Clamping device for glass plate laser drilling machine

A clamping device and laser drilling technology, which is applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of slow processing speed, easy deformation of glass plates under stress, and low drilling yield, so as to improve Efficiency, avoiding the lateral movement of the support, and reducing the effect of drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

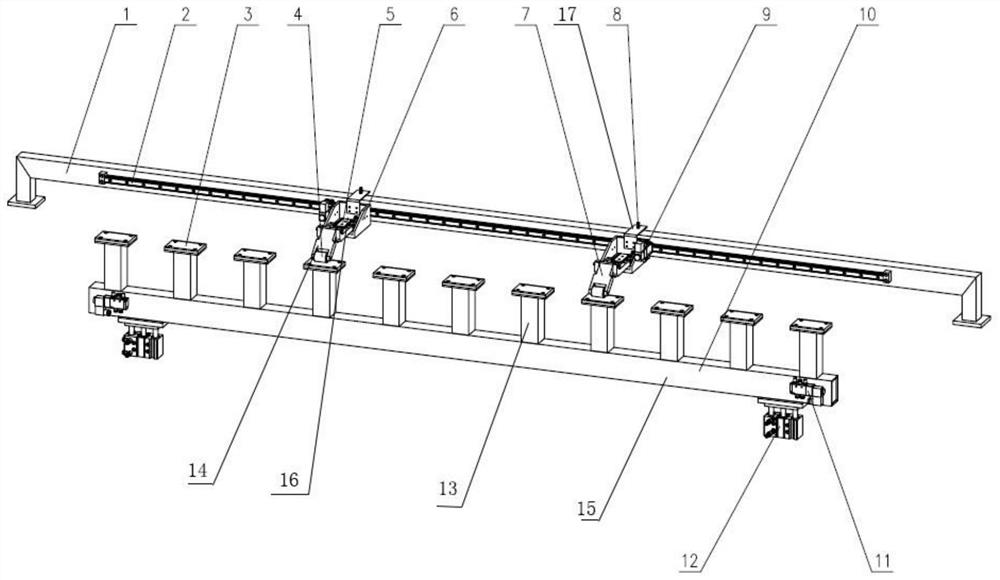

[0040] In further embodiments of the present invention, please continue to refer to figure 1 As shown, each first clamping assembly includes: a clamping cylinder 5, a clamping solenoid valve 9, a connecting rod 7 and a roller 4, a groove 16 is provided on the bracket 6, and the clamping cylinder 5 is fixed on the In the groove 16, the clamping solenoid valve 9 is arranged on one side of the bracket 6, one end of the connecting rod 7 is connected with the clamping cylinder 5, the other end of the connecting rod 7 is connected with the roller 4 in rotation, and the clamping solenoid valve 9 is connected with the clamping cylinder 5. Cylinder 5 is electrically connected.

[0041] Preferably, the roller 4 is made of polyurethane or rubber.

[0042] Further, as a preferred embodiment, a clamping device for a glass plate laser drilling machine further includes: a pin shaft, the pin shaft is arranged in one side of the connecting rod 7, and the two ends of the pin shaft are respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com