Patents

Literature

45results about How to "Meet the needs of drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based drilling fluid suitable for shale gas development

InactiveCN105255460AIncreased shale stabilityStable rheologyDrilling compositionShale gasDrilling fluid

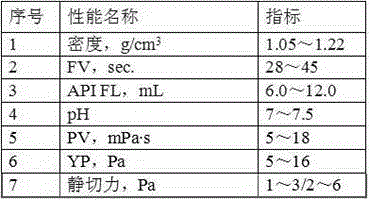

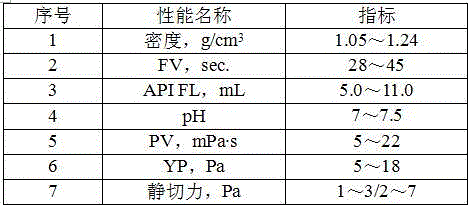

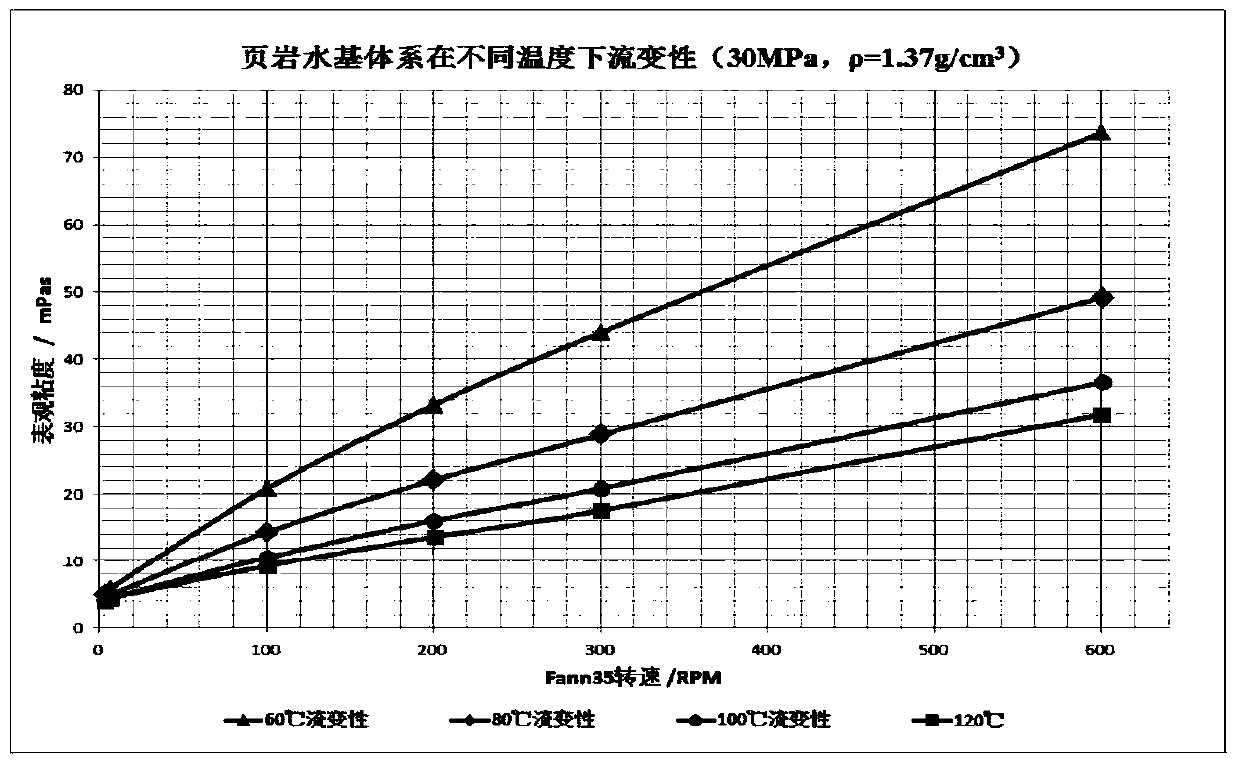

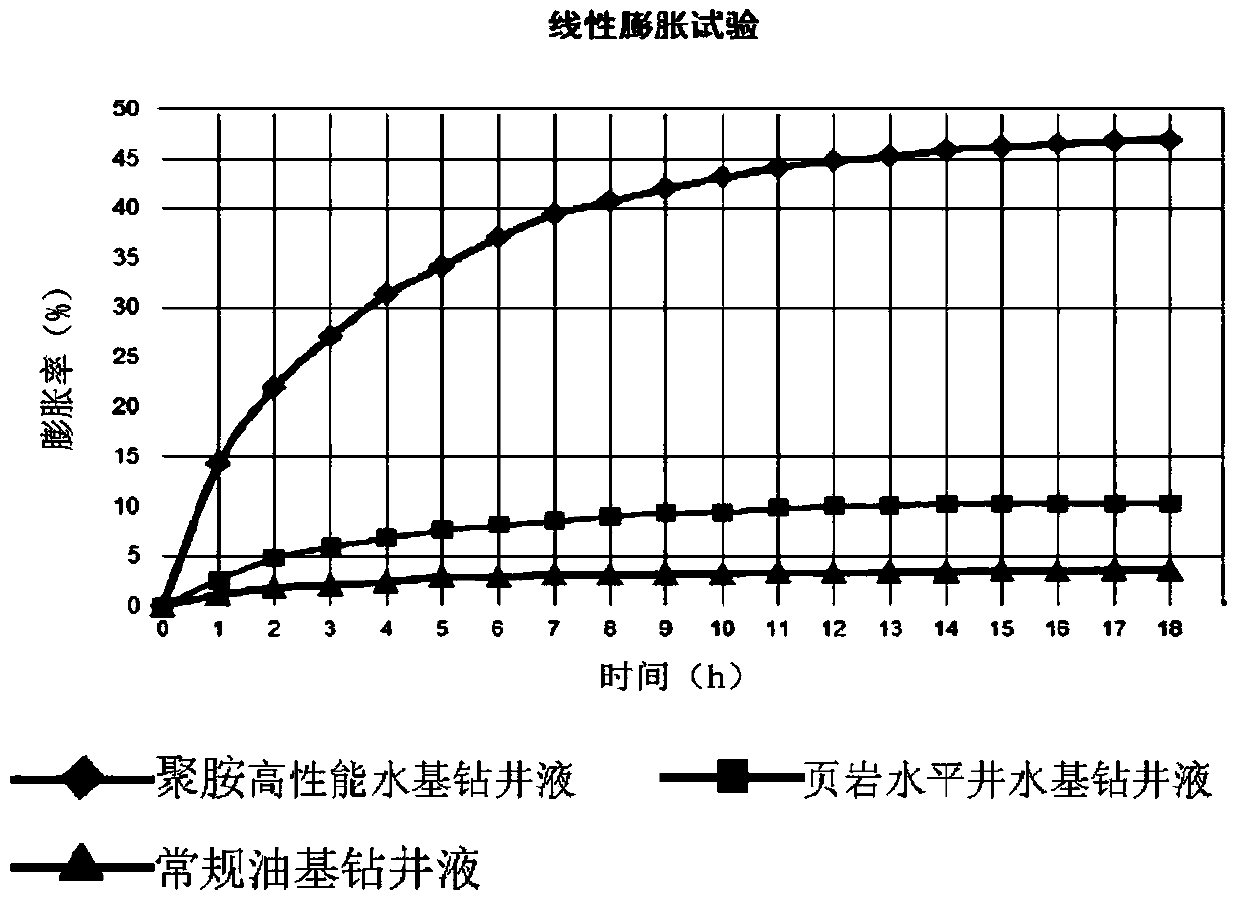

The invention provides a water-based drilling fluid suitable for shale gas development. The water-based drilling fluid is prepared from the following raw materials in volume on the basis of water: 100 percent of water, 2 to 6 percent of lubricating agents, 1 to 5 percent of inhibitors, 1 to 5 percent of blocking anti-collapse agents, 1 to 5 percent of shale blocking agents, 1 to 5 percent of nanometer blocking agents, 1 to 3 percent of fluid loss additives, 1 to 3 percent of additives, 0 to 0.4 percent of shearing potentiator, 0.1 to 0.6 percent of pH regulator and 0 to 300 percent of weighting agents. The water-based drilling fluid has low filter loss, shale cracks can be effectively blocked, and the stability of a well wall is increased; the lubricating performance is good, and the problems of friction and torque caused by a shale gas horizontal well are preferably solved; the rheological property is excellent.

Owner:SINOPEC JIANGHAN OILFIELD SERVICE CORP +1

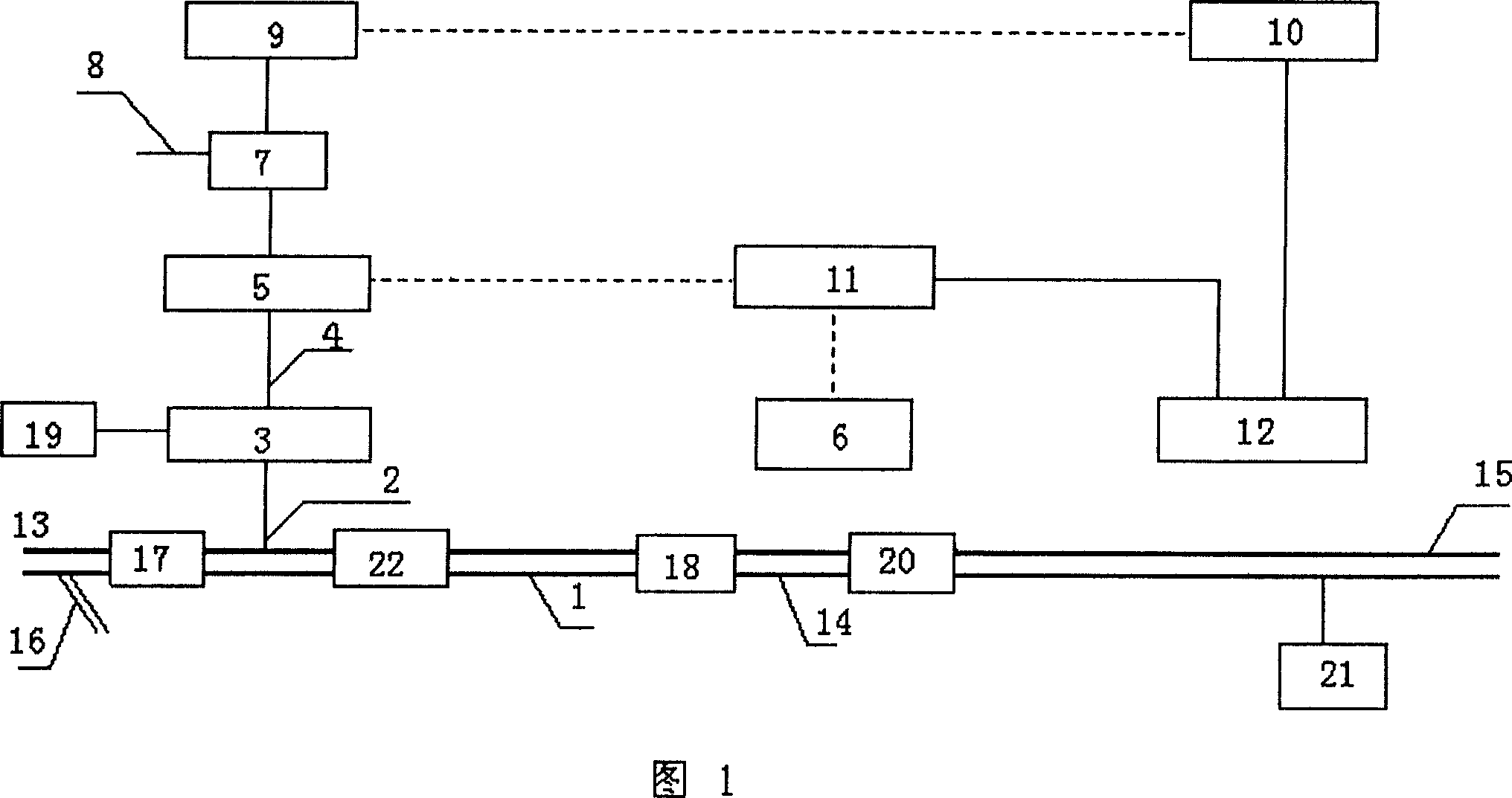

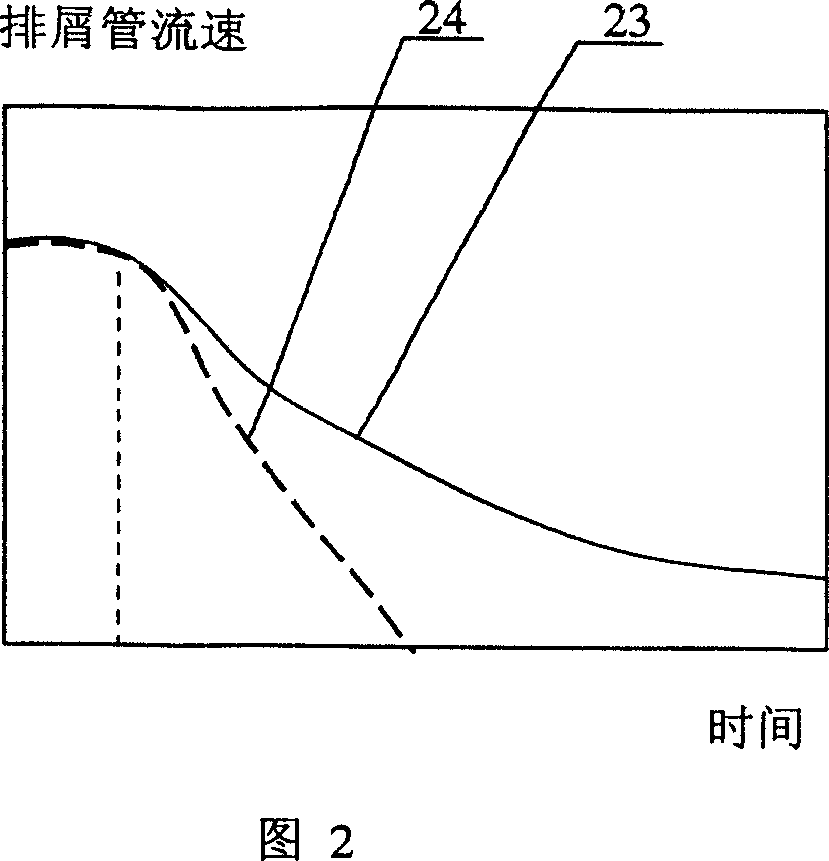

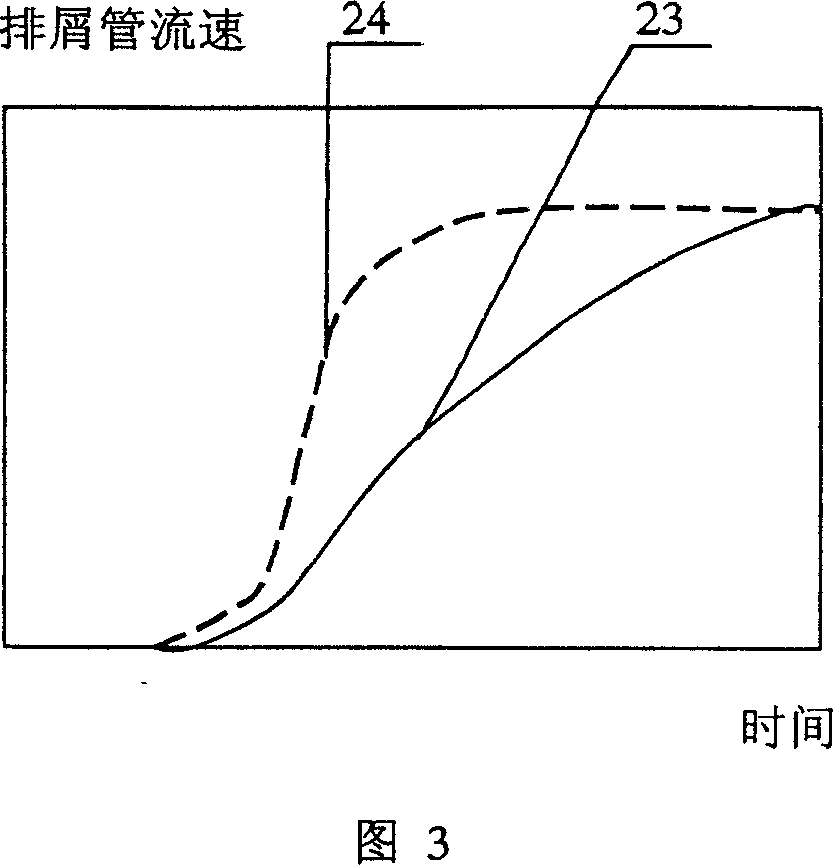

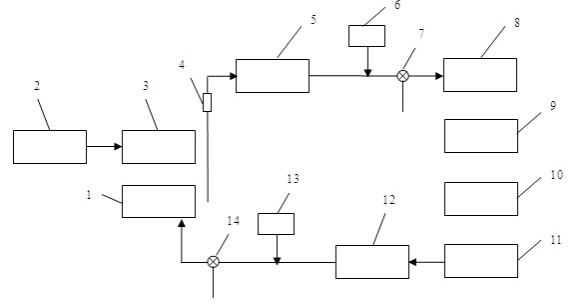

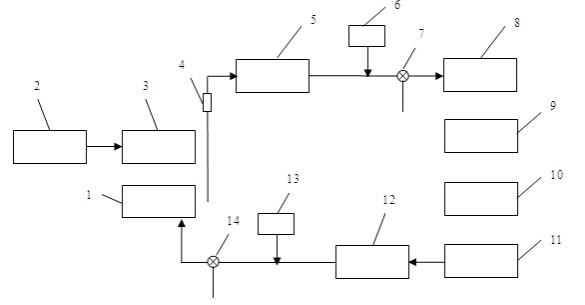

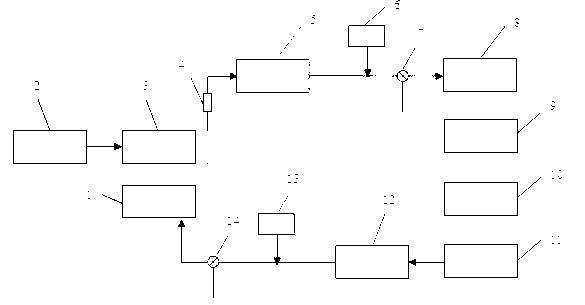

Method for continuouslly monitoring gas well-boring state under well

InactiveCN101029564AMeet the needs of drillingEnsure safetySurveyConstructionsAnalysis dataLine tubing

A continuous monitor method for oil well includes: sampling the gas at the spigot line; after de-dust and de-water procedure, the gas flow through a flow meter and monitor system to the analysis instrument; the analysis data is collected and sent to a PC module, so to realize auto-monitor, analysis and comparison.

