Patents

Literature

38results about How to "Oscillation effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

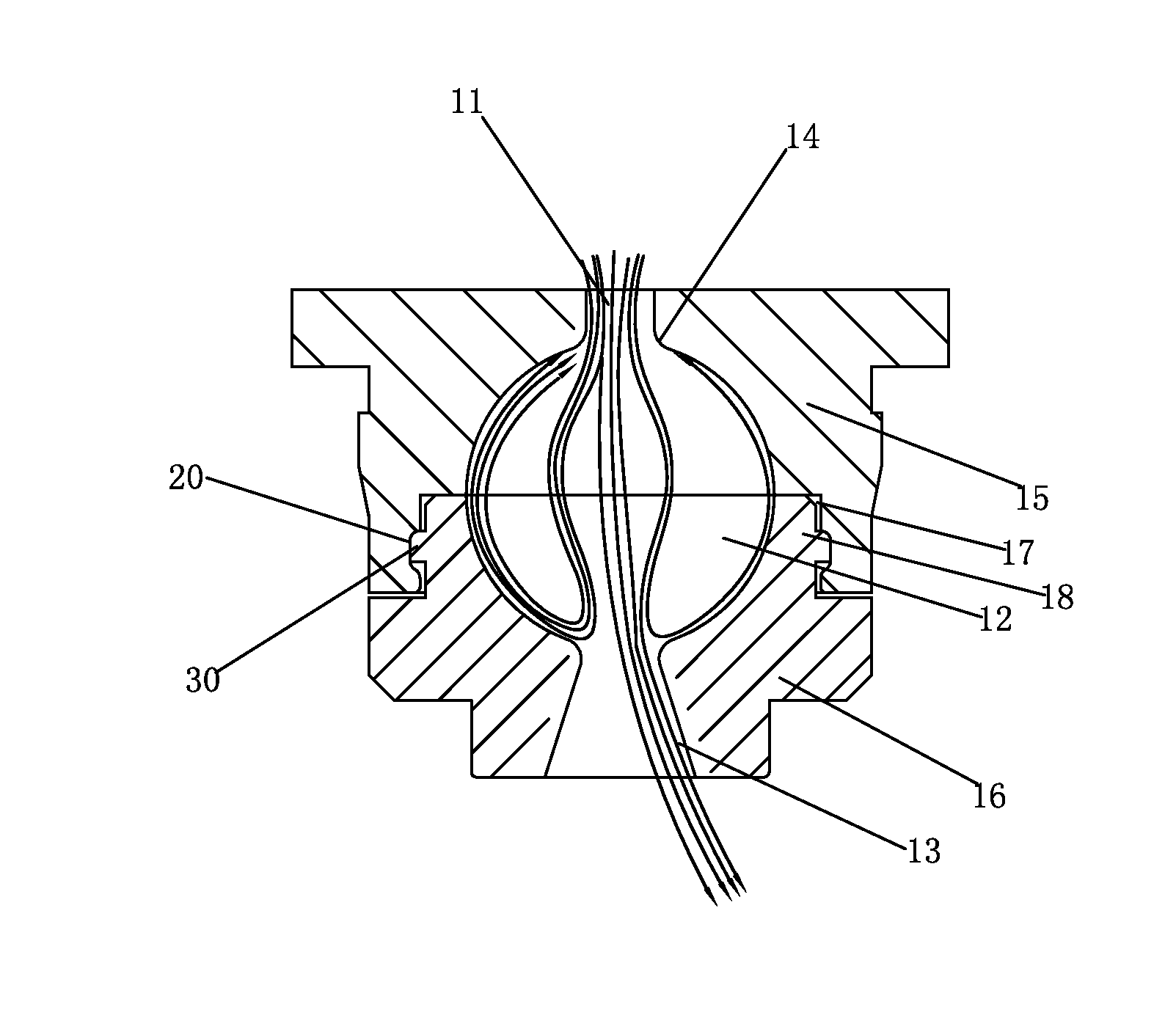

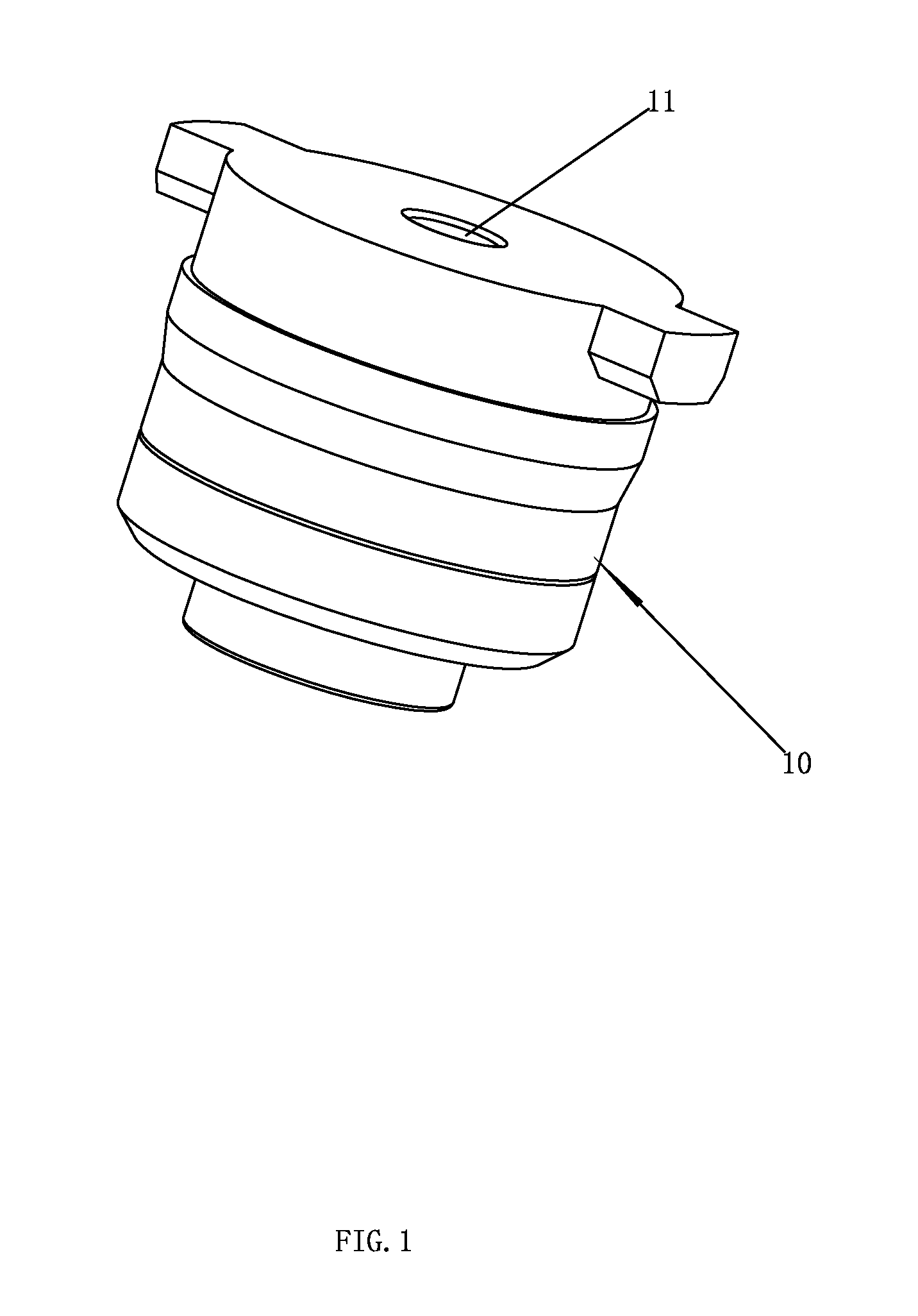

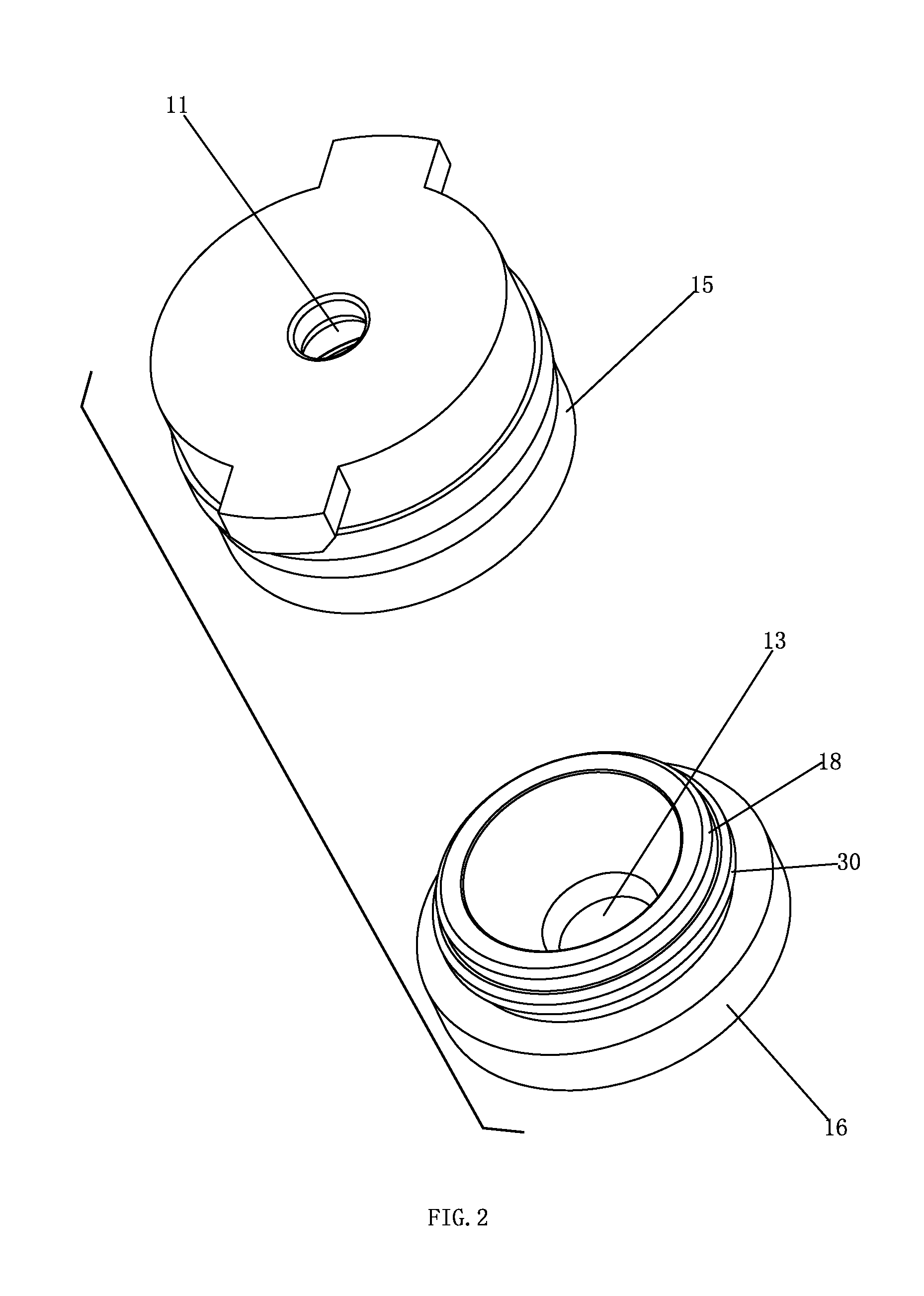

Showerhead with oscillating water

InactiveUS20160082447A1Increase the oscillation frequencyLow loss in energySpray nozzlesDomestic plumbingEngineeringCavity wall

