Patents

Literature

51results about How to "Meet drilling requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

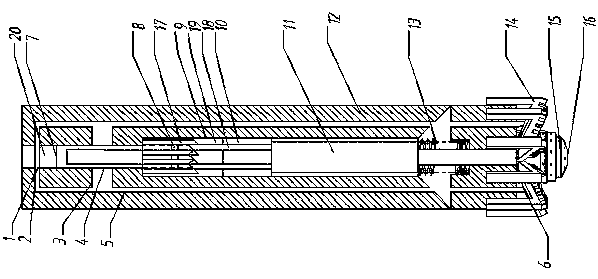

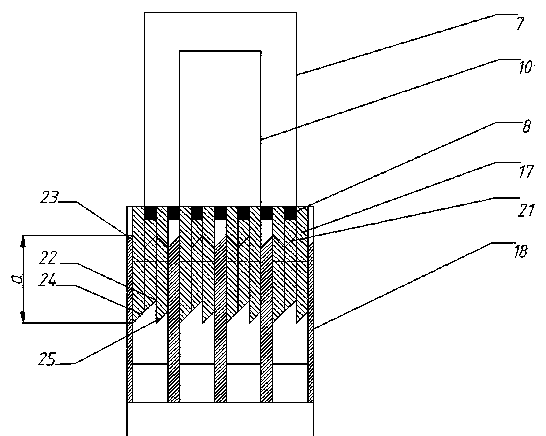

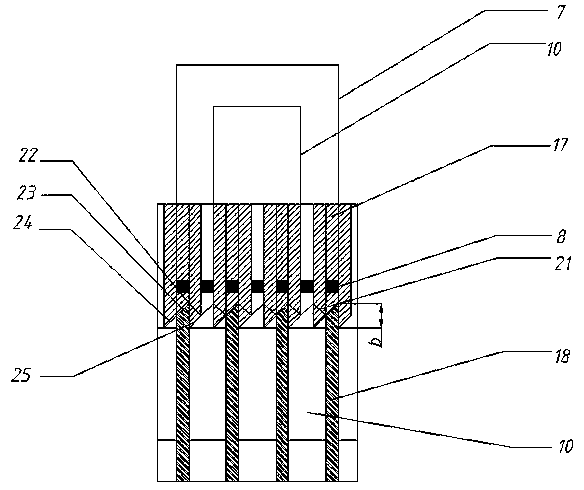

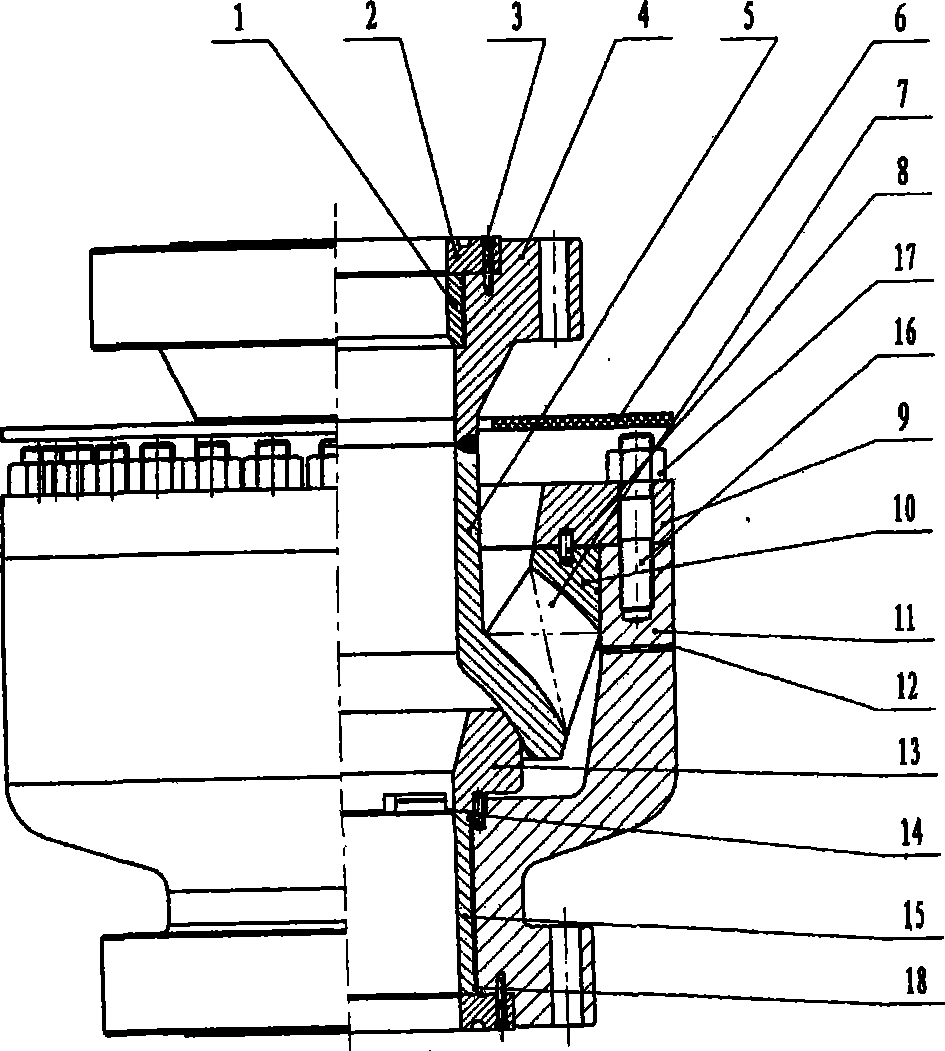

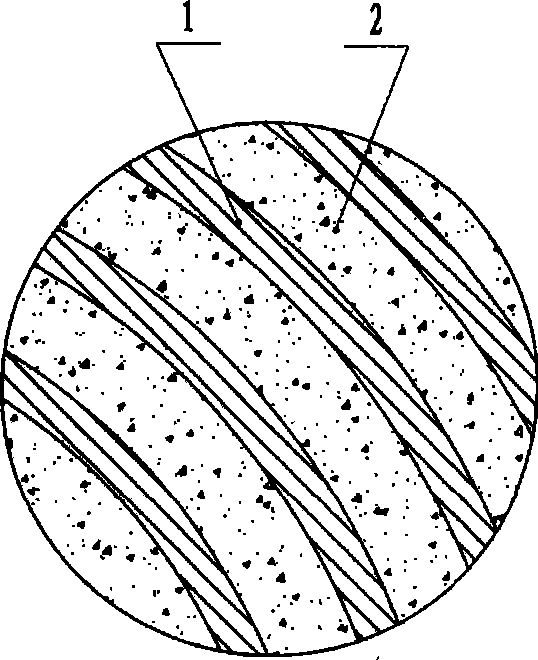

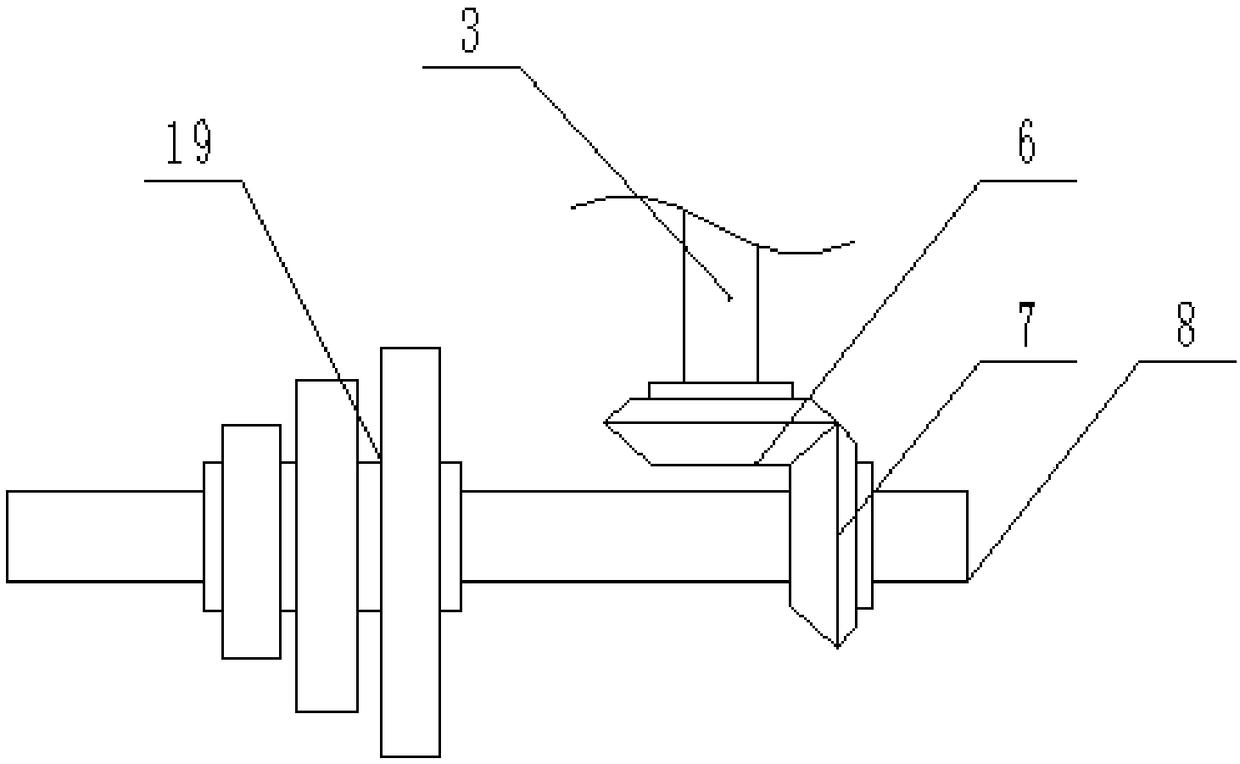

Driving retractable combination drill bit

InactiveCN105156039ATake advantage ofMeet drilling requirementsDrill bitsWell drillingPolycrystalline diamond

The invention relates to a driving retractable combination drill bit which mainly comprises a drill bit body, a well drilling liquid accommodating space, a well drilling liquid channel, a drill bit barrel, a compressive block, limiting stoppers, protruded rib plates in walls, a rotary retractable block, a retractable column, PDC (polycrystalline diamond compact) cutter wings and a cone. The PDC cutter wings are peripherally arranged along the outer wall of the drill bit body to form a central hollow groove; the retractable column which is positioned inside the drill bit barrel axially penetrates the central hollow groove, and the cone is fixedly arranged at the tail end of the retractable column; the retractable column can axially move up and down under the control of a retractable device; a hollow flow channel is axially fixedly connected onto the PDC cutter wings; the well drilling liquid accommodating space is jointly formed by the upper end surface of the compressive block and the side walls of the drill bit body; the protruded rib plates in the walls are peripherally arranged along the inner side of the drill bit barrel at intervals, and the limiting stoppers can axially move in slide grooves. The driving retractable combination drill bit has the advantages that merits of PDC drill bits and cone drill bits are sufficiently utilized, and accordingly the driving retractable combination drill bit is high in rock breaking speed and efficiency and long in service life under soft and hard staggered stratum conditions.

Owner:SOUTHWEST PETROLEUM UNIV

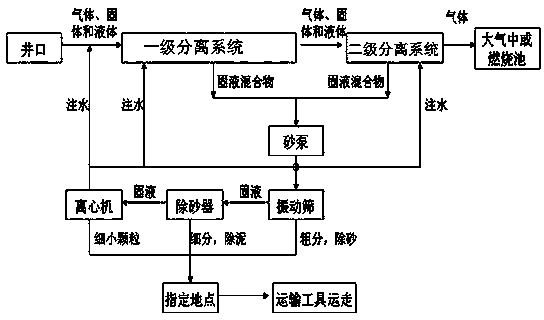

Rock debris separating method for gas drilling

ActiveCN103993845AImprove primary separation effectAchieve drillingConstructionsWater circulationEnvironmental geology

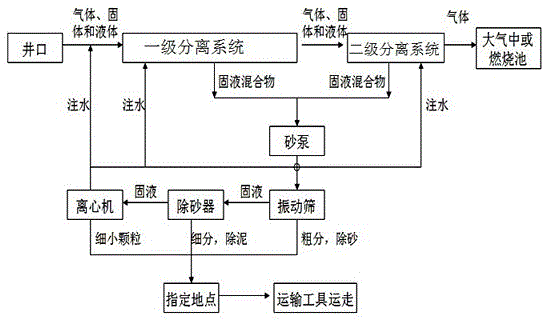

The invention discloses a rock debris separating method for gas drilling. The rock debris separating method for gas drilling comprises the steps of firstly enabling water in a whole system to circularly flow to achieve balance and beginning to perform gas drilling; mixing gas and solid with the water to form a mixed fluid to enable dust in the solid to be dissolve in the water during drilling and before the gas returned from a well mouth and the solid are separated; enabling the mixed fluid to firstly flow into a primary separation system to remove coarse particles, discharging the gas carried with fine particles, water drops or water mist into a secondary separation system; removing the fine particles, water drops or water mist so as to obtain purified gas and a solid-liquid mixture after water bath washing is performed; delivering the solid-liquid mixture to a circulating water treatment system, and separating the coarse particles through primary treatment separation; removing the fine particles through secondary treatment separation; removing fine particles through tertiary treatment separation. The rock debris separating method for gas drilling can achieve returned fluid treatment under the condition that a grit chamber does not exist through gas drilling, gas meeting the direct emission standard is finally obtained, and the gas drilling requirement under different conditions can be met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