Owner:SOUTHWEST PETROLEUM UNIV

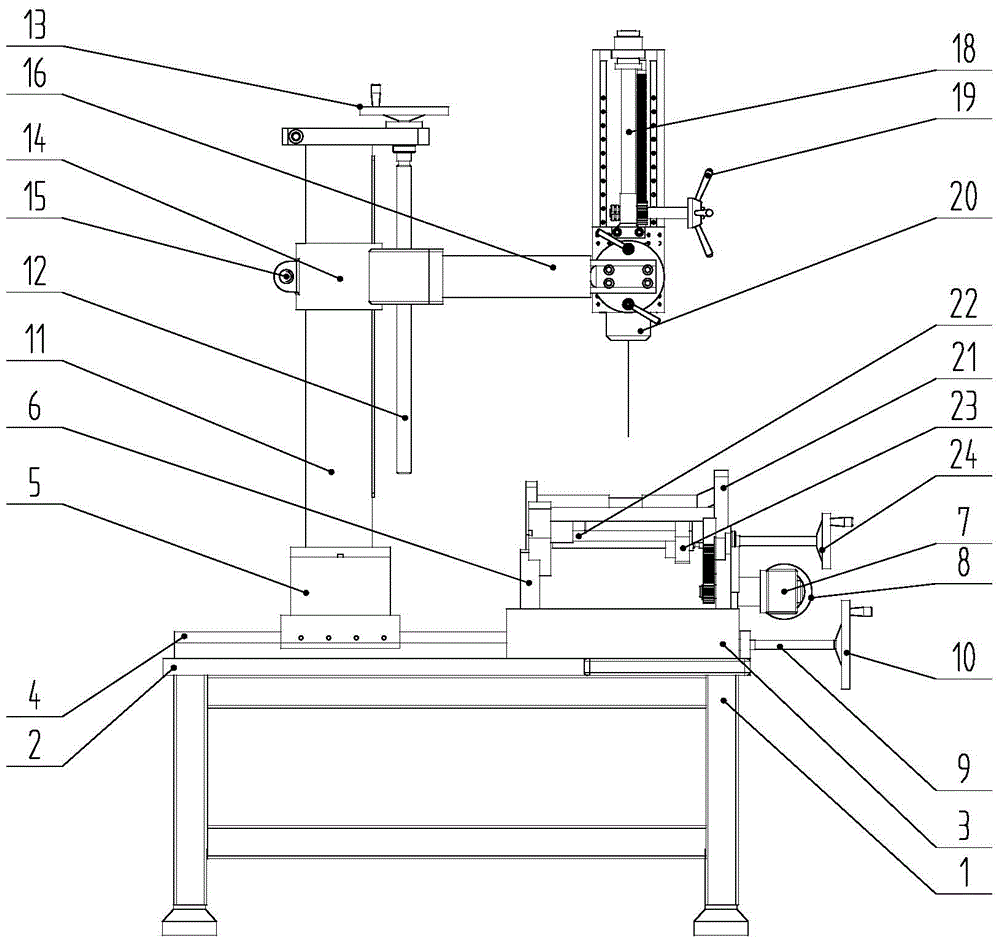

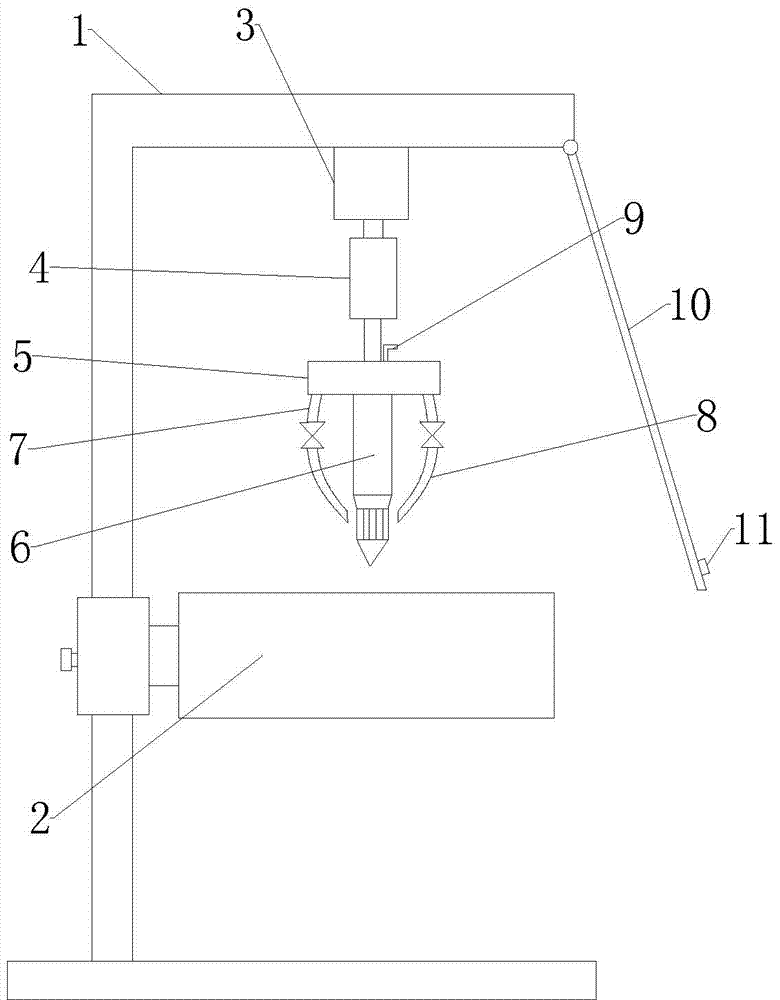

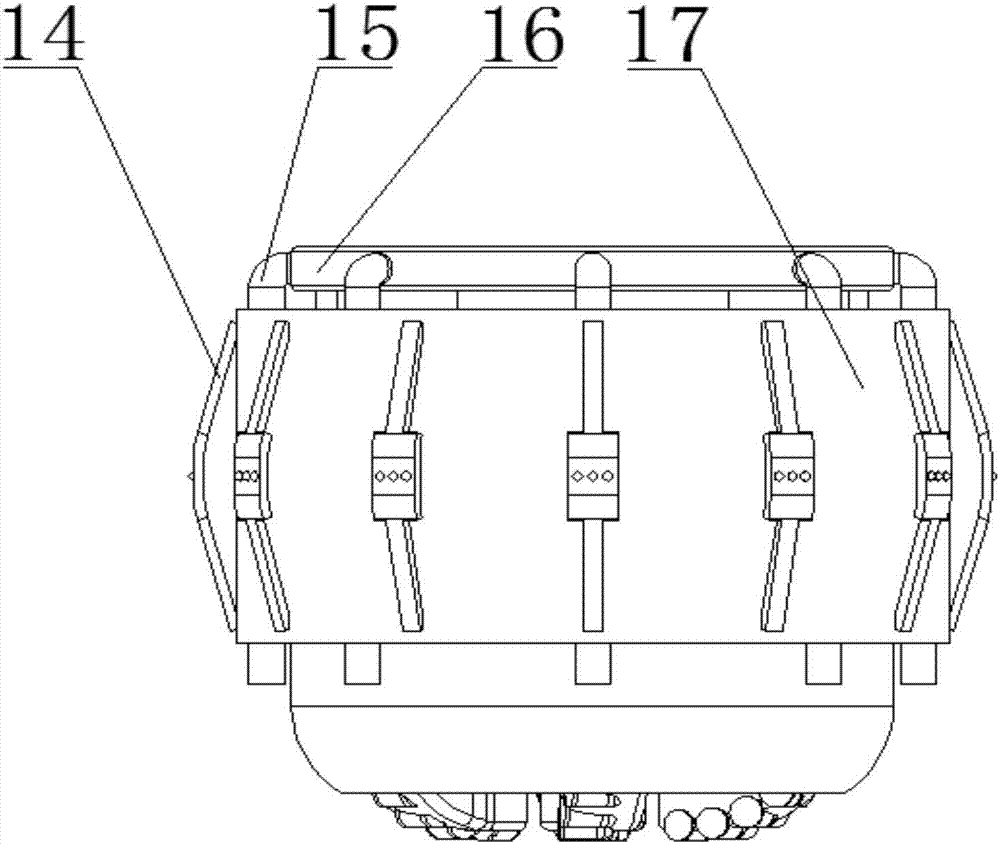

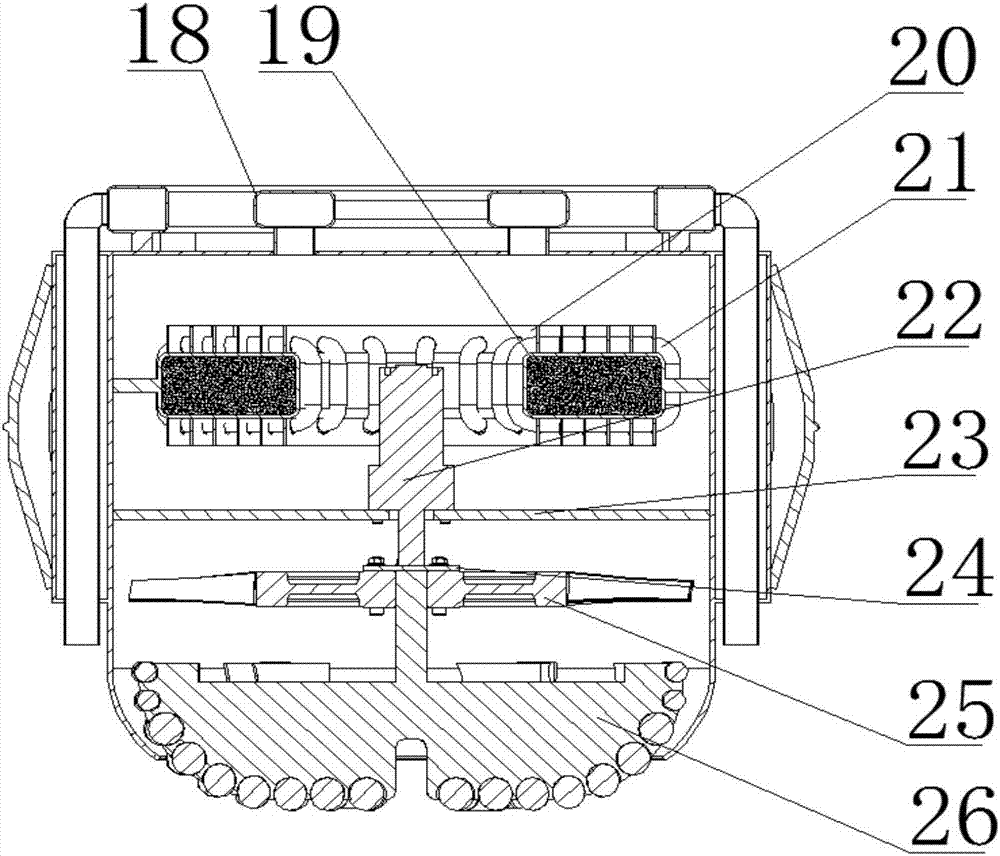

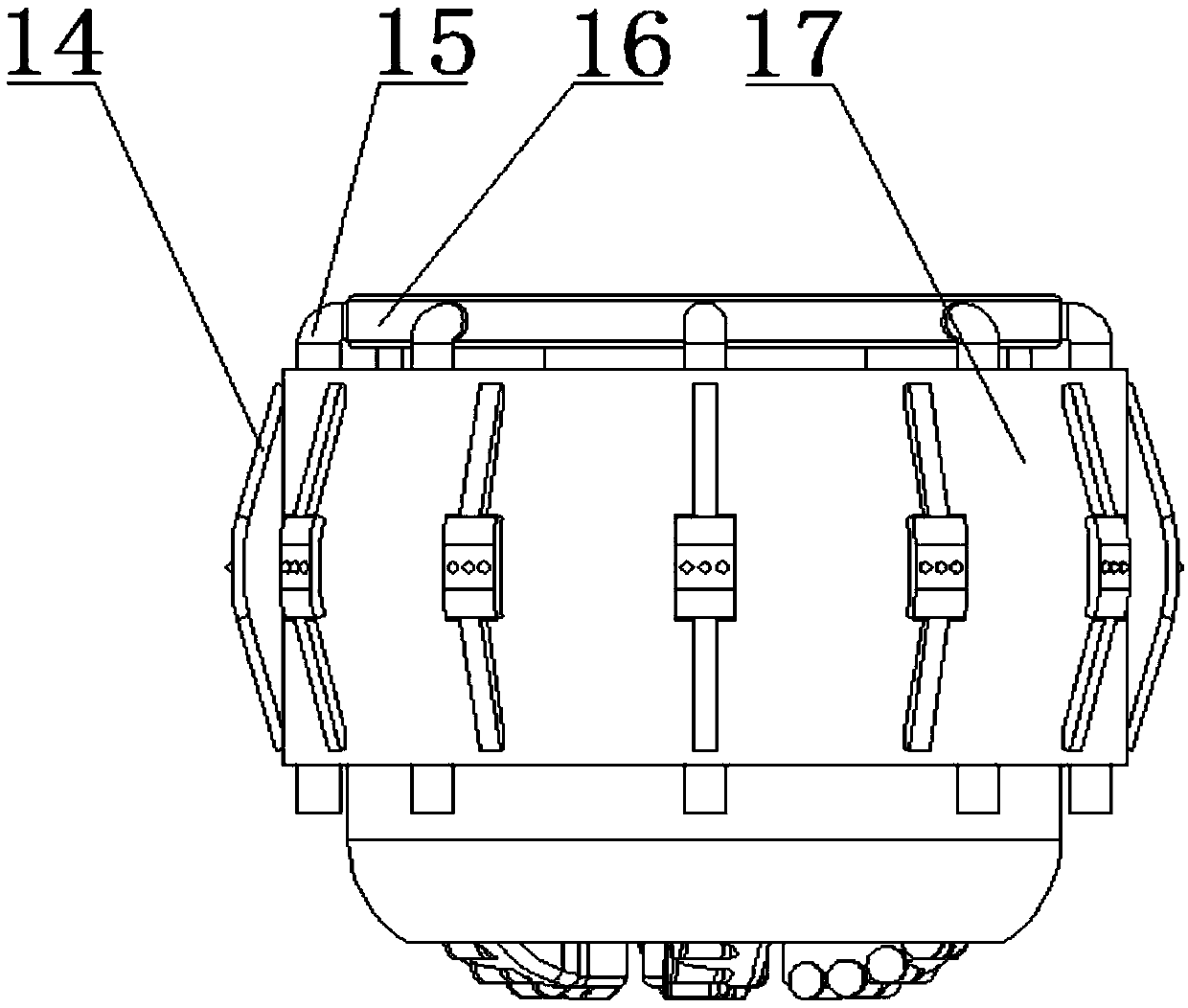

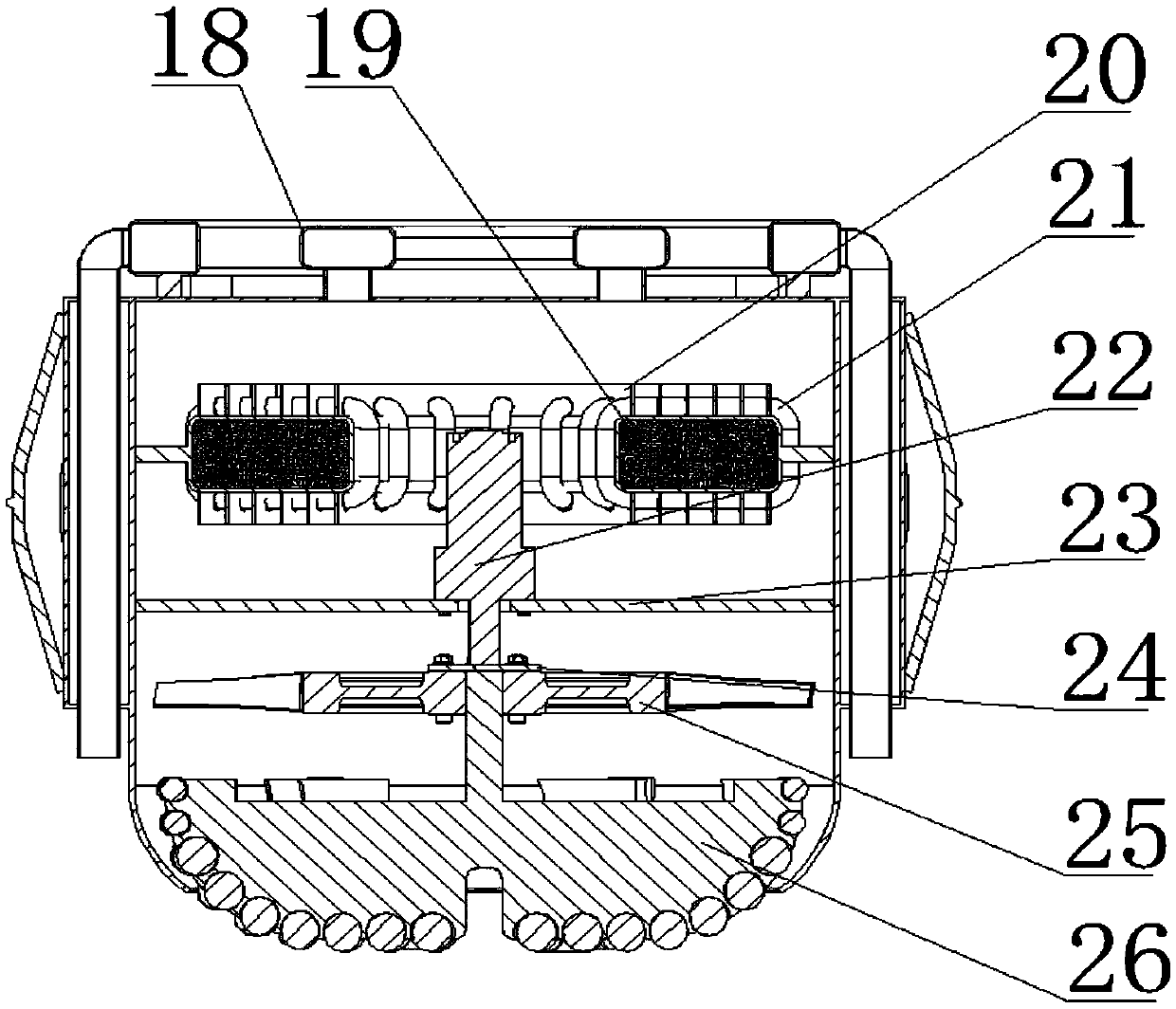

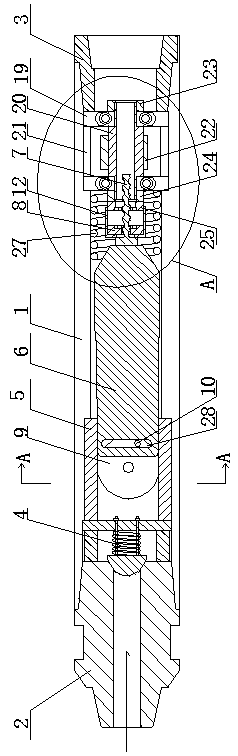

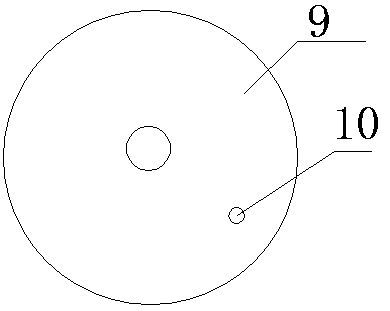

Tooth implantation drilling robot based on small cavity

InactiveCN105496579ALarge range of motionIncrease flexibilityDental implantsSurgical robotsTOOTH IMPLANTATIONSDrive shaft

The invention relates to a tooth implantation drilling robot based on a small cavity. The robot comprises a bearing chassis, a mechanical arm, a clamp, a drilling executor, a control box, a chassis turbine box and a driving arm base. The lower portion of the chassis turbine box is fixed to the bearing chassis. The upper portion of the chassis turbine box is connected with the driving arm base. The upper portion of the driving arm base is provided with a connection hole. The control box is connected with an external computer through a wire and meanwhile fixed to the chassis turbine box. One end of the mechanical arm is connected with the connection hole in the driving arm base. The other end of the mechanical arm is connected with one end of the clamp. The other end of the clamp is connected with the drilling executor. The tooth implantation drilling robot is characterized in that the drilling executor comprises a medical special brushless motor, a speed reducer, a rear axle housing, a front axle housing, a machine head shell, a drill bit, a small connecting rod, a crank, a large connecting rod, a rear transmission shaft, a front transmission shaft, a bevel gear, a one-piece gear spindle and a universal joint pin. The medical special brushless motor is connected with one end of the rear transmission shaft through the speed reducer, and the other end of the rear transmission shaft is connected with one end of the front transmission shaft through the universal joint pin.

Owner:HEBEI UNIV OF TECH

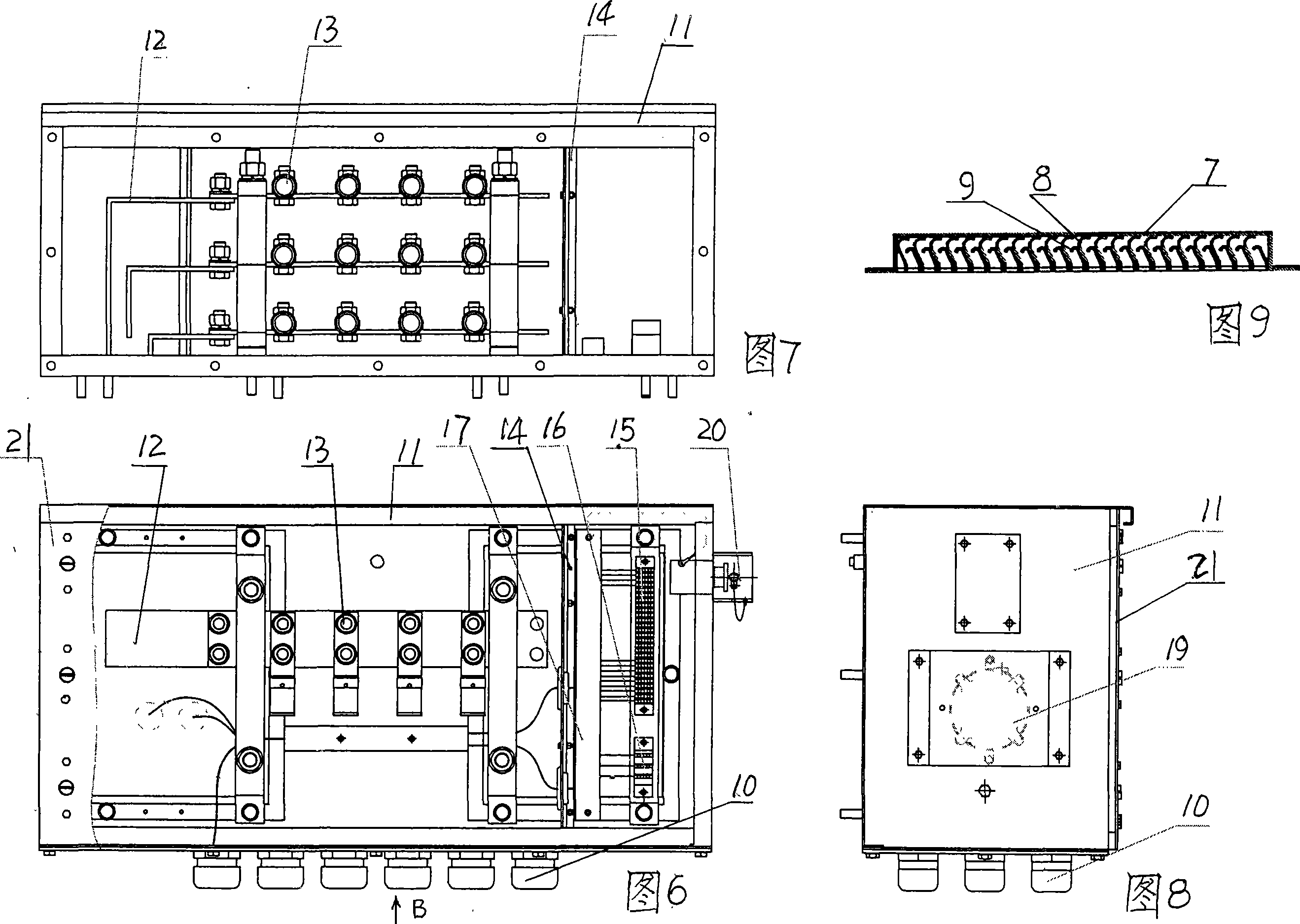

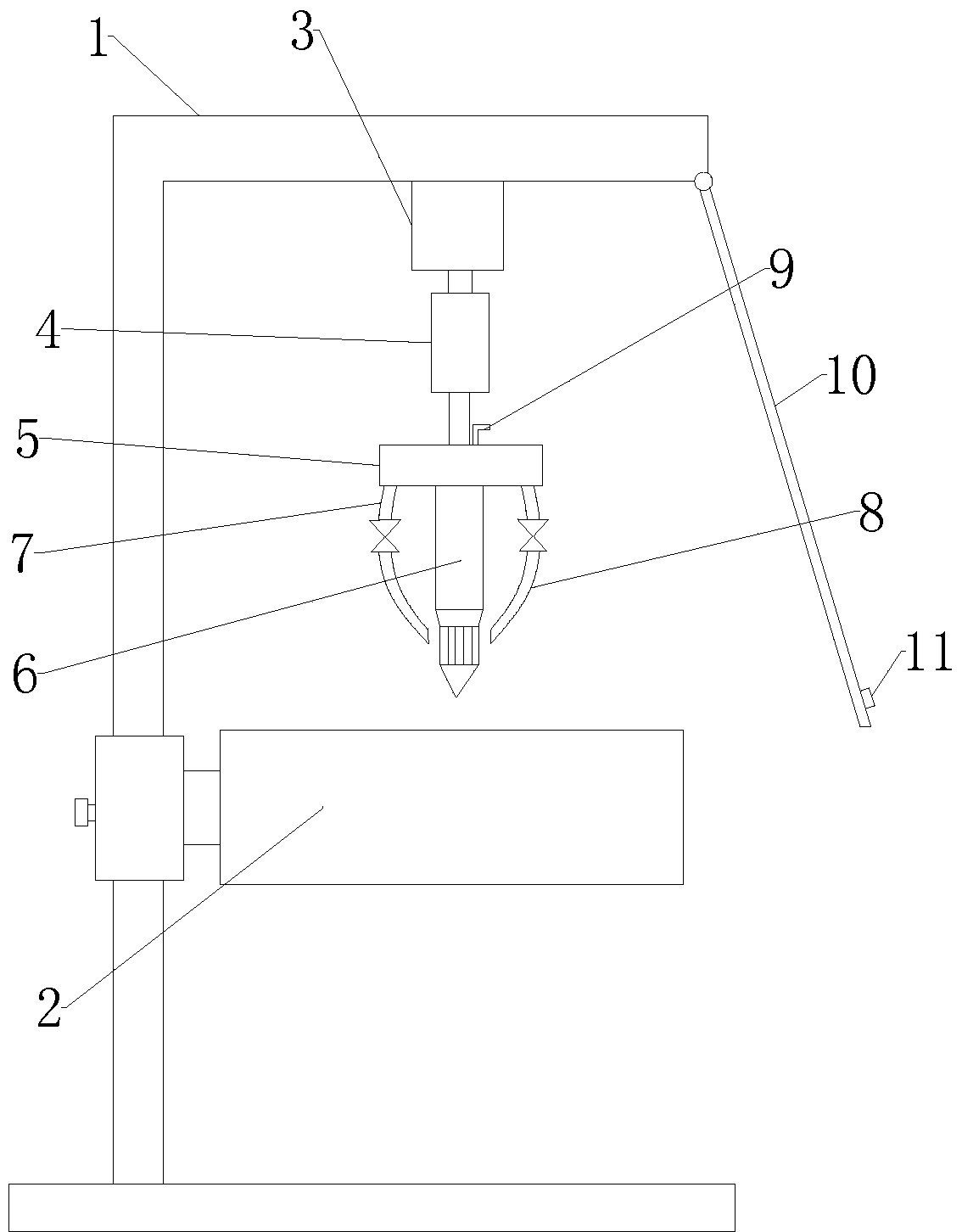

Pattern block air hole drilling machine

InactiveCN104985220AFlexible processingMeet the needs of drillingMetal working apparatusPositioning apparatusEngineeringMachining