A showerhead with oscillating water includes an inlet passage connected to an outlet passage and an oscillator assembled inside the shower head. The oscillator has a main body with an inlet, a ball shaped oscillating cavity, and an outlet. The ratio of the inner diameter of the inlet, the inner diameter of the oscillating cavity and the minimum inner diameter of the outlet is 1:2.5-5:1.1-1.35. The water of the inlet flowing into the oscillating cavity divides into a main waterway and a feedback waterway, water of the main waterway flowing out of the outlet through the oscillating cavity, water of the feedback waterway flows back to the inlet through the cavity wall of the oscillating cavity, water of the main waterway flows out of the outlet in a circumferential cyclical shaking way under the compact of the water of the feedback waterway.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD +1

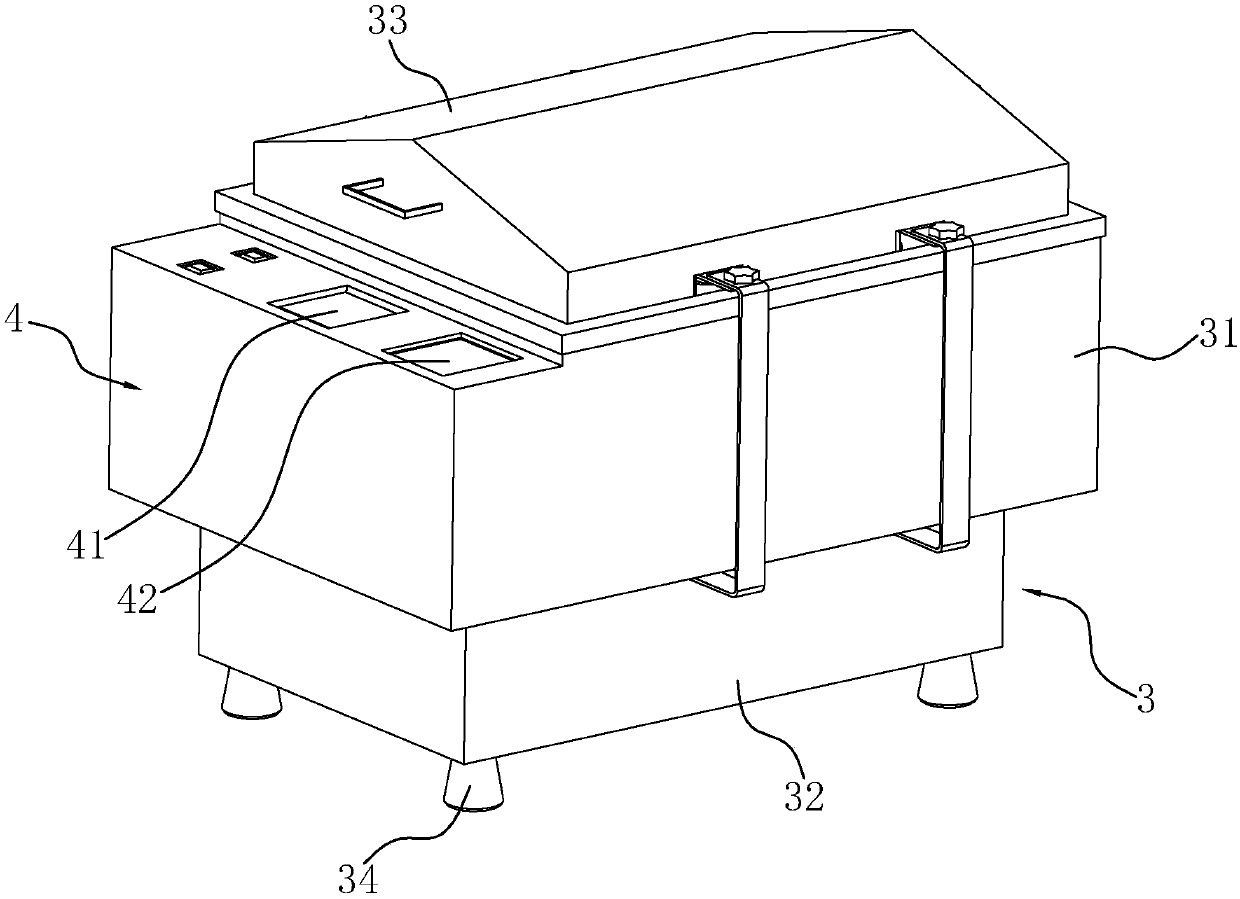

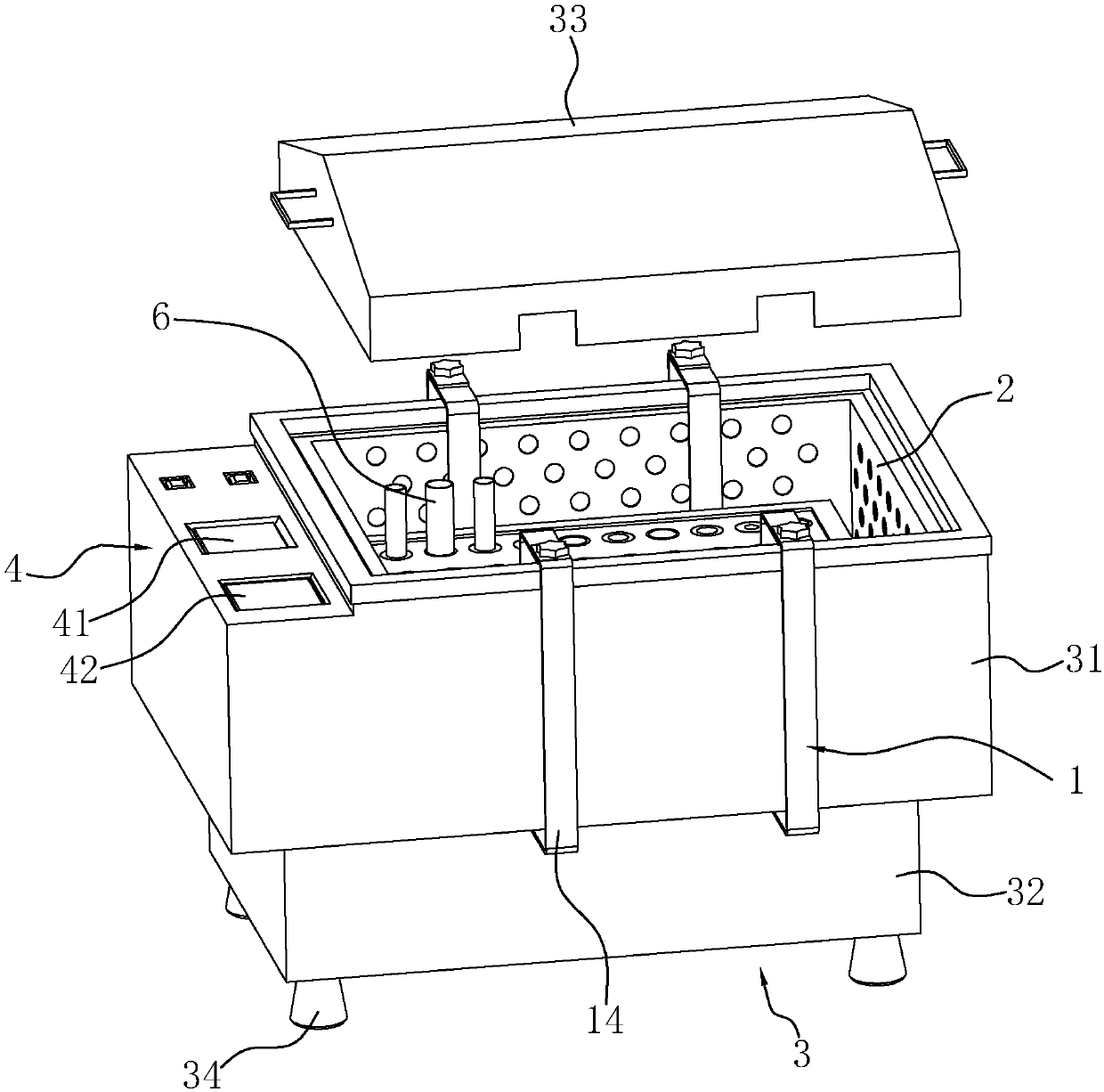

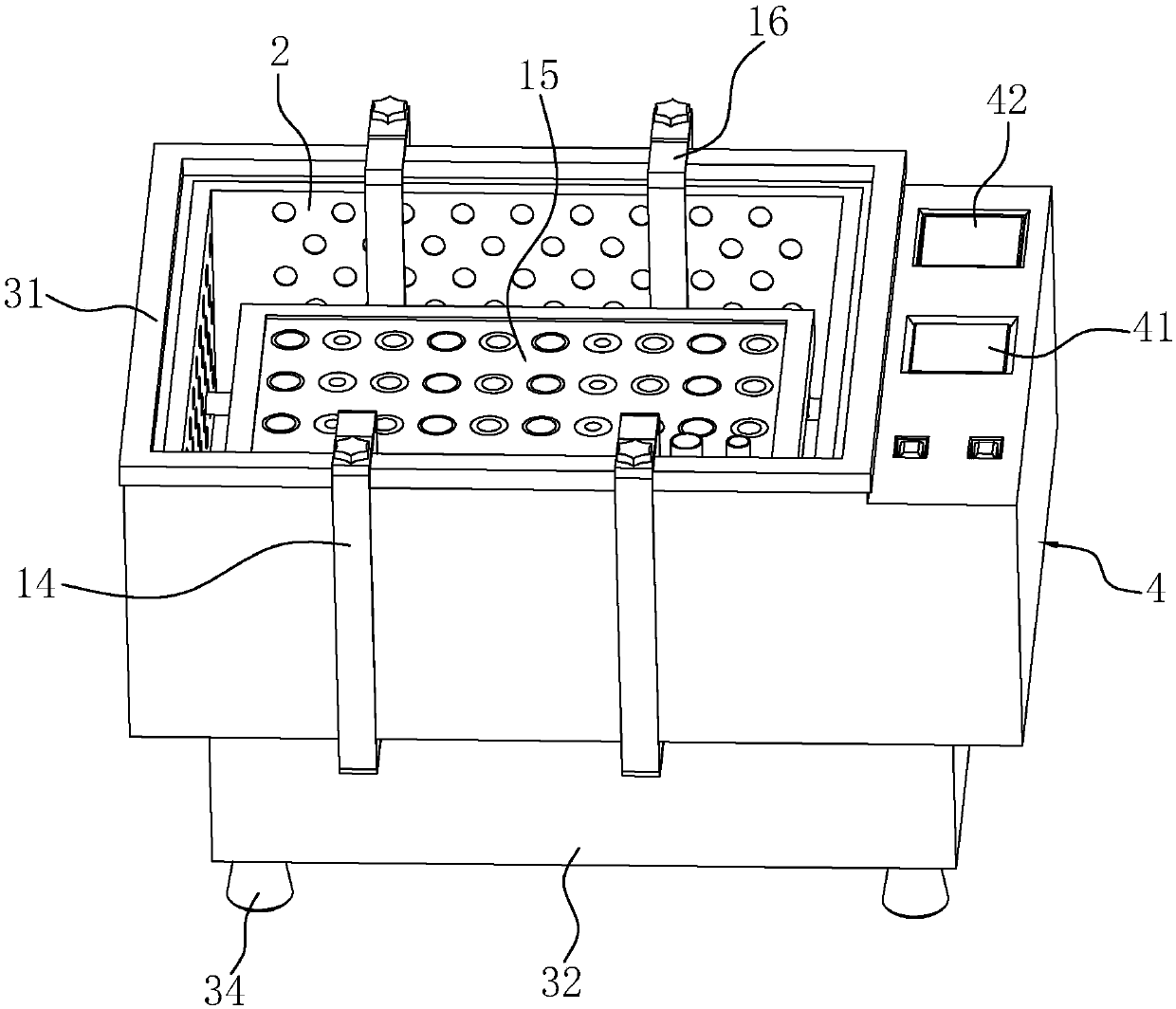