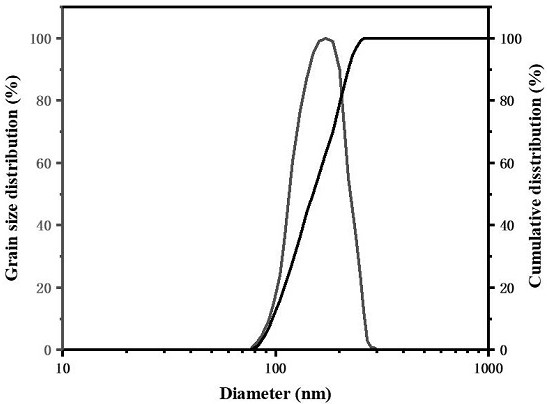

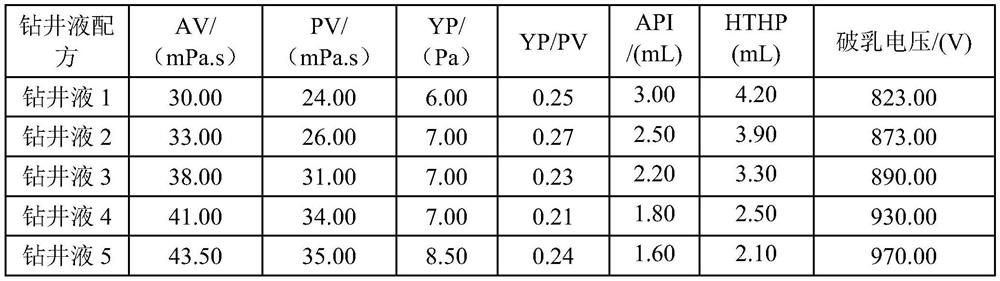

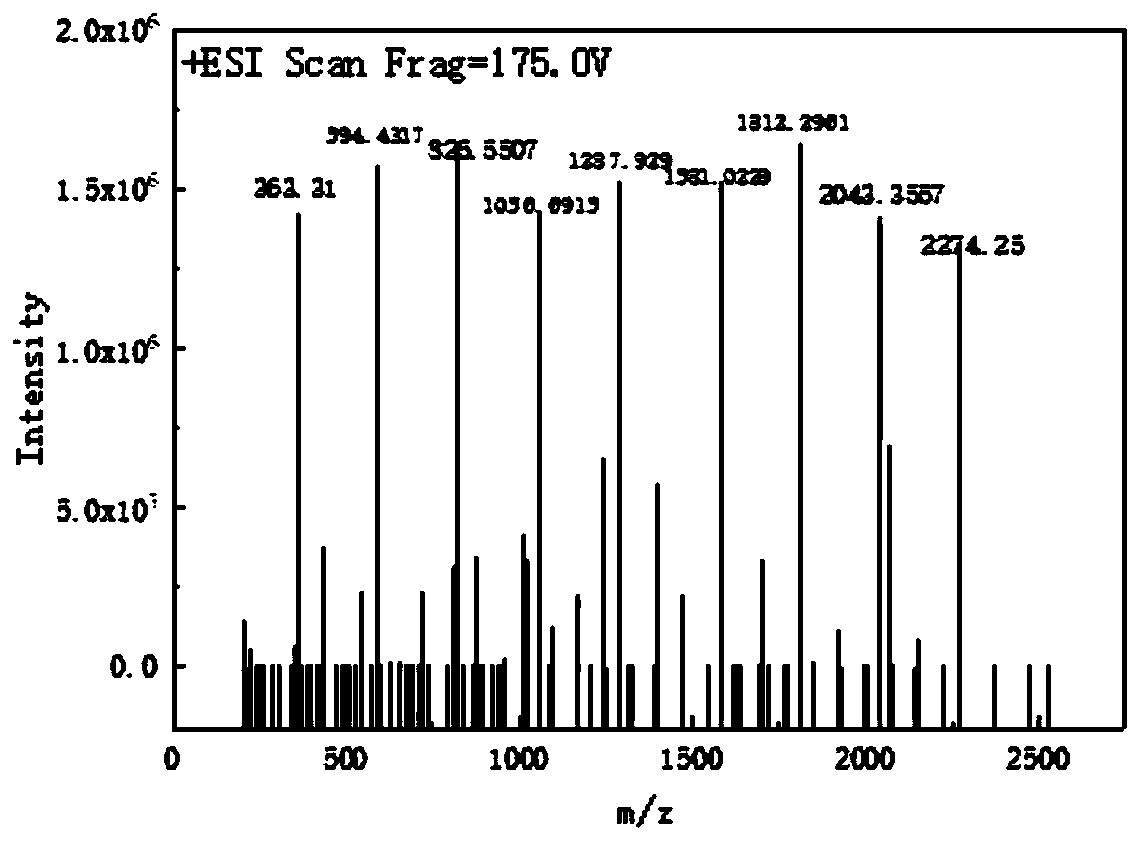

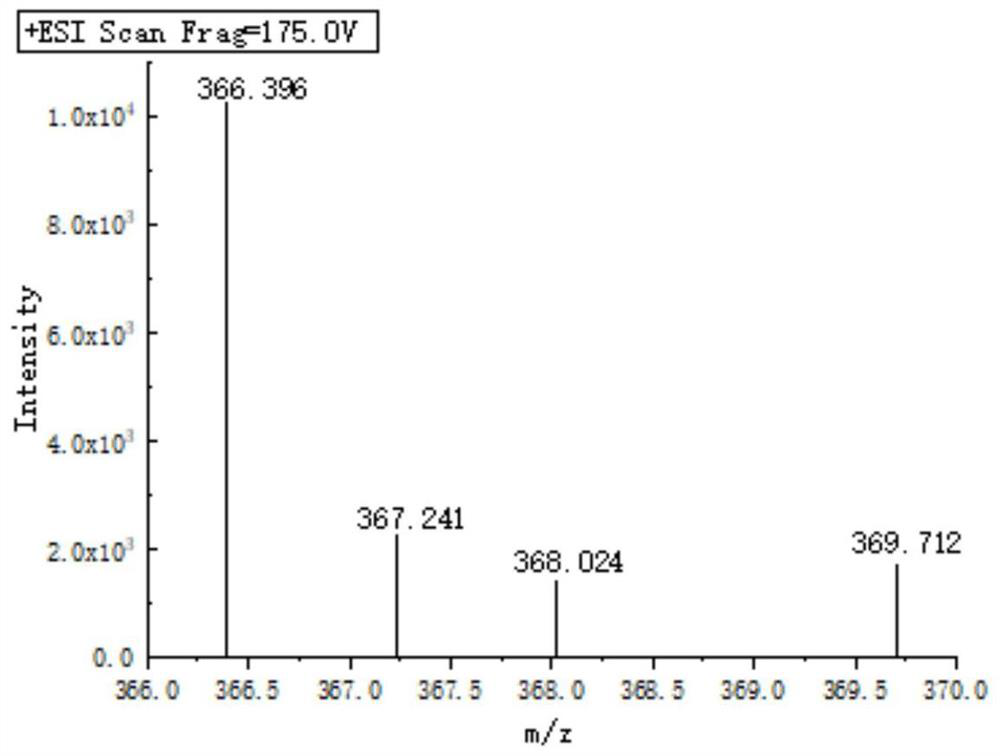

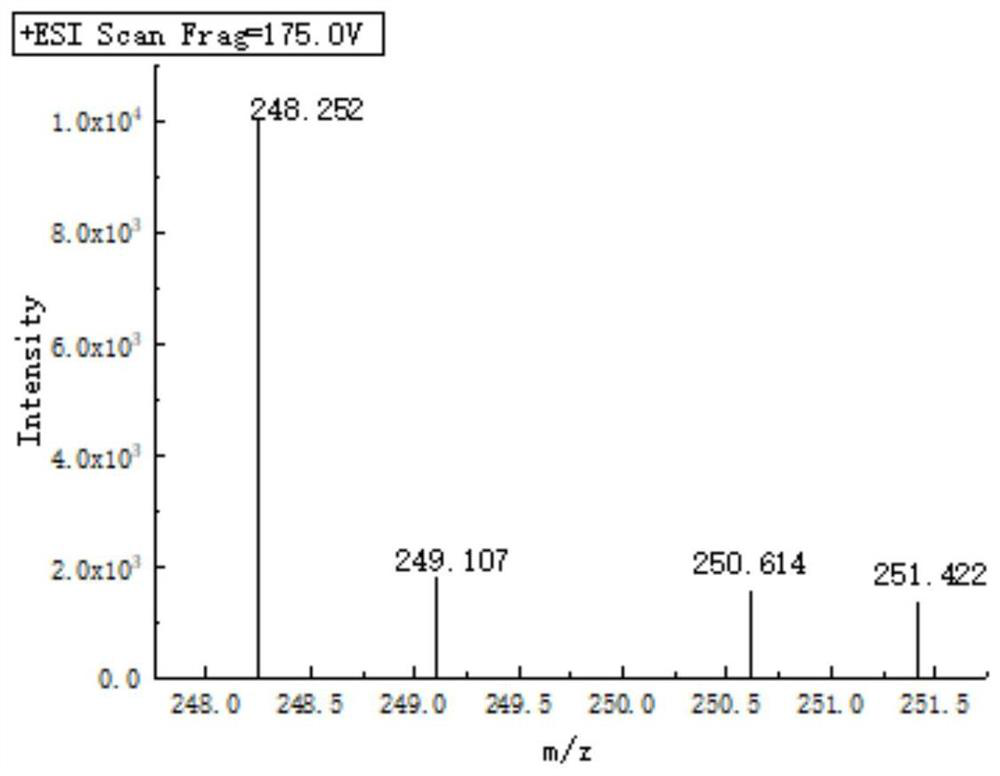

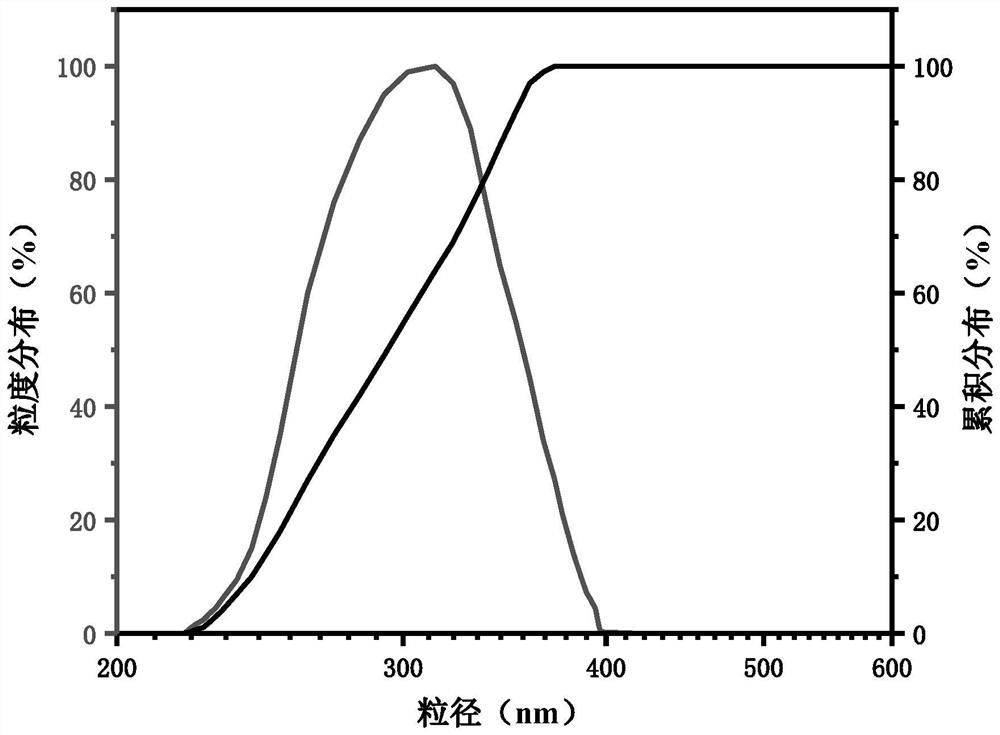

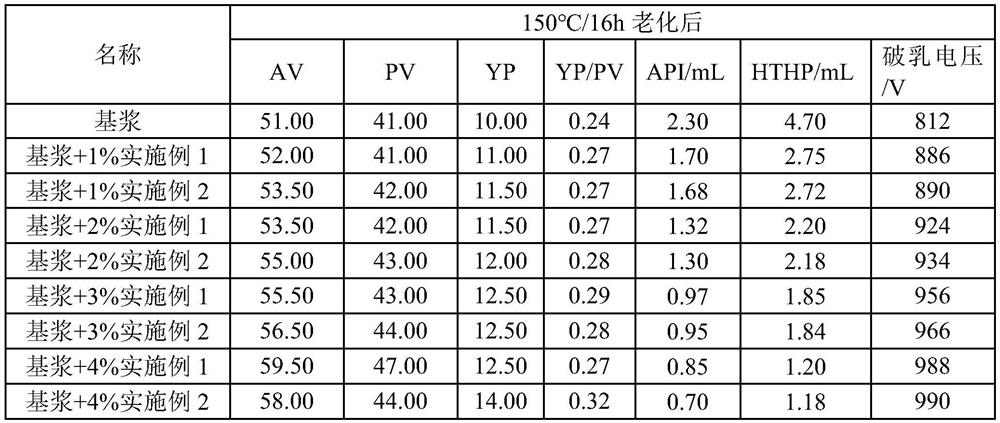

High-temperature-resistant modified nano silicon dioxide blocking agent and oil-based drilling fluid

The invention discloses a high-temperature-resistant modified nano silicon dioxide blocking agent and an oil-based drilling fluid, and belongs to the technical field of oil and gas field drilling. The high-temperature-resistant modified nano silicon dioxide blocking agent is synthesized by modifying silicon dioxide with an enamine compound, a diallyl compound, an olefinic bond-containing long-chain alkyl ester compound, an amino-containing silane coupling agent and a cross-linking agent divinyl benzene through a step-by-step synthesis method. The particle size of the blocking agent prepared from the high-temperature-resistant modified nano silicon dioxide is 78-300 nm, the blocking performance is remarkably improved compared with that of similar blocking agents, and the blocking agent is resistant to high temperature and can be applied to deep wells and ultra-deep wells. The blocking agent also has the advantages of easily available raw materials, low price and the like, and the provided synthesis method is stable, reliable, simple, rapid and suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

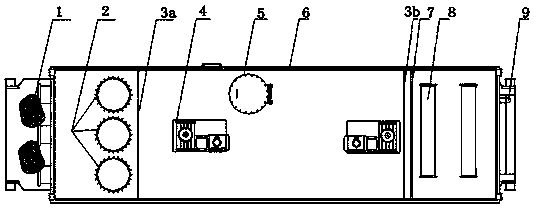

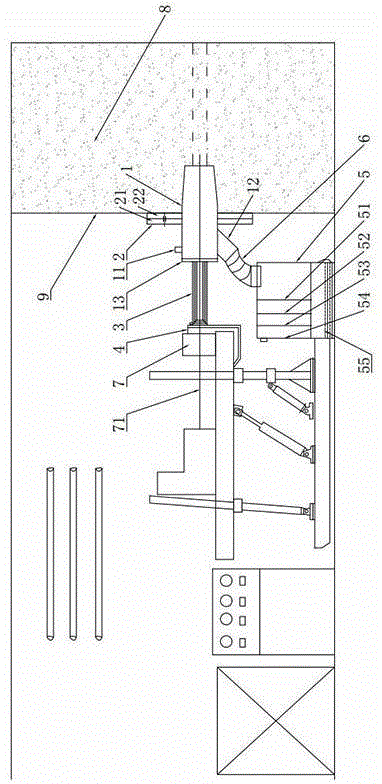

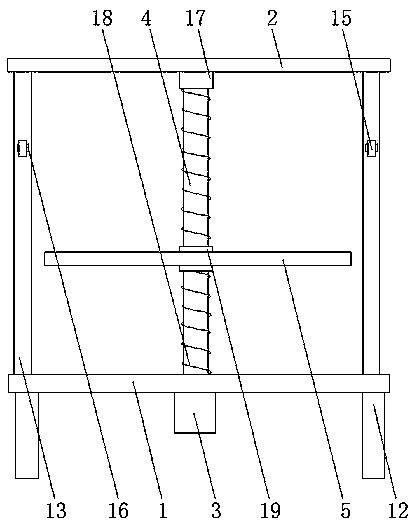

Outburst-prevention, dust collection and slag discharging integrated device for coal roadway drilling construction

InactiveCN104453751AMeet drilling requirementsRealize integrationConstructionsGas removalSlagEngineering

The invention discloses an outburst-prevention, dust collection and slag discharging integrated device for coal roadway drilling construction. The device comprises a drilling machine system, a hydraulic system, a compressed air system and a power supply system and further comprises an orifice dust collection device, a movable outburst-prevention baffle, a hydraulic automatic feeding device, a fixed connection device, a dust removal and slag discharging device, a hydraulic branch system and a compressed air branch system. A compressed air branch connector is formed in the upper portion of the rear end of the orifice dust collection device, a slag discharging pipe is arranged below the compressed air branch connector and inclined downwards, the movable outburst-prevention baffle is fixed to the orifice dust collection device, the hydraulic automatic feeding device is connected with the orifice dust collection device, the fixed connection device fixes the hydraulic automatic feeding device to a drilling machine, and the dust removal and slag discharging device is connected with the slag discharging pipe of the orifice dust collection device through a connecting flexible hose. The integrated device organically combines the outburst-prevention device, the dust collection device and the slag discharging device, the problem that existing orifice-series dust removal device equipment is disperse is effectively solved, multiple functions are achieved through one device, and the integrated device is easy to operate and low in cost.

Owner:HUNAN UNIV OF SCI & TECH

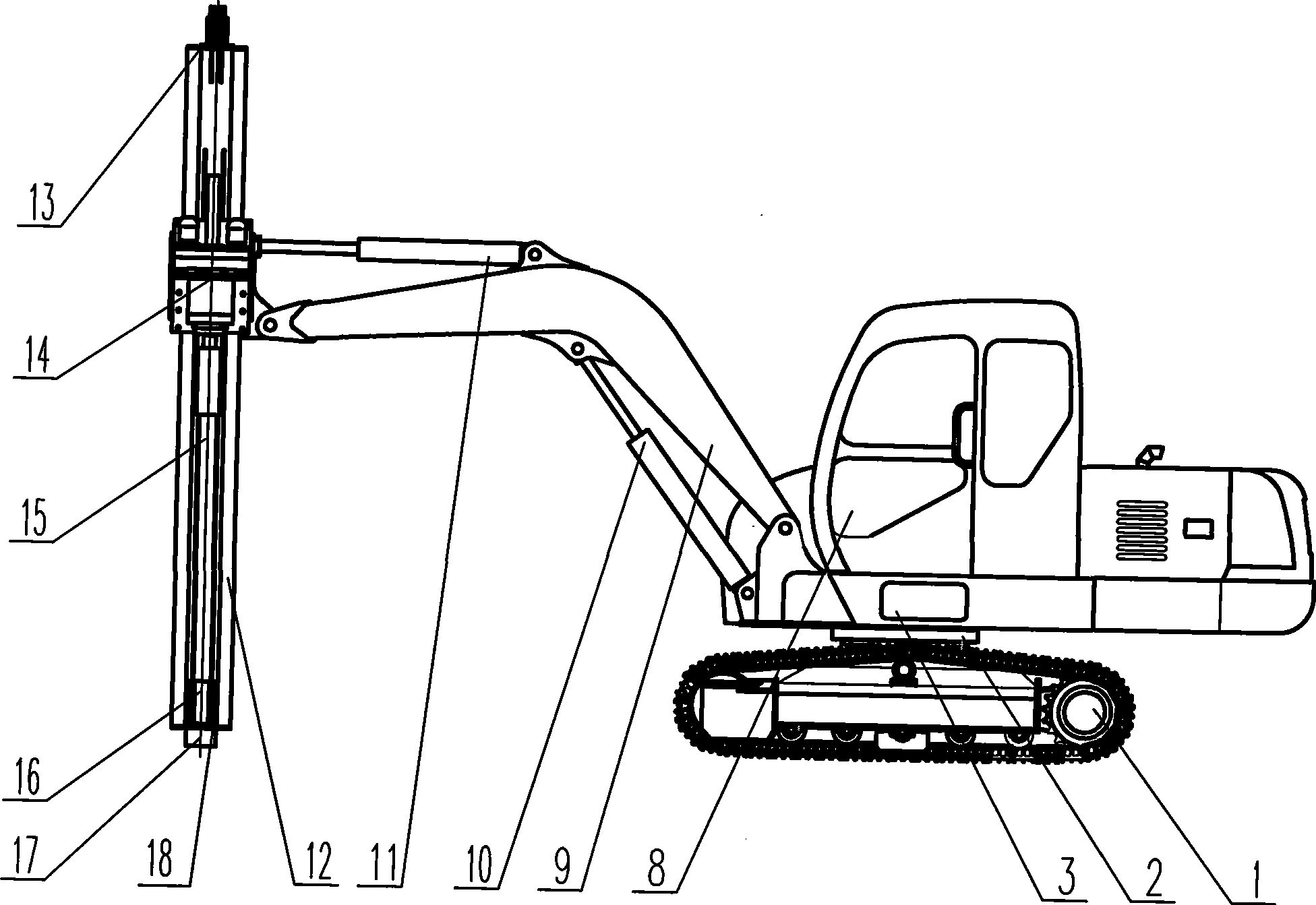

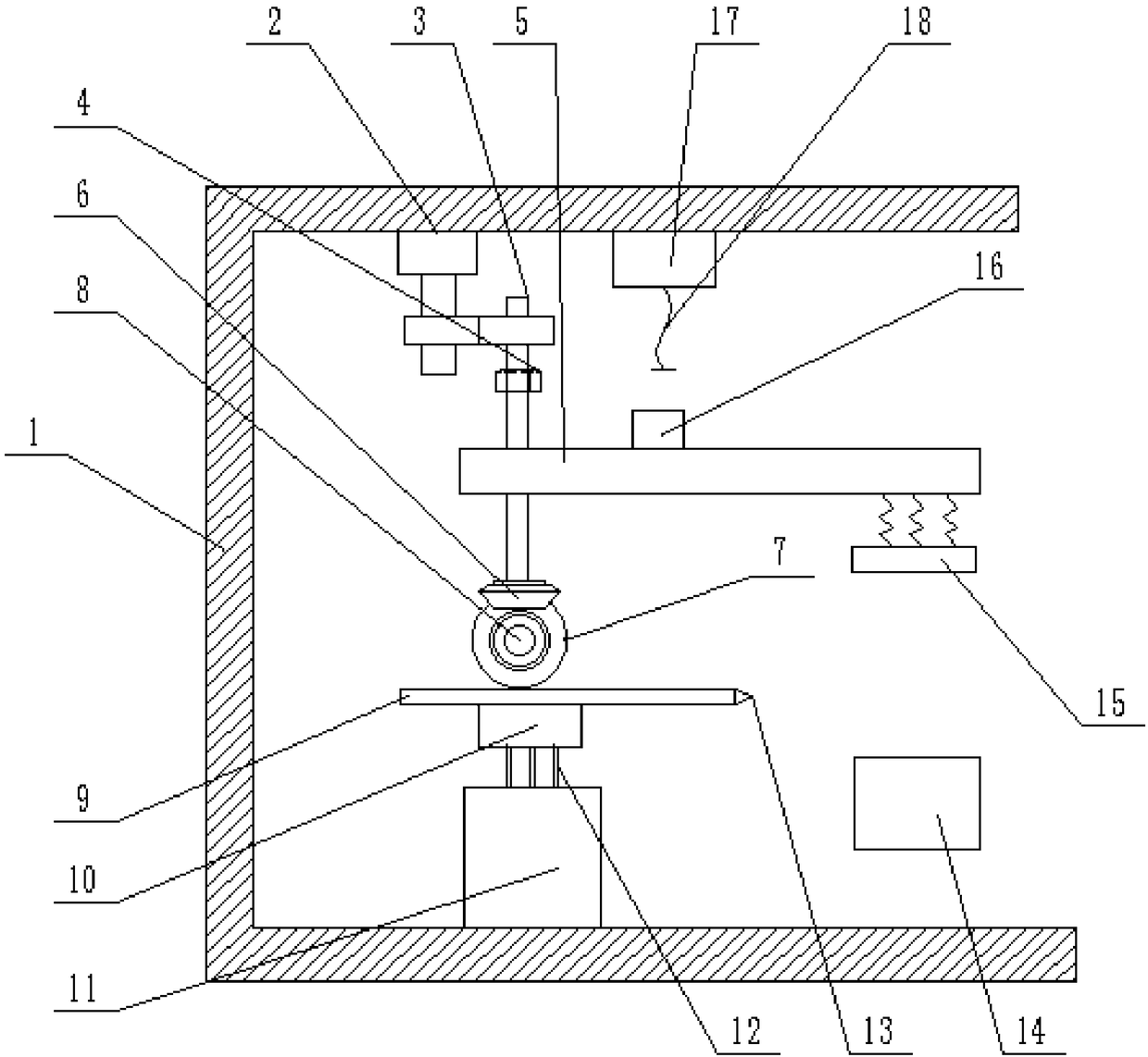

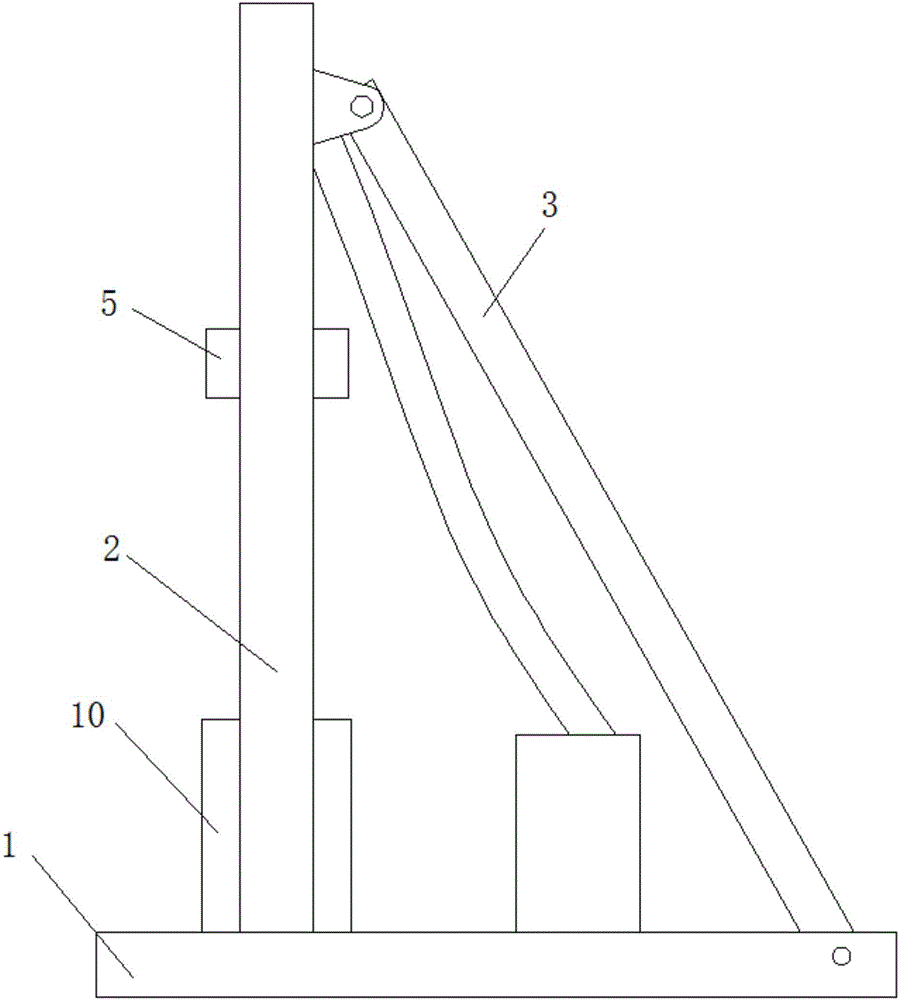

Dredger type drill

InactiveCN101382041AAvoid vibrationGreat driving forceConstructionsDerricks/mastsControl systemControl engineering