The invention discloses a pattern block air hole drilling machine. The drilling machine comprises a machine frame, wherein a base is arranged above the machine frame, a small base is arranged above the base and located at the right side, and a rail is arranged above the base and located at the left side; a sliding block is arranged on the upper side of the rail, a fixing mechanism is arranged above the small base, and a rotary mechanism is arranged at the right side of the fixing mechanism; a Y-axis hand wheel is connected to the rotary mechanism, an X-axis lead screw is arranged at the right side of the small base, and an X-axis hand wheel is connected to the X-axis lead screw; a stand column is arranged on the upper side of the sliding block, a lifting lead screw is arranged at the right side of the stand column, and a Z-axis hand wheel is connected to the top end of the lifting lead screw; a lifting sleeve is connected to the lifting lead screw and the stand column in a chained mode, a locking bolt is arranged at the left side of the lifting sleeve, and a cross beam is arranged at the right side of the lifting sleeve; a spindle mechanism is connected to the right side of the cross beam, and a spindle penetrates through the center of the spindle mechanism. The drilling machine has the beneficial effects that machining is flexible, the requirement for drilling in different directions can be met, clamping is convenient, and due to the fact that a rotary mechanism is used for adjusting a workpiece, repeated fixation and calibration are not needed and working efficiency is improved.

Owner:ZHUCHENG ZHIXIN MOLD EQUIP

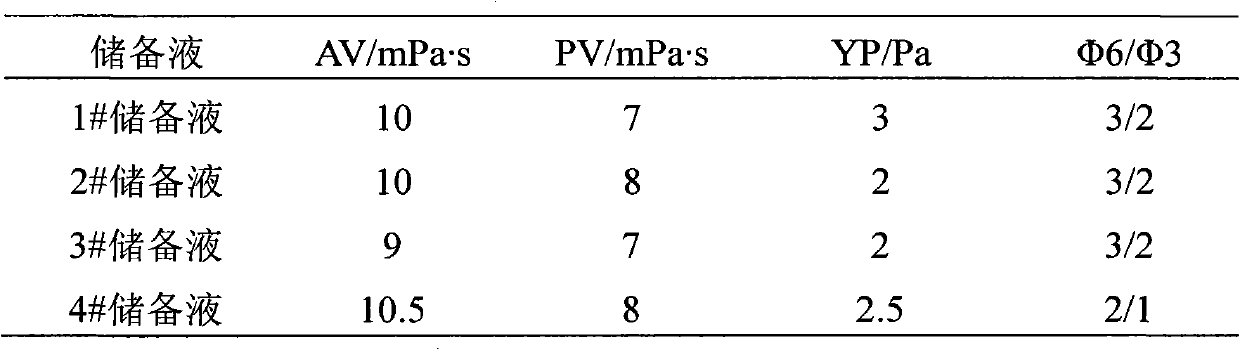

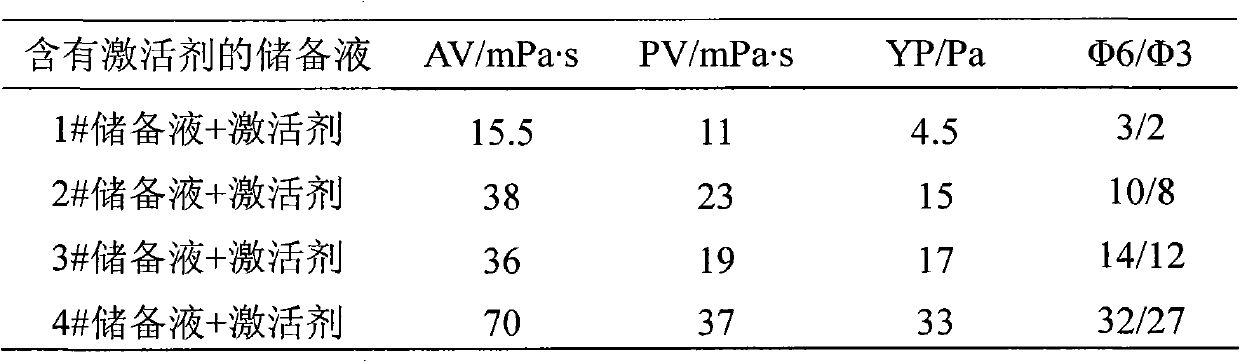

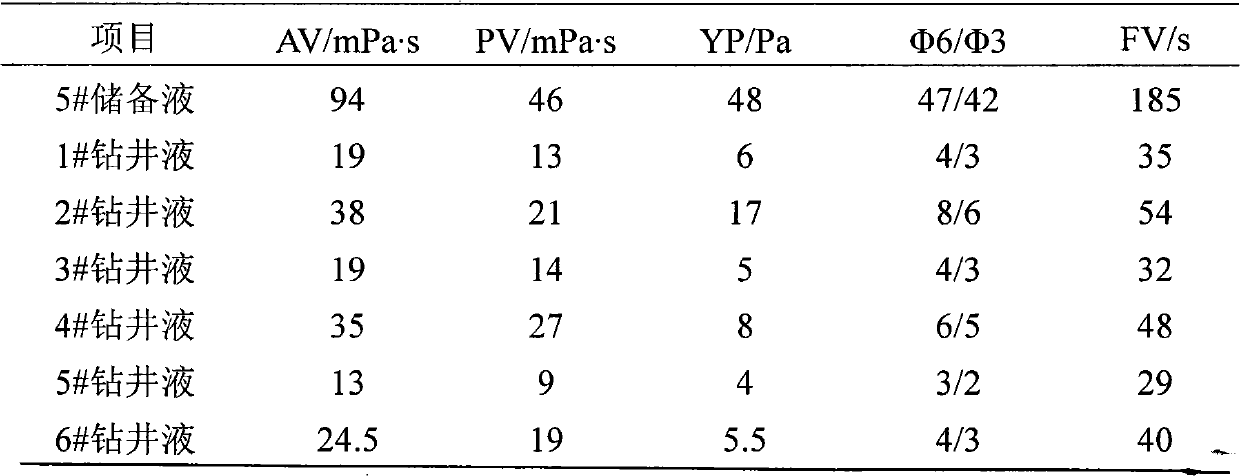

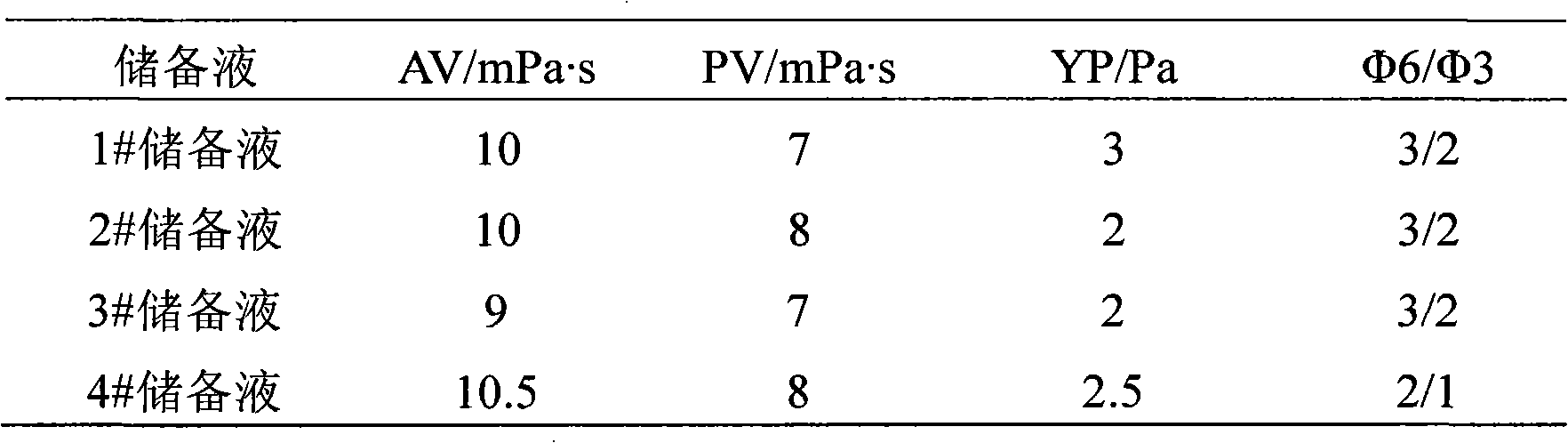

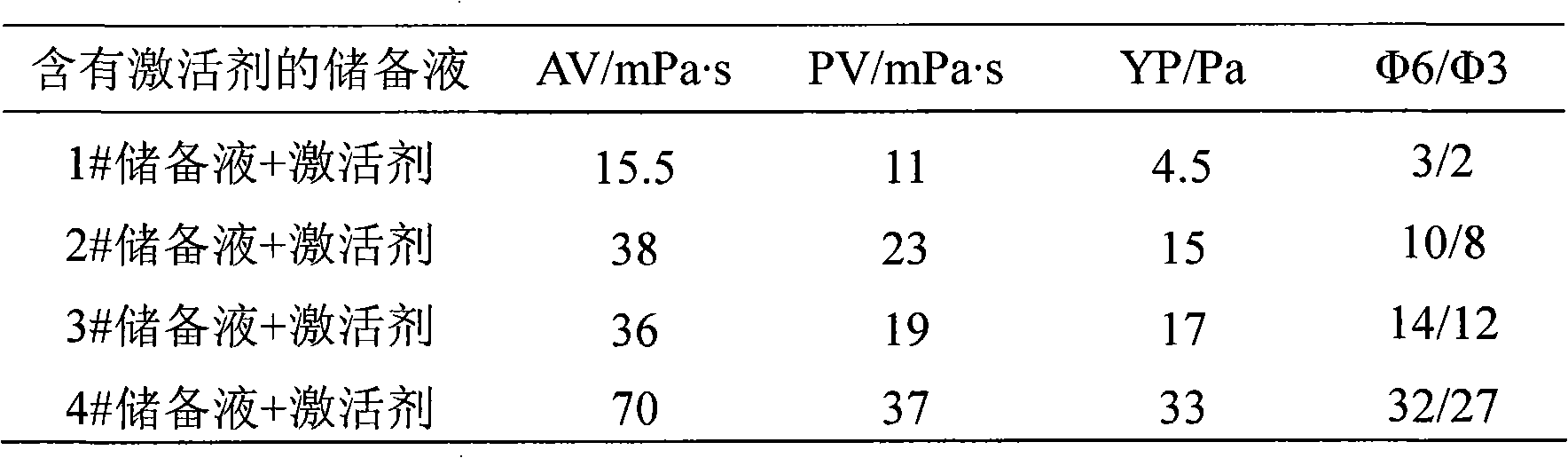

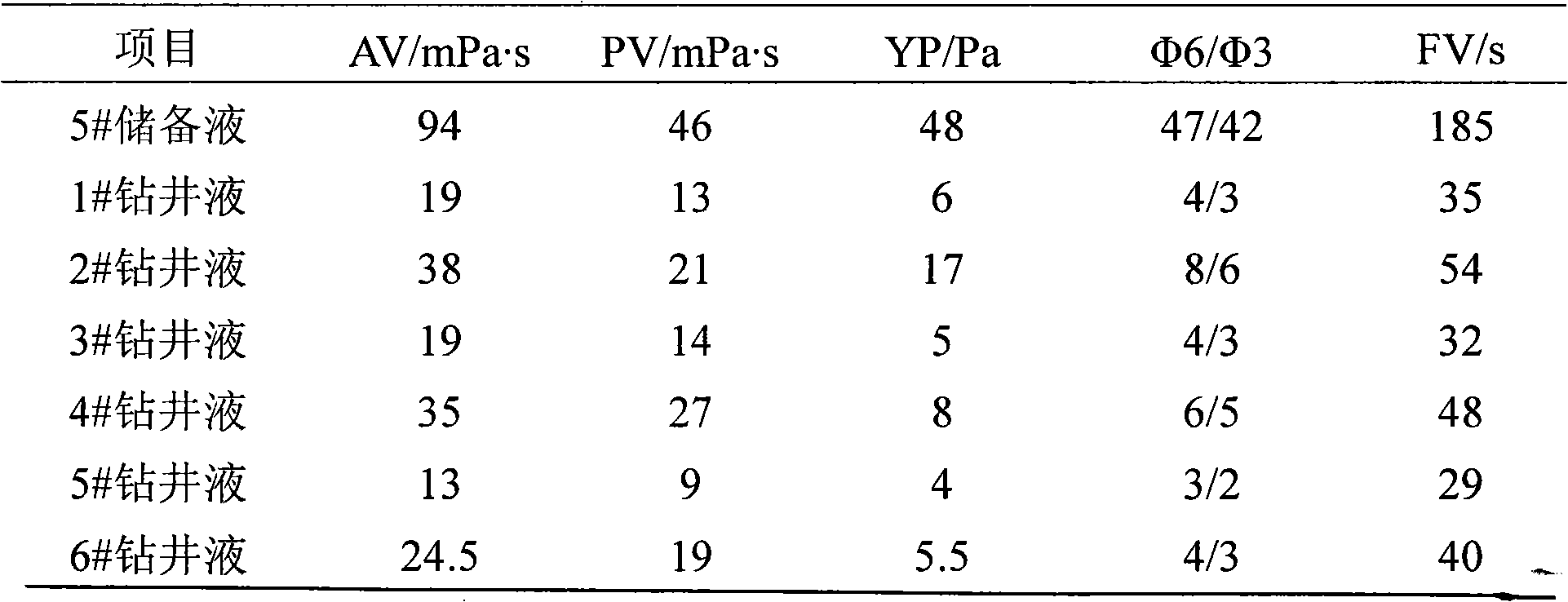

Tackifier, drilling fluid containing tackifier, and stock solution of drilling fluid

ActiveCN102558425AReduce volumeMeet the requirements of on-site pumpingDrilling compositionCelluloseAqueous solution

The invention provides a tackifier, a drilling fluid containing the tackifier, and a stock solution of the drilling fluid. The tackifier is characterized by being able to be passivated and activated. The stock solution of the drilling fluid consists of water, bentonite, polyanion cellulose, xanthan gum, the tackifier and a passivator at the mass part ratio of (85-90) to (4-6) to (0.4-0.6) to (0.3-0.4) to (6-10) to (0.2-0.3). The drilling fluid consists of the stock solution, an activating agent and water at the mass part ratio of (35-85) to (0.2-0.3) to (15-16). The drilling fluid consists of a water solution of the stocking solution and the activating agent, and under the action of the reactivating agent, the passivated tackifier is activated to play a role of tackifying, thereby making up the declination of viscous force and shearing force of the drilling fluid due to dilution of a large quantity of water, and further meeting the requirements on drilling on a deep-water surface.

Owner:CHINA NAT OFFSHORE OIL CORP +1

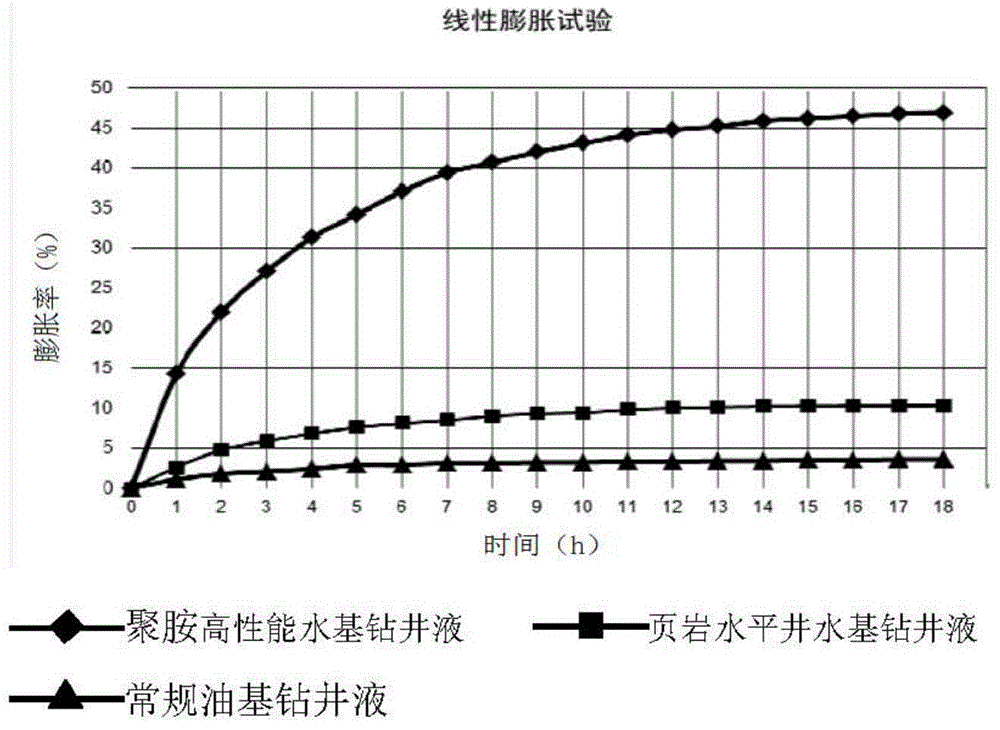

Strong-inhibition anti-caving polyamine drilling fluid for slim-hole drilling of gas wells and horizontal wells and preparation method thereof

InactiveCN108822811ASuitable for drilling needsEnsure stabilityDrilling compositionHorizontal wellsRaw material

The invention provides a strong-inhibition anti-caving polyamine drilling fluid used for slim-hole drilling of gas wells and horizontal wells and capable of preventing the collapse of mudstone, and apreparation method thereof. The drilling fluid comprises the following raw materials by mass: 0.3 to 0.4% of organic amine mainly used as a powerful mudstone inhibitor and an auxiliary alkalinity regulating agent, 3 to 5% of a soluble salt used as an inhibitor and a liquid phase weighting agent, 0.2 to 0.4% of a tackifier, 1.5 to 2.5% of a filtrate reducer, 4.0 to 6.0% of a plugging agent, 0.05 to0.1% of a n alkalinity controlling agent, 1.5 to 2.5% of a lubricant and a weighting agent, with the balance being water. The drilling fluid provided by the invention is applicable to casing window sidetrack drilling of slim-hole horizontal wells in the Sulige gas field in Changqing, especially to construction of long open-hole sections, i.e., inclined shaft sections and horizontal sections, containing mudstone well sections prone to sloughing. The drilling fluid has powerful anti-caving performance, conducts good anti-caving effect on mudstone well sections prone to hydration and sloughing,allows borehole walls to be stable and regular, reduces the incidence rate of accidents in the pit, improves production time efficiency and produces good economic benefits.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