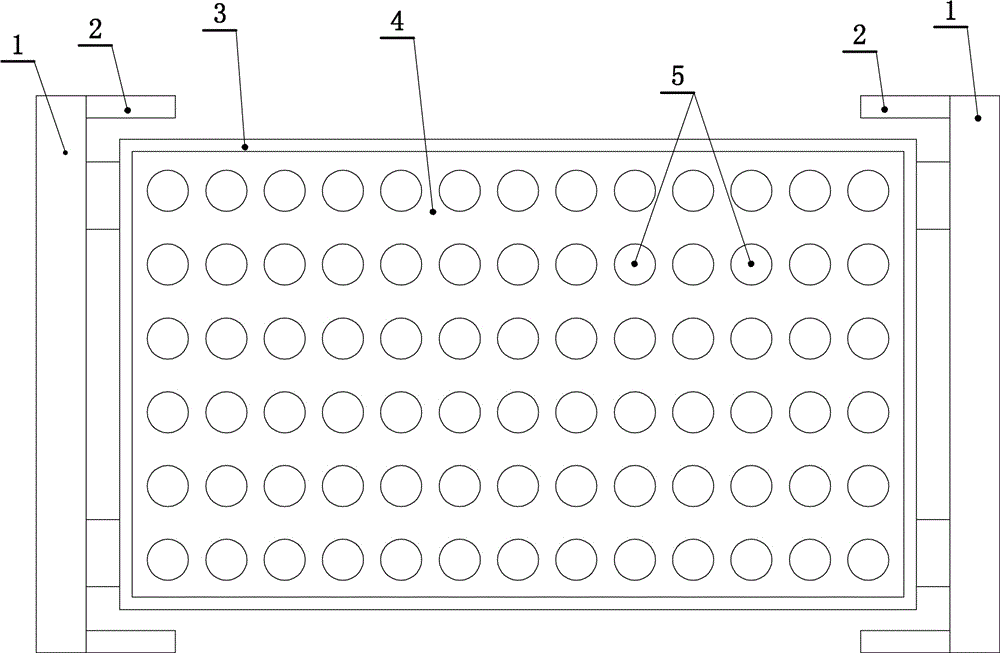

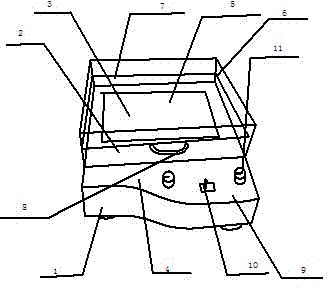

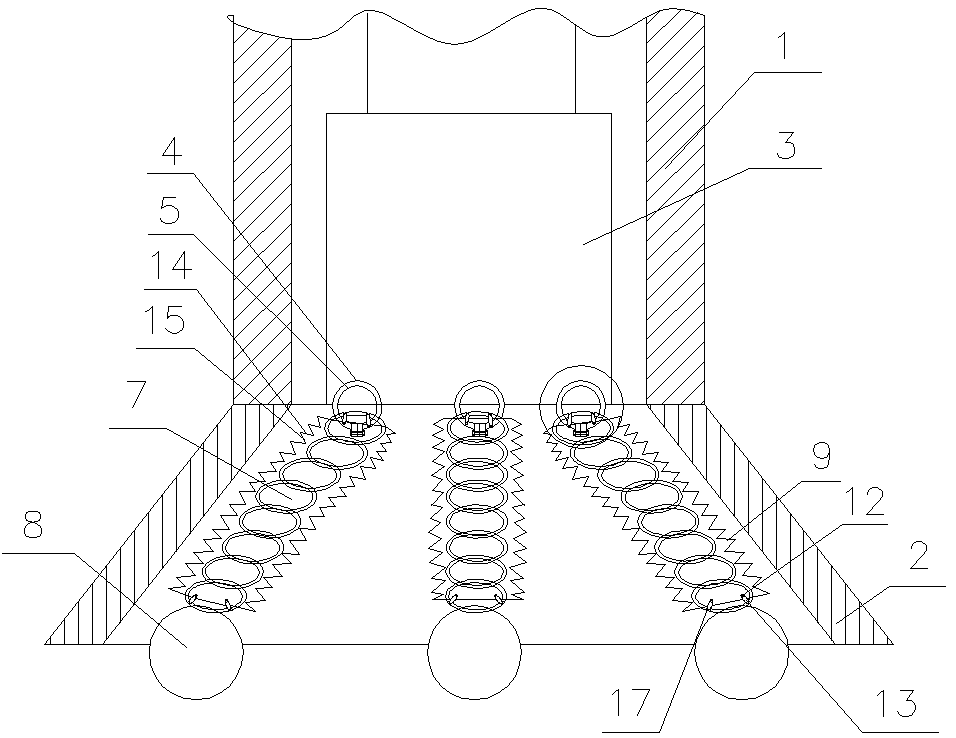

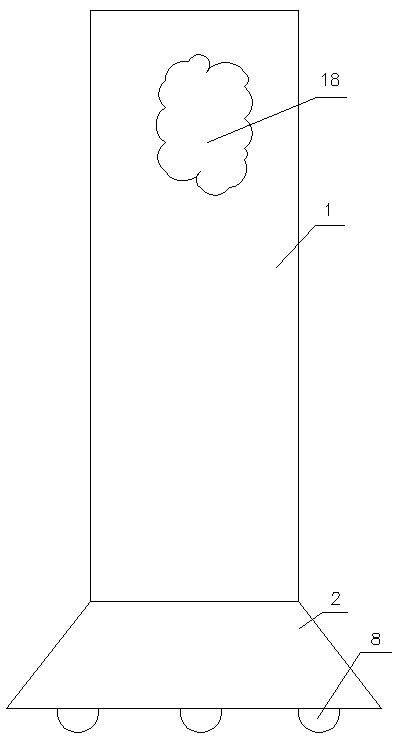

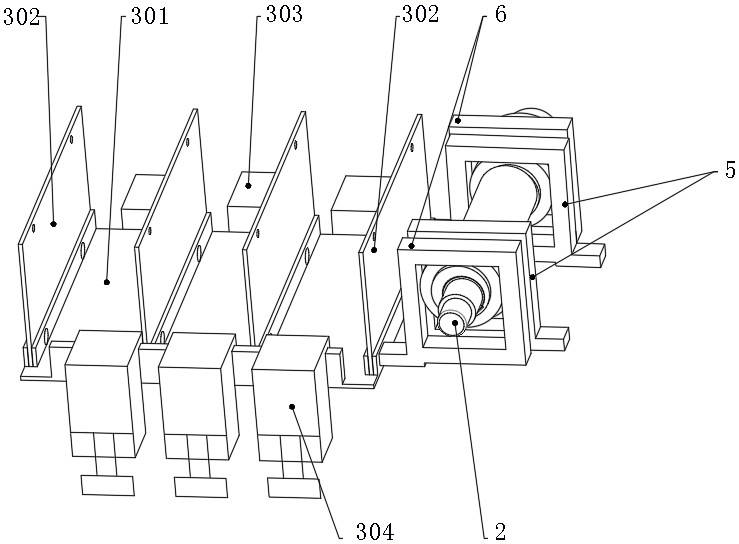

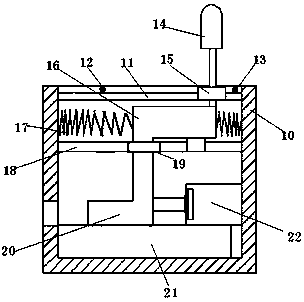

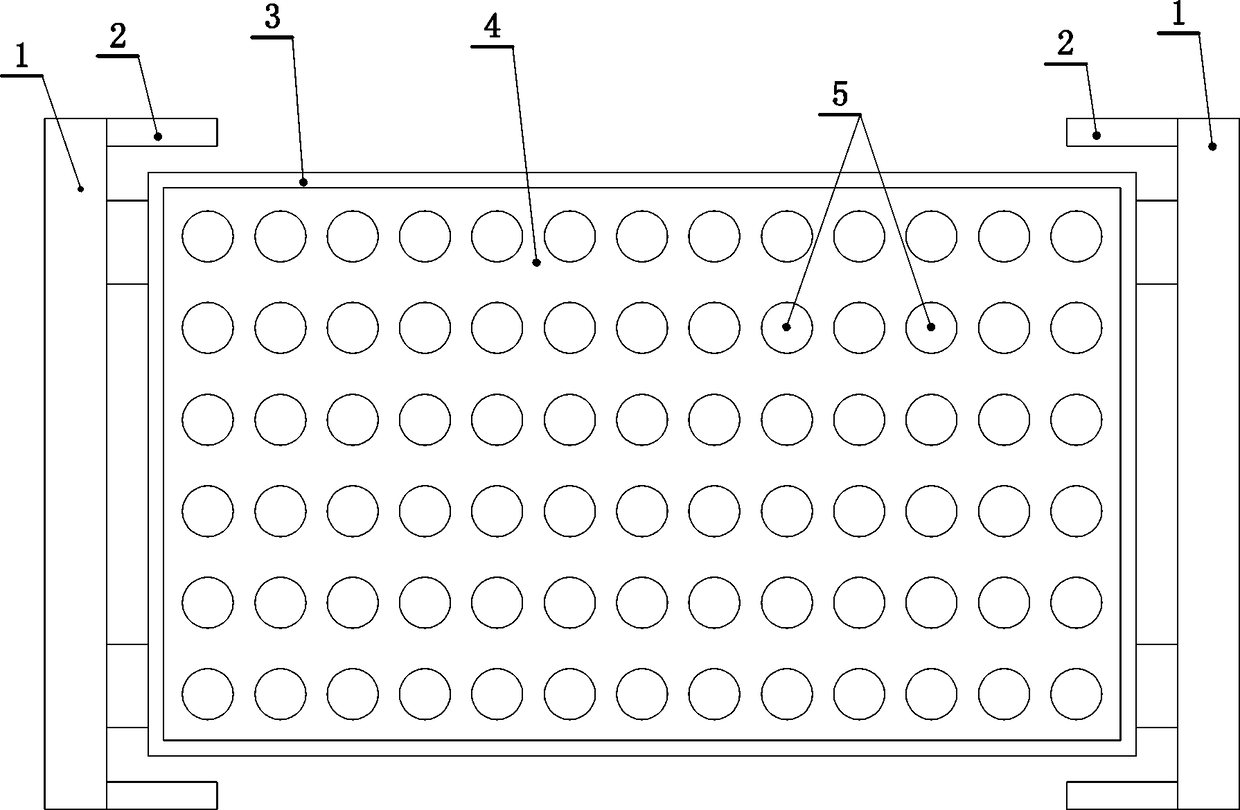

Water-bath constant-temperature oscillator

InactiveCN107930493AEasy to installNot easy to shakeShaking/oscillating/vibrating mixersTransportation and packagingWater bathsEngineering

The invention discloses a water-bath constant-temperature oscillator. The water-bath constant-temperature oscillator is technically characterized by comprising a bearing plate, wherein test tube holesare formed in the bearing plate; a test tube is inserted into each test tube hole; a filling part is filled into a gap between each test tube hole and the test tubes of different diameters so as to fasten the test tubes. The water-bath constant-temperature oscillator has the advantage that the easiness in shaking of the test tubes of different diameters is avoided in the oscillation process.