The invention discloses a digging machine type drill which comprises a walking chassis (1), a platform returning mechanism (2), a platform (3), a power system, a hydraulic system (5), a movable arm (9), a movable arm lifting cylinder (10) and an operating control system (7). A hydraulic drill is hinged with the front end of the movable arm (9), a drill tower tilting cylinder (11) hinged with the hydraulic drill is arranged on the movable arm (9), and the drill tower tilting cylinder (11) is hydraulically connected with a hydraulic part of the hydraulic drill and the hydraulic system (5). The digging machine type drill has a compact structure, good maneuverability, capability of meeting various drilling requirements, wide operating range, low energy consumption, high efficiency, convenient and flexible operation, simple maintenance, low use cost, and environmental friendliness.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

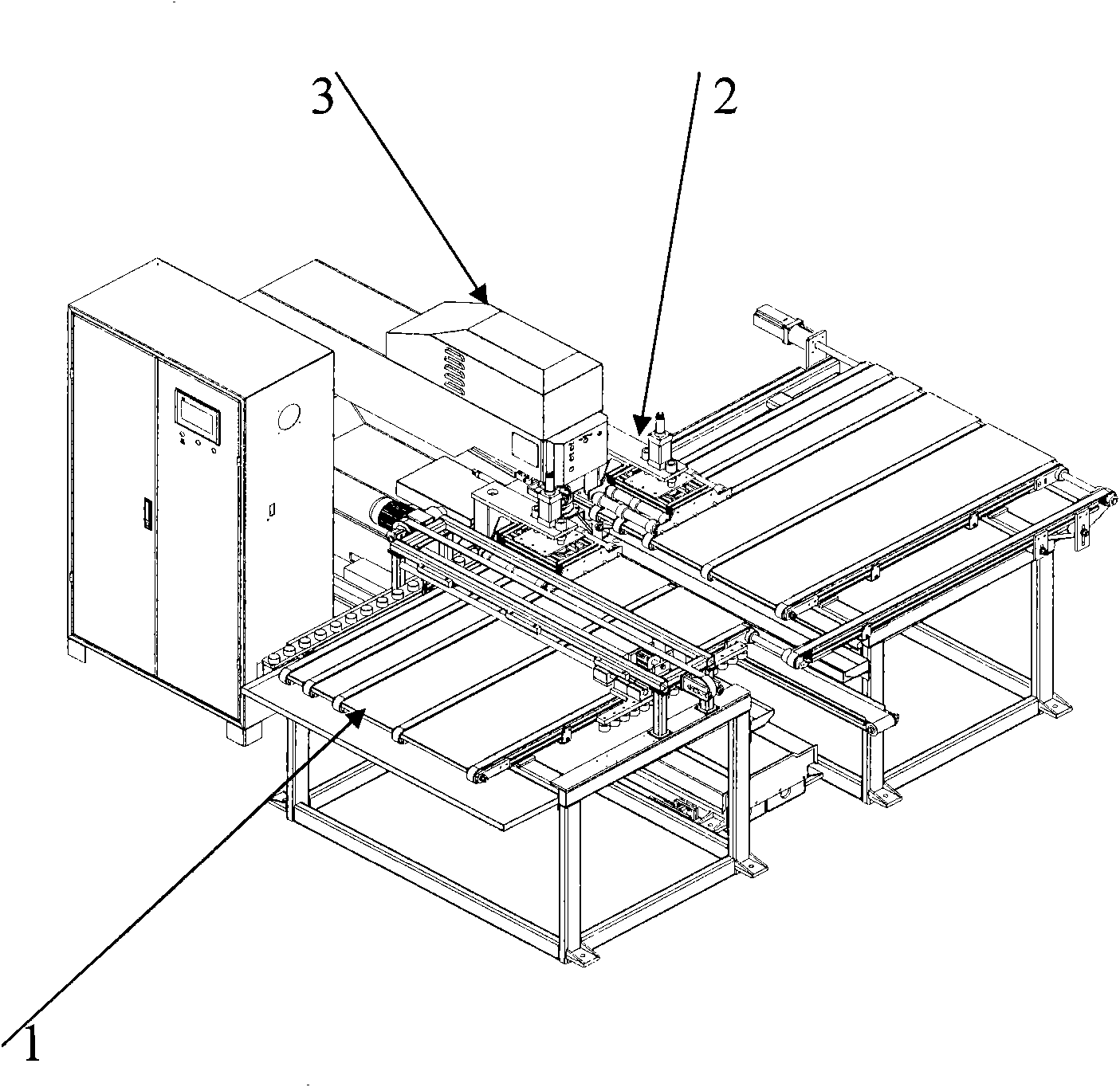

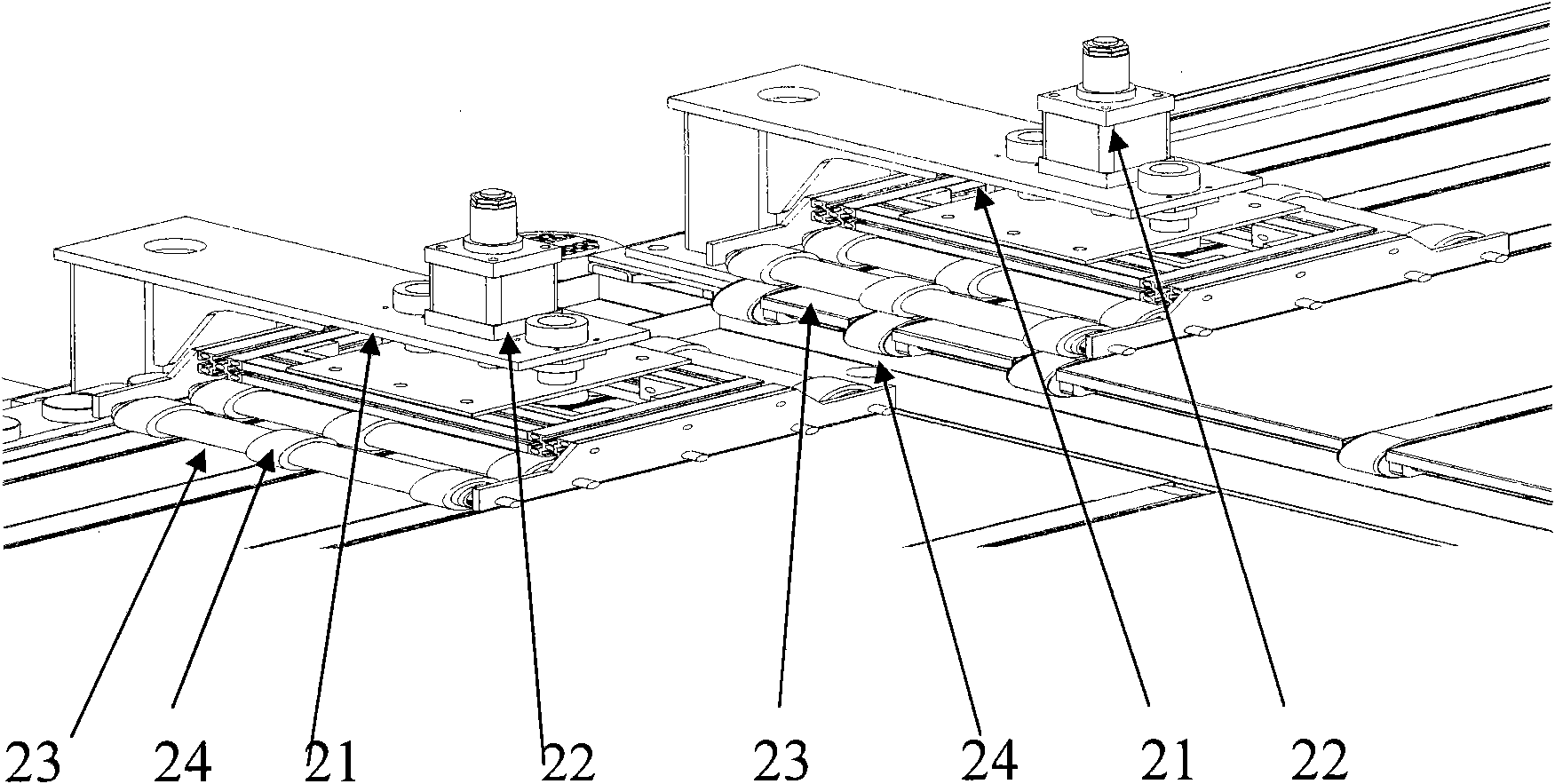

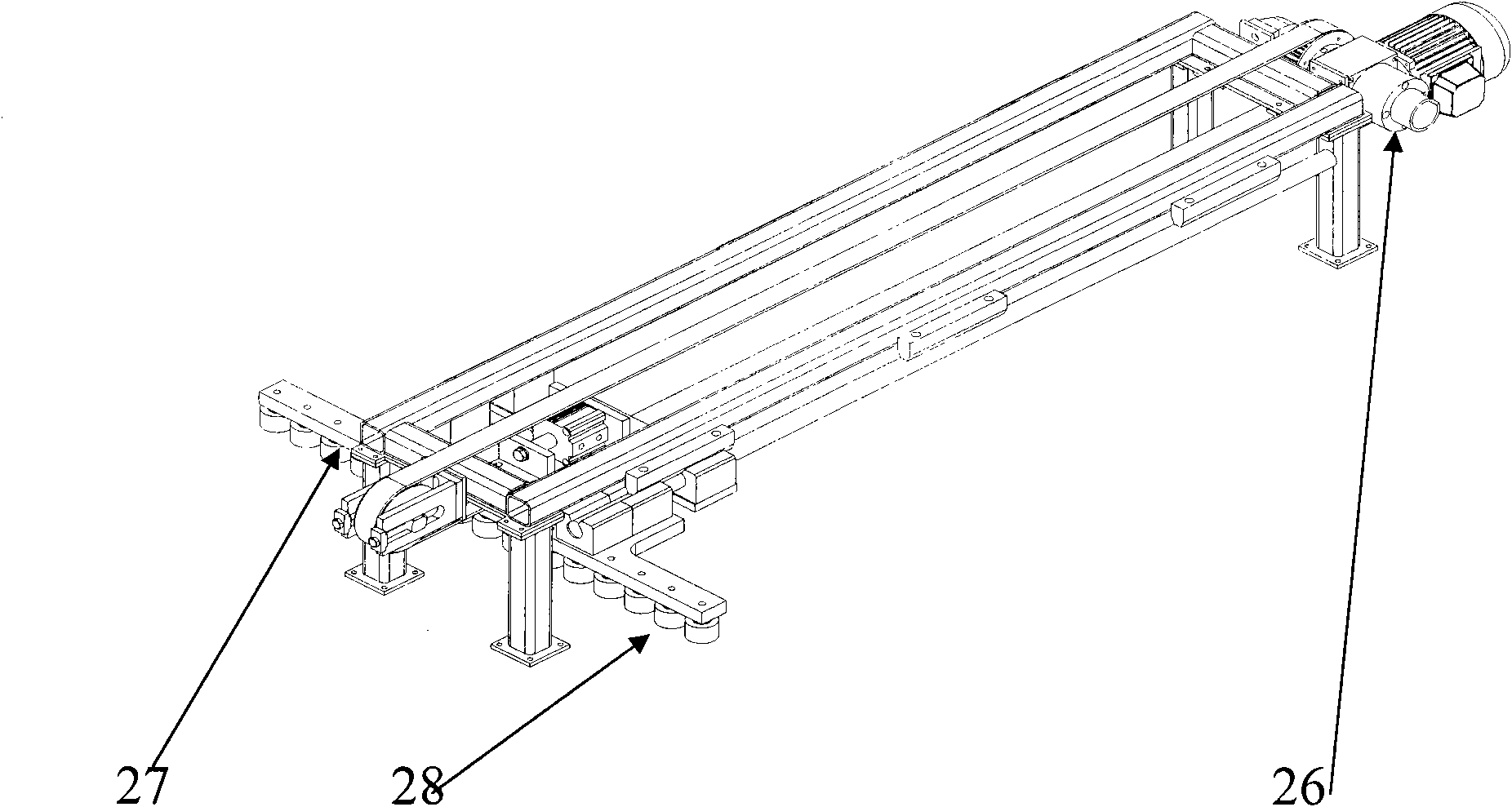

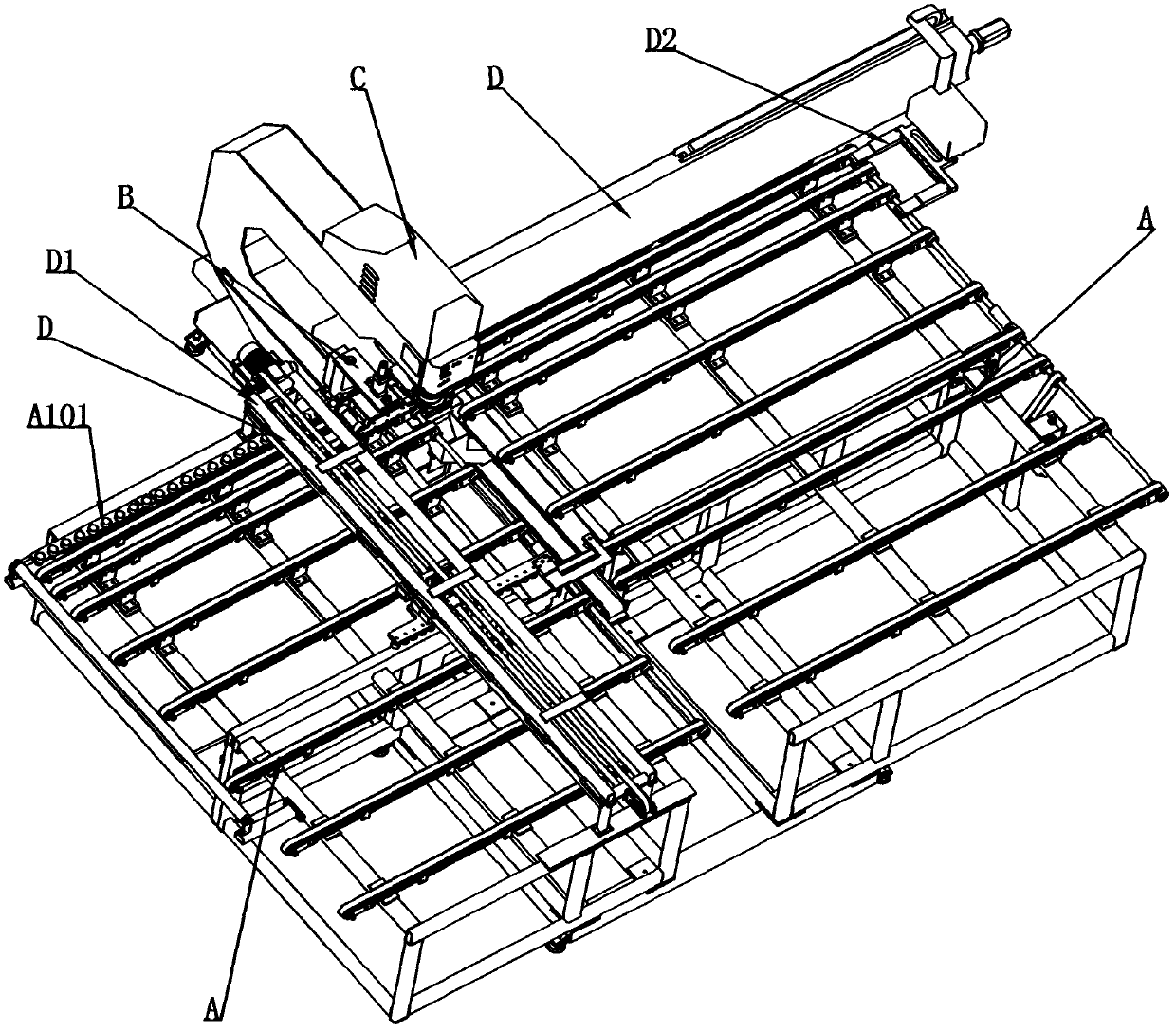

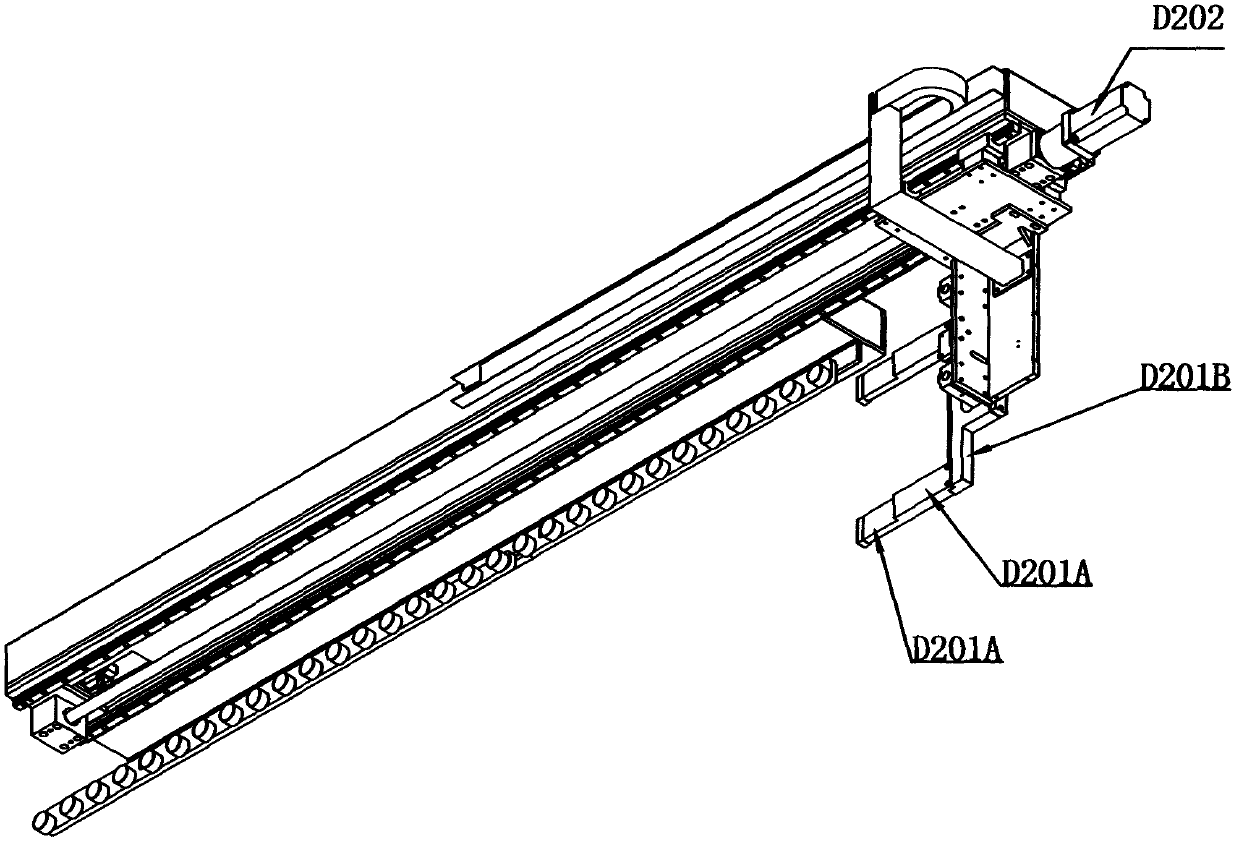

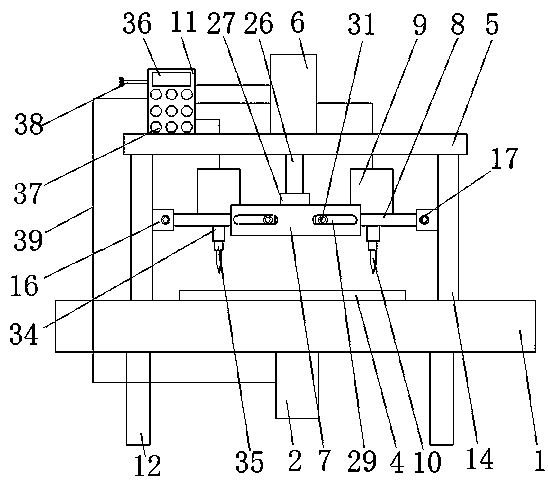

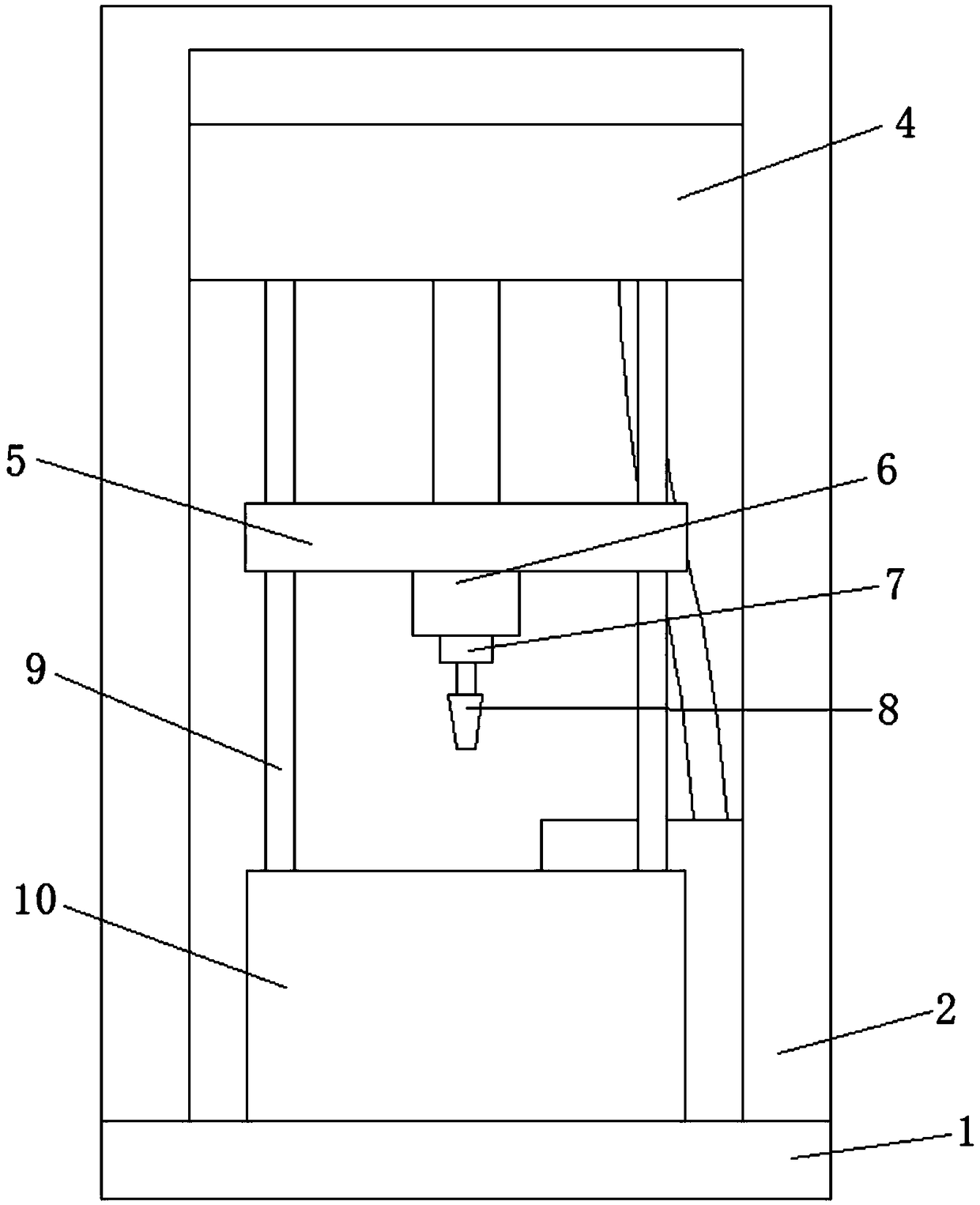

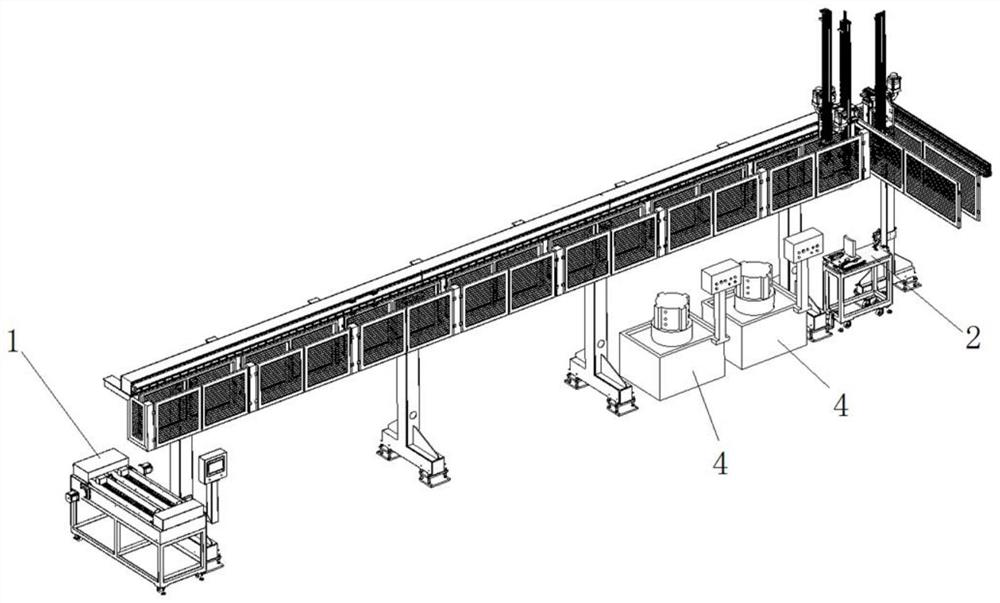

Numerical control grass drill

InactiveCN102001821AImprove work efficiencyQuality improvementGlass severing apparatusProduction lineNumerical control

The invention relates to an automatic electromechanical integration machine for glass drilling, in particular to automatic numerical control and electromechanical integration equipment for glass drilling, belonging to the technical field of glass processing machinery. The equipment comprises a glass conveying device, a compacting device, a drilling device and a corresponding control device, wherein the glass conveying device comprises a plurality of guide rails and a motor for driving a conveyor belt, the compacting device comprises upper compacting mechanisms and a side compacting mechanism, wherein the upper compacting mechanisms are respectively arranged above the glass conveying device and the front side and the rear side of the drilling device, and the drilling device comprises a base, a drilling motor and a drill bit arranged from top to bottom correspondingly, a control mechanism, circulating cooling water and a glass chip collecting device. The invention provides a numerical control glass drill with high automation degree, simple operation and high positioning accuracy, which is suitable for large-scale production lines, is used for continuous drilling operation, realizes drilling automation, and has simple structure and high practicability.