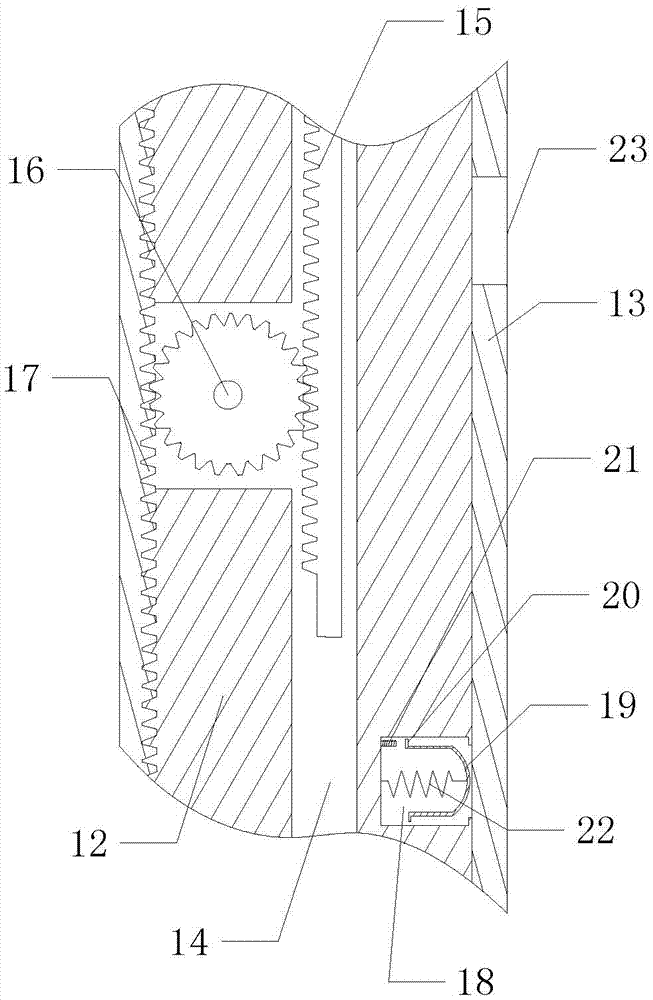

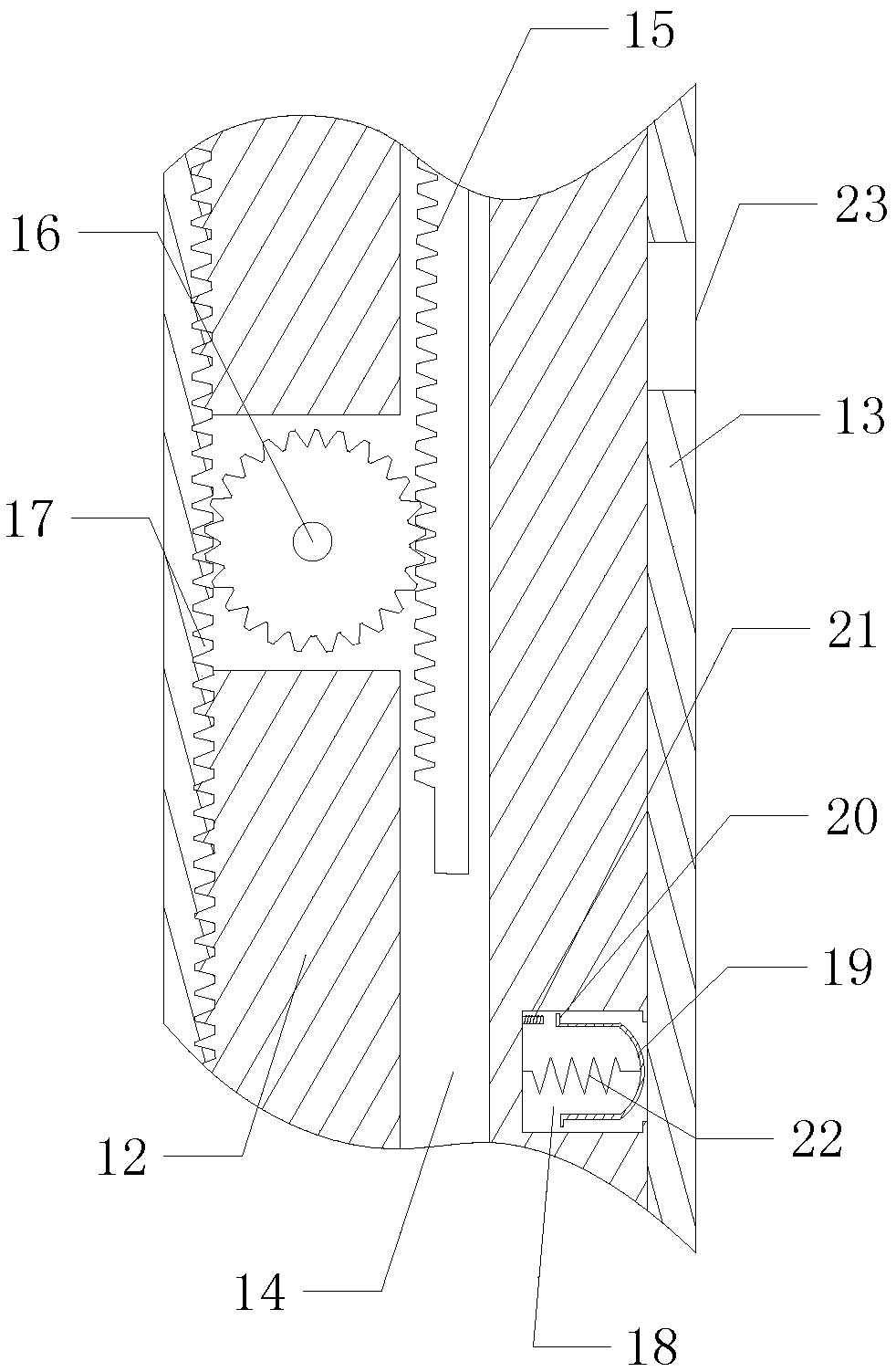

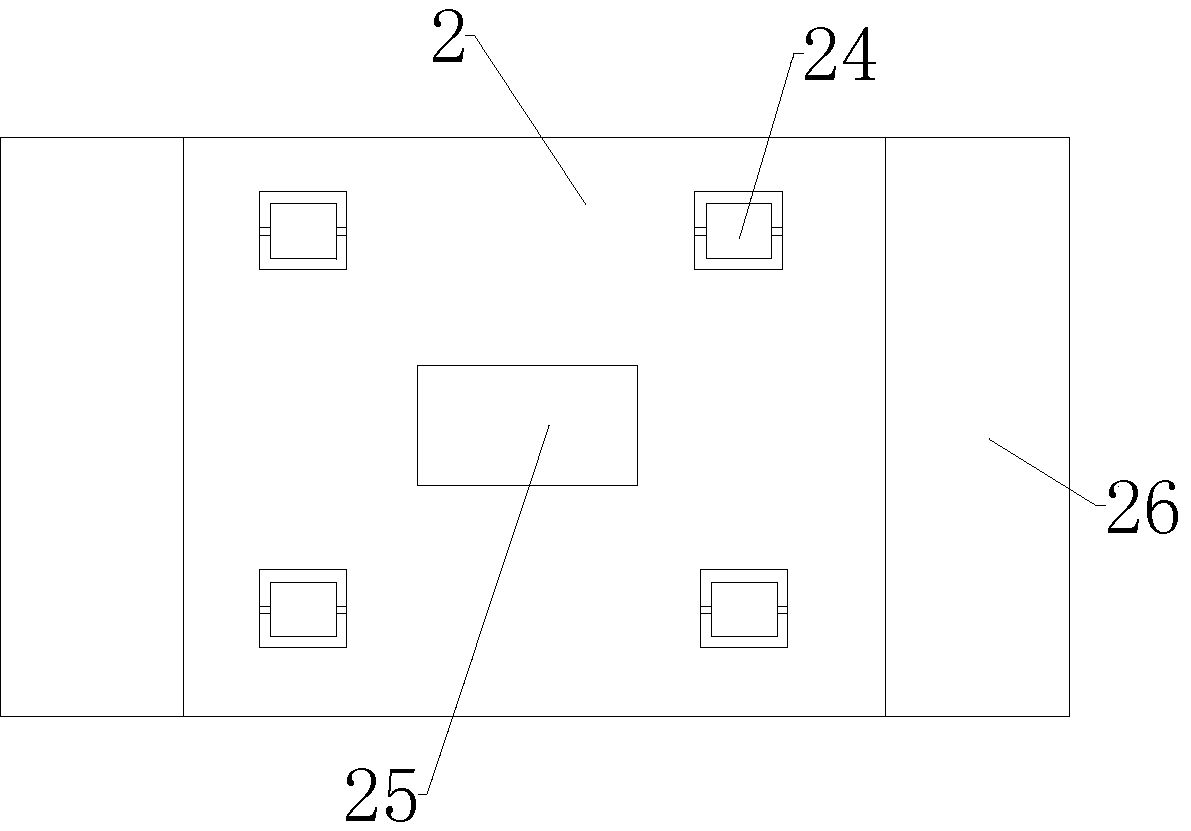

Plate punching device with variable-diameter drill head

ActiveCN106985219AAvoid compromising qualityMeet the needs of drillingStationary drilling machinesPunchingPore diameter

The invention discloses a plate punching device with a variable-diameter drill head. A frame is connected with a control console and a motor; the motor is connected with a cylinder; the cylinder is connected with a rotary disc; the rotary disc is connected with the drill head and provided with a first through hole; the drill head comprises a small drill head and a diameter increasing drill head; the diameter increasing drill head is provided with an open pore; a drill body is in spline connection with the diameter increasing drill head; a gear is rotationally arranged on the drill body; a second through hole is formed in the drill body; racks are arranged in the first through hole and the second through hole in a sliding mode; the gear is engaged with the racks; a plurality of gear teeth are arranged on the inner wall of the diameter increasing drill head and engaged with the gear; a groove is formed in the drill body; an arc block is arranged in the groove in a sliding mode; a spring is connected between the arc block and the inner wall of the groove; an iron block is connected to the arc block; and a solenoid is arranged inside the groove. Compared with the prior art, the plate punching device has the advantages that the diameter of the drill head can be conveniently adjusted and pores with different pore diameters can also be machined in plates.

Owner:重庆市永川区植成家俱厂

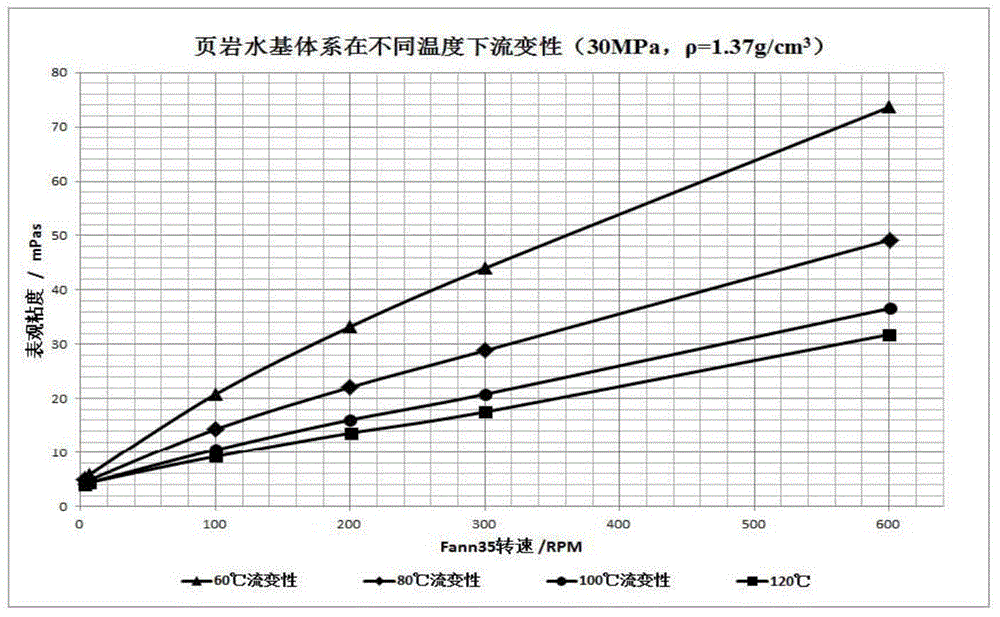

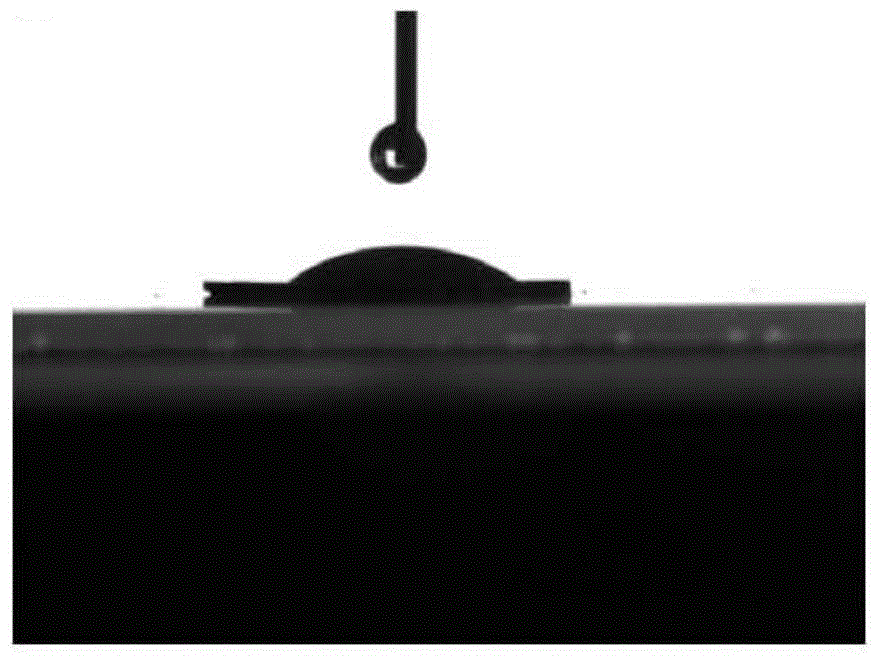

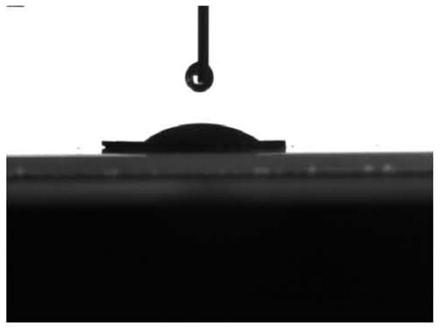

Water-based drilling fluid for shale horizontal well and preparation method of water-based drilling fluid

ActiveCN106147728AEnvironmentally friendlyLow costDrilling compositionWater basedPetroleum engineering

The invention relates to water-based drilling fluid for a shale horizontal well. The water-based drilling fluid comprises a reverse wetting agent. The invention further relates to a preparation method of the water-based drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

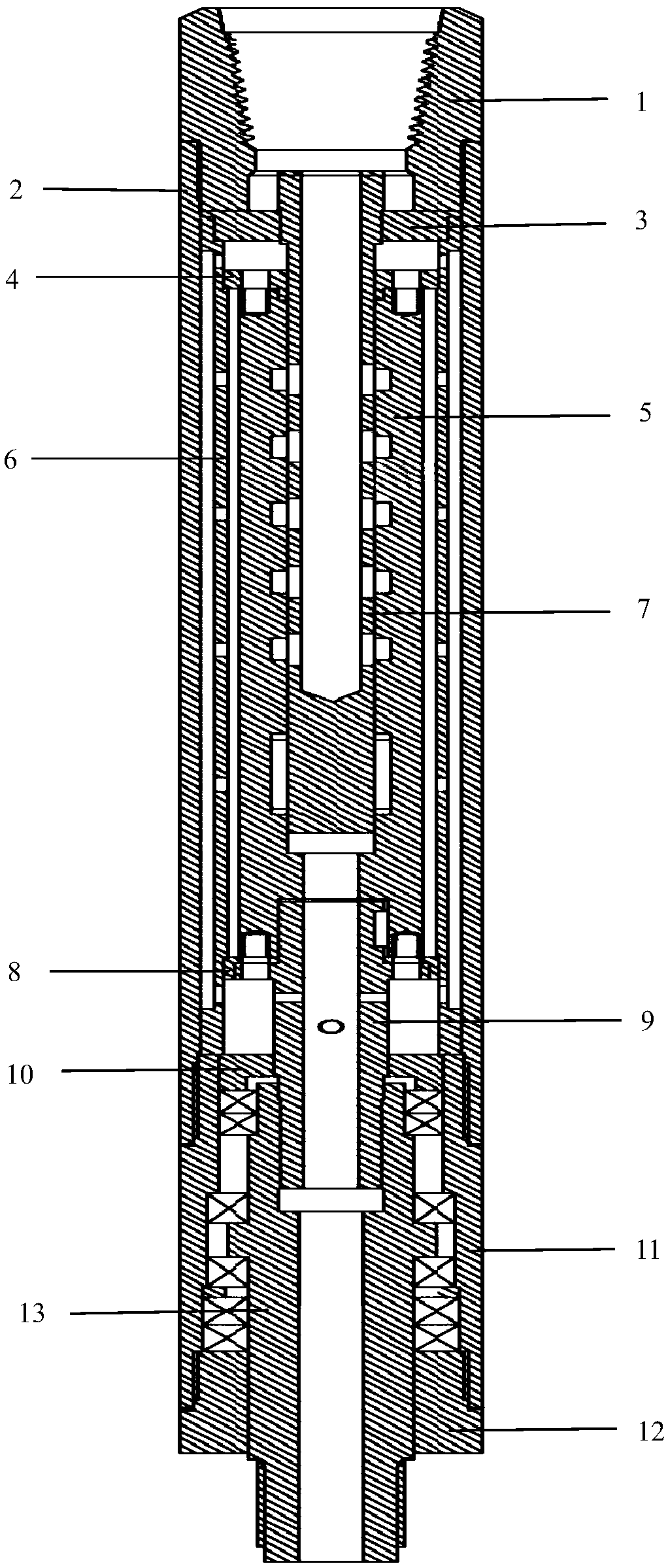

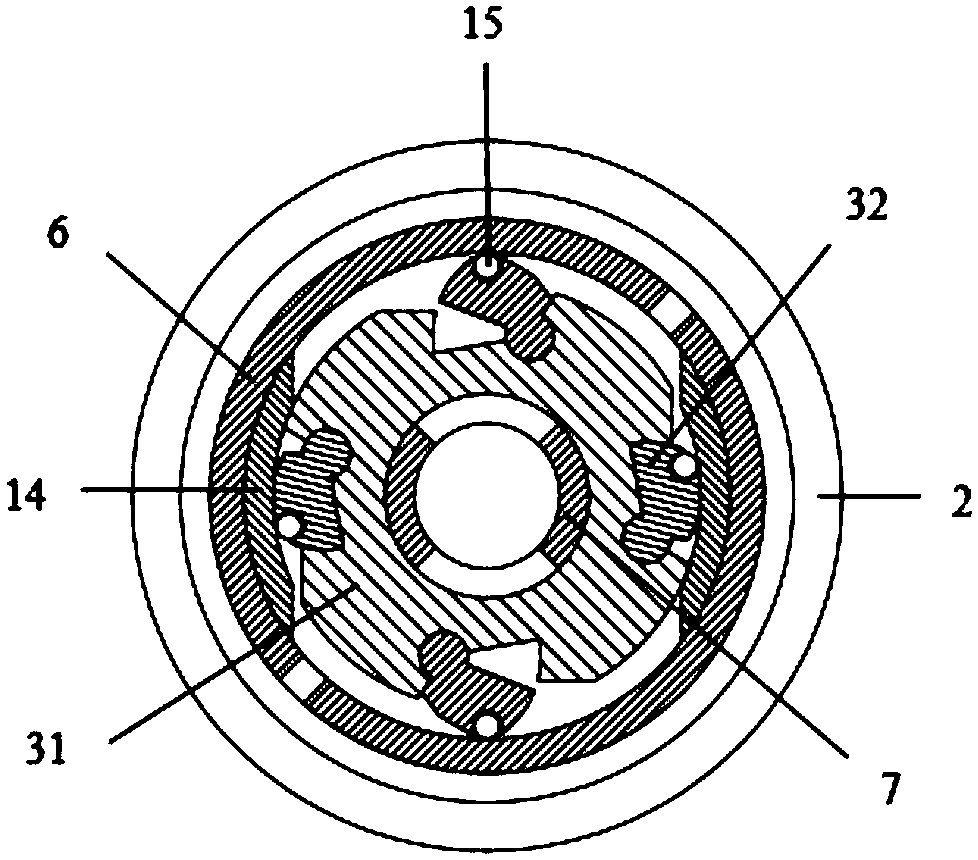

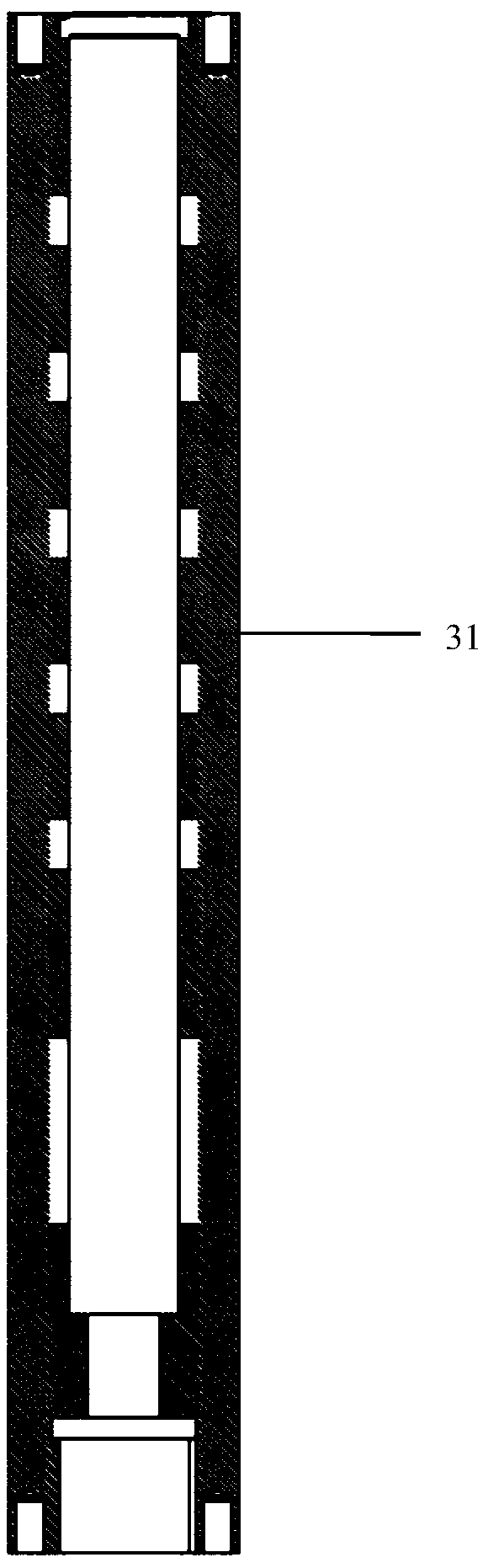

Dynamic push-abutting type rotary motor

PendingCN109505728AExtended service lifeMeet the needs of drillingEarth drilling toolsBorehole drivesTransfer mechanismStator

