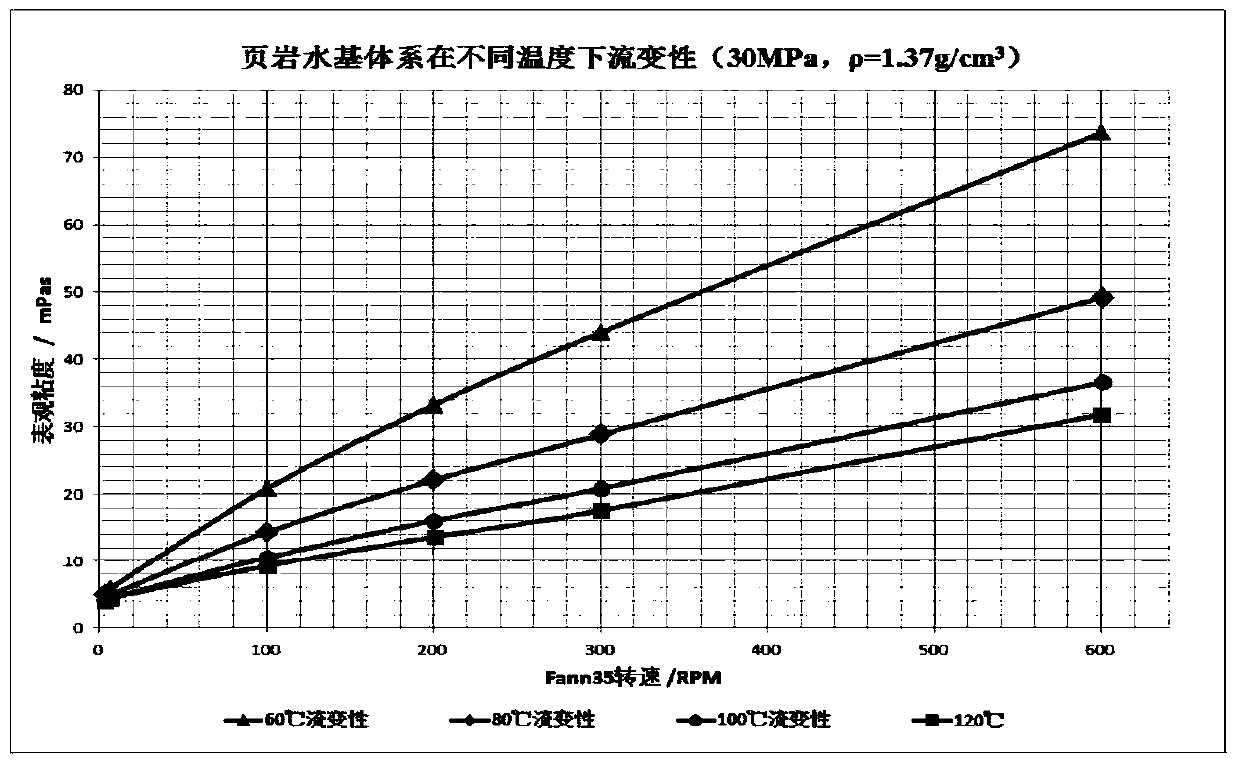

A kind of shale horizontal well water-based drilling fluid and preparation method thereof