Owner:北京中飞华正检测技术服务有限公司

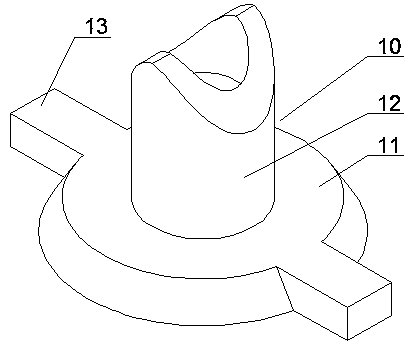

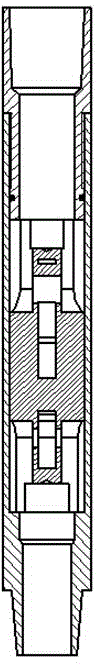

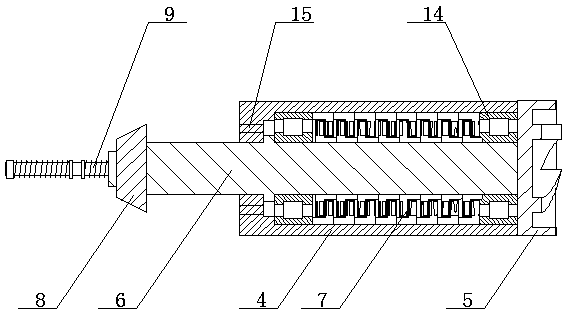

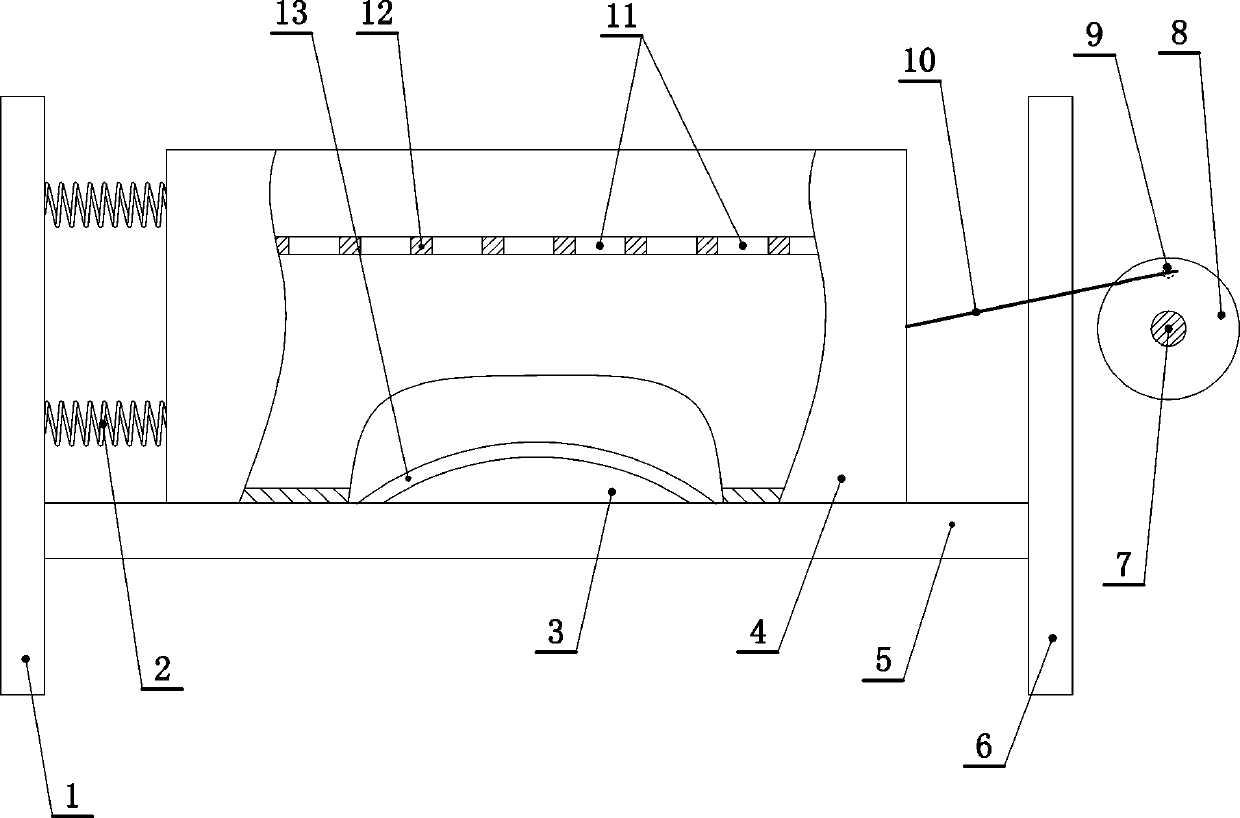

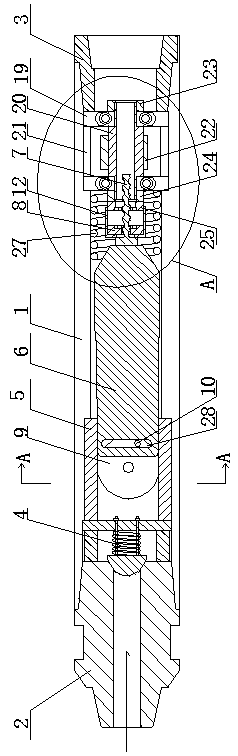

Three-dimensional hydraulic oscillator

ActiveCN108678675ASimple structureEasy to useMechanical vibrations separationVibration devicesUpper jointEngineering

The invention relates to a three-dimensional hydraulic oscillator, and belongs to the technical field of drilling tools. The three-dimensional hydraulic oscillator is formed by an upper shell, a lowershell, an upper joint, a lower joint and a threaded rod, wherein the upper shell is internally provided with an upper rotating shaft through alignment bearings which are symmetrically arranged; an upper cam is fixedly arranged on the lower end head of the upper rotating shaft; a lower cam is movably arranged in the upper shell below the upper cam; the upper cam and the lower cam are in contact connection; the threaded rod is arranged in the upper shell under the lower cam through a spring; the threaded rod is fixedly connected with the lower cam. During work, a lower rotating shaft drives aneccentric block to rotate, and a radial centrifugal force is generated through rotation of the eccentric block, so that a circumferential oscillation force is generated; the oscillation force is capable of reducing friction of a drilling tool during a rock breaking process of a drilling bit, so that the drilling efficiency can be improved; the problems that larger friction resistance exists afteran existing pipe column is in contact with a well wall, the drilling speed is affected, and the drilling efficiency is reduced are solved; the three-dimensional hydraulic oscillator has positive significances in reducing friction resistance and improving the drilling efficiency.

Owner:YANGTZE UNIVERSITY

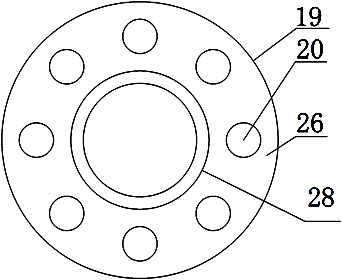

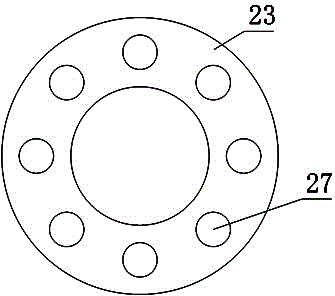

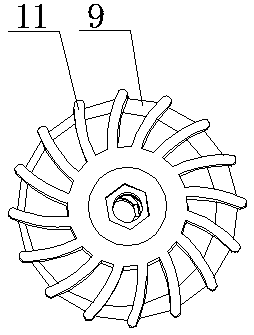

Hydraulic oscillator

ActiveCN106223889AIncrease ROPIncrease frictional resistanceVibration devicesWell drillingEngineering

The invention relates to a hydraulic oscillator. The hydraulic oscillator comprises a mandrel, an upper connector, a disc spring, a mandrel middle connector, a mandrel lower connector, a screw rod pump, a disc valve set, an outer barrel and a lower connector, wherein the mandrel is inserted into the upper connector; the mandrel lower connector is arranged at the bottom of the mandrel; the outer barrel is composed of an upper sleeve and a lower sleeve; the screw rod pump is mounted in a connection short section; an output end of the screw rod pump is fixedly connected with the upper end of a rotor; a stator sleeves the outer side of the rotor; the lower end of the rotor is connected with the upper end of a universal shaft; the lower end of the universal shaft is connected with the disc valve set; and the lower connector is connected with the outer barrel through a thread. The hydraulic oscillator provided by the invention has the advantages that the screw rod pump can rotate only if flow exists and the sizes of holes on a flow through disc and a flow adjusting disc are changed periodically to generate an oscillating phenomenon; the loss of pressure drop energy of well drilling liquid is small and the energy of the well drilling liquid can be sufficiently utilized; and the hydraulic oscillator has a relatively good oscillating effect and the friction resistance of a drilling tool in a drilling bit rock breaking process is reduced, so that the well drilling efficiency is improved.