Owner:EI AUTOMATION EQUIP

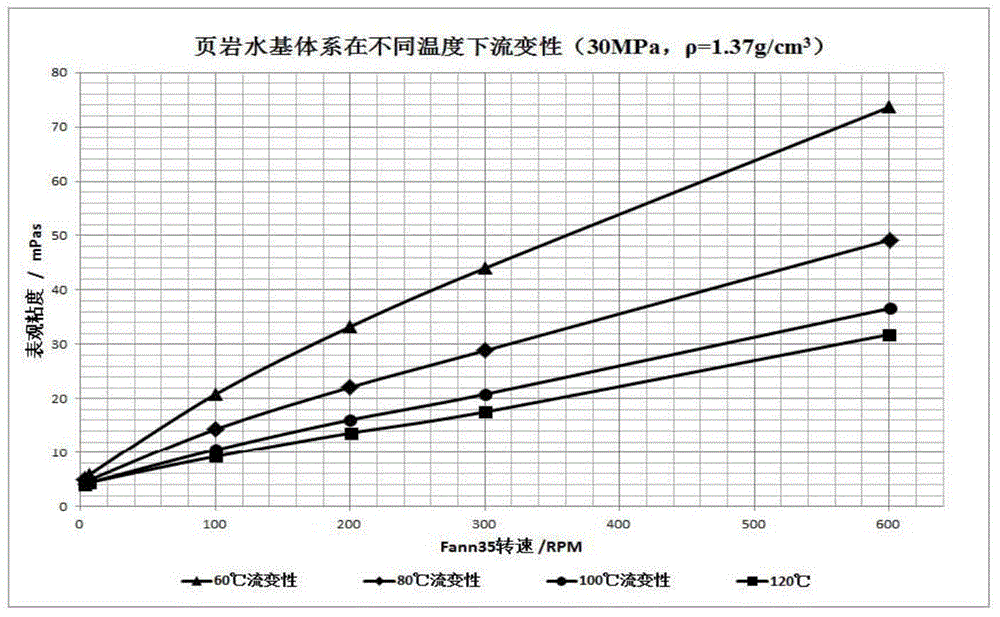

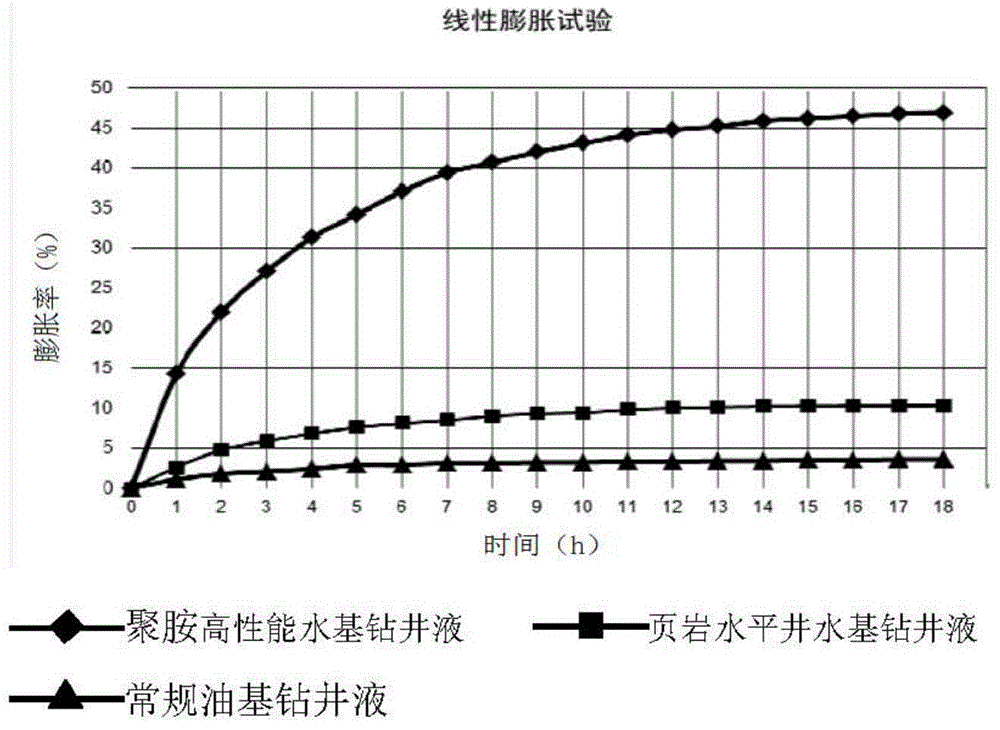

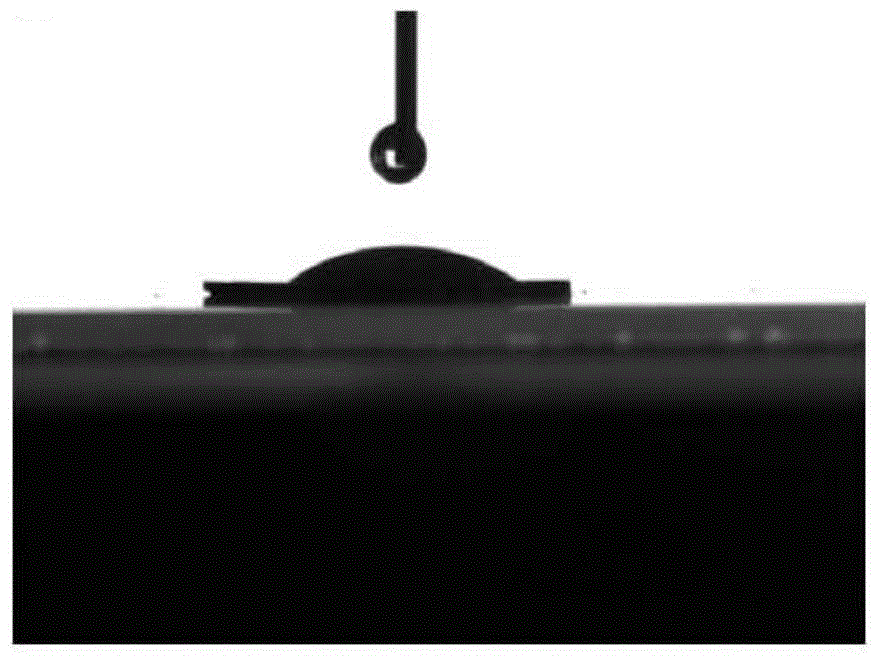

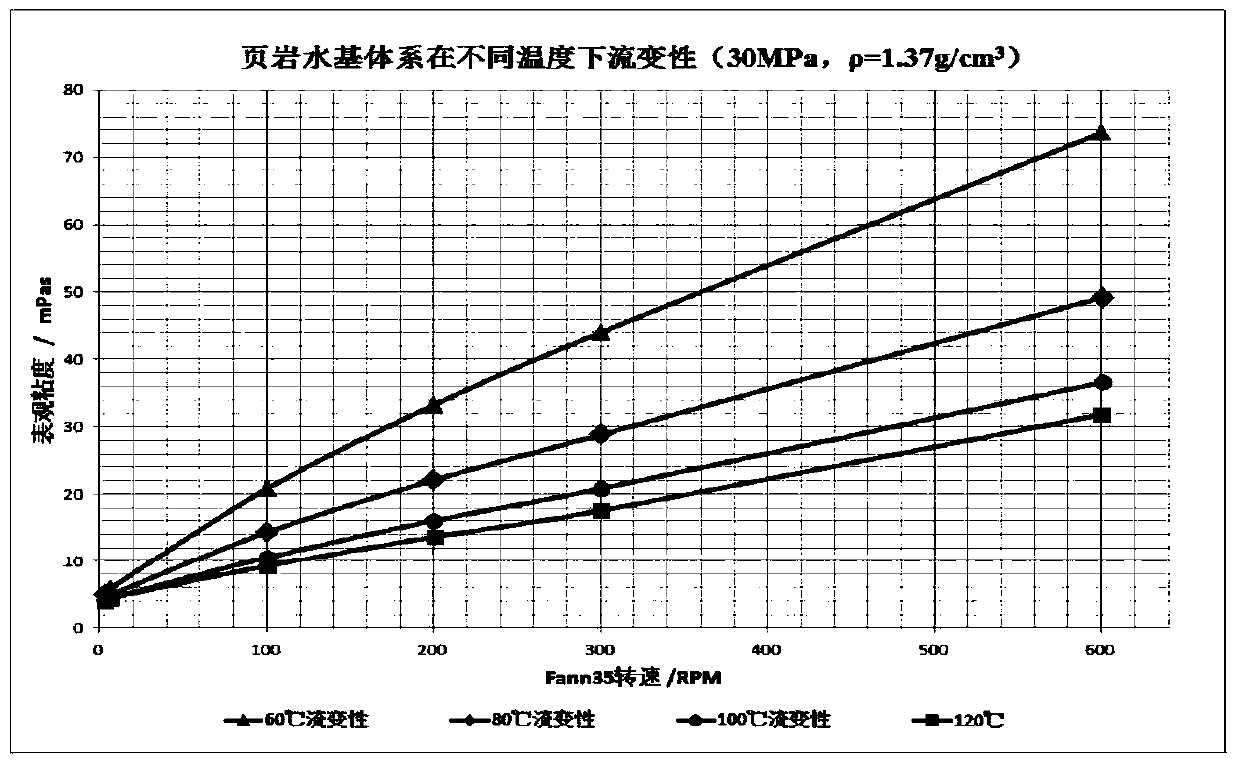

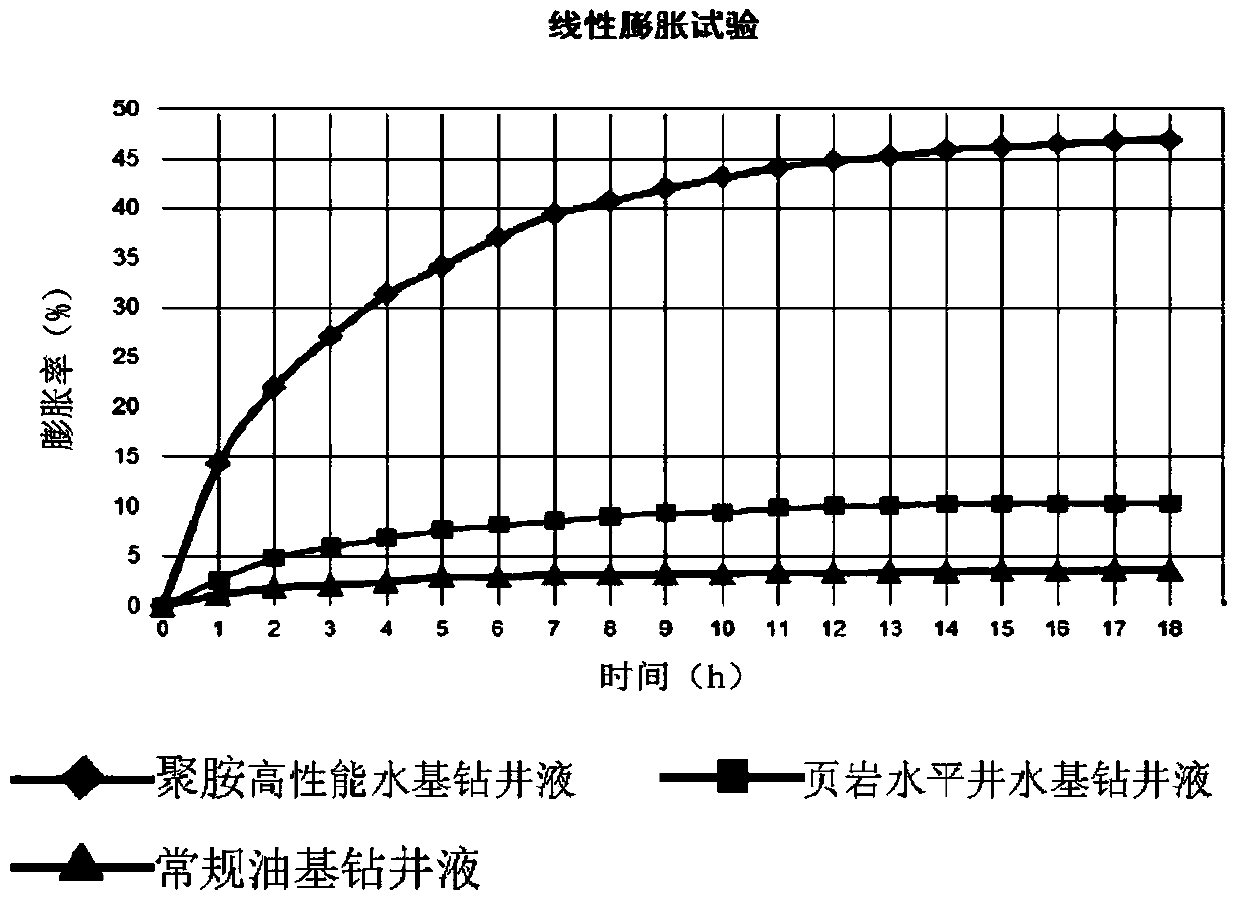

Water-based drilling fluid for shale horizontal well and preparation method of water-based drilling fluid

ActiveCN106147728AEnvironmentally friendlyLow costDrilling compositionWater basedPetroleum engineering

The invention relates to water-based drilling fluid for a shale horizontal well. The water-based drilling fluid comprises a reverse wetting agent. The invention further relates to a preparation method of the water-based drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Underwater flexible apparatus for sea well drilling

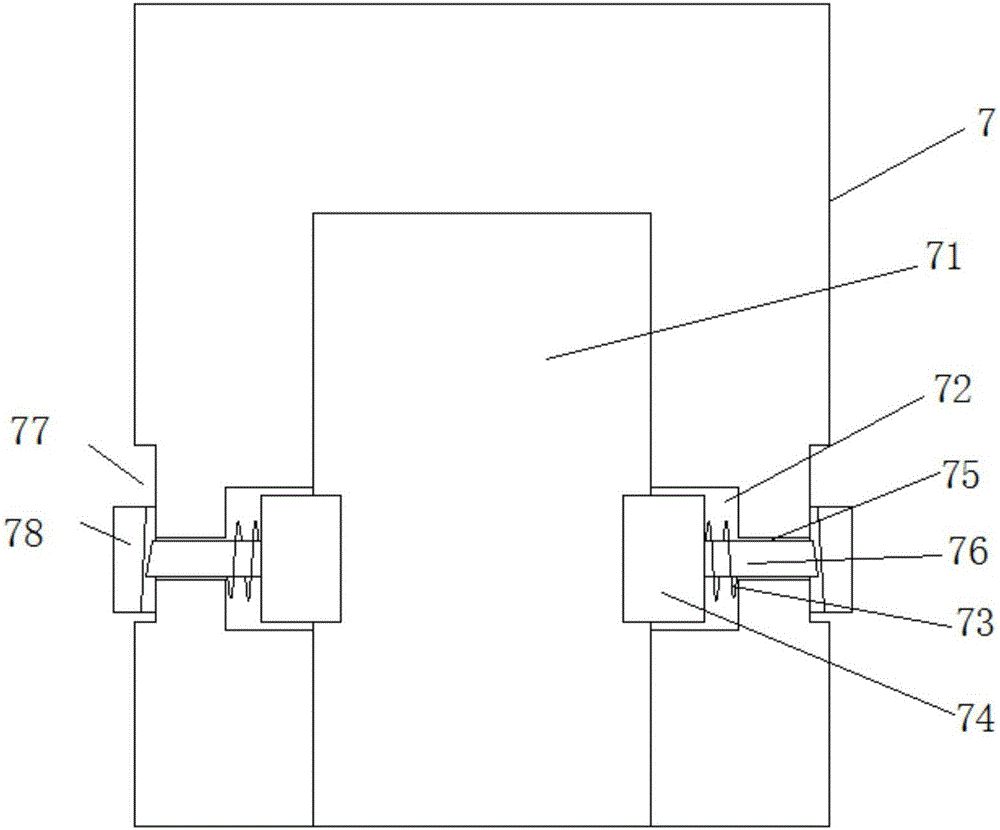

InactiveCN101377121AMeet drilling requirementsImprove shock absorptionDrilling rodsDrilling casingsWell drillingEngineering

The present invention relates to an underwater flexible unit used on an oceanic drilling riser. The flexible unit is mainly composed of a main structure and a flexible element assembly; wherein, the main structure is connected with the other parts of the riser and a lower annular blowout preventer; the flexible element assembly, which is positioned in the main structure and retained by the main structure, is composed of an upper spindle, a flexible element and a base; and the flexible element is connected with the upper spindle and the base and fixed in a body by a fixing flange, bolts and nuts. Adopting the rotational stiffness of the flexible element connection structure, the flexible unit is more effective than the spherical steel connection in terms of the control of the angle of the riser, and can be adapted to rotation in any direction, and the shock-absorbing and damping effects of the flexible unit are better than the shock-absorbing and damping effects of the spherical steel connection. The flexible unit can be flexibly designed in order to meet different oceanic drilling requirements. The flexible unit has the following advantages: the whole main structure has strong bearing capability, the structure is simple and compact, and maintenance and operation are convenient. Flexible units with different specifications can be designed according to different oceanic drilling requirements.