The invention discloses a dynamic push-abutting type rotary motor used by cooperating with a drill bit. Power is supplied to the drill bit at the position near the drill bit, the drilling rate can beeffectively increased, and the dynamic push-abutting type rotary motor can be used for various drilling technologies such as deep drilling, vertical drilling and a large-displacement horizontal well.The dynamic push-abutting type rotary motor comprises an outer pipe, an upper connector, an upper support, an upper centering ring, a rotor assembly, a sealing rod, a stator, a flow distribution valve, a lower supporting ring, a lower support, a connecting shaft, a connecting sleeve, a lower connector and a main shaft; and the rotor assembly comprises a rotor body and four rotor pushing blocks, and a reset block is arranged between the stator and the rotor assembly. According to the dynamic push-abutting type rotary motor, all the parts are metallic parts and high-temperature-resistant parts,and therefore the dynamic push-abutting type rotary motor can be used in a high-temperature environment at 250 DEG C or above. A volumetric fluid pressure transfer mechanism is applied in the workingprocess of the motor, the advantages of a screw motor are inherited well, no rubber part is used for sealing, and therefore the service life of the motor is effectively prolonged.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

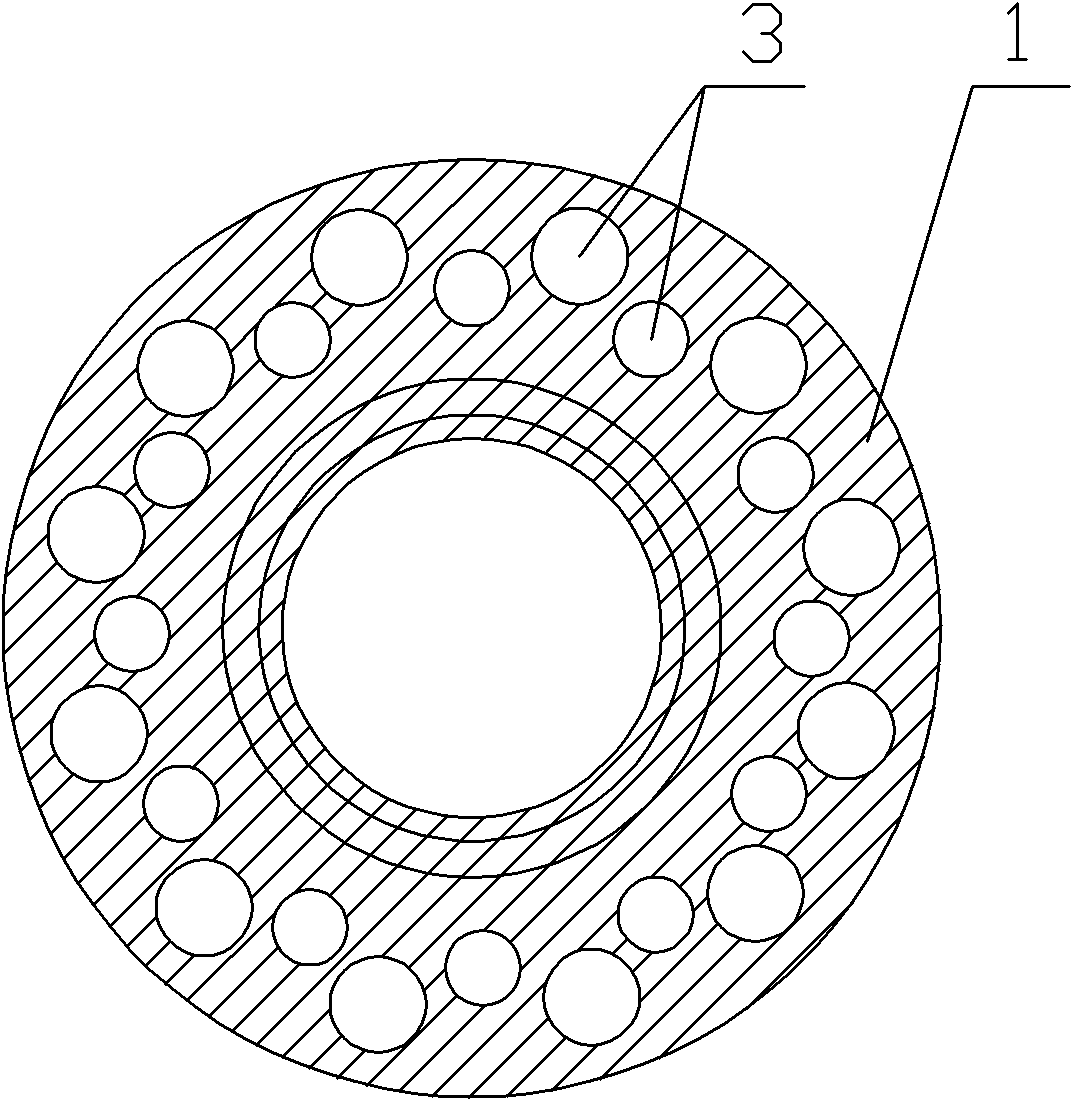

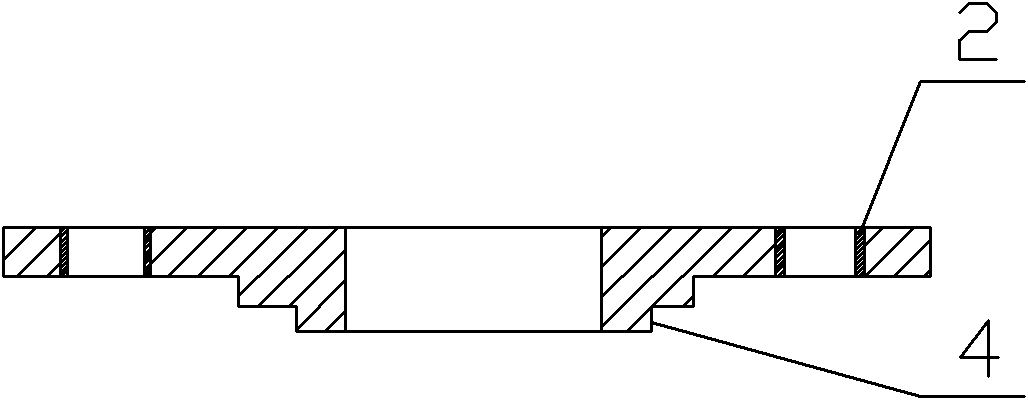

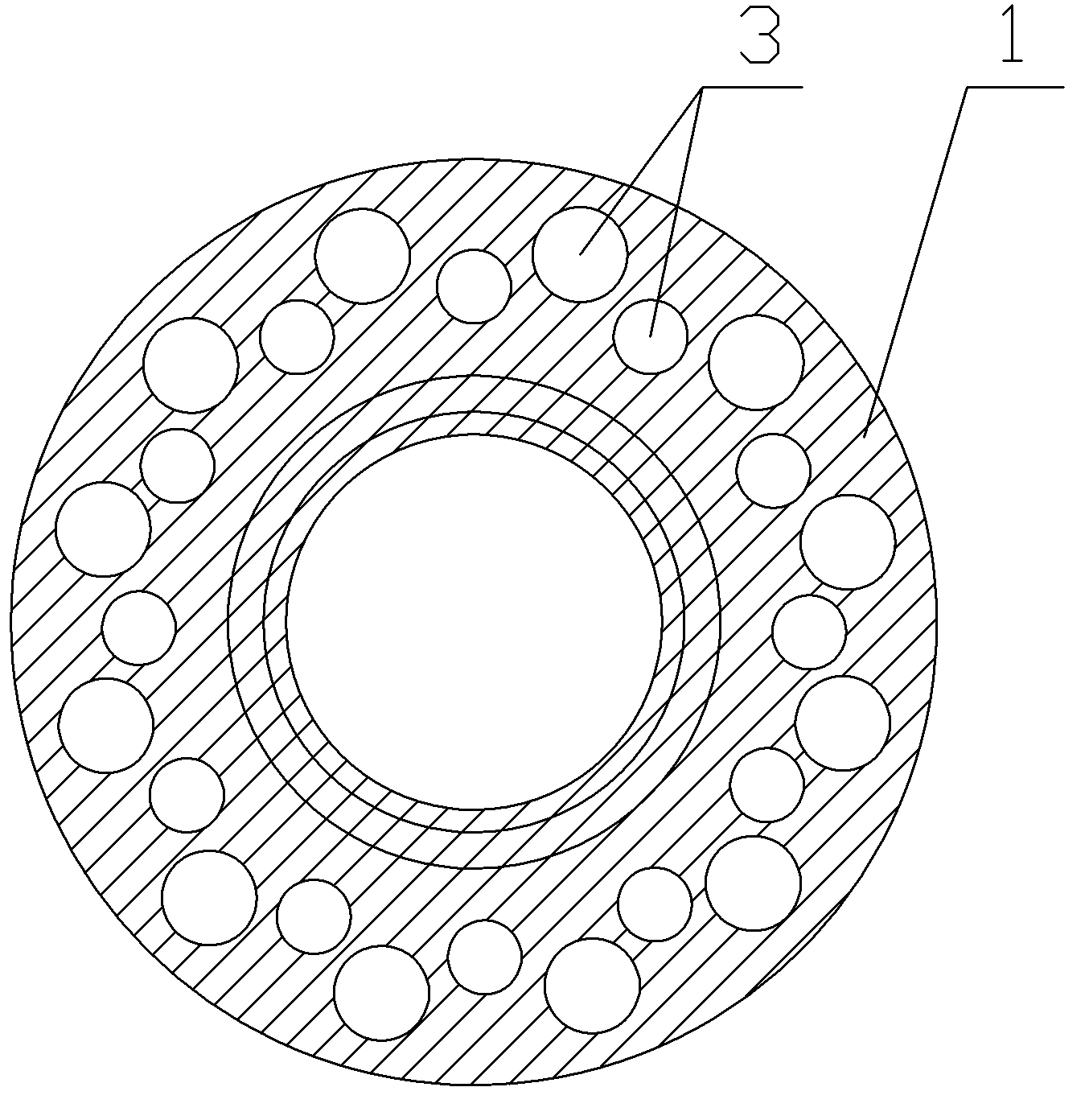

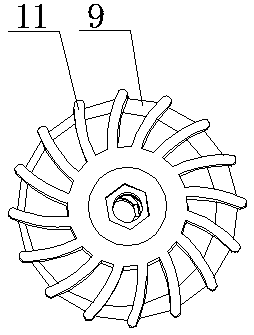

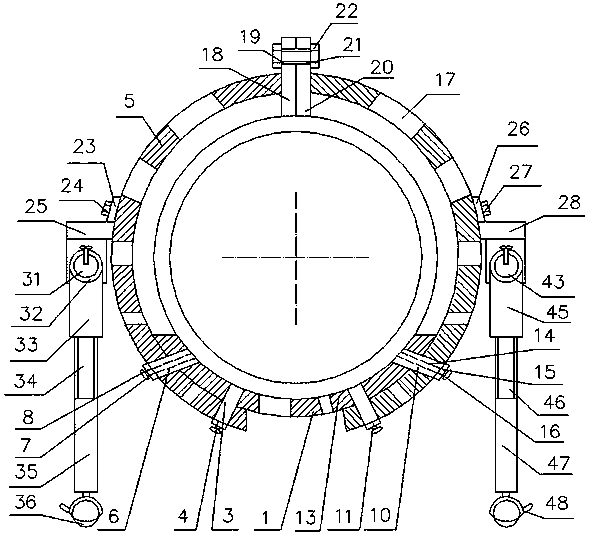

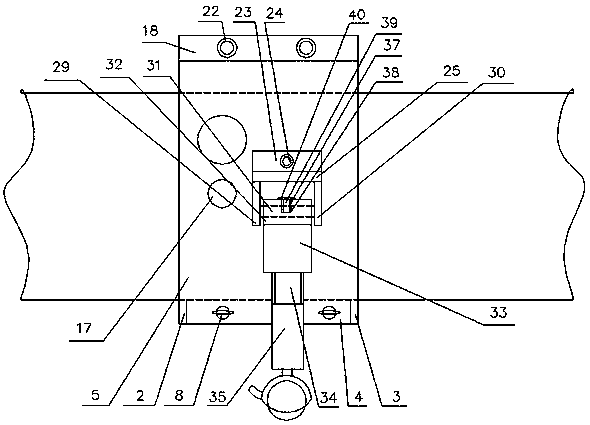

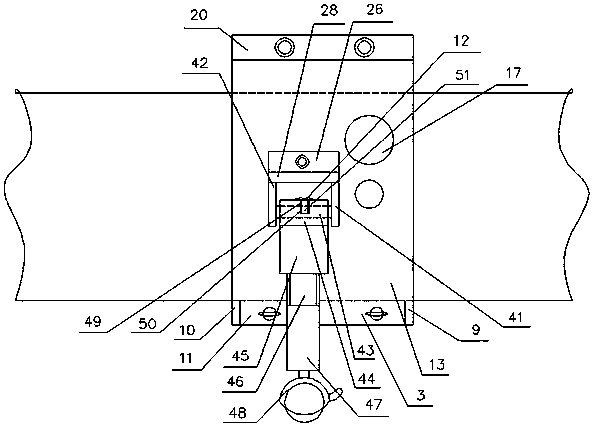

Drilling mould for flange connection hole at side of butterfly valve

InactiveCN101941091AGuaranteed interchangeabilityMeet the needs of drillingPositioning apparatusMetal-working holdersMating connectionButterfly valve

The invention relates to a drilling mould for a flange connection hole at the side of a butterfly valve, mainly comprising a ring-shaped drilling mould body and a drilling jig, wherein the ring-shaped surface of the drilling mould body is evenly distributed with drilling jig connection holes in cooperative connection with the drilling jig; and the concentric circle at one side of the drilling mould body is provided with a step table round spigot matched with the inner hole diameter of the butterfly valve body. The invention brings the beneficial effects of saving the labor and time consuming benchwork lining process and completing the drilling via directly installing the mould, guaranteeing the correct position of each hole and ensuring the interchangeability of the flange connection hole at the side of the butterfly valve. A double-row drilling jig connection hole design is adopted to satisfy the drilling demand of two flange connection holes with different specifications at the side of the butterfly valve, enlarge the using range and save the manufacturing cost.

Owner:天津津通瓦特阀门制造有限公司

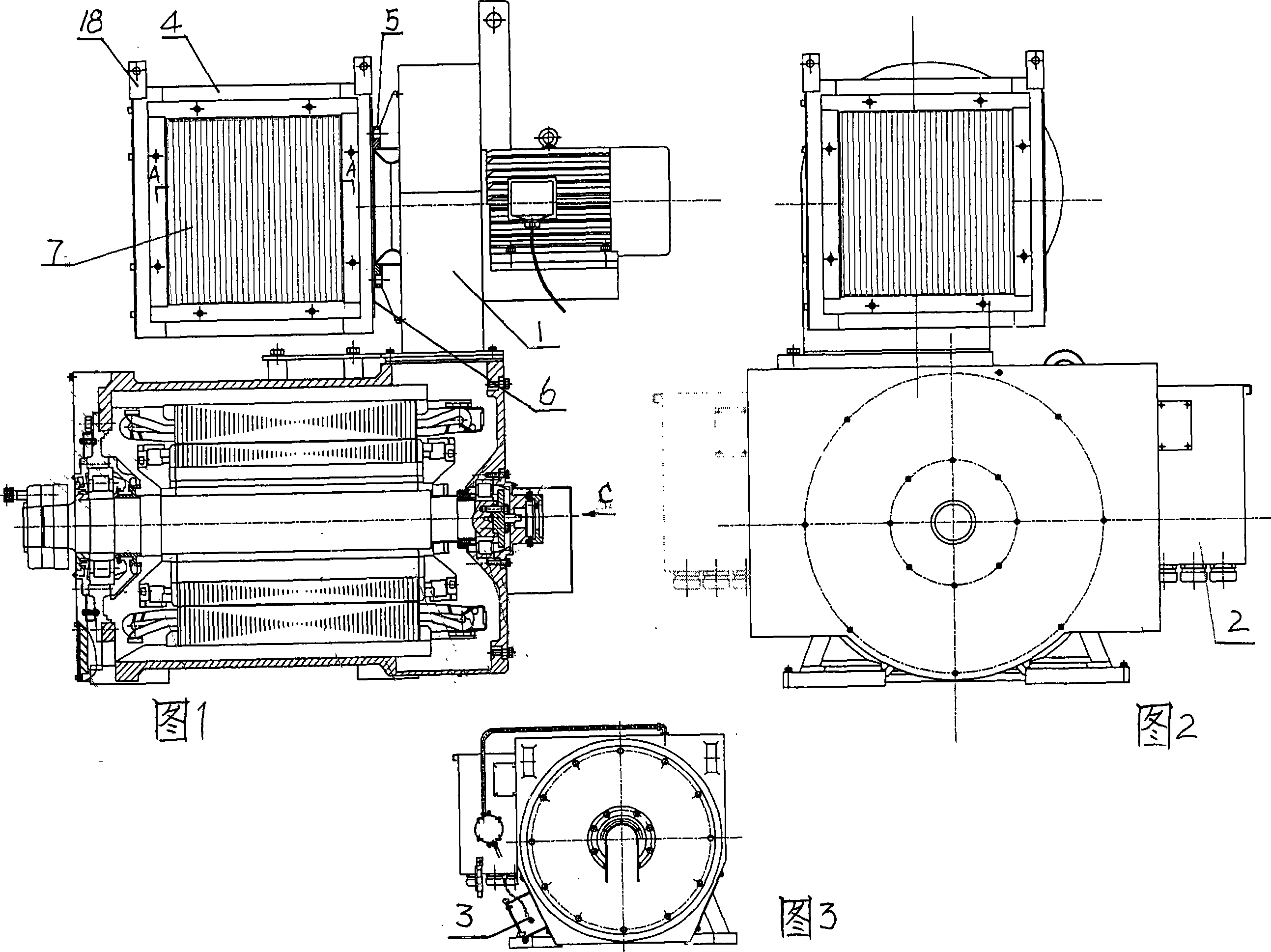

Asynchronous motor for oil field welldrilling

InactiveCN101022237AThe structure and function of the whole machine are perfectSupport development levelAsynchronous induction motorsManufacturing dynamo-electric machinesPetroleumOil field

This invention relates to an asynchronous motor including a centrifugal fan and a fan filter fixed on the top of a base, a junction box fixed on both sides of the base and a heater fixed on the base bottom, in which, the filter layer of the filter is improved so as to increase filter effect, three-phase copper lines are fixed in the box to increase current density, an anti-explosion structure is added in the heater to suit the worse situation of oil wells.

Owner:CRRC YONGJI ELECTRIC CO LTD

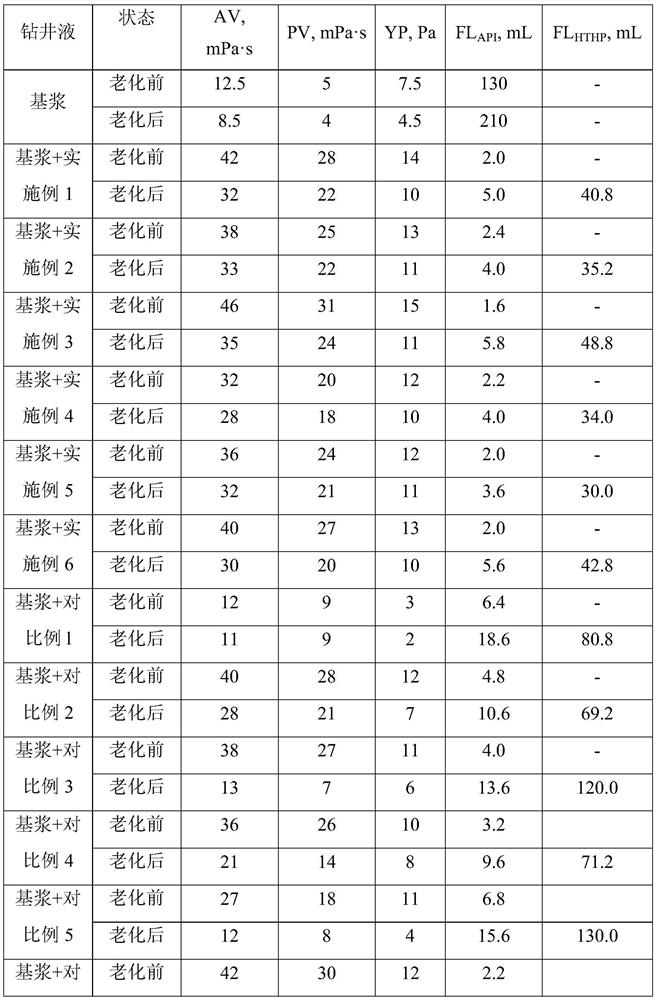

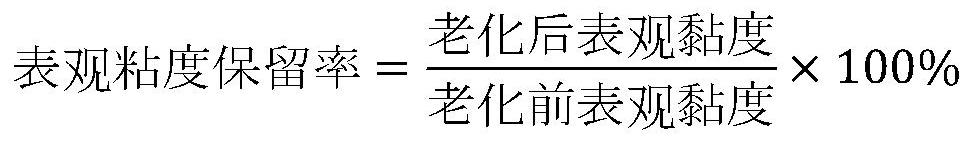

High-temperature-resistant and high-salt-resistant micro-crosslinking hydrophobic association tackifying filtrate reducer for water-based drilling fluid and preparation method of high-temperature-resistant and high-salt-resistant micro-crosslinking hydrophobic association tackifying filtrate reducer

PendingCN114773539AGood high temperature and salt resistanceReduce fluid lossDrilling compositionMaleic anhydrideCo solvent