Owner:四川保瑞特钻头有限公司

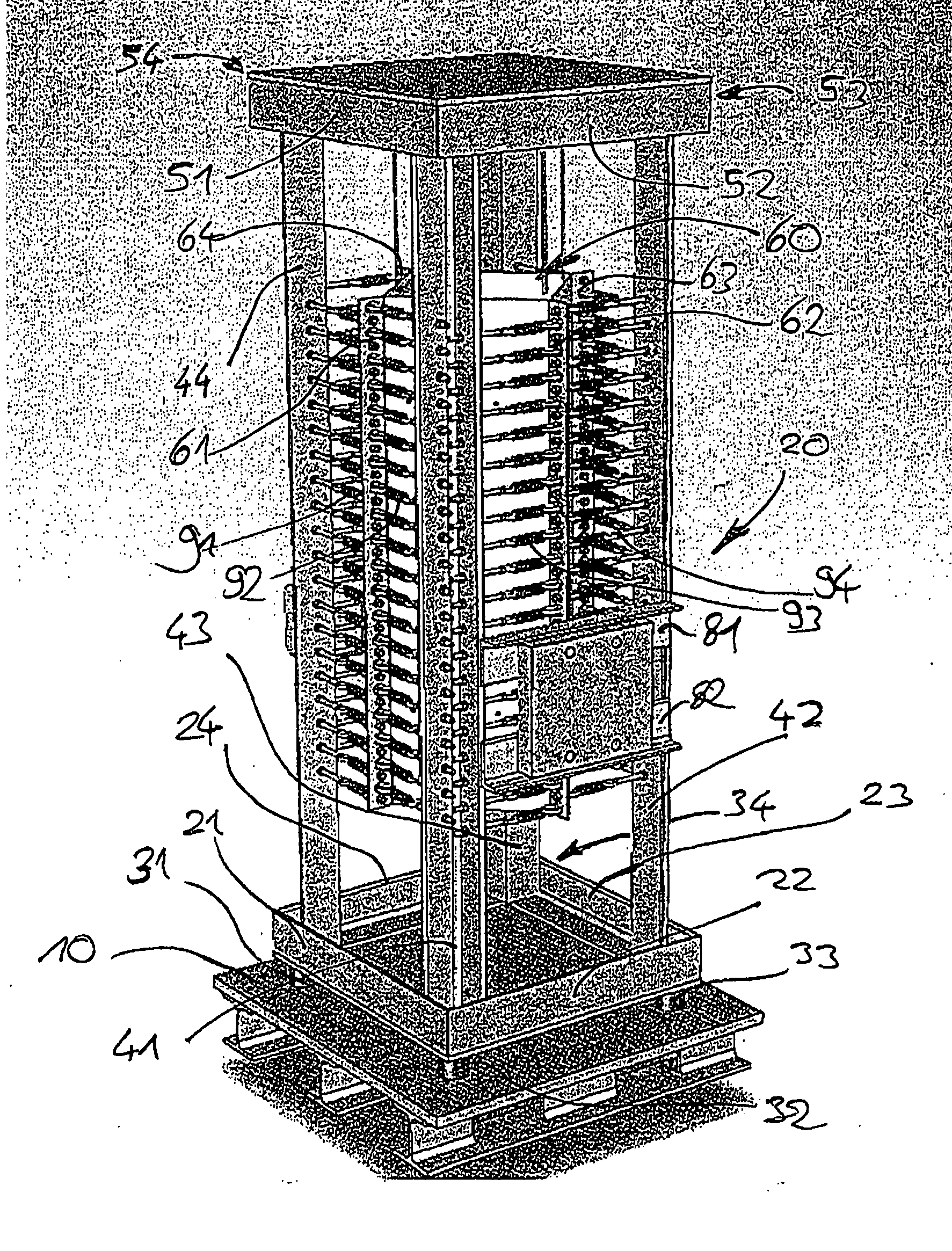

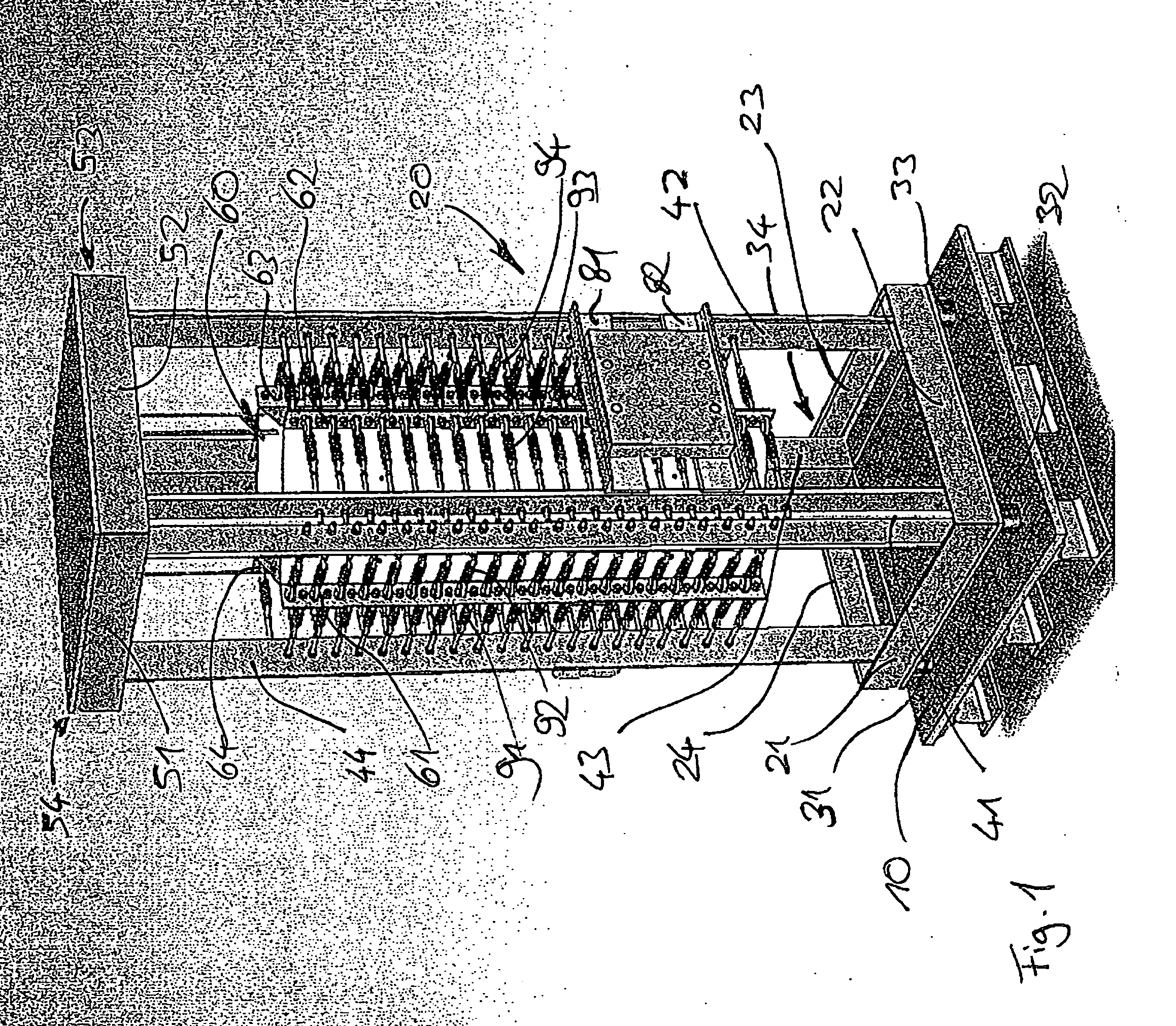

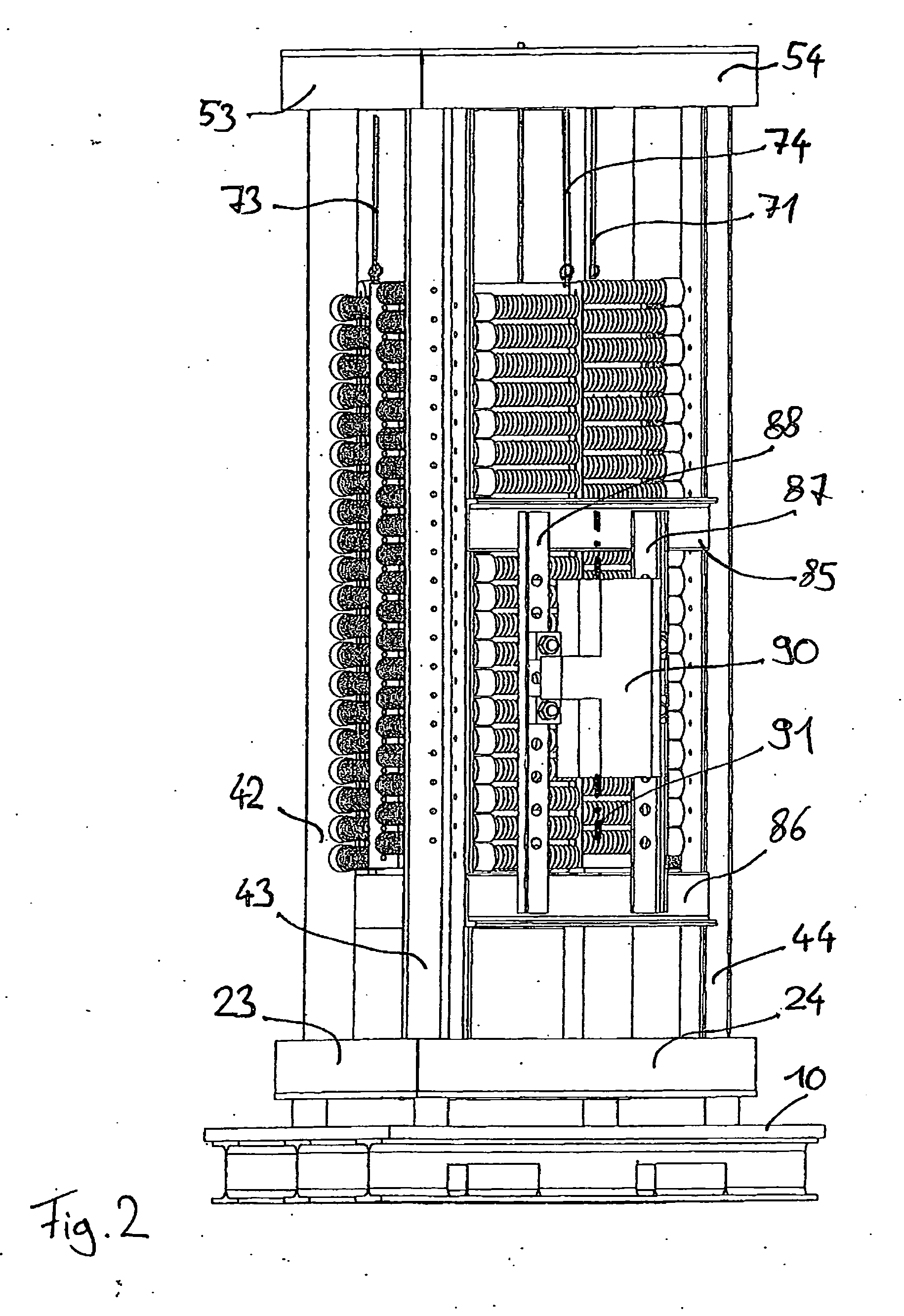

Drive device for a membrane filtration arrangement

ActiveUS20130193076A1Improve vibrationEfficient and economicalMembranesSemi-permeable membranesEngineeringMechanical engineering

The invention relates to a membrane filtration device comprising a plurality of planar membrane filter elements which are combined to form a membrane package and are disposed within the membrane package parallel to and spaced apart from one another. A wall encloses the membrane package on all sides, and within which at least one inlet chamber which is connected to at least one inlet, and at least one outlet chamber which is connected to at least one outlet. An oscillation unit is connected to the membrane package and the wall to induce oscillation in a direction parallel to the membrane filter elements. The oscillation unit is connected to a frame which encloses the membrane package and which is connected to the wall of the membrane package by means of least one spring, whose main direction of spring action extends parallel to the plane of the membrane filter.

