Dynamic push-abutting type rotary motor

A rotary motor and dynamic technology, applied in the field of drilling, can solve the problems of motor leakage failure, short service life of screw motor, easy to wear, etc., and achieve the effect of improving service life, easy disassembly and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0033] A dynamic push-back rotary motor, used in conjunction with the drill bit, can effectively increase the drilling rate by giving power to the drill bit near the drill bit, and can be used in various drilling processes, such as deep drilling, vertical drilling, extended displacement horizontal wells, etc. .

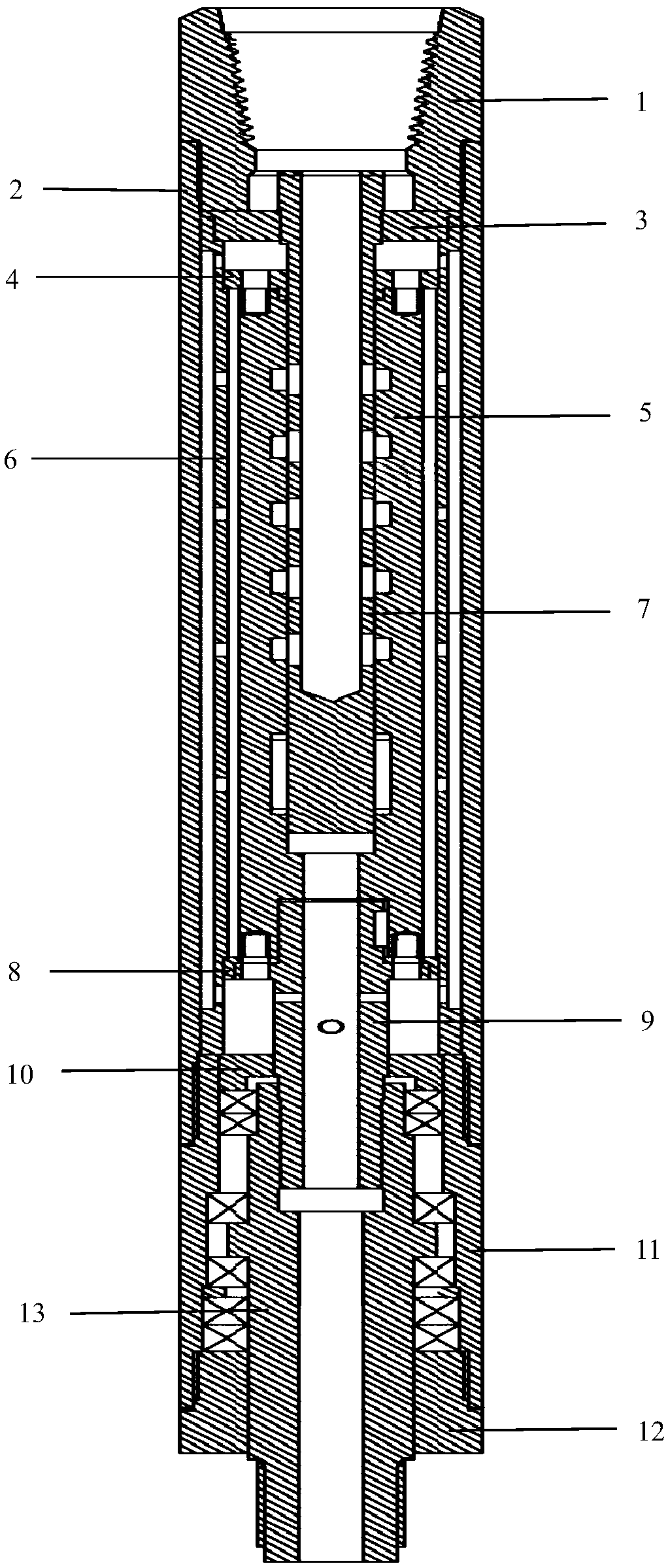

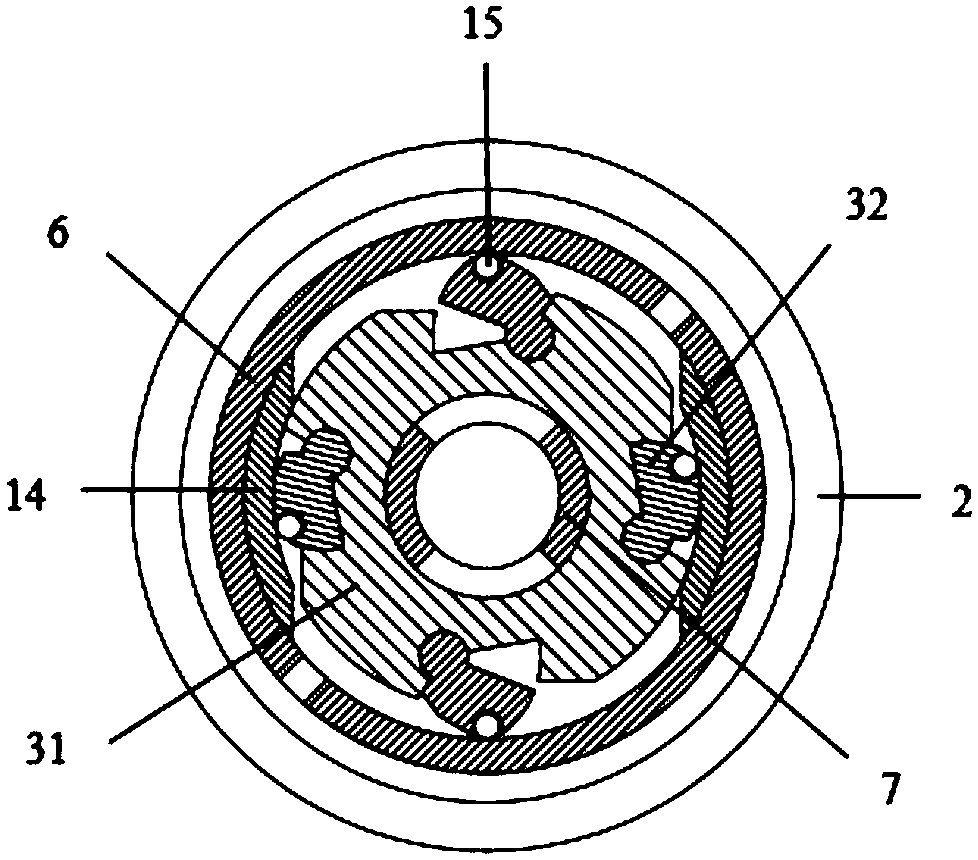

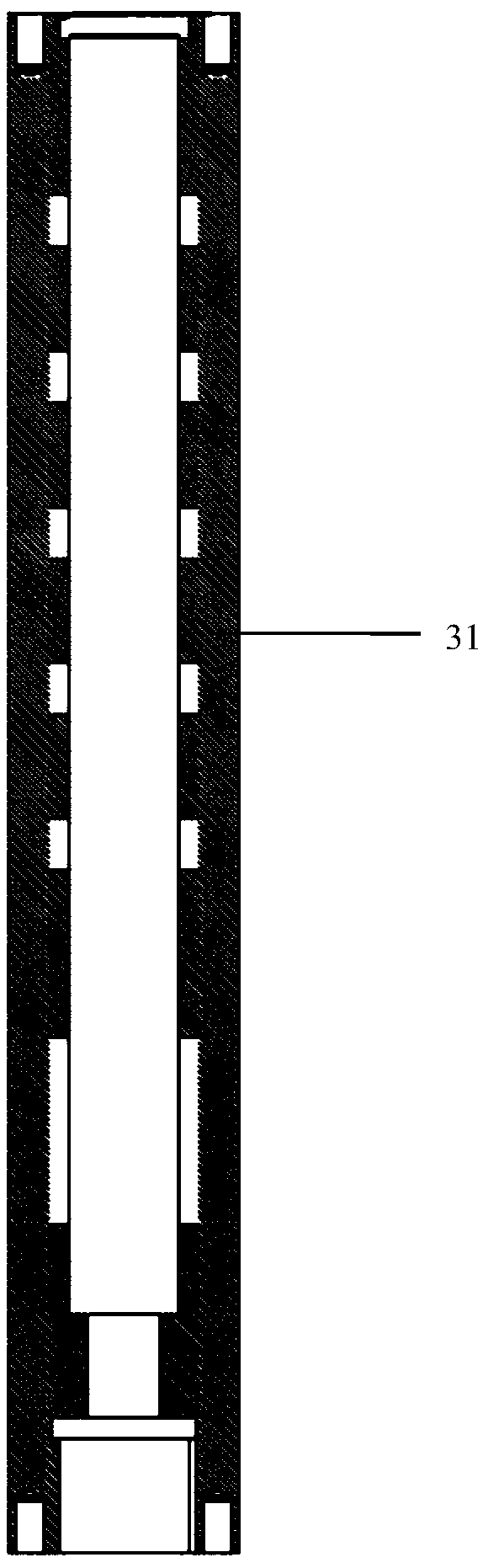

[0034] Dynamic push-on rotary motor, including outer tube 2, upper joint 1, upper support 3, upper centralizing ring 4, rotor assembly 5, sealing rod 15, stator 6, distribution valve 7, lower support ring 8, lower support 10, connection The shaft 9 , the connecting sleeve 11 , the lower joint 12 and the main shaft 13 , the rotor assembly 5 includes a rotor body 31 and four rotor push blocks 32 , and a reset block 14 is provided between the stator 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com