The invention provides a high-temperature-resistant and high-salt-resistant micro-crosslinking hydrophobic association tackifying filtrate reducer for a water-based drilling fluid and a preparation method of the high-temperature-resistant and high-salt-resistant micro-crosslinking hydrophobic association tackifying filtrate reducer. The tackifying filtrate reducer is prepared by copolymerizing a comonomer, a cross-linking agent, a cosolvent and an initiator in water, the comonomer comprises a vinyl monomer, sodium p-styrenesulfonate, maleic anhydride and a long hydrophobic chain ester monomer; wherein on the basis of 100 parts by weight of water, the comonomer accounts for 20-45 parts, and the cosolvent accounts for 0.5-1.5 parts; the mass of the cross-linking agent is 0.4-2% of the mass of the comonomer; and the mass of the initiator is 0.2-0.5% of the mass of the comonomer. The invention also provides a preparation method of the filtrate reducer. Under the high-temperature and high-salt conditions, the viscosity-increasing and filtrate-reducing agent can effectively reduce the filter loss of the drilling fluid, improve the viscosity of the drilling fluid and maintain the rheological stability of the drilling fluid, and can be applied to deep high-salt-content stratum oil and gas drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

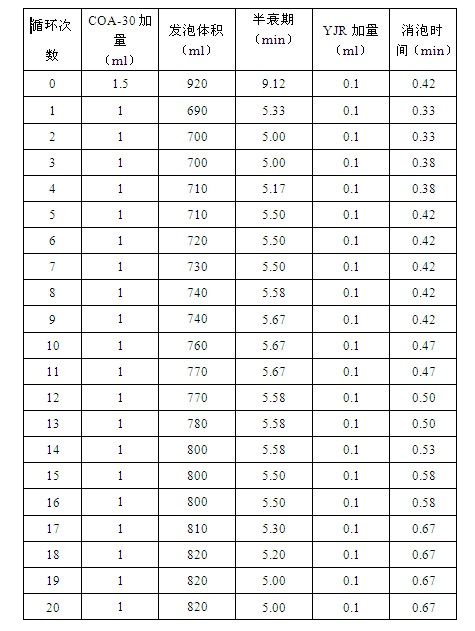

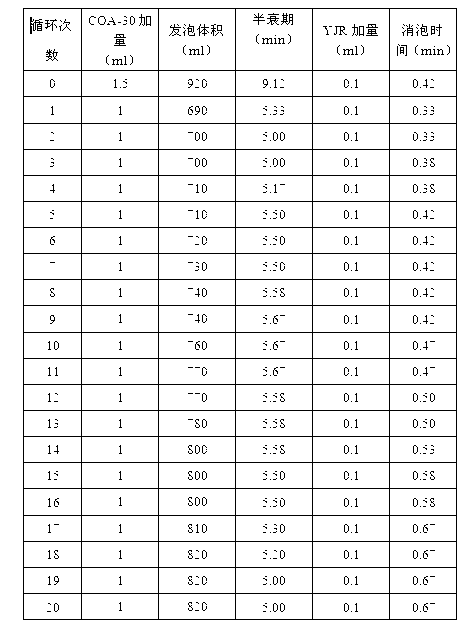

Circulated stable foams

The invention discloses circulated stable foams and relates to the technical field of foams in industries such as petroleum and gas exploitation, mining, and the like. The circulated stable foams comprise a base fluid and a de-foaming agent, wherein the base fluid comprises following components in parts by weight: 0.5-1.5 parts of foaming agent, 0.1-0.3 parts of stabilizing agent, 6-8 parts of inhibitor, 1-3 parts of wetting reversal agent and 100 parts of water; the de-foaming agent is silicone oil emulsion type de-foaming agent; and the percent by volume of the base fluid and the de-foamingagent is 0.066-0.068%. By using the circulated stable foams provided by the invention, the economical efficiency and applicability of the foam drilling can be increased and stabilized and the environmental pollution caused by the foams can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

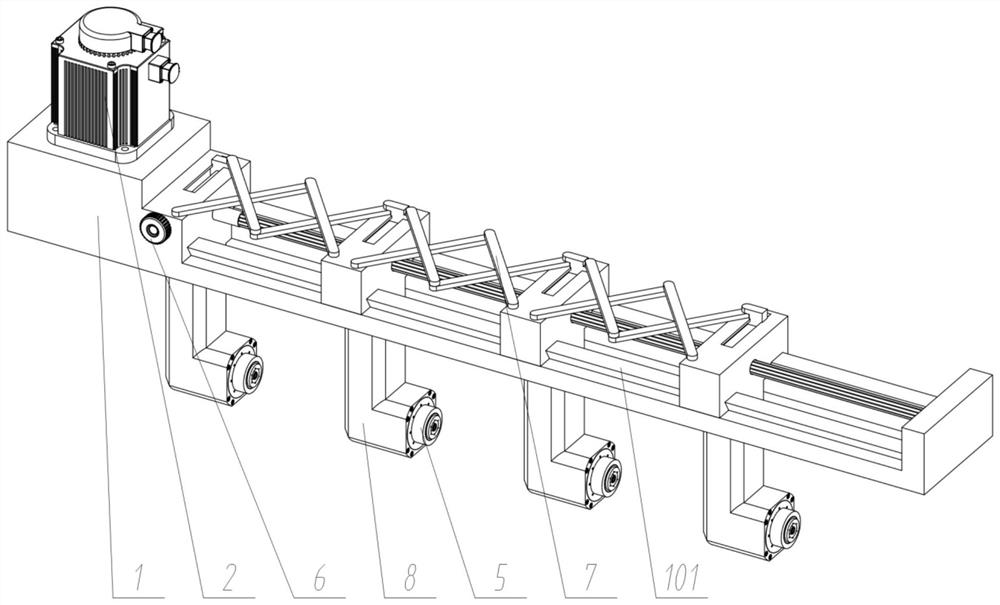

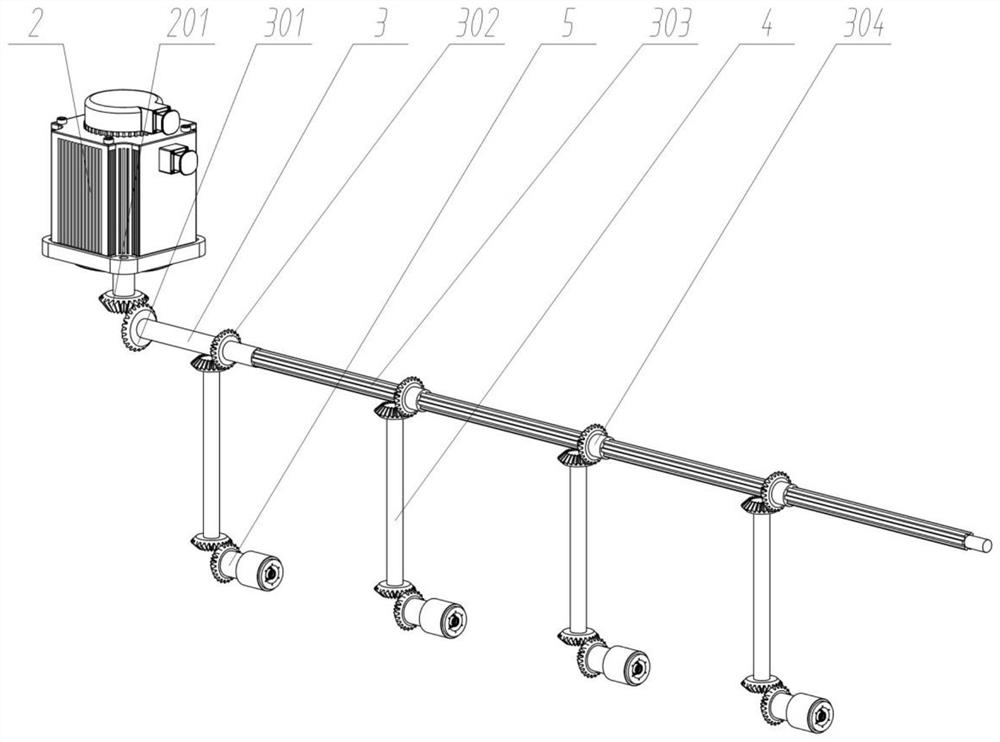

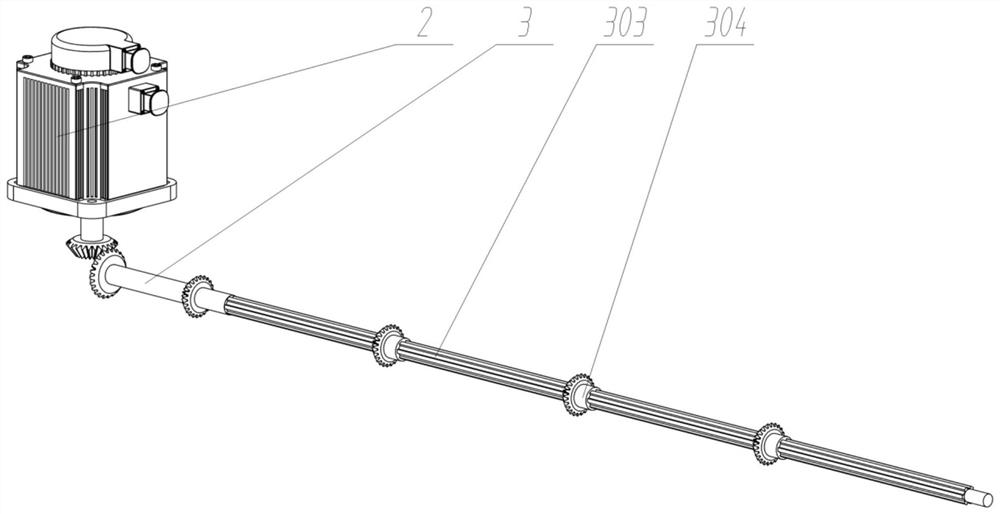

Matched drill boom facility of mining equipment bucket

PendingCN113059209ADrilling to achieveEven distance adjustmentLarge fixed membersBoring/drilling machinesStructural engineeringMachining

The invention discloses a matched drill boom facility of a mining equipment bucket, relates to the technical field of equipment processing, and solves the problems that repeated positioning errors easily occur during the processing of existing bucket lug plate holes, the form and location tolerance of the bucket lug plate holes is influenced, and the bucket lug plate holes are inconsistent. The matched drill boom facility comprises a drill boom body, wherein the top of the left side of the drill boom body is fixedly connected with a group of drilling driving pieces, a group of drilling middle transmission transverse shafts are rotationally connected into the drill boom body, and four groups of drilling bases are uniformly arranged at the lower part of the drilling boom body. By arranging the four groups of drilling bases, four groups of holes in a vertical plate can be drilled at the same time, the working efficiency is improved, meanwhile, repeated positioning errors are avoided, the machining precision is guaranteed, the problem that bucket lug plate holes are inconsistent is effectively solved, meanwhile, the distances between the four groups of drilling bases are evenly adjusted and can be adjusted according to needs in use, machining of buckets of different models is met, practicability is improved, and adjusting operation is easy.

Owner:张芳

Soluble weighting salt low-damage drilling fluid and preparation method thereof

InactiveCN103045190BRheology is easy to adjustHigh densityDrilling compositionInorganic saltsAlkalinity

The invention discloses a soluble weighting salt low-damage drilling fluid and a preparation method thereof. The soluble weighting salt low-damage drilling fluid comprises the following components in percentage by mass: 10-20% of organic salt, 3-5% of inorganic salt, 0.1-0.3% of viscosifier, 0.5-1.0% of fluid loss agent, 0.5-5.0% of temporary shielding agent, 0.1-0.3% of alkalinity control agent, 0.03-0.1% of preservative, 0.5-0.8% of deoxidant, 0.1-0.2% of corrosion inhibitor and the balance of water. The soluble weighting salt low-damage drilling fluid disclosed by the invention has stable performance and high liquid phase density, is easy to regulate, realizes good rheological property, can effectively protect the storage layer, maintain stability of the well wall and improve the drilling encounter ratio of the storage layer, and is particularly suitable for a horizontal-section storage layer of mudstone.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

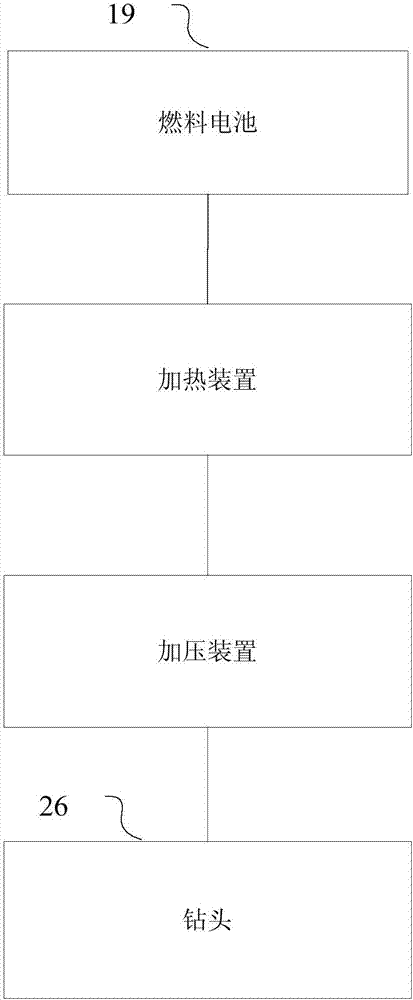

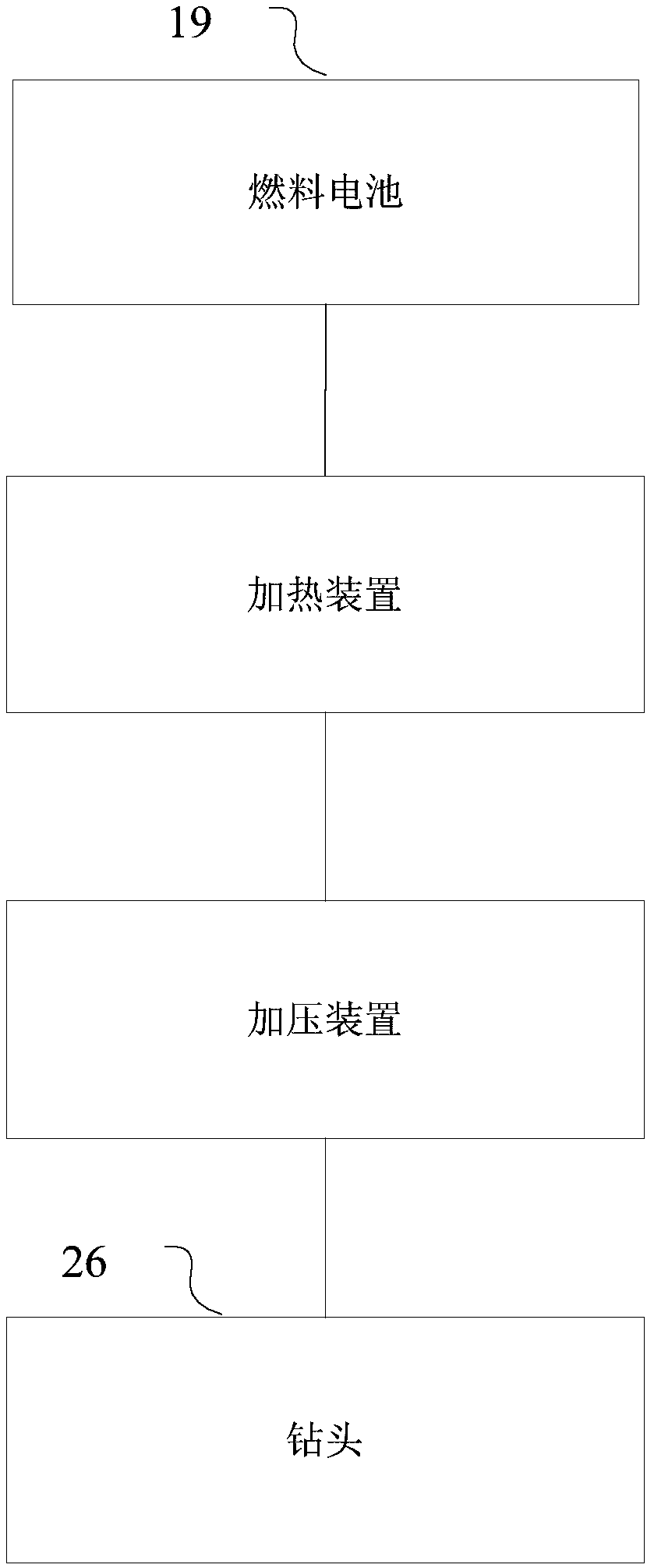

Underground power drilling bit device

ActiveCN106869795AMeet the needs of drillingReduce energy lossDrill bitsDrilling rodsFuel cellsHydrogen

The invention provides an underground power drilling bit device, and relates to the technical field of energy drilling. The underground power drilling bit device includes fuel batteries, a heating device, a pressurization device, and a drilling bit; the fuel batteries are used for receiving the hydrogen and the oxygen which are conveyed by an external portion, and allowing the hydrogen and the oxygen to perform reaction so as to release heat and electric energy; the heating device is used for absorbing the heat to perform heating on a drilling fluid, and forming supercritical drilling fluid to accelerate drilling at a specific temperature and pressure; and the pressurization device is used for pressurizing the gasified drilling fluid under the action of the electric energy, and ejecting the pressurized drilling fluid via the drilling bit so as to perform jet drilling. The underground power drilling bit device can achieve high-efficient and rapid drilling, can reach a greater drilling depth, and can meet the demand of drilling currently.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of plate drilling device with variable diameter of drill bit

ActiveCN106985219BAvoid compromising qualityMeet the needs of drillingStationary drilling machinesPunchingElectric machinery

The invention discloses a plate punching device with a variable-diameter drill head. A frame is connected with a control console and a motor; the motor is connected with a cylinder; the cylinder is connected with a rotary disc; the rotary disc is connected with the drill head and provided with a first through hole; the drill head comprises a small drill head and a diameter increasing drill head; the diameter increasing drill head is provided with an open pore; a drill body is in spline connection with the diameter increasing drill head; a gear is rotationally arranged on the drill body; a second through hole is formed in the drill body; racks are arranged in the first through hole and the second through hole in a sliding mode; the gear is engaged with the racks; a plurality of gear teeth are arranged on the inner wall of the diameter increasing drill head and engaged with the gear; a groove is formed in the drill body; an arc block is arranged in the groove in a sliding mode; a spring is connected between the arc block and the inner wall of the groove; an iron block is connected to the arc block; and a solenoid is arranged inside the groove. Compared with the prior art, the plate punching device has the advantages that the diameter of the drill head can be conveniently adjusted and pores with different pore diameters can also be machined in plates.

Owner:重庆市永川区植成家俱厂

Low-corrosion low-solid phase high-inhibition drilling fluid and preparation method thereof

ActiveCN103045191AReduce corrosionAlleviate the problem of high solid phase and high friction after the inert solid phase is aggravatedDrilling compositionAlkalinityPreservative

The invention discloses a low-corrosion low-solid phase high-inhibition drilling fluid and a preparation method thereof. The low low-corrosion low-solid phase high-inhibition drilling fluid comprises the following materials in percentage by weight: 10%-20% of soluble weighting agents, 0.1%-0.3% of viscosifiers, 0.5%-1.0% of fluid loss additives, 0.1%-0.3% of alkalinity control agents, 0.5%-0.8% of deoxidizers, 0.1%-0.2% of inhibitors, 0.03%-0.05% of preservatives and the balance of water. The low low-corrosion low-solid phase high-inhibition drilling fluid disclosed by the invention has good liquid-phase weighting capability, realizes the low-solid phase and high-inhibition characteristic and can solve the corrosion problem of the traditional drilling tool due to a low-corrosion characteristic.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