Owner:BIG DUTCHMAN INT

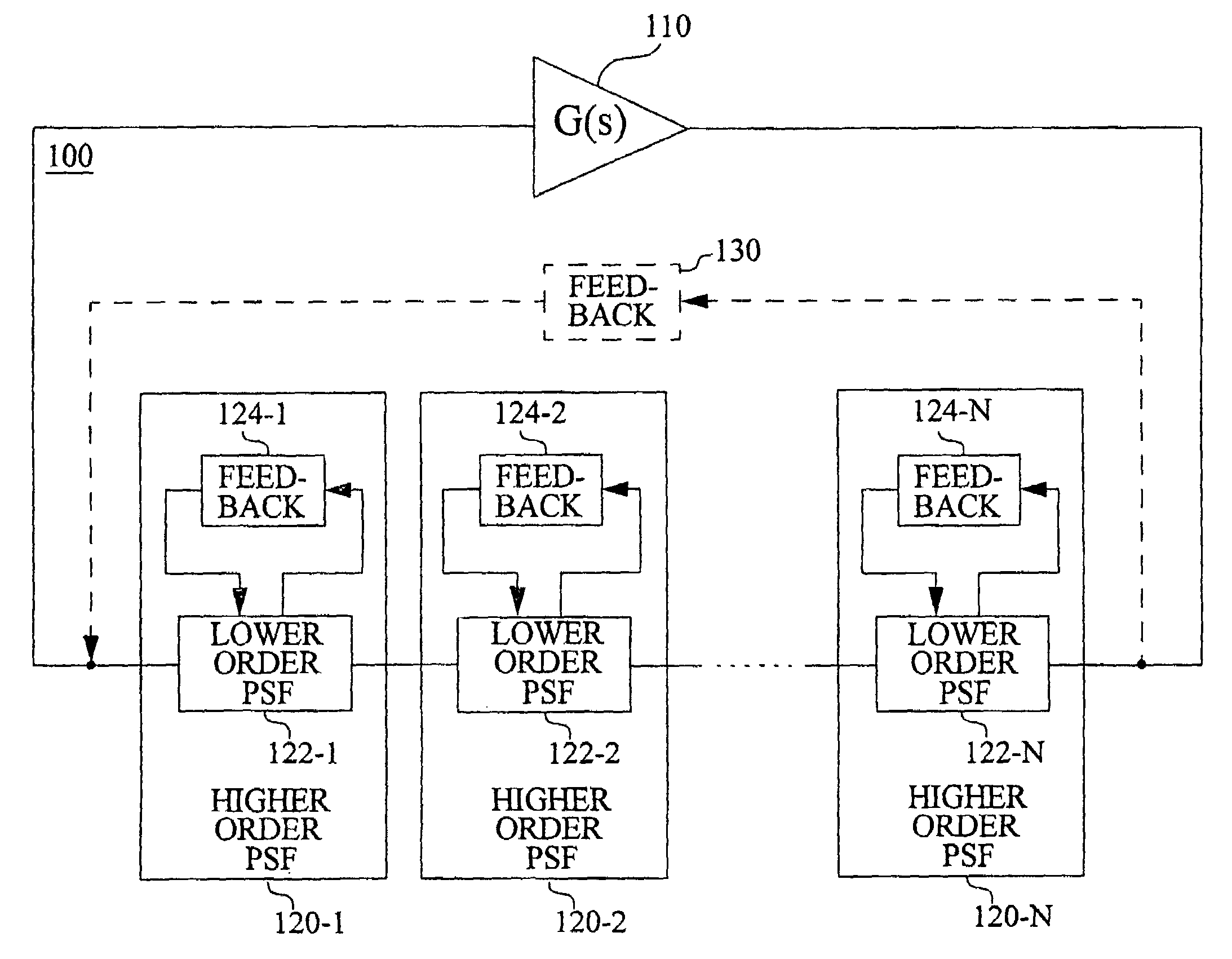

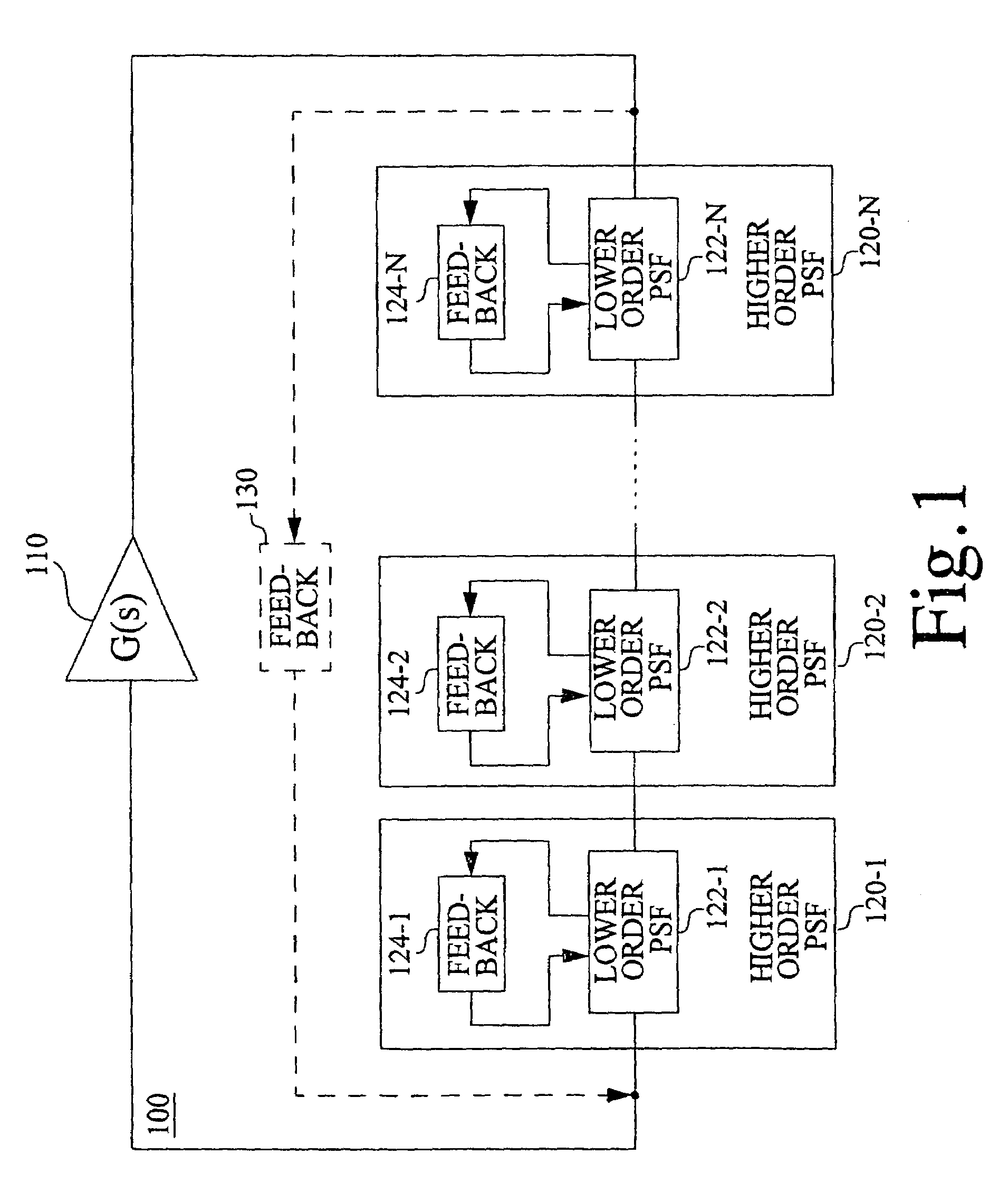

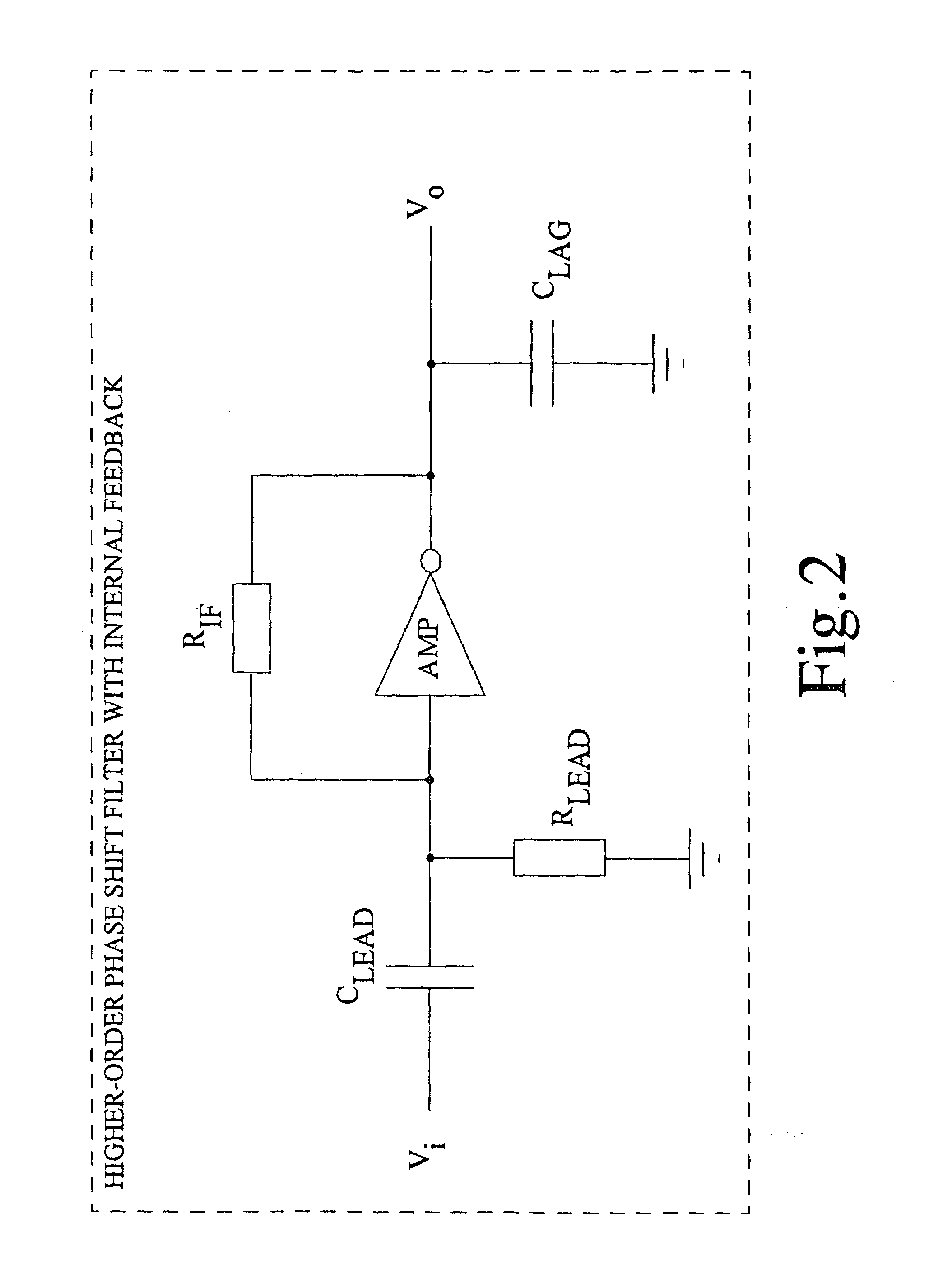

Oscillators with active higher-in-order phase shift filtering

InactiveUS7053723B2Oscillation effect is goodQuality improvementImpedence networksElectric pulse generatorPhase shiftedInductor

The present invention proposes a new way of improving the phase stability and frequency selectivity of a phase shift oscillator (100). By introducing a filter-order enhancing feedback loop (124) in association with a phase shift filter (122) in the oscillator, higher-order phase shift filtering can be achieved without using inductive elements as in conventional higher-order LC phase shift filters. This is a great advantage, since a high Q-value can be obtained without limited by the relatively high internal losses of inductive elements (L).

