Determination method of spindle spacing and drilling method of multi-spindle CNC sieve plate drilling equipment

A technology for drilling equipment and determining methods, which is applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., and can solve the problems of low drilling efficiency, long design cycle, cumbersome design and calculation work of multi-head drilling machines, etc. problem, to achieve the effect of reducing blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

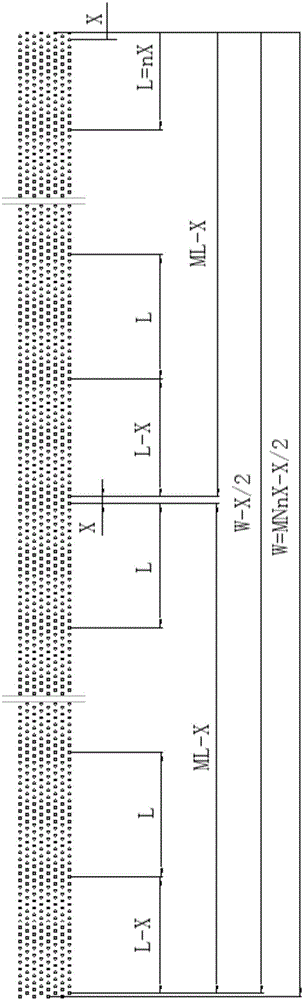

[0059] User requirements: The drilling width range is 900mm, and the distance between adjacent holes is 6.5mm. The existing drilling machine has 4 main shafts, the outer diameter of the main shaft is 80mm, the connecting bolts of the main shaft are M8 inner hexagonal bolts, and the diameter of the bolt head is

[0060] Clarify only the parameters: the drilling width range W=900mm, the distance between adjacent holes in a row Xm=6.5mm; the number of spindles of the sieve plate drilling machine M=4; the outer diameter of the spindle D=80mm; the gap between adjacent spindles should not be less than Y=12mm ;

[0061] Implementation process:

[0062] From formula (1), N≈225.81 / L,

[0063] From the inequality (2), L>92mm

[0064] In order to round up, the result should be N=2, L≈112.91mm

[0065] By formula (3), n=112.91 / X,

[0066] By inequality (4), X≤6.5mm

[0067] For rounding, the result should be n=18, X≈6.2727mm.

[0068] Results: When 4 spindles drill holes at the sam...

Embodiment 2

[0070] User requirements: The drilling width range is 800mm, and the distance between adjacent holes is 5mm. The existing drilling machine has 8 spindles, the outer diameter of the spindle is 80mm, the connecting bolts of the spindle are hexagon socket bolts M10, and the diameter of the bolt head is

[0071] Clarify only the parameters: the drilling width range W=800mm, the distance between adjacent holes in a row Xm=5mm; the number of spindles of the sieve plate drilling machine M=8; the outer diameter of the spindle D=80mm; the gap between adjacent spindles should not be less than Y=15mm;

[0072] Implementation process:

[0073] From formula (1), N≈100.31 / L,

[0074] From the inequality (2), L>95mm

[0075] In order to round up, the result should be N=1, L≈100.31mm

[0076] By formula (3), n=100.31 / X,

[0077] By inequality (4), X≤5mm

[0078] For rounding, the result should be n = 21, X ≈ 4.777 mm.

[0079] Result: When 8 spindles drill holes at the same time, the ...

Embodiment 3

[0081] User requirements: the drilling width range is 1300mm, and the distance between adjacent holes is 7mm. The existing drilling machine has 5 spindles, the outer diameter of the spindle is 100mm, the connecting bolts of the spindle are M10 inner hexagonal bolts, and the diameter of the bolt head is

[0082] Clarify only the parameters: the drilling width range W=1300mm, the distance between adjacent holes in a row Xm=7mm; the number of spindles of the sieve plate drilling machine M=5; the outer diameter of the spindle D=100mm; the gap between adjacent spindles should not be less than Y=15mm;

[0083] Implementation process:

[0084] By formula (1), N=260.7 / L,

[0085] From the inequality (2), L>115mm

[0086] For rounding, the result should be N=2, L=130.35mm

[0087] By formula (3), n=130.35 / X,

[0088] By inequality (4), X≤7mm

[0089] For rounding, the result should be n = 19, X ≈ 6.86 mm.

[0090] Result: When 5 spindles drill holes at the same time, the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com