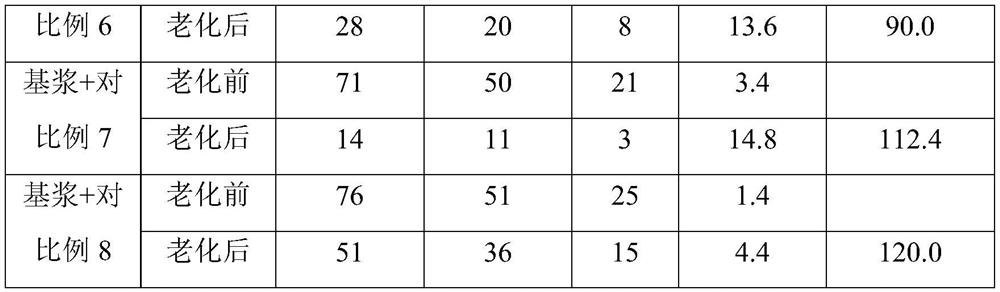

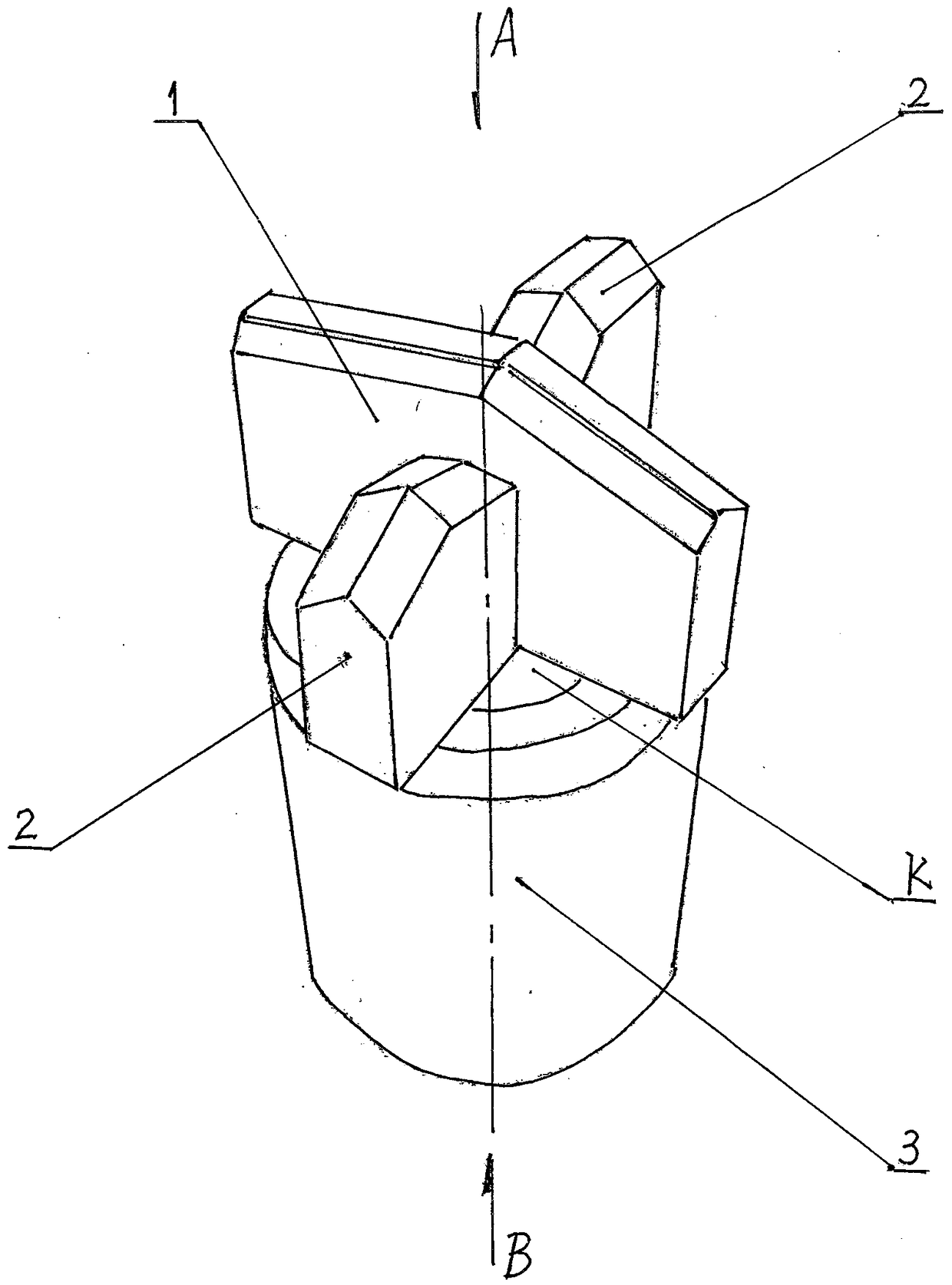

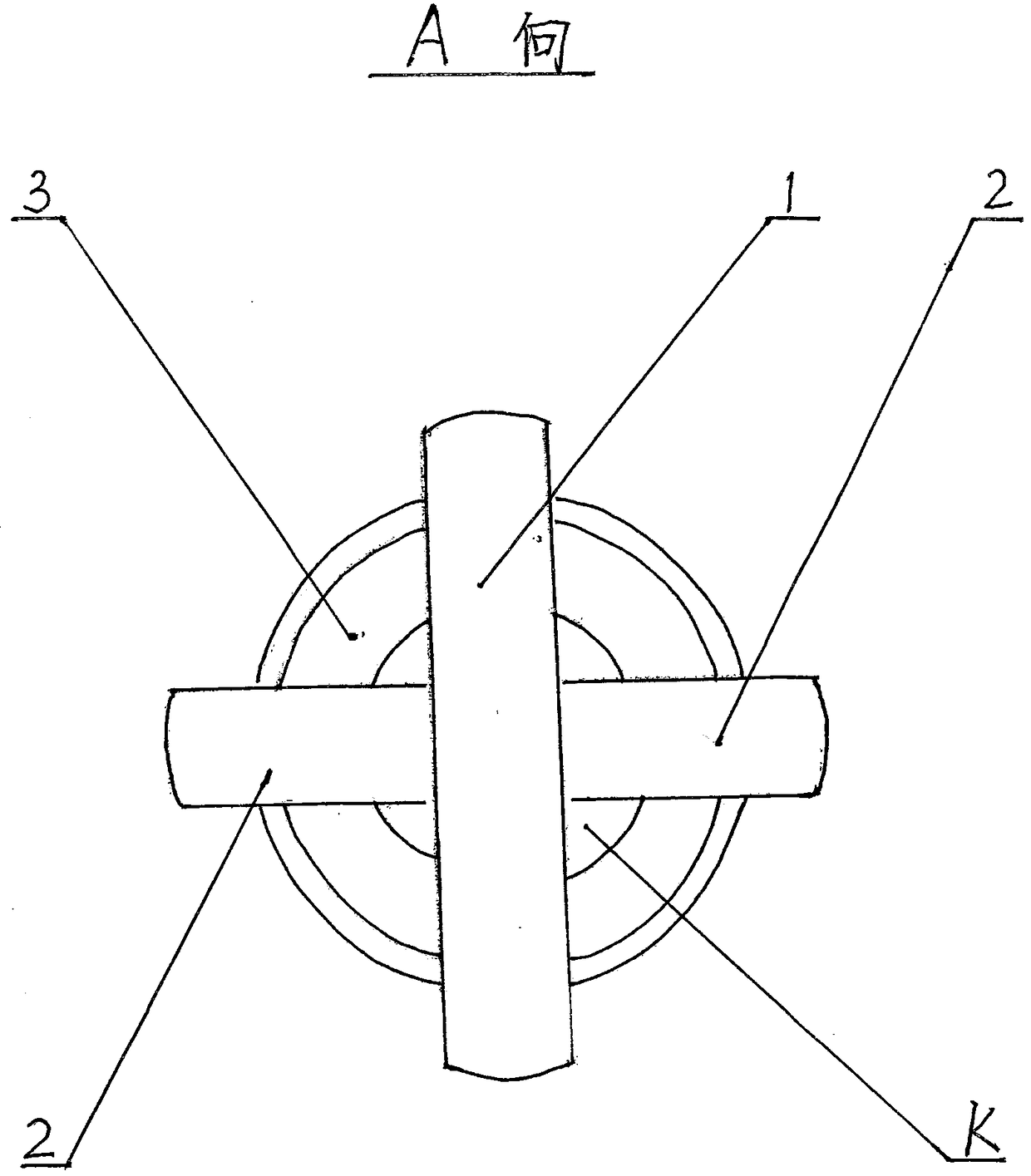

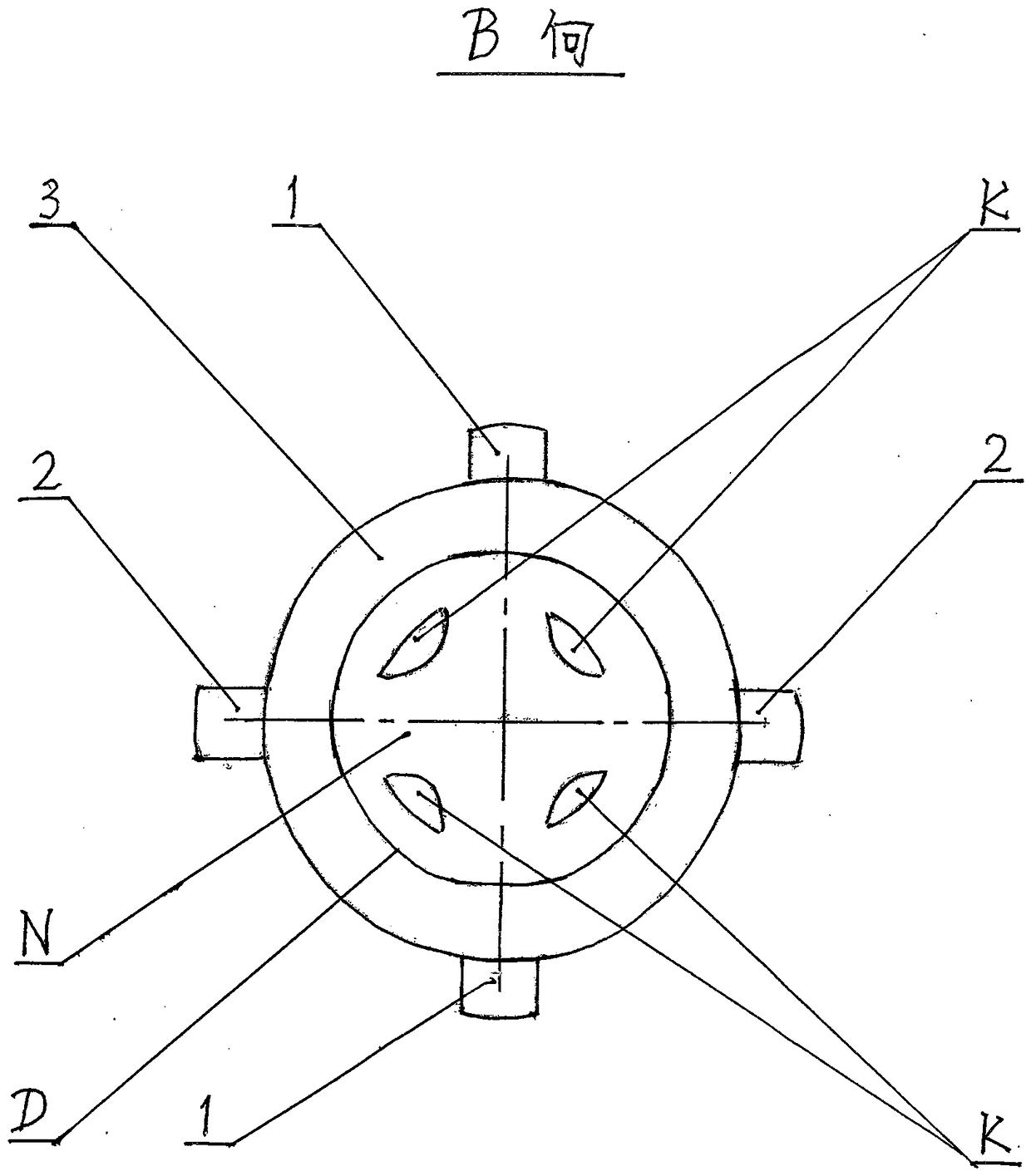

Conjoined cross drill bit for drilling blast furnace molten iron outlet and production method of conjoined cross drill bit

PendingCN109136435AImprove stabilityHigh drilling straightnessBlast furnace componentsBlast furnace detailsWhole bodyEconomic benefits

The invention discloses a conjoined cross drill bit for a drilling blast furnace molten iron outlet and a production method of the conjoined cross drill bit. A die bowl (6) is internally provided witha produced sand core (7), wherein a carbide bit (8) is putted on the sand core (7); the carbide bit (8), a longitudinal bit matrix and a transverse bit matrix form a cross drill bit top (1); after adrill bit matrix (5) is arranged on the sand core (7) and fixed, a gap between the drill bit matrix (5) and the sand core (7) is filled with an alloy powder; the die bowl (6) is equipped with an upperdie sleeve (9); the upper die sleeve (9) is filled with alloy particles; the whole body is putted into a sintering furnace, is electrified, heated to 1100 to 1200 DEG C and insulated for 6 to 8 hours; after power failure and cooling, the upper die sleeve (9) is opened. The carbide bit (8), melted alloy particles and alloy powder are subjected to sintering infiltration to obtain the drill bit top(1) which is sintered, bonded and fixed with a drill bit handle part (4) to form a whole body. The cross drill bit disclosed by the invention has the advantages of high strength, good safety, suitability for drilling the blast furnace molten iron outlet, long life, low cost, high production efficiency and good economic benefits.

Owner:SHANDONG TOPS DIAMOND BIT CO LTD

Environmental friendly drill of acid sodium pyrophosphate and preparing method thereof

InactiveCN106350037AImprove liquidityLarge solid phase capacityDrilling compositionEnvironmental resistanceAdhesive

The invention provides an environmental friendly drill of acid sodium pyrophosphate, composed of the following raw materials, by weight: 2-5% of sodium pyrophosphate, 0.2-1.5% of adhesive, 0.5-2.0% of filtrate reducer, 5-15% of weighting agent and water. The environmental friendly drill liquid of acid sodium pyrophosphate can not only provide excellent drill wall stabilizing ability, but also provide efficient sand-carrying capacity, and conforms to requirements for environmental protection, meets demands for upper drill section on Ecuador TARAPOA block, and gains good economic benefit and social benefit.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

A kind of shale horizontal well water-based drilling fluid and preparation method thereof

ActiveCN106147728BEnvironmentally friendlyLow costDrilling compositionHorizontal wellsPetroleum engineering

The invention relates to water-based drilling fluid for a shale horizontal well. The water-based drilling fluid comprises a reverse wetting agent. The invention further relates to a preparation method of the water-based drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

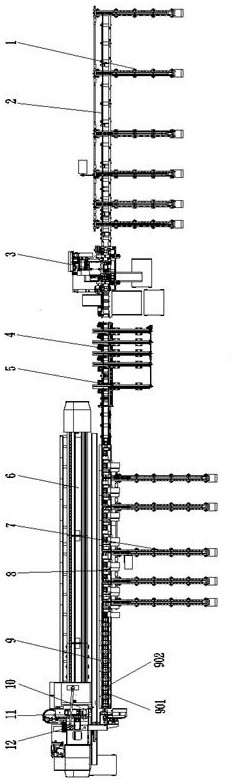

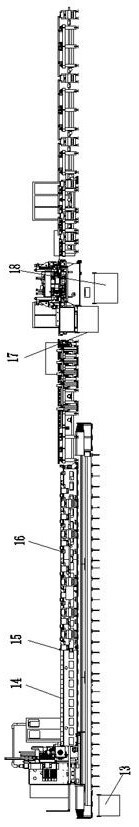

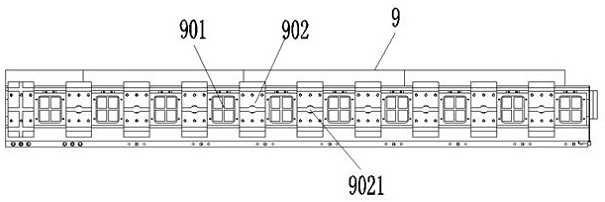

Sawing and drilling combined production line

PendingCN113134738ARealize automatic saw cutting detectionAccurate detectionOther manufacturing equipments/toolsProduction lineAlloy steel

The invention provides a sawing and drilling combined production line. The production line comprises a transverse feeding frame and a longitudinal feeding roller way; a sawing unit is arranged at the tail end of the longitudinal feeding roller way; a longitudinal middle power roller way and a transverse excess material discharging device are arranged at the discharging end of the saw cutting unit; a longitudinal workbench I and a longitudinal workbench II are arranged at the feeding tail end of the longitudinal middle power roller way; one side of the longitudinal workbench I is connected with a transverse discharging frame, and the other side is provided with a drilling unit; the drilling unit comprises a drilling unit lathe bed, a drilling unit stand column, a drilling unit power head and a code spraying system; the longitudinal moving stroke of the drilling unit power head along the drilling unit lathe bed is larger than the longitudinal total length of the longitudinal workbench I and the longitudinal workbench II. Automatic production of saw cutting and drilling of a steel rail piece in an alloy steel assembly frog is achieved; and the machining precision and the production efficiency of an alloy steel important component wing rail are improved. The production line is practical, reliable, labor-saving and efficient.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Tackifier, drilling fluid containing tackifier, and stock solution of drilling fluid

ActiveCN102558425BReduce volumeMeet the requirements of on-site pumpingDrilling compositionCelluloseSodium Bentonite

The invention provides a tackifier, a drilling fluid containing the tackifier, and a stock solution of the drilling fluid. The tackifier is characterized by being able to be passivated and activated. The stock solution of the drilling fluid consists of water, bentonite, polyanion cellulose, xanthan gum, the tackifier and a passivator at the mass part ratio of (85-90) to (4-6) to (0.4-0.6) to (0.3-0.4) to (6-10) to (0.2-0.3). The drilling fluid consists of the stock solution, an activating agent and water at the mass part ratio of (35-85) to (0.2-0.3) to (15-16). The drilling fluid consists of a water solution of the stocking solution and the activating agent, and under the action of the reactivating agent, the passivated tackifier is activated to play a role of tackifying, thereby making up the declination of viscous force and shearing force of the drilling fluid due to dilution of a large quantity of water, and further meeting the requirements on drilling on a deep-water surface.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A downhole dynamic drill bit device

ActiveCN106869795BMeet the needs of drillingReduce energy lossDrill bitsDrilling rodsHydrogenFuel cells

The invention provides an underground power drilling bit device, and relates to the technical field of energy drilling. The underground power drilling bit device includes fuel batteries, a heating device, a pressurization device, and a drilling bit; the fuel batteries are used for receiving the hydrogen and the oxygen which are conveyed by an external portion, and allowing the hydrogen and the oxygen to perform reaction so as to release heat and electric energy; the heating device is used for absorbing the heat to perform heating on a drilling fluid, and forming supercritical drilling fluid to accelerate drilling at a specific temperature and pressure; and the pressurization device is used for pressurizing the gasified drilling fluid under the action of the electric energy, and ejecting the pressurized drilling fluid via the drilling bit so as to perform jet drilling. The underground power drilling bit device can achieve high-efficient and rapid drilling, can reach a greater drilling depth, and can meet the demand of drilling currently.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

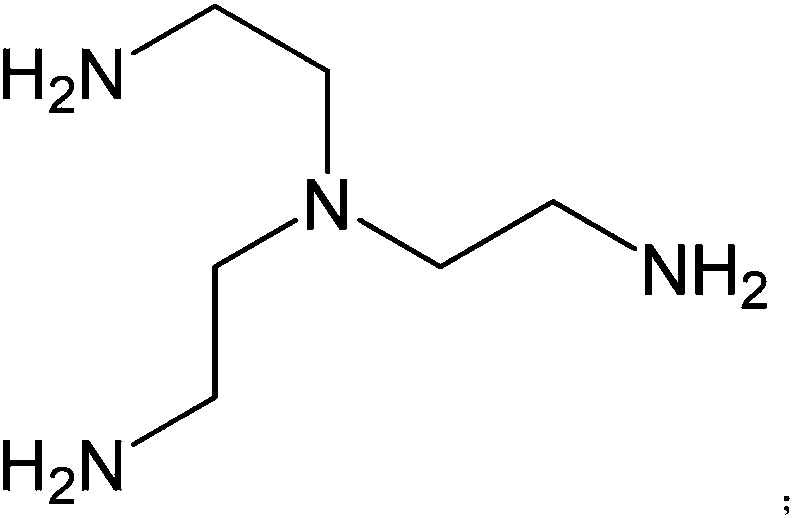

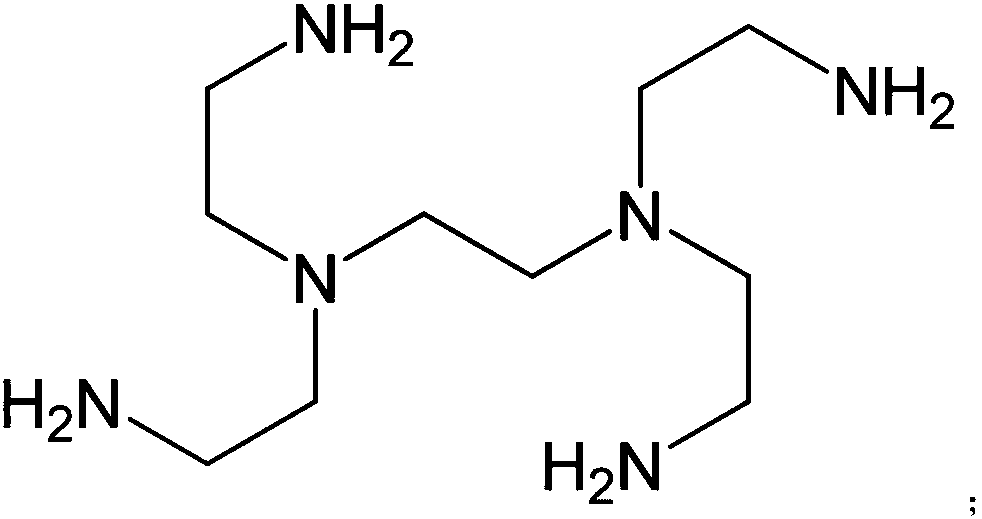

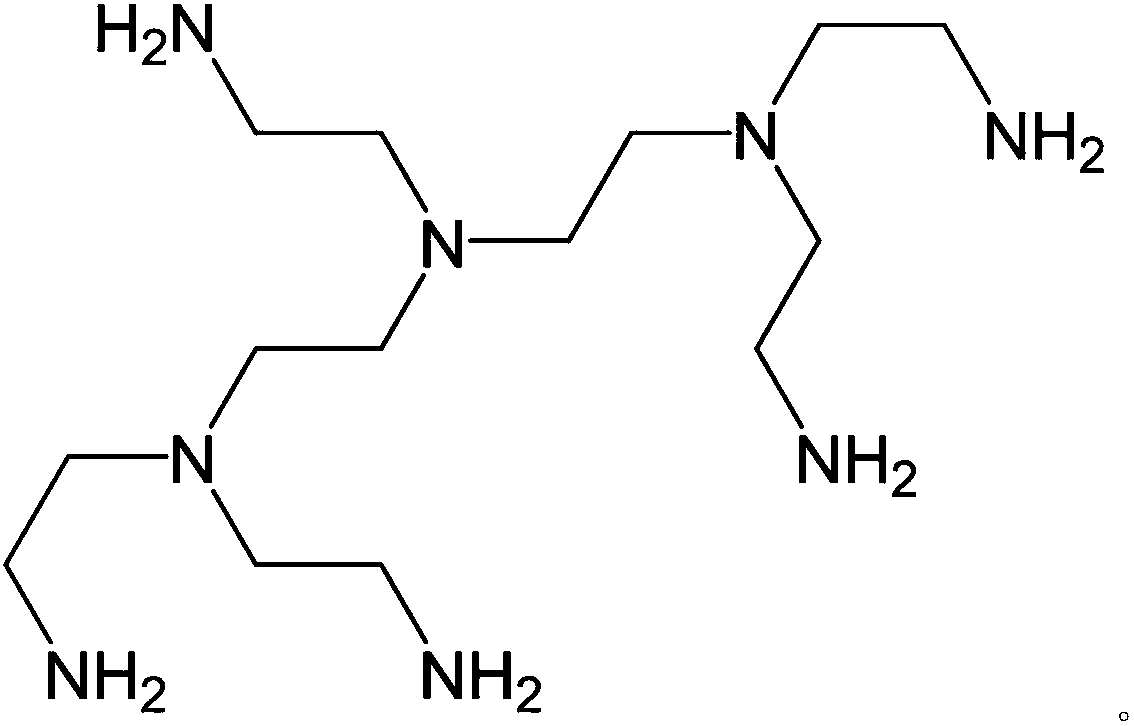

A kind of ultra-low molecular weight intercalation inhibitor and preparation method thereof

ActiveCN106281263BReduce instabilityMeet the needs of useDrilling compositionEnvironmental resistanceDiethylenetriamine

The invention relates to an ultralow-molecular weight intercalation inhibitor and a preparation method thereof. The ultralow-molecular weight intercalation inhibitor contains any one or more of amino triethylamine, ethylenediamine tetraethylammonium and diethylenetriamine pentaethylamine and is prepared from the component and clear water in a ratio of 0.5-3%; the amino triethylamine is synthesized from nitrilotriacetic acid; the ethylenediamine tetraethylammonium is synthesized from ethylenediamine tetraacetic acid; and the diethylenetriamine pentaethylamine is synthesized from diethylenetriamine pentaacetic acid; and the preparation method comprises the following steps: adding the raw materials into absolute ethyl alcohol; adding concentrated sulfuric acid for reacting; adding an organic solvent and introducing ammonia water; and stirring and distilling to obtain the product. According to the invention, the inhibition performance of a drilling fluid system can be remarkably improved, the temperature resistance exceeds 240 DEG C, the needs of ultra-deep well drilling are completely met, and the problem of unstable well wall caused by shale hydration and dispersion is effectively reduced; and moreover, the synthesis technology is simple and environment-friendly, the yield is relatively high, the production cost is low, and the ultralow-molecular weight intercalation inhibitor is suitable for industrial production.