Owner:TELEFON AB LM ERICSSON (PUBL)

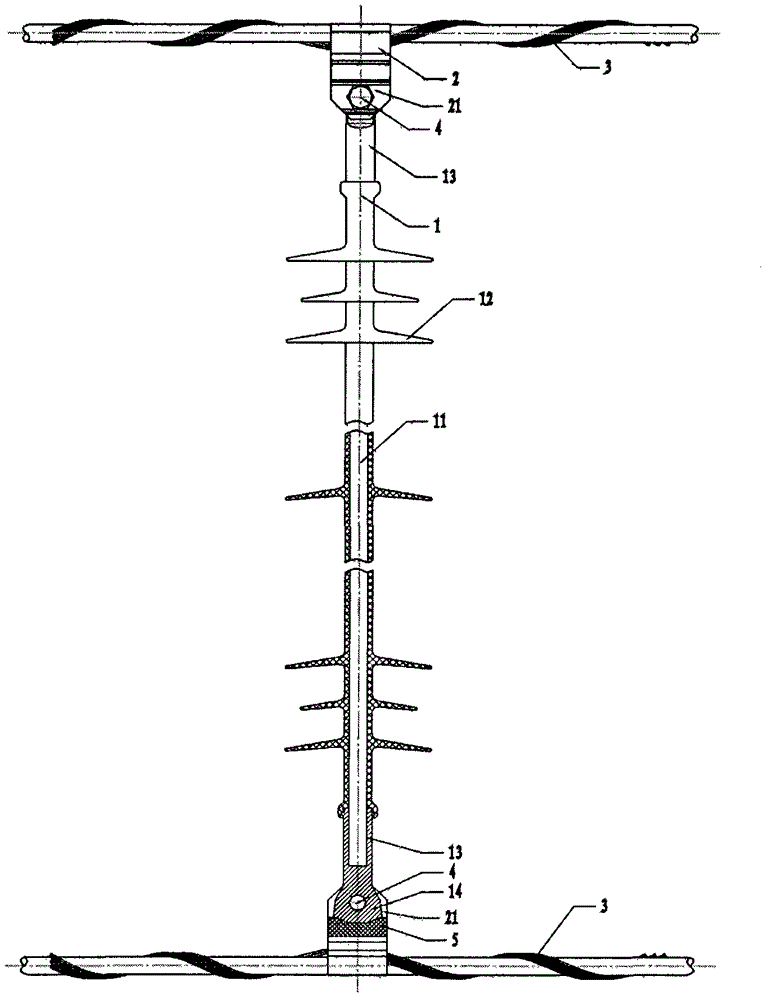

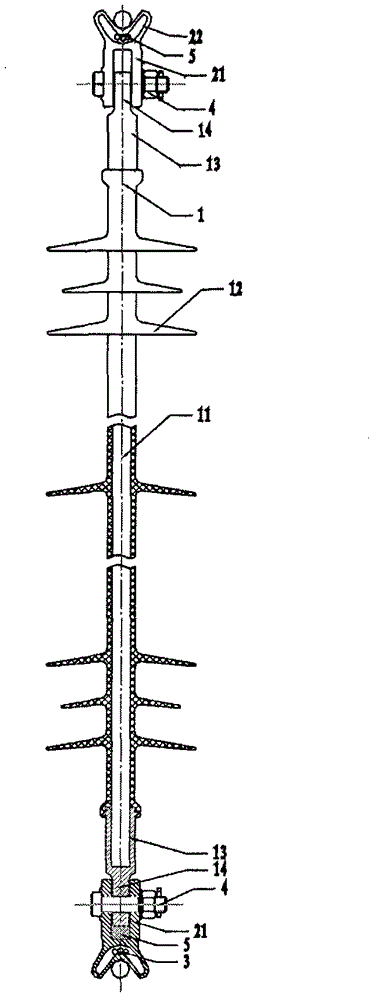

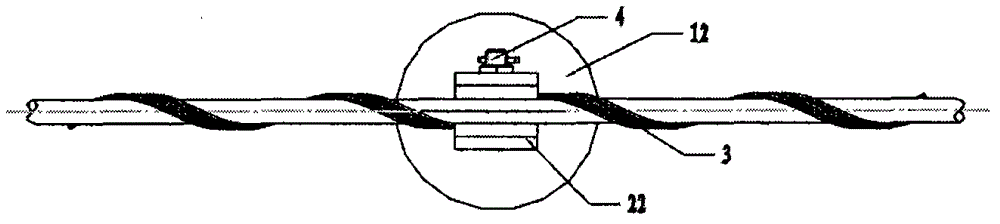

Phase-to-phase spacing bar

InactiveCN102723686AConstant gripNo maintenanceMaintaining distance between parallel conductorsEngineeringCam

The invention relates to a phase-to-phase spacing bar. The invention relates to a swinging prevention device, in particular to a spacing bar which is used for fixing a phase-to-phase conducting wire and preventing the swinging of the conducting wire on a high-voltage power transmission circuit. The phase-to-phase spacing bar mainly consists of a bar-shaped insulator, two wire clips, two groups of pre-twisted wires, two groups of bolt pins and two damping mats; and the bar-shaped insulator consists of a mandrel, two end connection armor clamps and a silicon rubber umbrella sleeve, the two end connection armor clamps are in a triangular cam shape and form the channel-type connection with the lower ends of the wire clips through the bolt pins, the two damping mats are arranged inside the channel-type structure on the lower end of each wire clip to be closely propped against the cam-shaped outer side of the connection armor clamp, the upper end of each wire clip is in a V-shaped ring-shaped structure, the upper part of a V-shaped ring is contacted with an installed conducting wire, one group of pre-twisted wire passes through the inside of the V-shaped ring, and two ends of the pre-twisted wire are respectively used for winding the installed conducting wire. Compared with the prior art, the phase-to-phase spacing bar has advantages of convenience in installation, constant grasping force, prevention of vibration and swinging of the conducting wire, no damage of the conducting wire, no maintenance and the like.