Owner:BAOJI PETROLEUM MASCH CO LTD

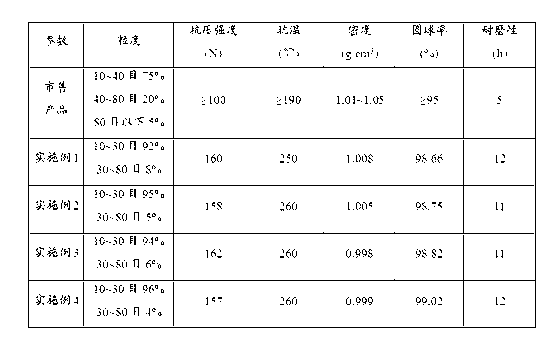

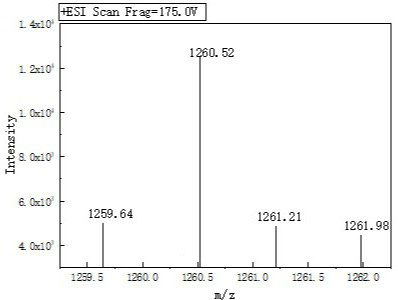

Plastic ball solid lubricating agent for drilling fluid and method for preparing plastic ball solid lubricating agent

ActiveCN103013462AAvoid stickingGuaranteed shapeDrilling compositionBenzoyl peroxidePolyvinyl alcohol

The invention discloses a plastic ball solid lubricating agent for drilling fluid and a method for preparing the plastic ball solid lubricating agent. The plastic ball solid lubricating agent for the drilling fluid is prepared from the raw materials in parts by weight: 35-56 parts of styrene, 6-10 parts of divinylbenzene, 5-10 parts of acrylic acid, 5-10 parts of polytetrafluoroethylene, 10-20 parts of paraffin, 10-15 parts of silicon dioxide, 0.5-1 part of benzoyl peroxide, 0.5-1 part of polyvinyl alcohol and 0.5-1.5 parts of dodecylbenzene sulfonic acid. The method for preparing the plastic ball solid lubricating agent comprises the following five steps of resistance removing, soaking, crosslinking, sepherical boiling and grading. The high temperature resistance and extrusion resistance of the plastic ball solid lubricating agent for the drilling fluid are improved, the density is close to water density, and the plastic ball solid lubricating agent can realize the purposes of effectively lubricating and preventing blockaged.

Owner:河北华运鸿业化工有限公司

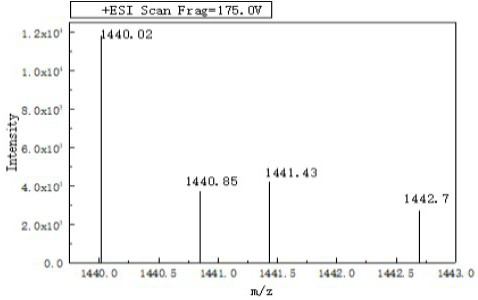

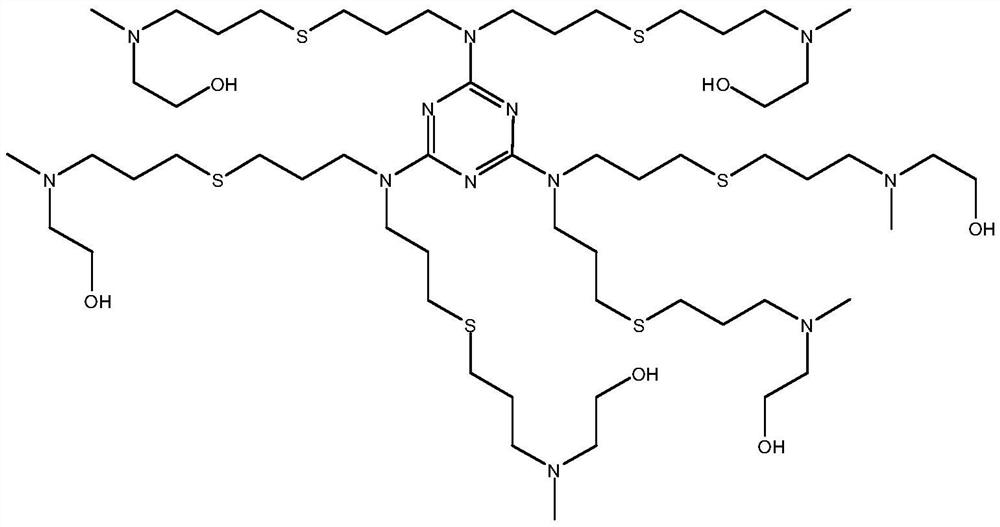

Low-molecular-weight branched shale inhibitor and water-based drilling fluid thereof

ActiveCN111778001AThe preparation method is stable and reliableHigh yieldOrganic chemistryDrilling compositionWell drillingSlurry

The invention discloses a low-molecular-weight branched shale inhibitor and a water-based drilling fluid thereof, belongs to the technical field of oil and gas field drilling, the inhibitor is prepared from a compound containing a secondary amino group, melamine and diallyl sulfide, and can be directly added into drilling fluid base slurry to form a water-based drilling fluid system. The low-molecular-weight branched shale inhibitor and the water-based drilling fluid thereof provided by the invention can effectively inhibit shale expansion, have good temperature resistance, have good compatibility with other treating agents, can play a role in inhibiting for a long time, and are simple in synthesis method, easily available in raw materials and suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

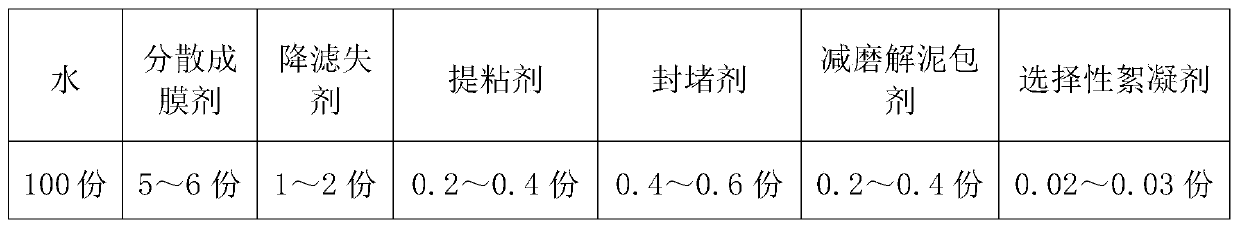

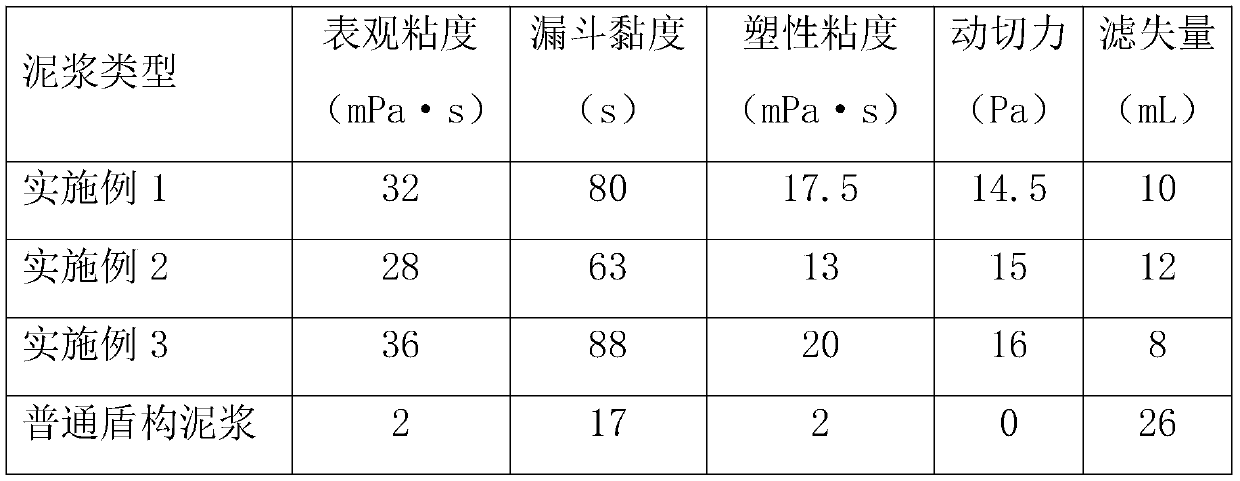

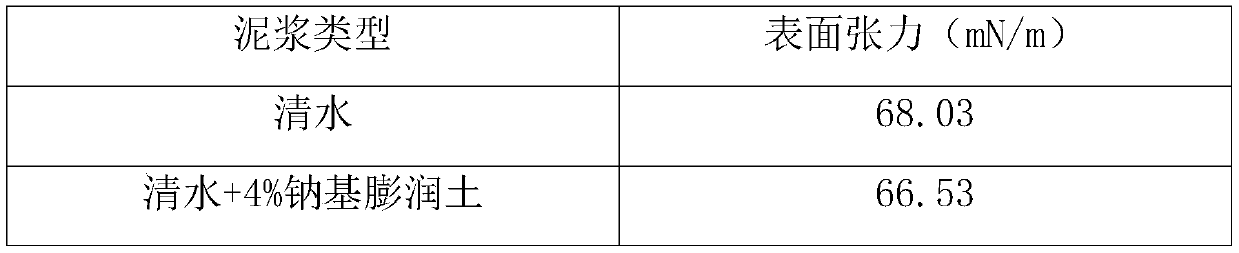

Shield mud system applicable to extra-large-diameter tunnel and preparation method

InactiveCN109762534AImprove recycling ratesQuality improvementDrilling compositionMud systemsFiltration

The invention provides a shield mud system applicable to an extra-large-diameter tunnel. The shield mud system is prepared from the following raw materials in parts by mass: 100 parts of water, 5 to 6parts of a dispersion film-forming agent, 1 to 2 parts of a filtration-reducing agent, 0.2 to 0.4 part of a viscosity improving agent, 0.4 to 0.6 part of a plugging agent, 0.2 to 0.4 part of an anti-wear and mud ball splitting agent and 0.02 to 0.03 part of a selective flocculating agent. The shield mud system provided by the invention has the beneficial effects that the shield mud system has unique 'lubrication and anti-wear performance' and has the effects of protecting a shield bit tool and improving the footage drilling efficiency; a dense mud film can be formed, the filtration loss amount is reduced and the soil pressure is balanced, so that the stability of a well wall is enhanced, the sticking coefficient can be reduced and a mud ball of the shield bit tool is prevented; and the shield mud system has good rheological performance, filtration-reducing performance and lubricating performance and can meet the requirements of shield mud drilling, and has the advantages of environment protection and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

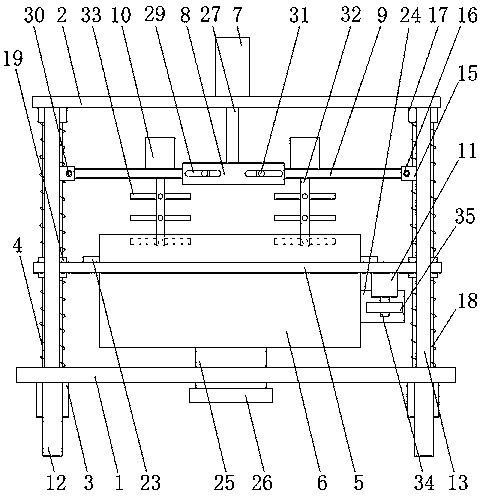

Punching die for automobile covering parts

InactiveCN108213180AMeet drilling requirementsAccurate HorizontalPerforating toolsMetal-working feeding devicesEngineeringDrill bit

The invention belongs to the field of dies for automobile part processing and particularly discloses a punching die for automobile covering parts. The punching die comprises a frame, an upper die baseand a lower die base are arranged on the frame, a power source is arranged at the top of the frame and connected with a wire, a first electrode plate is connected to the lower end of the wire, the upper die base is provided with an electromagnet below the wire, and a second electrode plate is arranged on the electromagnet. A first rotating shaft comprises a spline section, a threaded section anda clamping section sequentially from top to bottom, the spline section is externally connected with a spline sleeve, a first bevel gear is arranged at the bottom of the first rotating shaft, a secondbevel gear meshed with the first bevel gear is arranged on the second rotating shaft which is further provided with a multiplex gear. A rack meshed with the multiplex gear is in slide connection withthe top end of a fixing seat, the fixing seat is provided with magnets on two sides of the rack, and a drill bit is connected to one end, close to the lower die base, of the rack. By adoption of the scheme, the inclined hole processing requirement of the drill bit is met.

Owner:CHONGQING YINSHENG MOLD

Shale intercalation inhibitor prepared from environment-friendly hyperbranched polyamino acid

ActiveCN111592654AHas low biological toxicitySafe and biodegradableDrilling compositionPolymer sciencePhenylpiperazine

The invention discloses a shale intercalation inhibitor prepared from environment-friendly hyperbranched polyamino acid, and belongs to the technical field of oil and gas field drilling. The hyperbranched polyamino acid is synthesized by taking monoprimary amine amino acids with different hydrophobic chain lengths, N-phenylpiperazine and ester compounds containing diene bonds as raw materials through the following steps: S1, synthesizing amino acid methyl ester; S2, synthesizing a hyperbranched polyamino acid intermediate; and S3, synthesizing hyperbranched polyamino acid. The shale intercalation inhibitor prepared from hyperbranched polyamino acid is prepared from hyperbranched polyamino acid and water, wherein the mass ratio of hyperbranched polyamino acid in the shale intercalation inhibitor is 0.5-3%. The hyperbranched polyamino acid has good biodegradability, is safe and non-toxic, and has obviously improved inhibition performance compared with similar shale intercalation inhibitors, the raw materials are easy to obtain and low in price, and the provided synthesis method is stable and reliable, and is suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

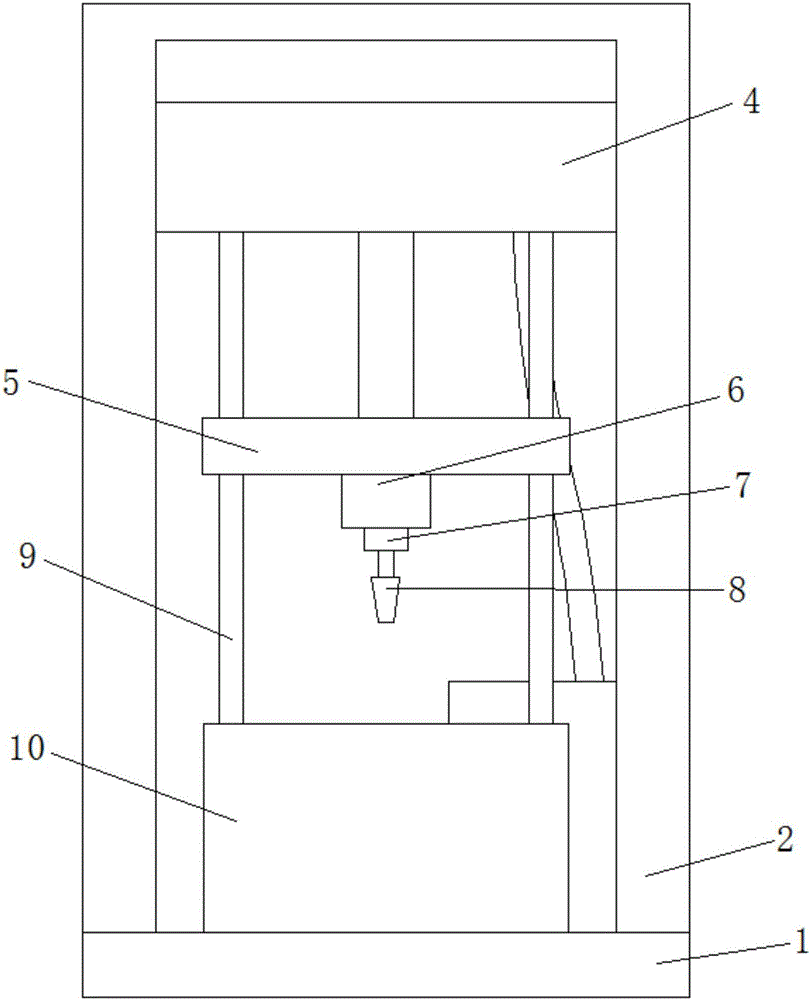

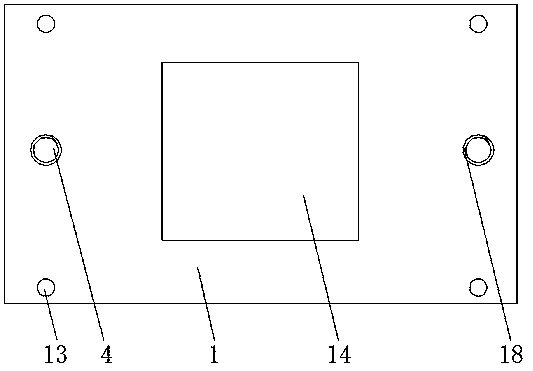

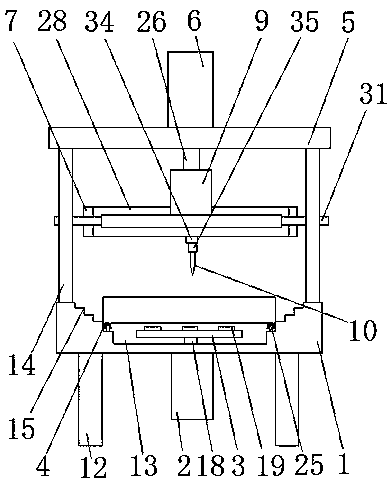

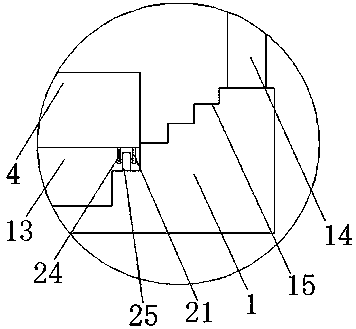

Accurate positioning glass drilling machine

InactiveCN102603177AHigh positioning accuracyMeet drilling requirementsGlass severing apparatusNumerical controlProduction line

The invention relates to an electromechanical integrated automated machine for glass drilling, which belongs to the technical field of glass processing machinery and particularly relates to a numerical controlled electromechanical integrated automated accurate positioning glass drilling machine. The glass drilling machine comprises a glass conveying device, a pressing device and a drilling device; a glass positioning device is also arranged on the conveying device in the direction of glass moving; and the positioning device comprises a side positioning device and an end point positioning device which are arranged in front and rear of the pressing device. The glass drilling machine is provided with the glass positioning device, as the positioning device comprises the side positioning device and the end point positioning device, the glass drilling machine can perform both lateral positioning and longitudinal positioning, the positioning accuracy is obviously improved, the glass drilling machine is applicable to large-scale production lines and used for glass continuous drilling, the drilling automation is realized, the structure is simple, and the practicability is high.

