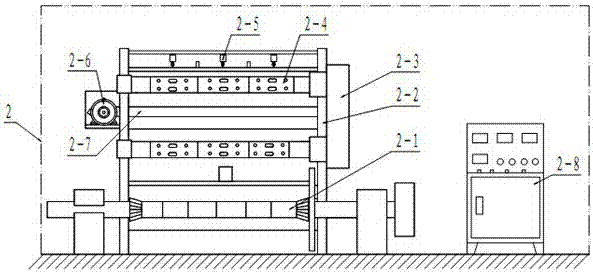

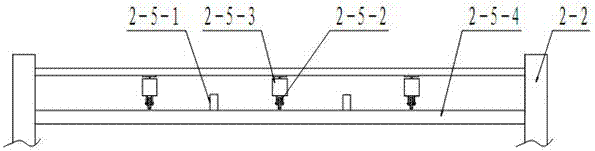

[0021] See figure 2 , image 3 , The present invention includes a feeding mechanism 2-1, a slitting actuator 2-5, a receiving mechanism 2-4, a driving motor 2-6, a transmission shaft 2-7, a transmission mechanism 2-3, a frame 2-2 and a control Cabinet 2-8, the rack 2-2 and the control cabinet 2-8 are fixed on the horizontal ground, the feeding mechanism 2-1, the slitting actuator 2-5 and the material receiving mechanism 2-4 are installed on the rack On 2-2, the drive motor 2-6 is installed on one side frame of the frame 2-2, the transmission mechanism 2-3 is installed on the other side frame of the frame 2-2, and the drive motor 2 6 The transmission shaft 2-7 is connected with the transmission mechanism 2-3. The transmission mechanism 2-3 transmits the power to the feeding mechanism 2-1, the slitting actuator 2-5 and the receiving mechanism 2-4. The special feature is : The slitting actuator 2-5 is provided with a set of straight cutters 2-5-1 and a set of disc cutters 2-5-2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com