Owner:SOUTHWEST PETROLEUM UNIV

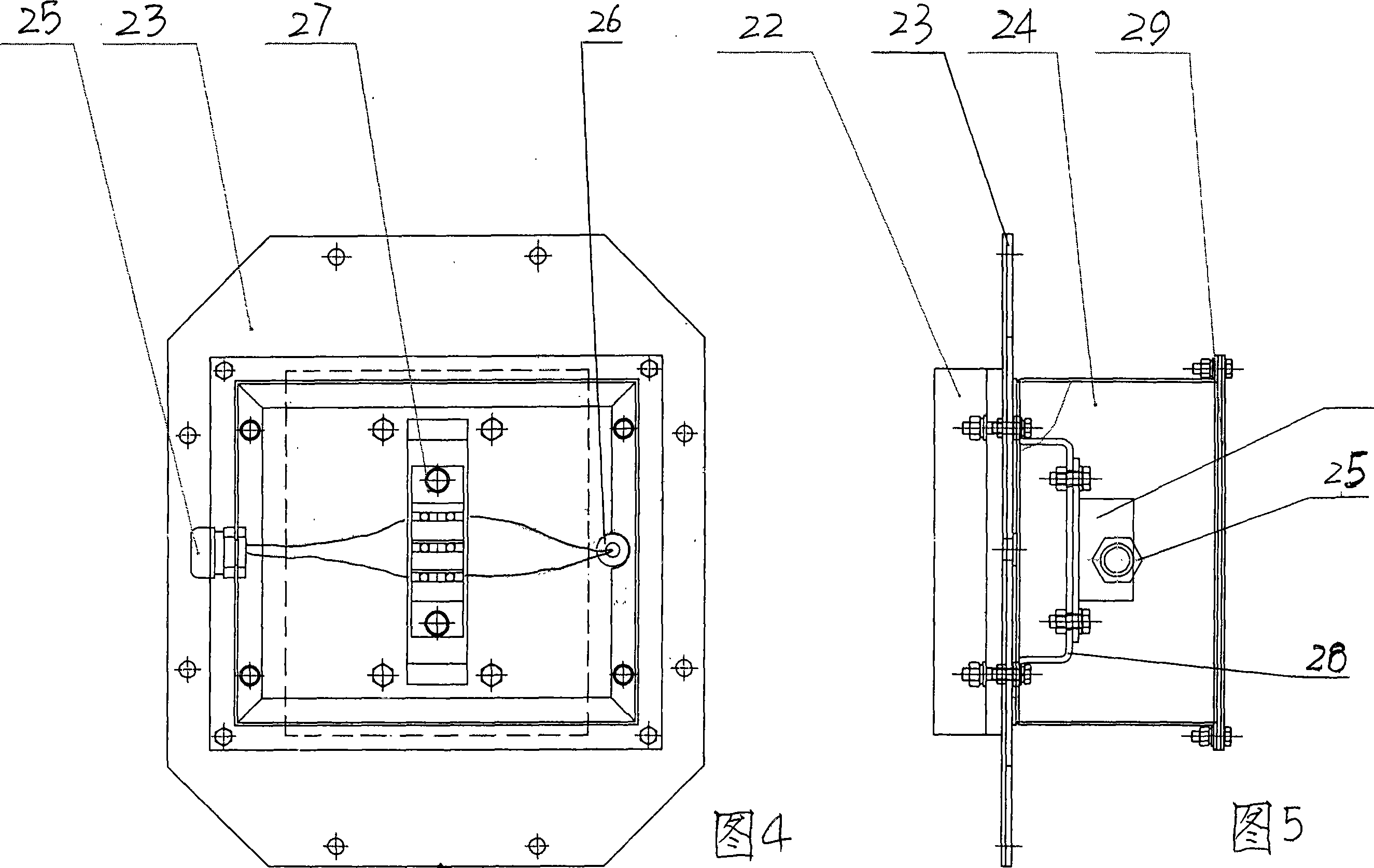

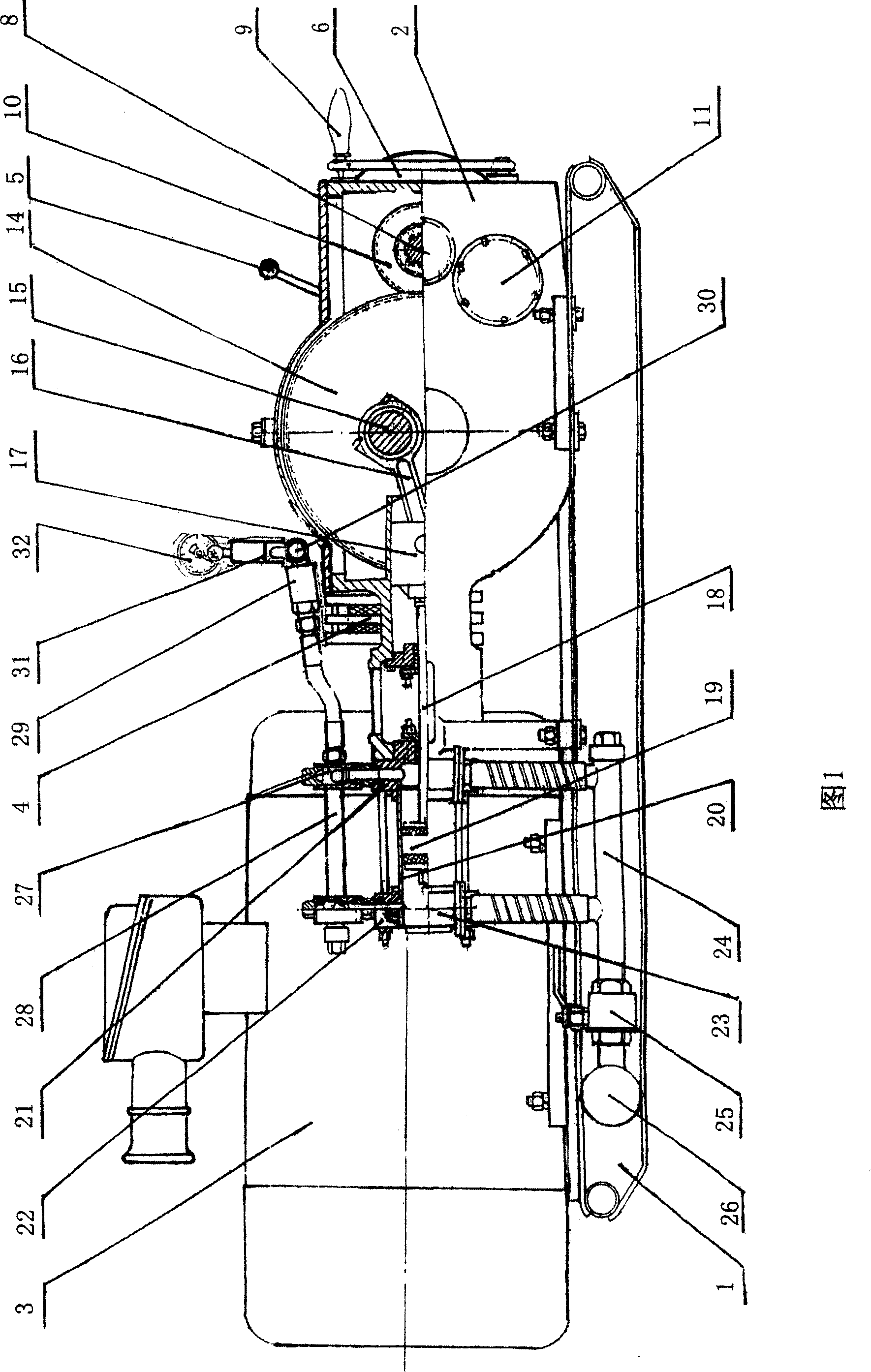

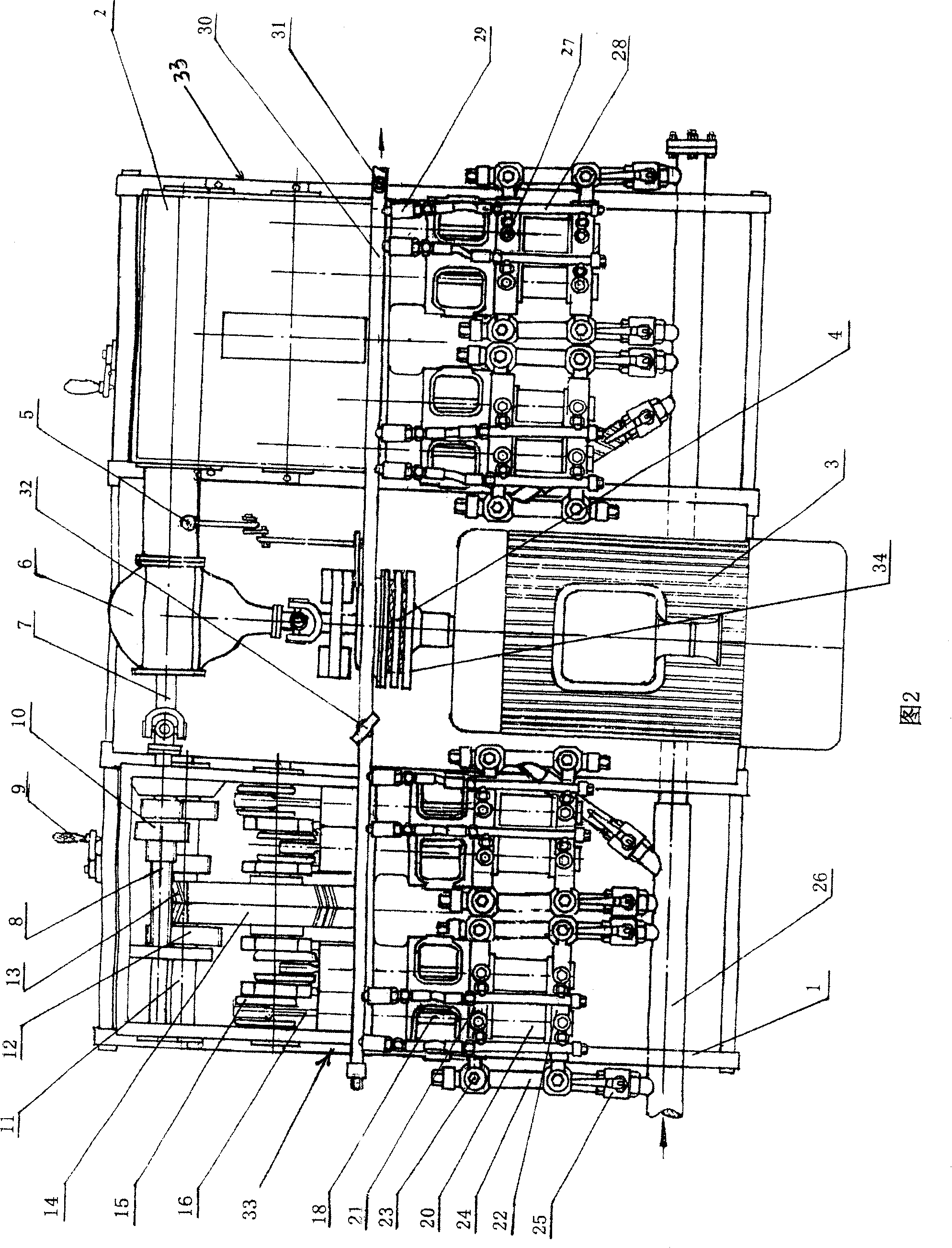

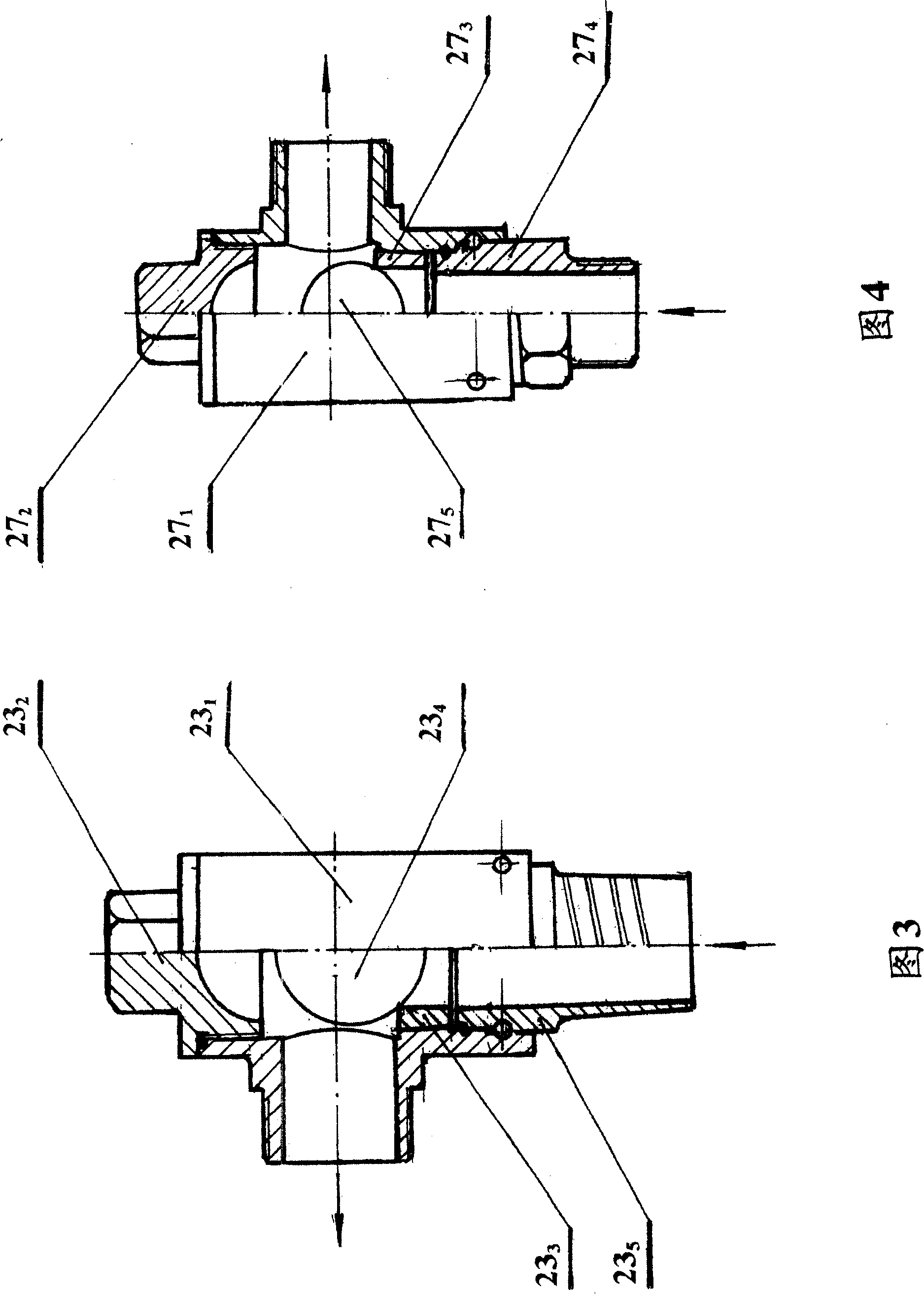

Double-body multi-cylinder high-pressure injection pump

InactiveCN100387835CEasy to operateGood effectPumpsPositive-displacement liquid enginesElectric machineReducer

The invention relates to a dual-element multi-cylinder high-temperature mud injection pump, which comprises two multi-pulp cylinder pumps, an electromotor, a clutch, and a speed reducer. It is characterized in that: said two multi-pulp cylinder pumps have same structure, which are symmetrically arranged at two sides of electromotor; the output axle of electromotor is mounted with clutch, which via universal coupler is connected to the input axle of speed reducer; two sides of speed reducer individually have one output axle; two output axles via universal coupler are connected to the speed-variable slide key axles of relative multi-pulp cylinder pump. The invention has simple operation, easy maintenance, high drilling speed, and reduced cost. The invention uses 8 pulp cylinder pistons to work repeatedly, with lower motion speed (0.15-0.42m / s) and strong self-adsorption ability. The invention has 8 types of electromotor as (75-315kw).

Owner:魏德华

Circulated stable foams

The invention discloses circulated stable foams and relates to the technical field of foams in industries such as petroleum and gas exploitation, mining, and the like. The circulated stable foams comprise a base fluid and a de-foaming agent, wherein the base fluid comprises following components in parts by weight: 0.5-1.5 parts of foaming agent, 0.1-0.3 parts of stabilizing agent, 6-8 parts of inhibitor, 1-3 parts of wetting reversal agent and 100 parts of water; the de-foaming agent is silicone oil emulsion type de-foaming agent; and the percent by volume of the base fluid and the de-foamingagent is 0.066-0.068%. By using the circulated stable foams provided by the invention, the economical efficiency and applicability of the foam drilling can be increased and stabilized and the environmental pollution caused by the foams can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

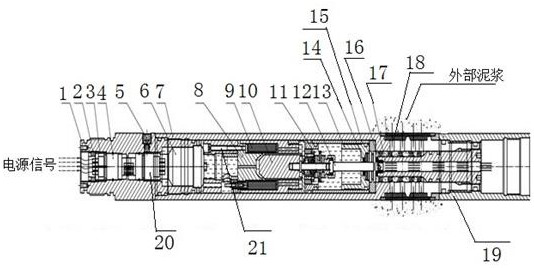

A Small Diameter Metal Piston Type Pulse Generator

The invention provides a small-diameter metal piston-type pulse generating device, wherein one end of the connector fixing sleeve is fixed by a lock nut, and the other end of the connector fixing sleeve is fixed with a connector A, and the connector A is sequentially connected with Connector B, plug seat, the plug seat is connected with the electromagnetic actuator; the static armature is fixed on the shell of the electromagnetic actuator and the wire winding. Spring assembly; there is a sealing device between the ceramic telescopic rod and the balance piston, the overflow sleeve is installed on the telescopic valve, the telescopic valve is fixed in the outer cylinder of the electromagnetic actuator, and a mud filter is installed on the outer cylinder of the electromagnetic actuator. The outer cylinder of the electromagnetic actuator is connected; the advantages are: the invention has strong downhole applicability and meets the needs of various types of drilling; the structure size is small and meets the needs of slim hole drilling; high temperature resistance, high pressure resistance, and erosion resistance are enhanced; the application range is wide, Strong applicability and low downhole risk.

Owner:DONGYING ZHICHENG ELECTROMECHANICAL TECH DEV

Push rod type three-dimensional hydraulic oscillator

ActiveCN111021961AOscillation effect is goodIncrease the oscillation frequencyVibration devicesVibration drillingBall bearingUpper joint

The invention relates to a hydraulic oscillator, in particular to a push rod type three-dimensional hydraulic oscillator. The push rod type three-dimensional hydraulic oscillator is composed of a shell, an upper joint, a lower joint, a one-way valve, a transmission part and an oscillating part. The upper joint is mounted at the end of one end of the shell in a threaded mode. The lower joint is mounted at the end of the other end of the shell in a threaded mode. The transmission part is arranged in the shell on one side of the upper joint. The one-way valve is mounted in the shell between the transmission part and the upper joint. The oscillating part is mounted in the shell between the transmission part and the lower joint through symmetrically arranged ball bearings, and is connected withthe transmission part. The push rod type three-dimensional hydraulic oscillator has the characteristics of good oscillation effect and high oscillation frequency, solves the problems of the simplex oscillation mode and low oscillation frequency of an existing oscillator, and meets requirements of petroleum drilling.

Owner:YANGTZE UNIVERSITY

Gathering pipeline hole drilling device and using method

InactiveCN110253043AAccurate drilling positionMeet the needs of drillingDrill jigsBoring/drilling machinesEngineeringDrill bit

The invention provides a gathering pipeline hole drilling device and a using method. The product comprises a bottom elastic arc plate which is connected with a left front limiting plate and a right front limiting plate; the left front limiting plate and the right front limiting plate are connected through a front limiting plate; a front elastic arc plate is provided with a front fixed screw hole; the front limiting plate is provided with a front positioning screw hole; after the front elastic arc plate and the bottom elastic arc plate are adjusted, the front positioning screw hole and the front fixed screw hole coincide with each other and are fixed through a front hand screwing screw; the bottom elastic arc plate is connected with a left rear limiting plate and a right rear limiting plate which are connected through a rear limiting plate; a rear elastic arc plate is provided with a rear fixed screw hole, the rear limiting plate is provided with a rear positioning screw hole; and after the rear elastic arc plate and the bottom elastic arc plate are adjusted, the rear positioning screw hole and the rear fixed screw hole coincide with each other and are fixed through a rear hand screwing screw; and the bottom elastic arc plate, the front elastic arc plate and the rear elastic plate are each provided with a hole drilling positioning hole, and the hole drilling positioning holes are used in cooperation with a drill bit. The gathering pipeline hole drilling device is used for gathering pipeline hole drilling.

Owner:金广军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com