Owner:广东亿海机械制造有限公司

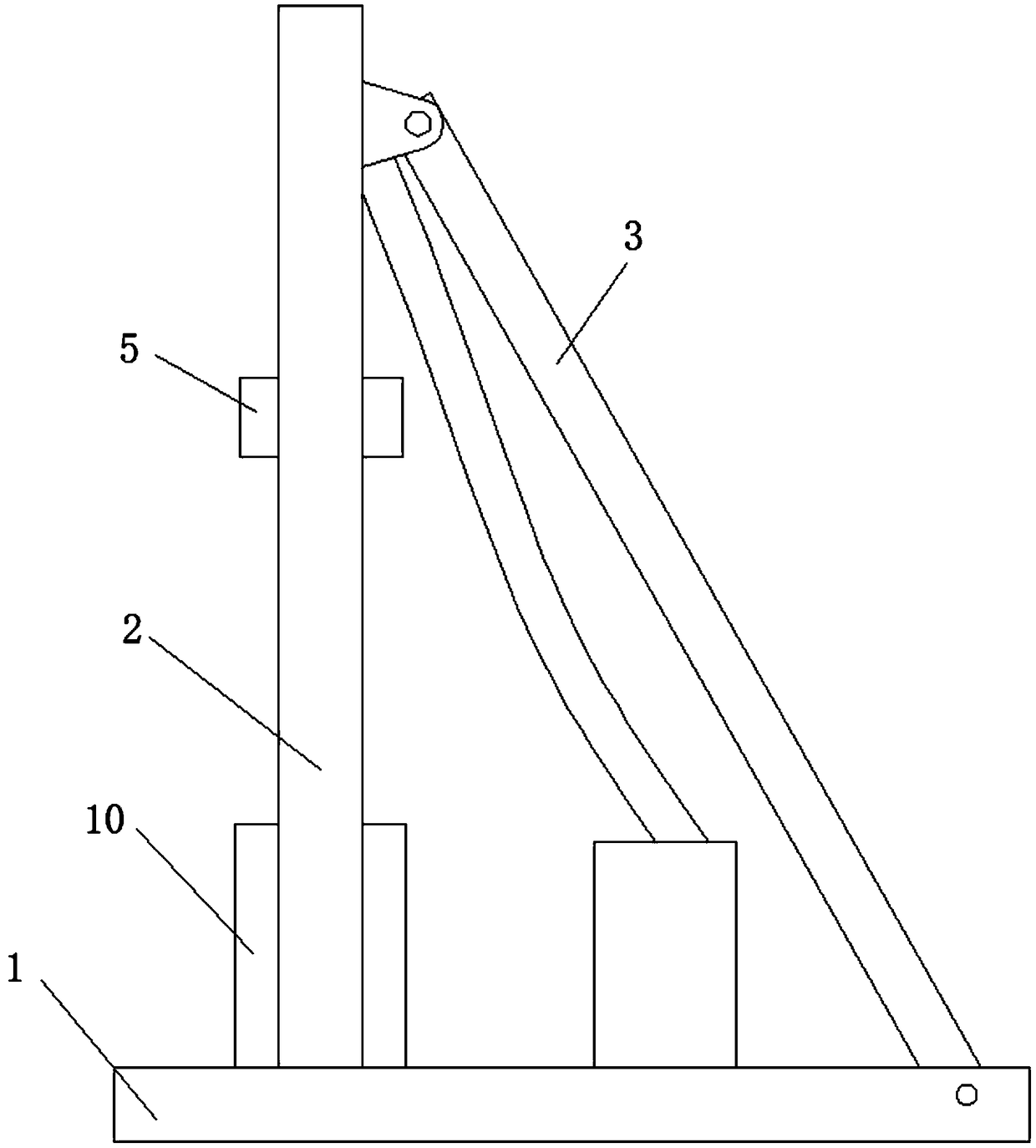

Small multi-function drilling machine

ActiveCN106761378APrevent fallingMeet drilling requirementsDrilling rodsConstructionsWell drillingEngineering

The invention relates to the technical field of drilling machines, in particular to a small multi-function drilling machine. The small multi-function drilling machine comprises a base, a mast and a power device are arranged on the base, a pedestal is arranged at the bottom of the power device, and a power head is arranged at the bottom of the pedestal. A clamping device is arranged at the bottom of the power head and comprises a clamping head, a plurality of first grooves are formed in the clamping head, and a second annular groove is formed in the outside of the clamping head. Inserting rods are arranged between the second annular groove and the first grooves in a communicating mode, clamping blocks matched with the first grooves are arranged in the first grooves, and the inserting rods are arranged on the backs of the clamping blocks and penetrate through inserting holes. Lantern rings are arranged at the ends of the inserting rods in a wedge-shaped matched mode, the contacting faces of the inserting rods and the lantern rings are matched in a threaded mode, and the lantern rings are arranged in the second annular groove in a sleeved mode. The inserting rods are sleeved with springs, one ends of the springs are connected with the clamping head, the other ends of the springs are connected with the bottoms of the first grooves, and a drill bit is arranged in the clamping head in an inserting mode. According to the small multi-function drilling machine, requirements of countryside well drilling are met, the clamping effect is good, and an anti-dust device is additionally arranged for avoiding flying dust.

Owner:徐州市茗尧机械制造有限公司

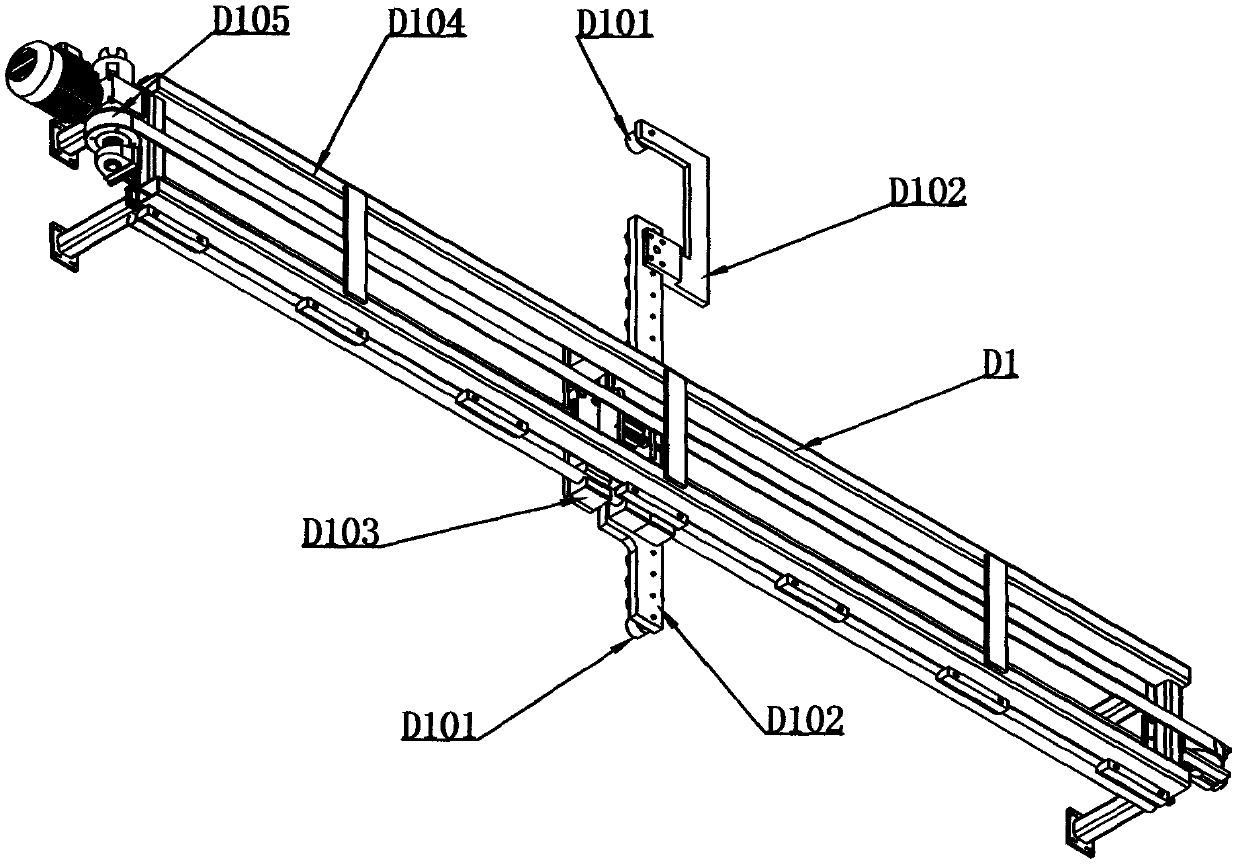

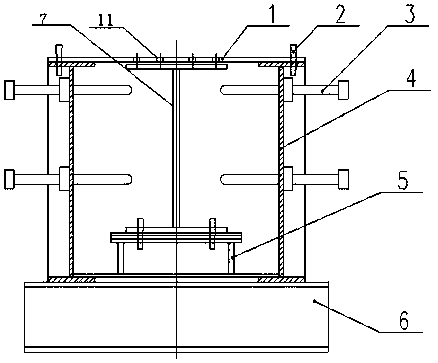

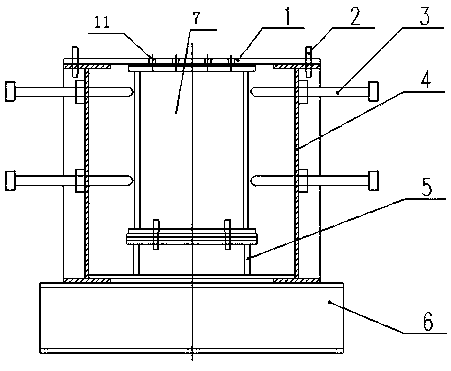

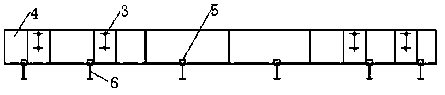

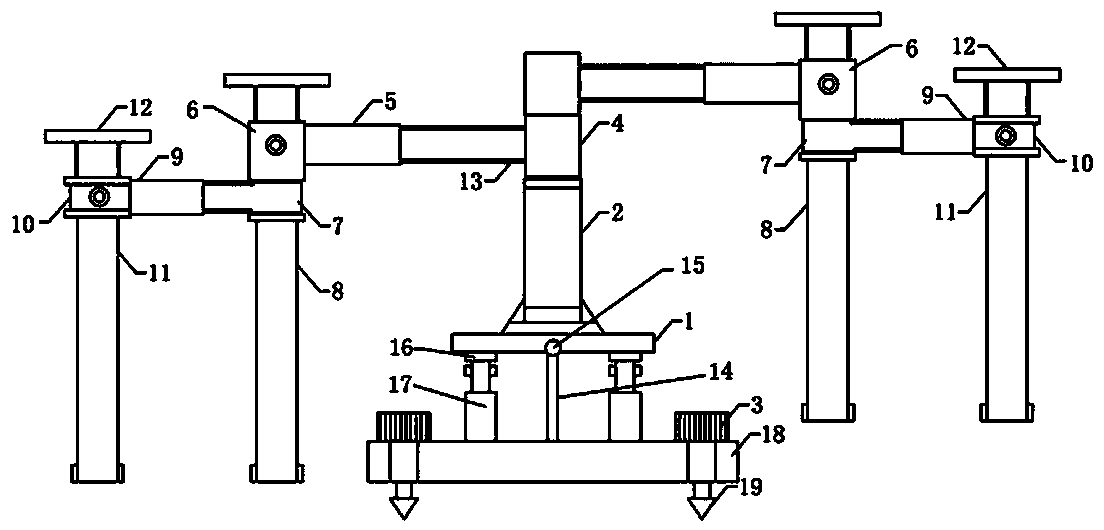

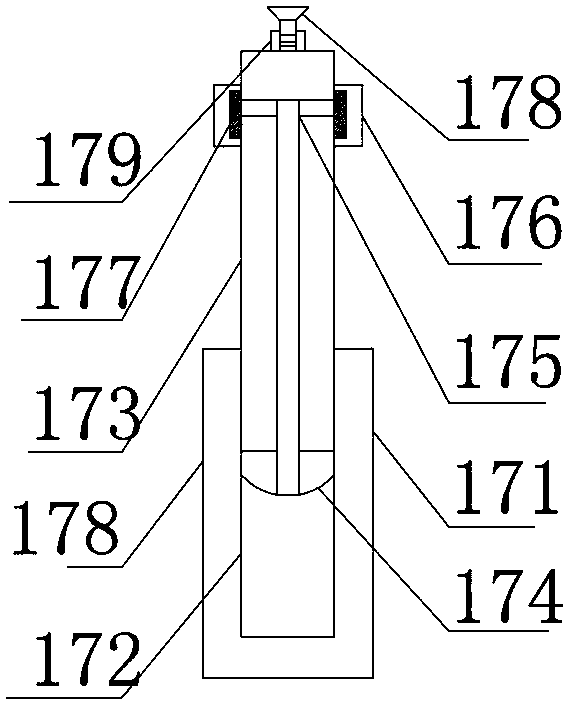

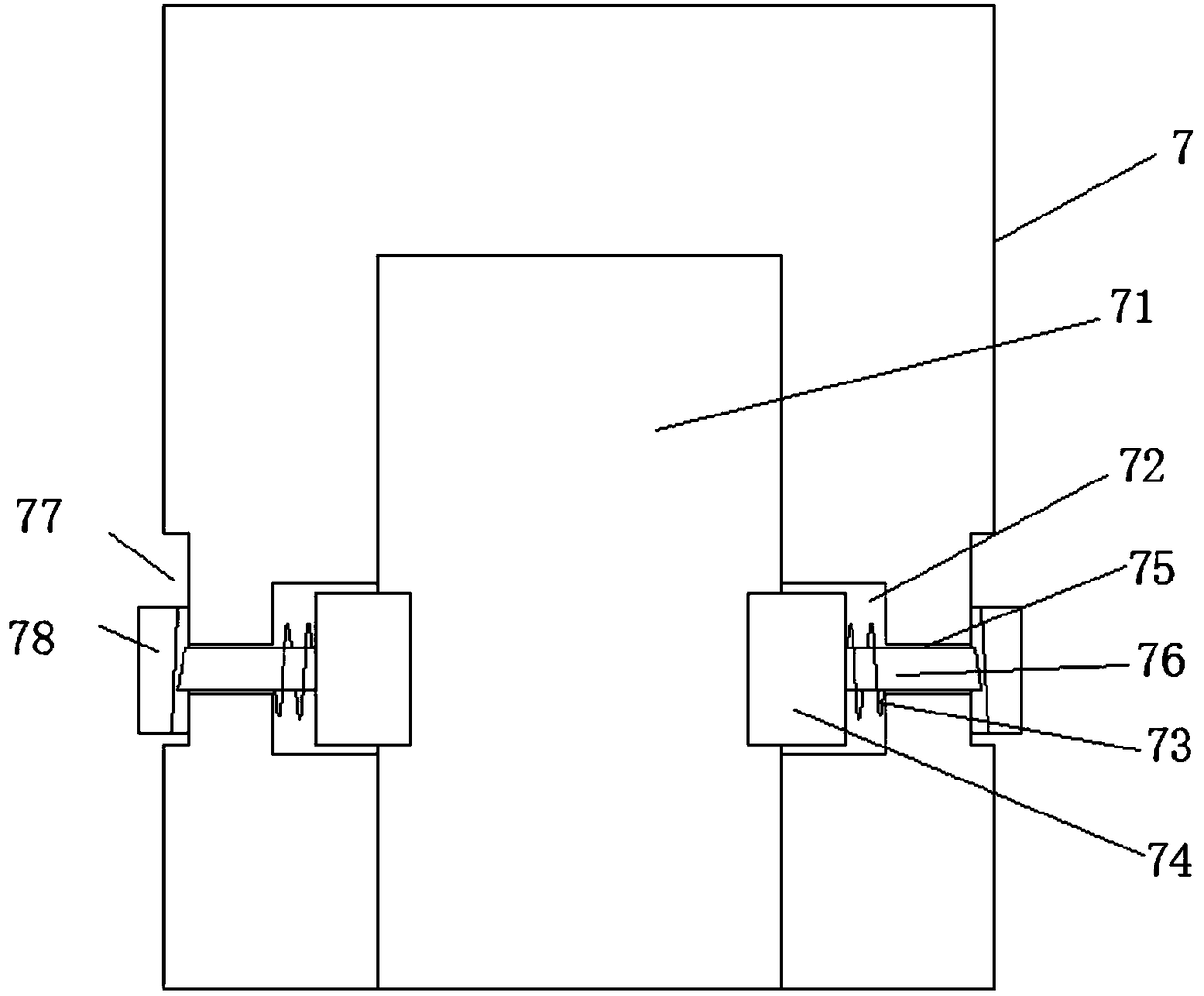

Positioning drilling system for I-beam and box beam

PendingCN109465479AMeet drilling requirementsAdjust alignment quicklyDrill jigsEngineeringDrilling system

A positioning drilling system for an I-beam and a box beam, comprising a pad beam, wherein the upper end of the pad beam is provided with a height adjustment pad, the upper end of the height adjustment pad is provided with a workpiece, tooling bed-jigs are arranged at two sides of the height adjustment pad on the upper end of the pad beam and are provided with a plurality of lateral adjustment screw rods, the upper end of the workpiece is provided with a drilling mold plate, and both ends of the drilling mold plate are respectively fixed to the tooling bed-jigs at two sides of the height adjustment pad by positioning pins. The system can accurately locate and drill the I-beam and the box beam, ensure the accuracy of the workpiece hole group and greatly improve the efficiency, and is suitable for the factory manufacturing of batch I-beams or box beams.