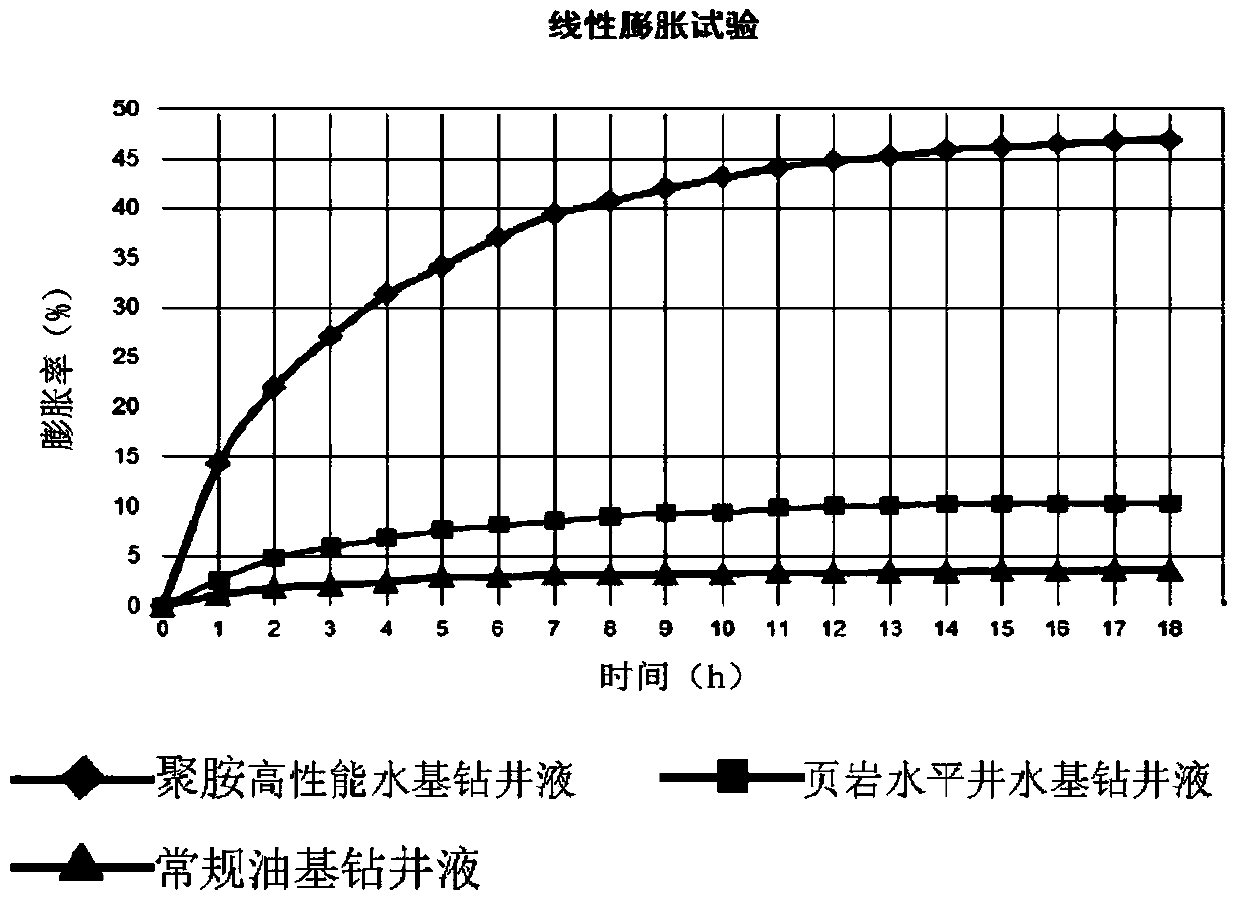

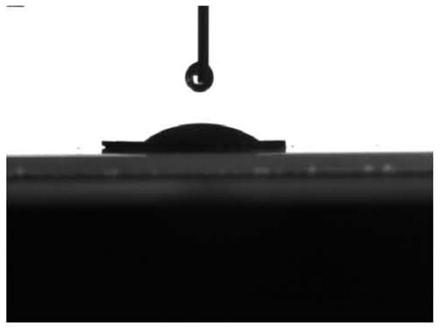

A water-based drilling fluid and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of enhanced plugging ability, excellent lubricity, and excellent inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] All the embodiments of the present invention are prepared according to the preparation method and steps of water-based drilling fluid for shale horizontal wells. Shale horizontal well water-based drilling fluid preparation method and steps:

[0046] a. Base slurry configuration: Add 3 parts by weight of sodium carbonate and 20-30 parts by weight of sodium bentonite to 1000 parts by weight of water, stir for 30-60 minutes, and pre-hydrate for 24 hours.

[0047]b. Add fluid loss reducer: Add 10-20 parts of environmentally friendly modified starch by weight into the base slurry obtained in step a, add carboxymethyl cellulose sodium salt fluid loss reducer with 5-10 parts by weight, Add 20-40 parts by weight of sulfonated phenolic resin and stir.

[0048] c. Adding inhibitors: adding 5-10 parts of amino polyether by weight into the drilling fluid obtained in step b, adding potassium chloride by 50-70 parts by weight, and complexed aluminum by 20-40 parts by weight, Stir. ...

Embodiment 1

[0058] The mass parts of the components of the shale horizontal well water-based drilling fluid provided in this example are: 400ml of fresh water, 8g of sodium bentonite, 1.2g of sodium carbonate, 4g of environmentally friendly modified starch, and 4g of carboxymethyl cellulose sodium salt reducer. Dehydration agent, 12g sulfonated phenolic resin, 4g amino polyether, 28g potassium chloride, 12g complexed aluminum, 1.2g hydrolyzed polyacrylamide potassium salt, 12g sulfonated pitch, 6g nano silicon dioxide, 12g ultrafine carbonic acid Calcium, 2g of wetting reversal agent, 12g of extreme pressure lubricant SMJH-1, 60g of crude oil, 2g of emulsifier OP-10, 1.2g of flow regulator XCD.

[0059] The basic performance parameters of the water-based drilling fluid for shale horizontal wells in this example were tested, and compared with the polyamine high-performance water-based drilling fluid in the prior art. The data analysis is shown in Table 1 and Table 2.

[0060] Table 1 Compa...

Embodiment 2

[0106]The mass parts of the components of the shale horizontal well water-based drilling fluid provided in this example are: 400ml fresh water, 10g sodium bentonite, 1.2g sodium carbonate, 4g environmentally friendly modified starch, 4g carboxymethyl cellulose sodium salt reducer Dehydration agent, 12g sulfonated phenolic resin, 4g amino polyether, 20g potassium chloride, 12g complexed aluminum, 1.2g hydrolyzed polyacrylamide potassium salt, 12g sulfonated pitch, 6g nano silicon dioxide, 12g ultrafine carbonic acid Calcium, 4g of wetting reversal agent, 16g of extreme pressure lubricant SMJH-1, 60g of crude oil, 2g of emulsifier OP-10, 1.2g of flow regulator XCD.

[0107] Test the basic performance parameters of the water-based drilling fluid for shale horizontal wells of the present invention, and compare it with the high-performance water-based drilling fluid. The data analysis is shown in Table 7 and Table 8

[0108] Table 7 Comparison of basic performance parameters of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com