Owner:CHINA RAILWAY JIUJIANG BRIDGE ENG

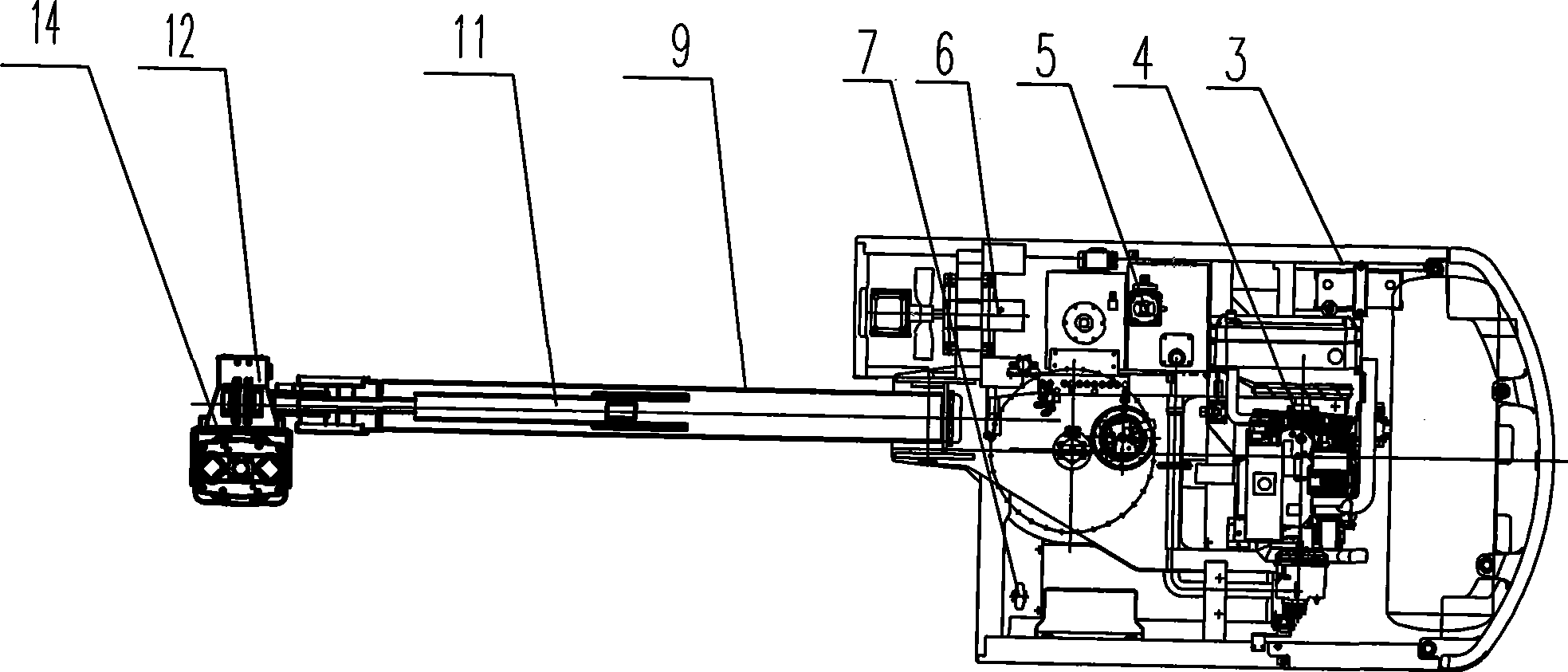

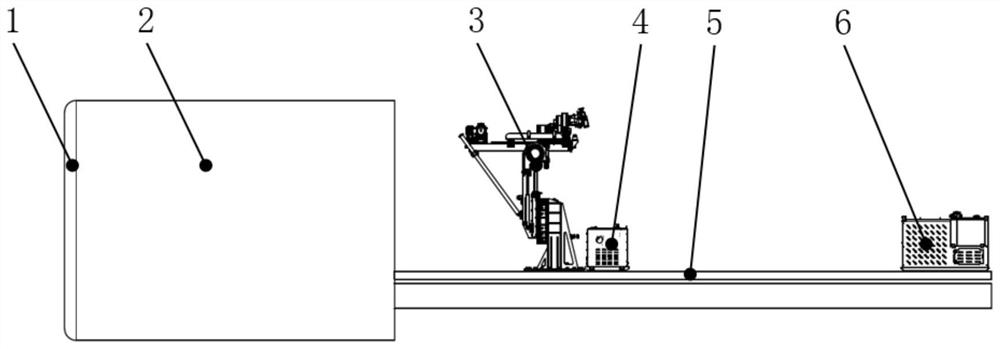

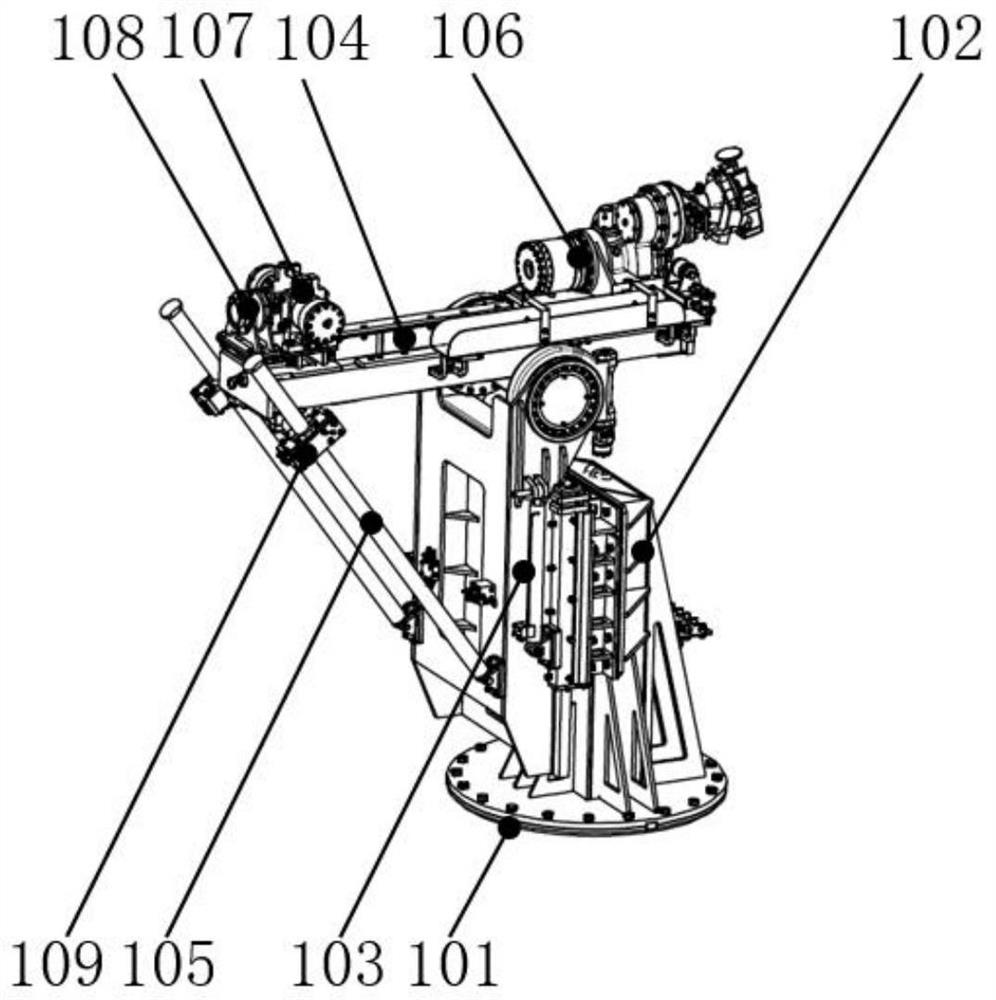

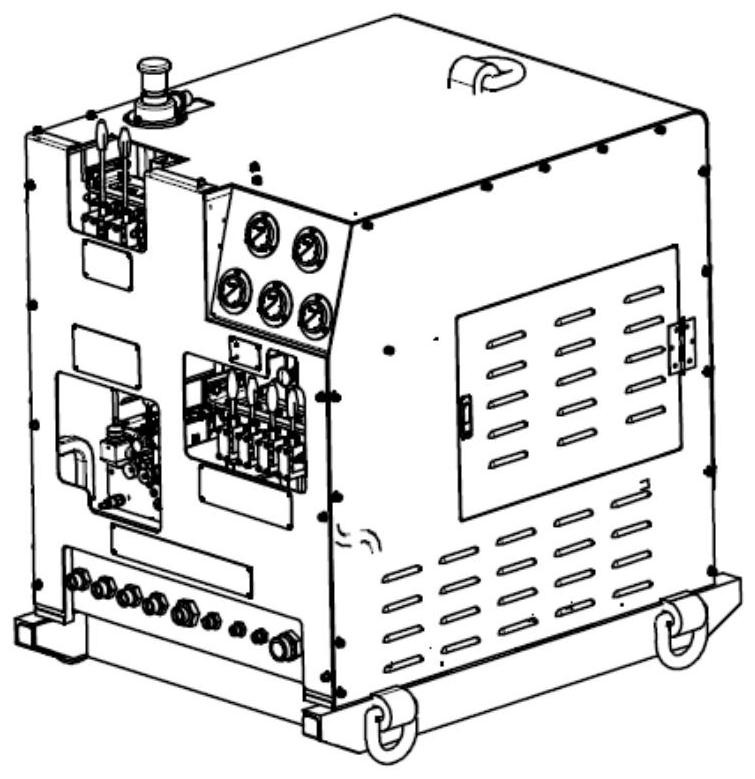

Coal mine TBM advanced exploration split type remote control drilling machine and advanced exploration construction method

The invention relates to a drilling machine and a construction method, belongs to the technical field of drilling, and particularly relates to a coal mine TBM (Tunnel Boring Machine) advanced exploration split type remote control drilling machine and an advanced exploration construction method. Compared with a conventional TBM advanced exploration drilling machine with the construction capacity of 30-50 m, the drilling machine is a special deep hole drilling machine with the larger torque and propulsive force, advanced drilling construction of deep holes with the length larger than 300 m can be completed, for coal mine roadway tunneling construction with the mandatory requirement of exploration before tunneling, the drilling and tunneling alternating frequency can be greatly reduced, and the comprehensive construction efficiency is effectively improved. The main machine part of the drilling machine is of an independent structure and is arranged on a trailer platform behind a TBM propelling mechanism, and the large-range adjustment of a circumferential angle, a main shaft inclination angle and a working radius can be achieved so as to meet the special advanced hole exploration site requirement of TBM. The drilling machine is controlled through electric control and remote control, and an operation table and a pump station can be flexibly arranged according to the TBM layout. In addition, the invention further provides the advanced exploration construction method suitable for the coal mine TBM.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Environment-friendly low-molecular-weight branched polyether ammonia shale intercalation inhibitor

ActiveCN111676003ABiologically non-toxicReliable technologyCarbamic acid derivatives preparationOrganic compound preparationEtherOne-pot synthesis

The invention provides application of environment-friendly low-molecular-weight branched polyether amine as a shale intercalation inhibitor, belonging to the technical field of oil and gas field drilling. The low-molecular-weight polyether amine is synthesized from ester compounds with amino groups and ether bonds and ether compounds containing olefinic bonds through a one-pot synthesis method ora step-by-step synthesis method. The shale intercalation inhibitor prepared from the low-molecular-weight branched polyether ammonia is prepared by mixing the low-molecular-weight branched polyether ammonia and water, wherein the mass ratio of the low-molecular-weight branched polyether ammonia in the shale intercalation inhibitor is 0.5%-3%. The shale intercalation inhibitor prepared from the low-molecular-weight branched polyether amine provided by the invention has good biodegradability, is safe and non-toxic, and has obviously improved inhibition performance compared with similar intercalation inhibitors, the raw materials are easy to obtain and low in price, and the provided synthesis method is stable and reliable and is suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

Asphalt stirring equipment and operation method thereof

InactiveCN111569743AImprove drilling qualityImprove stabilityShaking/oscillating/vibrating mixersTransportation and packagingHydraulic cylinderRotational axis

The invention discloses asphalt stirring equipment. The asphalt stirring equipment comprises an operation table, a top plate, a motor I, a rotating shaft, a bearing plate, a stirring barrel, a hydraulic cylinder, a connecting plate, an adjusting plate, a motor II and a motor III. The asphalt stirring equipment is characterized in that the operation table is arranged on a support; the top plate isconnected with the top ends of stand columns; the motor I is arranged on the back face of the operation table; the bottom end of the rotating shaft is connected with the motor I; connecting rings arearranged at the two ends of the bearing plate; positioning rods are arranged on the outer walls of the two opposite sides of the stirring barrel; the hydraulic cylinder is arranged on the top plate; the connecting plate is connected with a piston rod; and connecting shafts I are arranged on the two opposite sides of one end of the adjusting plate. The adjusting plate can be in a horizontal state or a state that one end is high and the other end is low, asphalt raw materials in the stirring barrel are stirred at different angles through a transmission shaft I and a stirring rod on the transmission shaft I, so the asphalt raw materials are fully mixed, and the stirring and mixing efficiency and the stirring and mixing quality of asphalt are improved.

Owner:张玮

Adjustable board multi-angle drilling device for furniture processing

InactiveCN108527543AIncrease the scope of applicationIncreased drilling requirementsStationary drilling machinesWood working safety devicesEngineeringWood panel

The invention discloses an adjustable board multi-angle drilling device for furniture processing. The adjustable board multi-angle drilling device for furniture processing comprises a base, a first air cylinder, a pushing plate, a bearing block, a top plate, a second air cylinder, a connecting plate, an adjusting plate, a motor, a drilling column and a controller; the device is characterized in that the base is arranged on a support, a positioning plate is arranged on a stand column, the first air cylinder is arranged on the bottom of the base, the pushing plate is arranged on a first piston rod, a bearing groove is formed in the bearing block, the top plate is arranged on the stand column, the second air cylinder is arranged on the top plate, the connecting plate is arranged on a second piston rod, a movable rolling sleeve is arranged in a fixed groove, and connecting shafts are arranged on the side faces of the two ends of the adjusting plate. The drilling column is arranged to be ofa structure capable of being replaced on a transmission shaft through a mounting block, according to the drilling need of a board, the drilling column of the proper structure is selected, the application range of the drilling device is widened, and the board drilling need is improved.

Owner:萧县智鑫知识产权运营有限公司

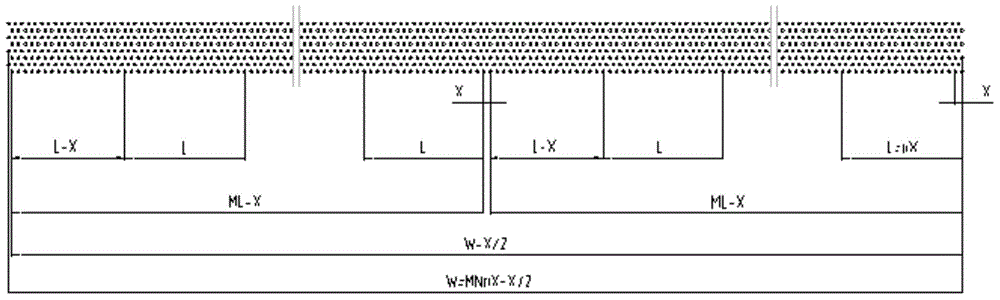

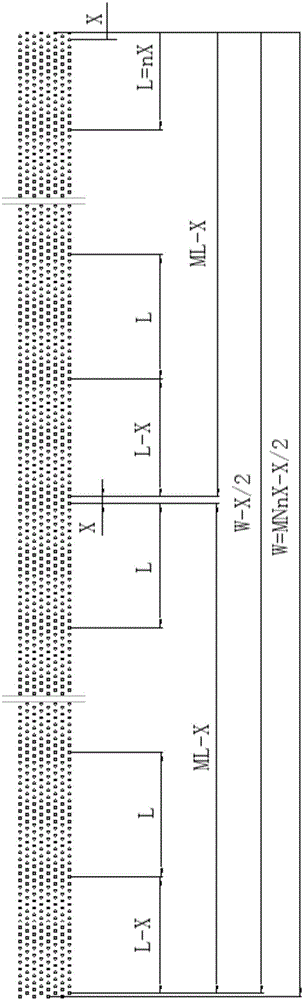

Determination method of spindle space and drilling mode of multi-spindle numerical control sieve plate drilling equipment

ActiveCN104475798AMeet drilling requirementsReduce blindnessBoring/drilling machinesNumerical controlEngineering

The invention discloses a determination method of a spindle space and a drilling mode of multi-spindle numerical control sieve plate drilling equipment. The method is characterized by comprising the following steps: 1, defining known parameters: drilling region width range W, adjacent hole maximum space Xm, spindle external diameter D and adjacent spindle minimum gap Y; 2, trialing and determining large-step drilling frequency N and adjacent spindle space L, wherein the formula is N=(2W+Xm) / 2ML(1)L>D+Y(2); solving the large-step drilling frequency N and adjacent spindle gap L according to the equation (1) and the inequality (2), wherein N is rounded off to be an integer, L is the minimum value of the inequality; 3, determining small-step drilling frequency n in each big step and final hole space X, wherein the formula is L=nX(3); X is less than or equal to Xm; (4) trialing according to the equation and the inequality and solving the small-step drilling frequency n in each big step and the finally determined drilling space X, wherein n is decimal which is rounded off to be an integer; X is the maximum value meeting the inequality.

Owner:济南法特数控机械有限责任公司

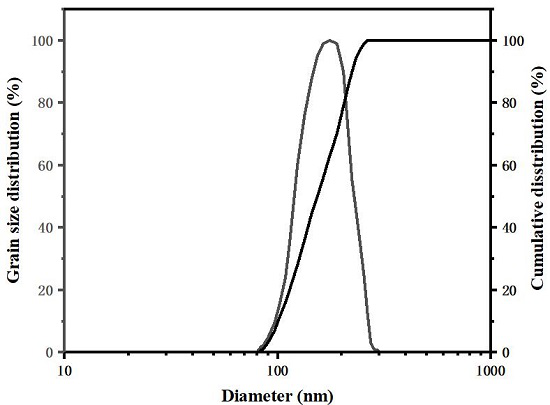

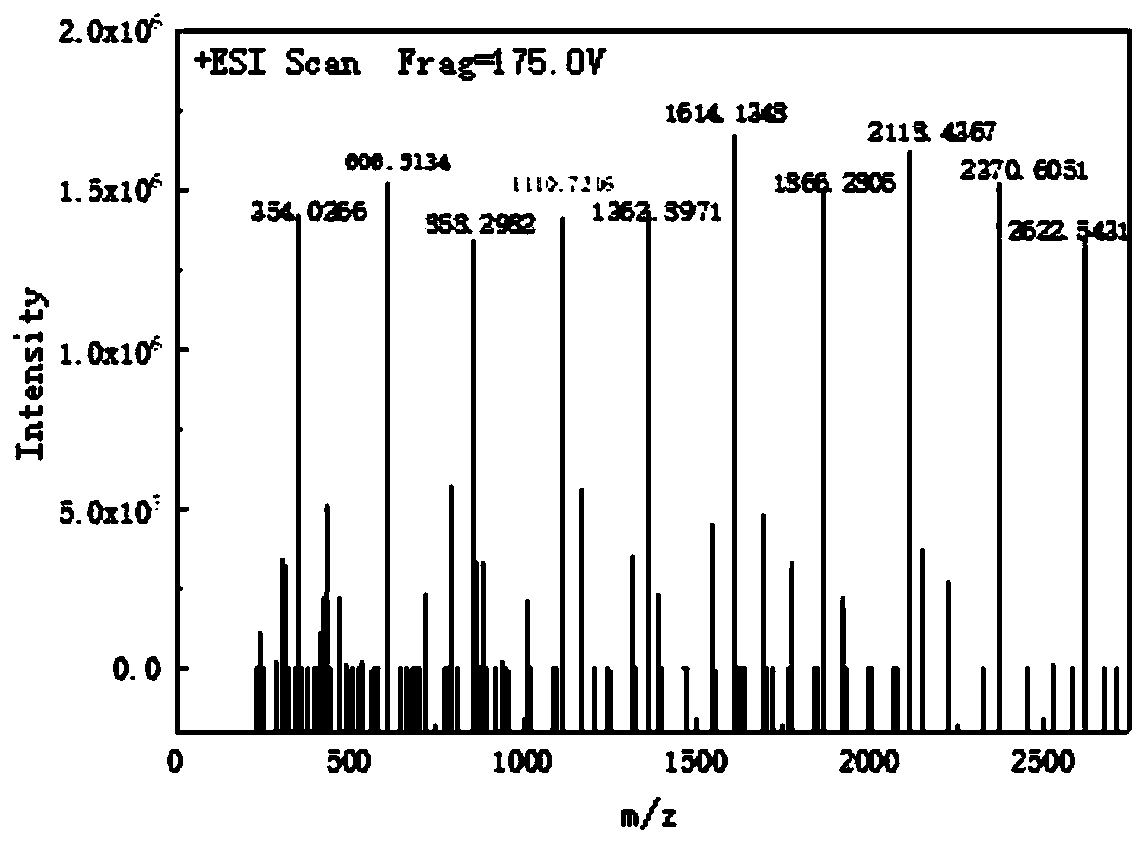

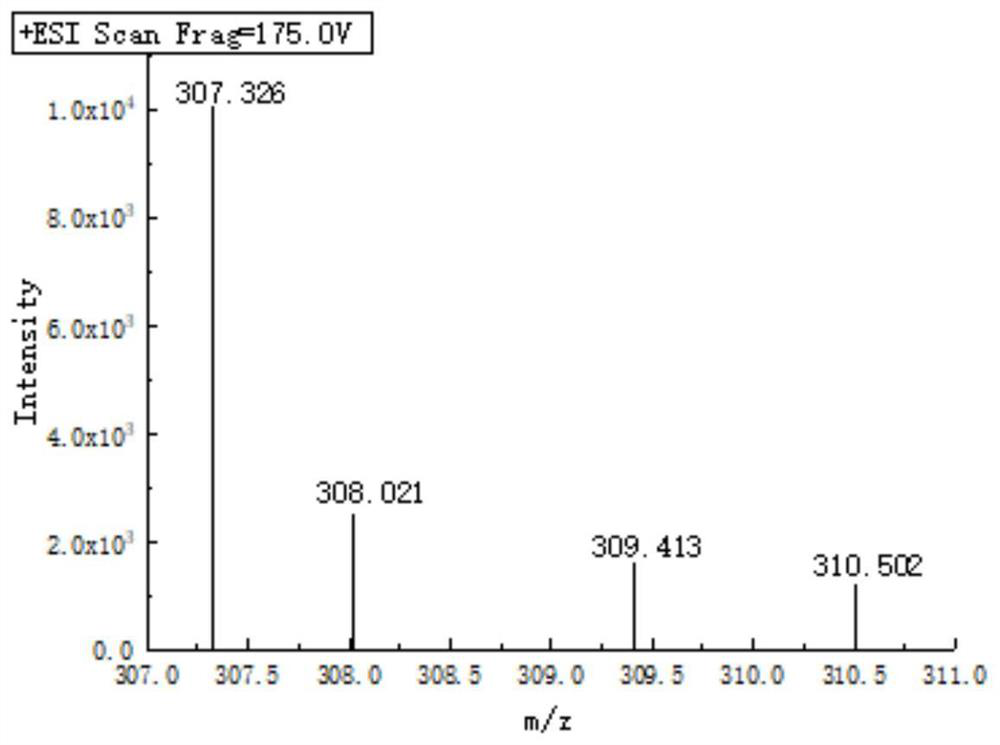

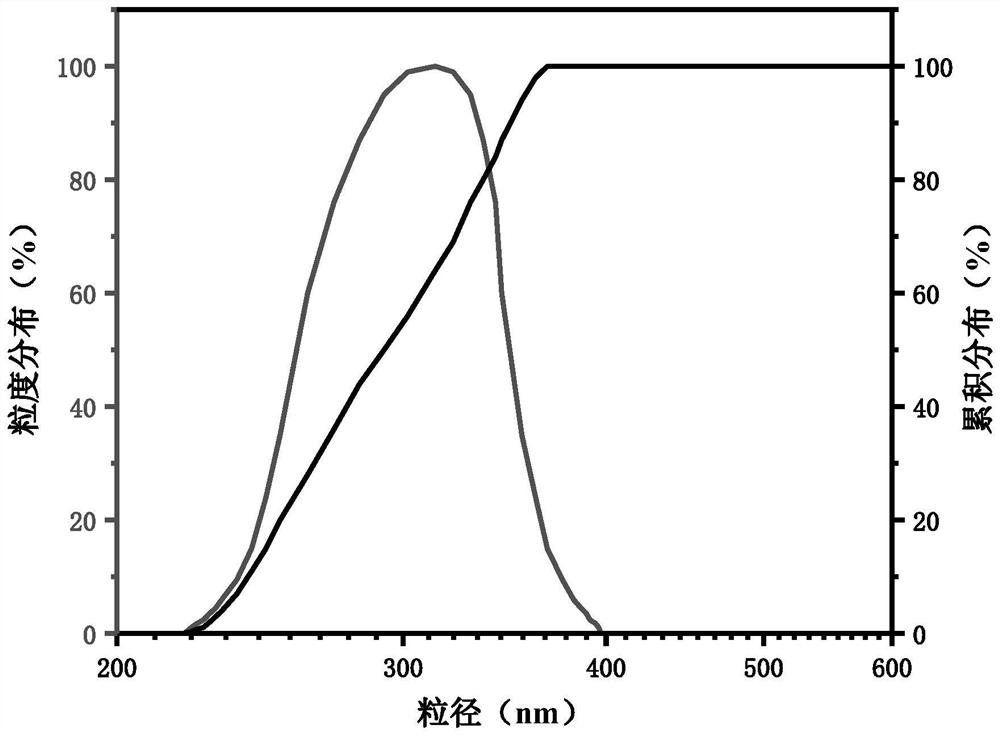

Flexible-outside rigid-inside multi-walled carbon nanotube nano plugging agent and oil-based drilling fluid

PendingCN114214047ALow priceThe synthesis method is simpleDrilling compositionSilanesCarbon nanotube

The invention discloses a flexible-outside rigid-inside multi-walled carbon nanotube nano plugging agent and an oil-based drilling fluid, and belongs to the technical field of oil and gas field drilling. The external-flexible internal-rigid multi-walled carbon nanotube nano plugging agent is prepared from hydroxylated multi-walled carbon nanotubes (5-15 nm), an amino-containing silane coupling agent, a diallyl urea compound, a vinyl benzene compound containing a diene bond, a long-chain acrylate compound and a triallyl crosslinking agent. The particle size of the external-soft and internal-rigid multi-walled carbon nanotube nano plugging agent provided by the invention is 220-397 nm, the plugging performance is remarkably improved compared with that of similar plugging agents, besides the plugging performance, the plugging agent also resists high temperature, has small influence on performance parameters of oil-based drilling fluid, and can be applied to shale formations of deep wells and ultra-deep wells. The plugging agent also has the advantages of easily available raw materials, low price and the like, and the provided synthesis method is stable, reliable, simple, rapid and suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

Hyperbranched polytertiary amine shale inhibitor

ActiveCN113416315AEnhanced inhibitory effectLow priceDrilling compositionHydrazine compoundPhysical chemistry

The invention relates to a hyperbranched polytertiary amine shale inhibitor, and belongs to the technical field of oil and gas field drilling. Hyperbranched polytertiary amine is synthesized by using a hydroxyl-containing hydrazine compound, a diallyl compound and an acrylamide compound as raw materials. The shale inhibitor prepared from the hydrazine compound containing hydroxyl, the diallyl compound and the acrylamide compound is prepared by mixing hyperbranched polytertiary amine and water, wherein the mass ratio of the hyperbranched polytertiary amine in the shale inhibitor is 0.6%-3.5%. The inhibition performance of the shale inhibitor prepared from the hyperbranched polytertiary amine provided by the invention is obviously improved compared with that of similar inhibitors, the raw materials are easy to obtain and low in price, and the provided synthesis method is stable and reliable and is suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

Cuttings Separation Method for Gas Drilling

ActiveCN103993845BAchieve drillingMeet drilling requirementsConstructionsWater bathsEmission standard

The invention discloses a rock debris separating method for gas drilling. The rock debris separating method for gas drilling comprises the steps of firstly enabling water in a whole system to circularly flow to achieve balance and beginning to perform gas drilling; mixing gas and solid with the water to form a mixed fluid to enable dust in the solid to be dissolve in the water during drilling and before the gas returned from a well mouth and the solid are separated; enabling the mixed fluid to firstly flow into a primary separation system to remove coarse particles, discharging the gas carried with fine particles, water drops or water mist into a secondary separation system; removing the fine particles, water drops or water mist so as to obtain purified gas and a solid-liquid mixture after water bath washing is performed; delivering the solid-liquid mixture to a circulating water treatment system, and separating the coarse particles through primary treatment separation; removing the fine particles through secondary treatment separation; removing fine particles through tertiary treatment separation. The rock debris separating method for gas drilling can achieve returned fluid treatment under the condition that a grit chamber does not exist through gas drilling, gas meeting the direct emission standard is finally obtained, and the gas drilling requirement under different conditions can be met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of shale horizontal well water-based drilling fluid and preparation method thereof

ActiveCN106147728BEnvironmentally friendlyLow costDrilling compositionHorizontal wellsPetroleum engineering

The invention relates to water-based drilling fluid for a shale horizontal well. The water-based drilling fluid comprises a reverse wetting agent. The invention further relates to a preparation method of the water-based drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rock stratum drilling positioning device for geological exploration

ActiveCN107939281AEasy to installSpacing is easy to adjustConstructionsDerricks/mastsMining engineeringStructural engineering

The invention discloses a rock stratum drilling positioning device for geological exploration. The rock stratum drilling positioning device comprises a bearing base. A vertical column is fixed to thebearing base; a notch is formed in the upper end face of the vertical column, and a first movable shaft sleeve is movably embedded in the vertical column notch; first telescopic connecting rods are arranged on the first movable shaft sleeve, wherein the first telescopic connecting rods and the first movable shaft sleeve are integrally arranged; adapting heads are fixedly mounted at one ends of thefirst telescopic connecting rods, and the first movable shaft sleeve is movably connected with the adapting heads through the first telescopic connecting rods; notches are formed in the bottom sidesof the adapting heads, and second telescopic connecting rods are connected in the notches of the adapting heads; and positioning connectors are fixedly mounted at one ends of the second telescopic connecting rods, and the adapting heads are movably connected with the positioning connectors through the second telescopic connecting rods. The structure is compact, and using is convenient; the requirement for drilling construction in different radius ranges can be met, drilling construction can be conducted rapidly and accurately, and the construction efficiency is improved; and meanwhile multiplehole sites can be positioned, the intervals between the hole sites are adjusted conveniently, and the various drilling construction demands are met.

Owner:SHANGQIU NORMAL UNIVERSITY

Determination method of spindle spacing and drilling method of multi-spindle CNC sieve plate drilling equipment

ActiveCN104475798BMeet drilling requirementsReduce blindnessBoring/drilling machinesNumerical controlElectrical and Electronics engineering

The invention discloses a determination method of a spindle space and a drilling mode of multi-spindle numerical control sieve plate drilling equipment. The method is characterized by comprising the following steps: 1, defining known parameters: drilling region width range W, adjacent hole maximum space Xm, spindle external diameter D and adjacent spindle minimum gap Y; 2, trialing and determining large-step drilling frequency N and adjacent spindle space L, wherein the formula is N=(2W+Xm) / 2ML(1)L>D+Y(2); solving the large-step drilling frequency N and adjacent spindle gap L according to the equation (1) and the inequality (2), wherein N is rounded off to be an integer, L is the minimum value of the inequality; 3, determining small-step drilling frequency n in each big step and final hole space X, wherein the formula is L=nX(3); X is less than or equal to Xm; (4) trialing according to the equation and the inequality and solving the small-step drilling frequency n in each big step and the finally determined drilling space X, wherein n is decimal which is rounded off to be an integer; X is the maximum value meeting the inequality.

Owner:济南法特数控机械有限责任公司

A small multifunctional drilling rig

ActiveCN106761378BPrevent fallingMeet drilling requirementsDrilling rodsConstructionsWell drillingEngineering

The invention relates to the technical field of drilling machines, in particular to a small multi-function drilling machine. The small multi-function drilling machine comprises a base, a mast and a power device are arranged on the base, a pedestal is arranged at the bottom of the power device, and a power head is arranged at the bottom of the pedestal. A clamping device is arranged at the bottom of the power head and comprises a clamping head, a plurality of first grooves are formed in the clamping head, and a second annular groove is formed in the outside of the clamping head. Inserting rods are arranged between the second annular groove and the first grooves in a communicating mode, clamping blocks matched with the first grooves are arranged in the first grooves, and the inserting rods are arranged on the backs of the clamping blocks and penetrate through inserting holes. Lantern rings are arranged at the ends of the inserting rods in a wedge-shaped matched mode, the contacting faces of the inserting rods and the lantern rings are matched in a threaded mode, and the lantern rings are arranged in the second annular groove in a sleeved mode. The inserting rods are sleeved with springs, one ends of the springs are connected with the clamping head, the other ends of the springs are connected with the bottoms of the first grooves, and a drill bit is arranged in the clamping head in an inserting mode. According to the small multi-function drilling machine, requirements of countryside well drilling are met, the clamping effect is good, and an anti-dust device is additionally arranged for avoiding flying dust.

Owner:徐州市茗尧机械制造有限公司

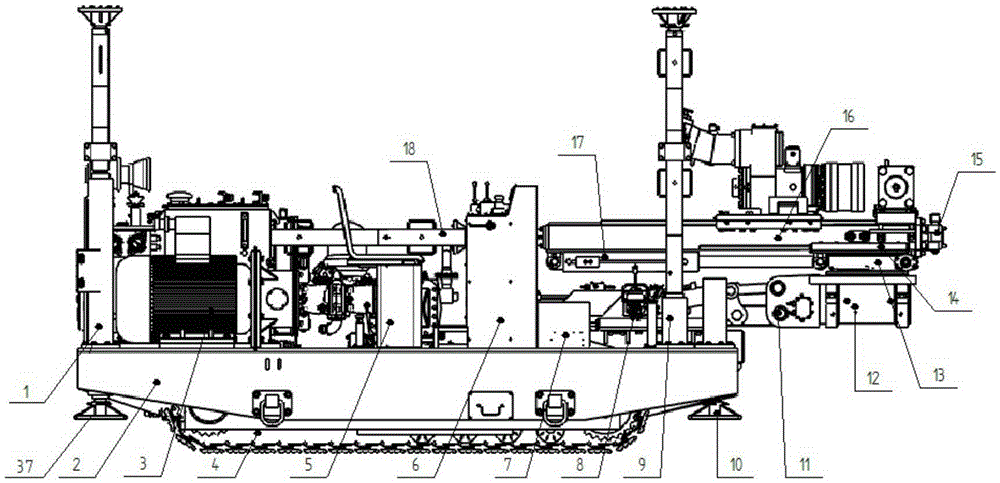

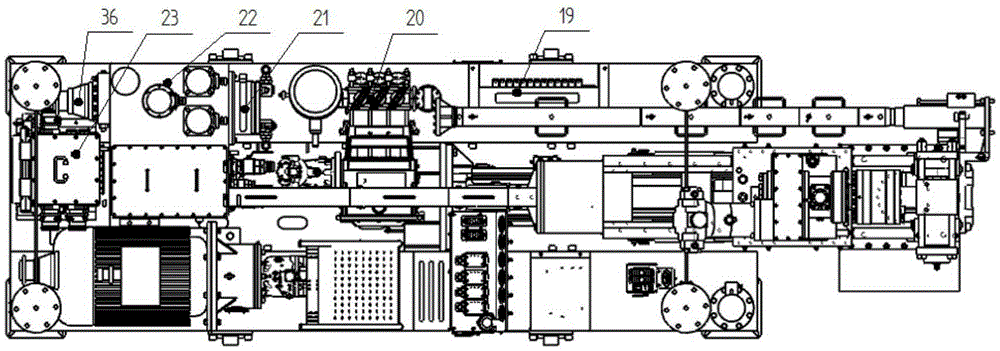

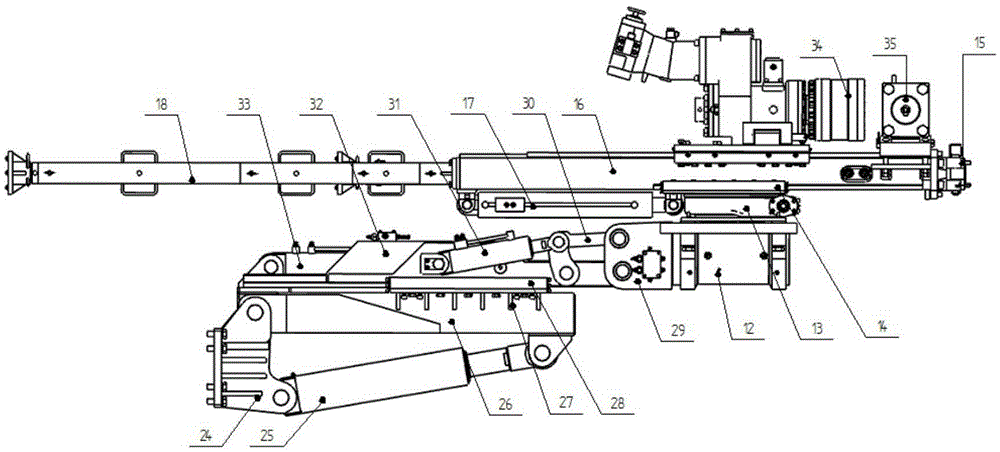

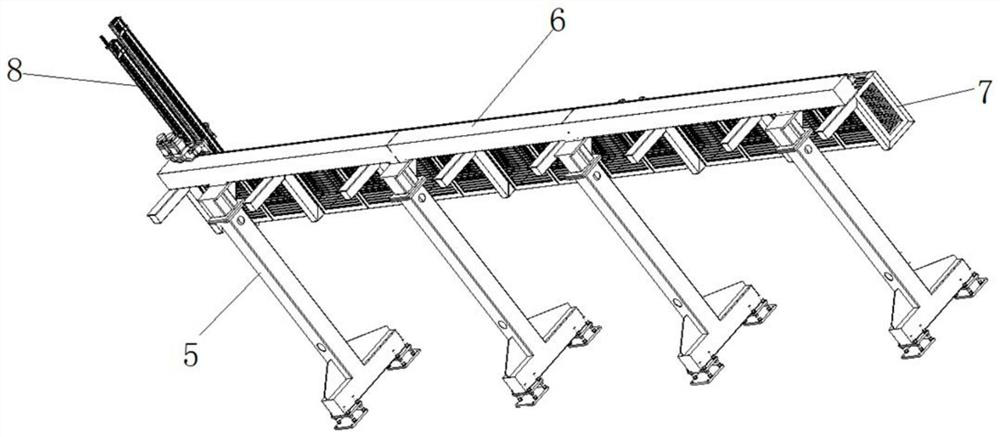

Coal Mine Tunnel Large Gas Drainage Crawler Drilling Rig

ActiveCN104141456BLarge height adjustment rangeWide range of heightsGas removalDrilling machines and methodsCoalDrill

The invention discloses a large mining height gas extracting caterpillar drill for a coal mine gallery. The large mining height gas extracting caterpillar drill at least comprises a body and a shift drilling device, wherein the body comprises a caterpillar body; two sides of the lower end of the caterpillar body are respectively provided with a caterpillar assembly; the shift drilling device is arranged at the front end of the caterpillar body and comprises a vehicle body connecting plate, a tail end connecting plate, a telescopic amplitude changing device, an orientation adjusting device, a dip angle adjusting device and a feeding device; one end of the telescopic amplitude changing device is connected to the vehicle body connecting plate, and the other end of the telescopic amplitude changing device is connected to the tail end connecting plate; the telescopic amplitude changing device ensures that the tail end connecting plate integrally parallelly moves in a plane relative to the vehicle body connecting plate; therefore, the large mining height gas extracting caterpillar drill is wide in drilling height range, and has the characteristic of wide range for adjusting the height of a center hole of the drill; in crossheading construction for a working face in tunneling, a construction range is wide, the whole working face can be involved, and the drill has obvious advantages in large mining height gas extraction drilling.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

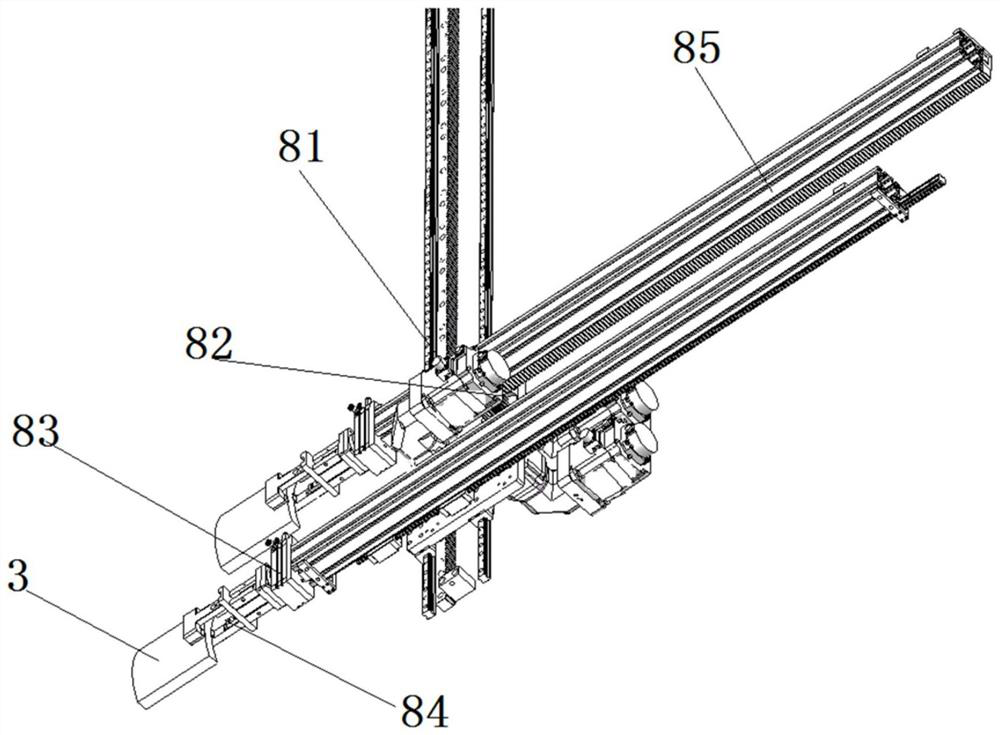

A sample feeding device for the production of drum brake pads

ActiveCN112207323BEasy to drillMeet drilling requirementsLarge fixed membersMetal working apparatusControl engineeringProcess engineering

The invention discloses a sample delivery device for drum brake pad production, which comprises a fixed support, a sample delivery beam, a sample delivery truss and a sample delivery mechanism, the sample delivery beam is installed on the fixed support, and the sample delivery truss is open up and down Cuboid structure, installed on the sample delivery beam, the sample delivery mechanism is movably installed on the sample delivery beam, and passes through the sample delivery truss, and moves along the length direction of the sample delivery beam. The sample delivery mechanism includes a translational servo component, a vertical servo component, The rotating assembly, the brake pad clamping assembly and the sample feeding pole; when in use, the rotating assembly rotates with the lower part holding the brake pad, and the brake can be applied according to the drilling position and the position of the drilling machine when the drilling machine is drilling. Adjust the orientation of the pad to meet the drilling requirements; at the same time, use the brake pad clamping assembly to clamp and fix the brake pad, which is convenient for drilling and material transportation. It has a reasonable structure design, easy to use, and easy to process the brake pad And the characteristics of sample delivery.

Owner:DONGGUAN POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com