Owner:GULIFA GRP CO LTD +1

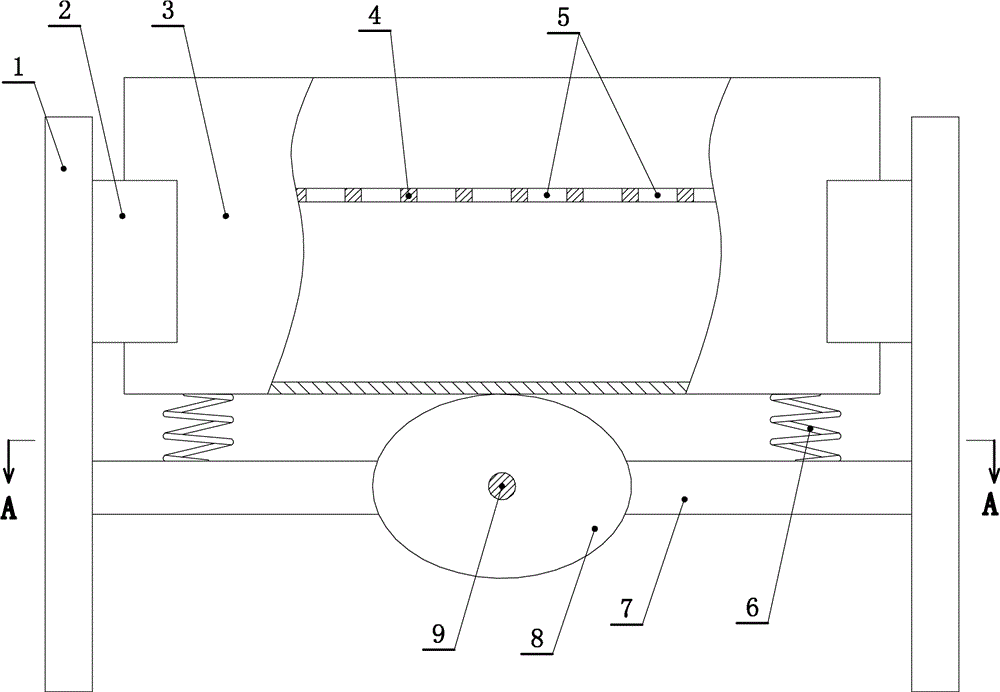

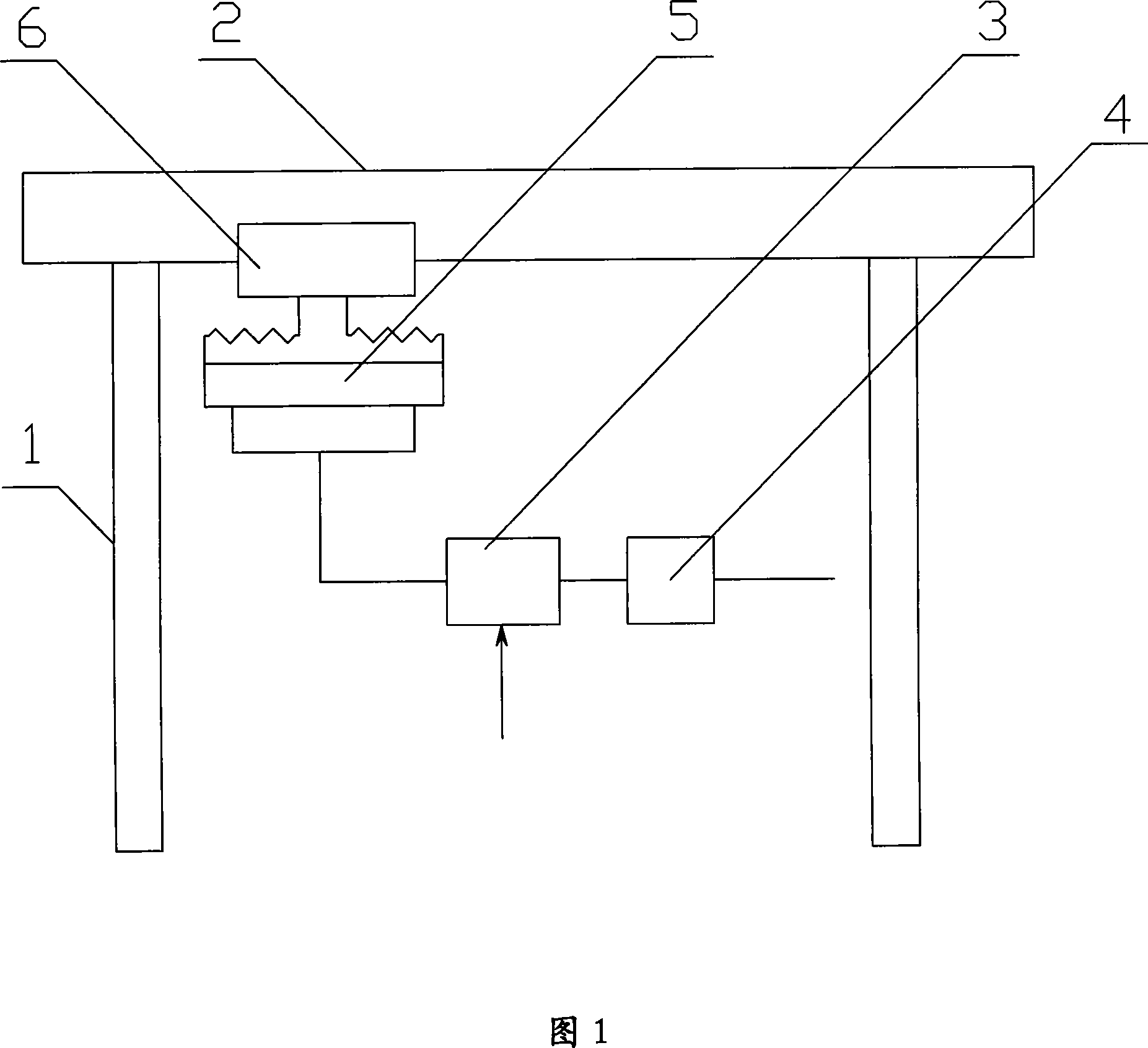

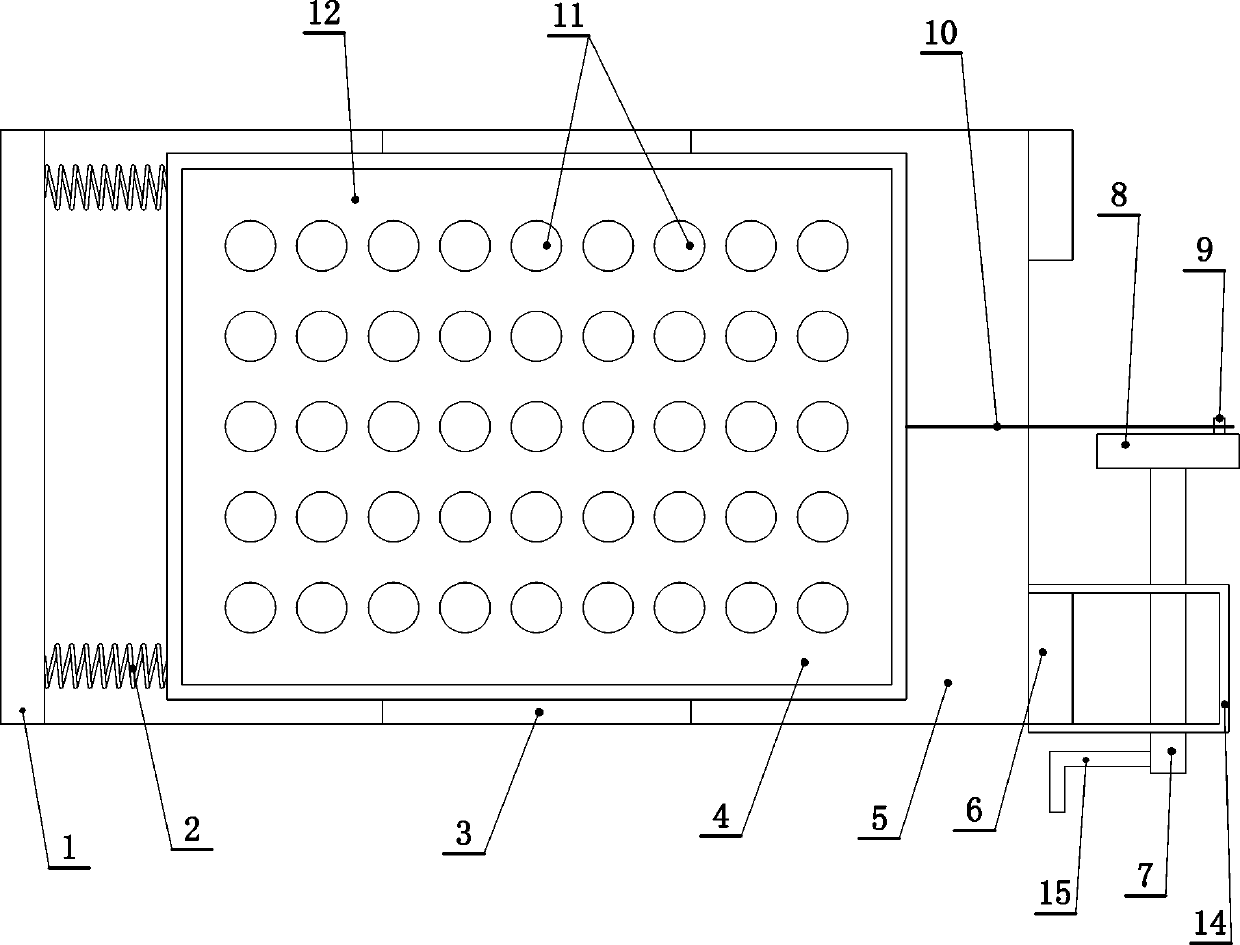

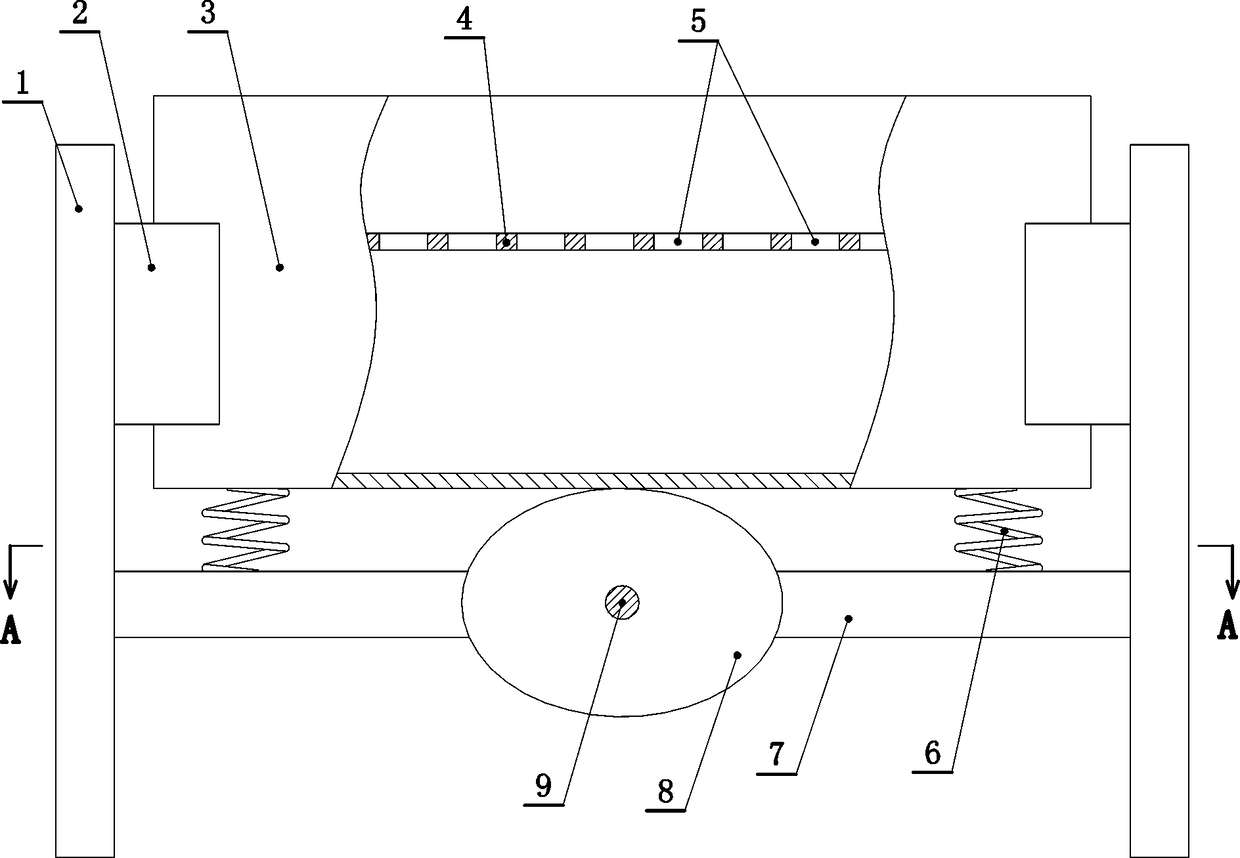

Lift rocking shaker

ActiveCN105478044ASimple structureLow costShaking/oscillating/vibrating mixersTransportation and packagingTest tubeEngineering

The invention provides a lift rocking shaker. A front cross beam and a rear cross beam which are correspondingly arranged are fixedly connected between a left support and a right support, multiple non-circular rotary discs are connected between the front cross beam and the rear cross beam through a rotary shaft in a relative rotation mode, the rotary discs are arranged side by side, and the sizes of the rotary discs are different. The rotary shaft is connected with the cross beams in a relative rotation mode, the rotary shaft is fixedly connected with the rotary discs, and one end of the rotary shaft is in transmission connection with a rocking bar. Vertically-arranged springs are fixedly connected to the cross beams, the upper ends of the springs are fixedly connected with hollow test tube containing boxes with upward openings, the test tube containing boxes are erected on the rotary discs and located between the left support and the right support, shelves are fixedly connected to the interiors of the test tube containing boxes, and multiple test tube penetrating holes are longitudinally and transversely formed in each shelf in rows. The rotary discs are one or more of ovals, triangles and rectangles. The intersections of the rotary discs and the rotary shaft deviate from the centers of the rotary discs. Baffles are fixedly connected to the inner sides of the supports, and the test tube containing boxes are located in the regions defined by the baffles. The baffles are triangular or rectangular or trapezoidal.

Owner:陈晓熠

Constant temperature vibrator

InactiveCN103357306ACutting costsMeet temperature requirementsShaking/oscillating/vibrating mixersMixer accessoriesEngineering

Owner:KUNSHAN HUAKUI MACHINERY ELECTRONICS

Cleaning process of optical glass lens

InactiveCN110802079AExcellent corrosion inhibitionImprove rust resistanceSpectales/gogglesNon-ionic surface-active compoundsPyridiniumOptical glass

The invention discloses a cleaning process of an optical glass lens. Firstly, cleaning fluid is combined with high-voltage pulse electric field treatment and double-frequency ultrasonic wave alternatetreatment for cleaning, oil dirt, dirt and other contaminants on the surface of the optical glass lens can be effectively removed, high-voltage pulse electric field treatment cooperates with taurinedihydroxyethyl amine oxide and cetyl pyridinium chloride in the cleaning fluid, mildew on the surface of the optical glass lens can be effectively killed, a good vibration effect is achieved through the cooperation of high-voltage pulse electric field treatment and double-frequency ultrasonic wave alternate treatment, the oil dirt, the dirt and other contaminants on the surface of the optical glass lens can be effectively separated out, and the cleaning effect is improved; and then deionized water is combined with double-frequency microwave alternate treatment and double-frequency ultrasonic wave alternate treatment for washing, the oil dirt, the dirt and other contaminants on the surface of the optical glass lens can be further removed through the vibrating performance of double-frequencymicrowave alternate treatment and double-frequency ultrasonic wave alternate treatment, and the cleaning efficiency is improved.

Owner:江苏鸿晨集团有限公司

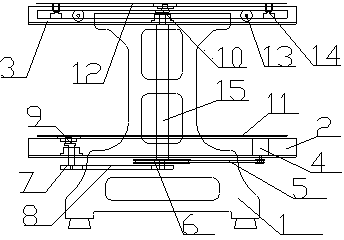

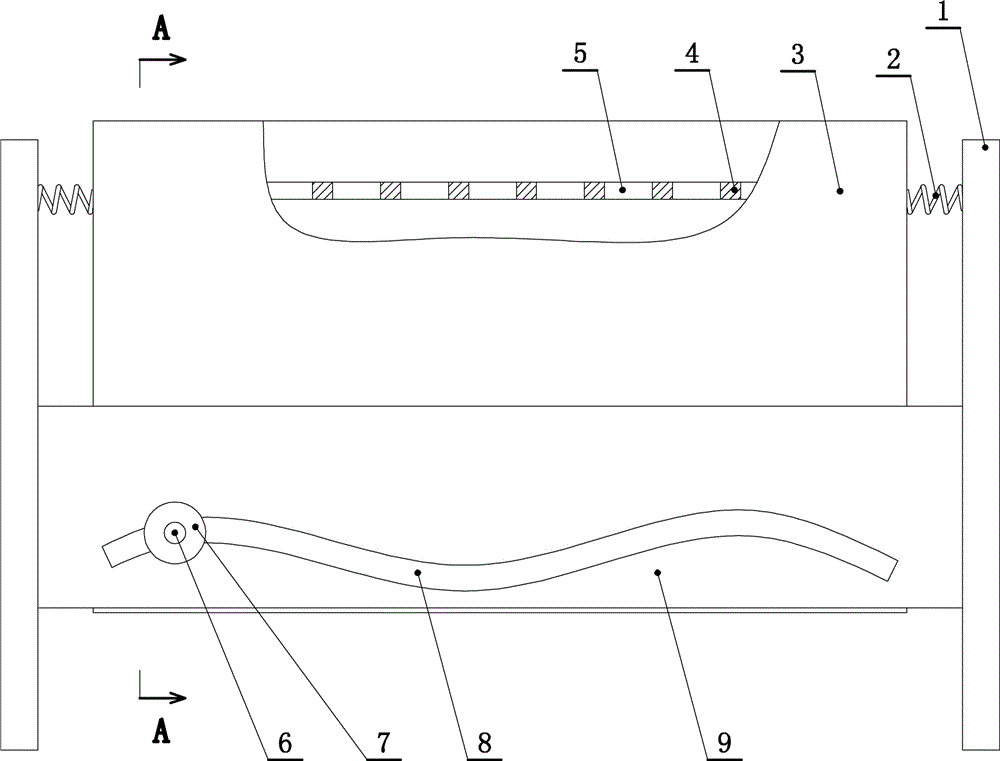

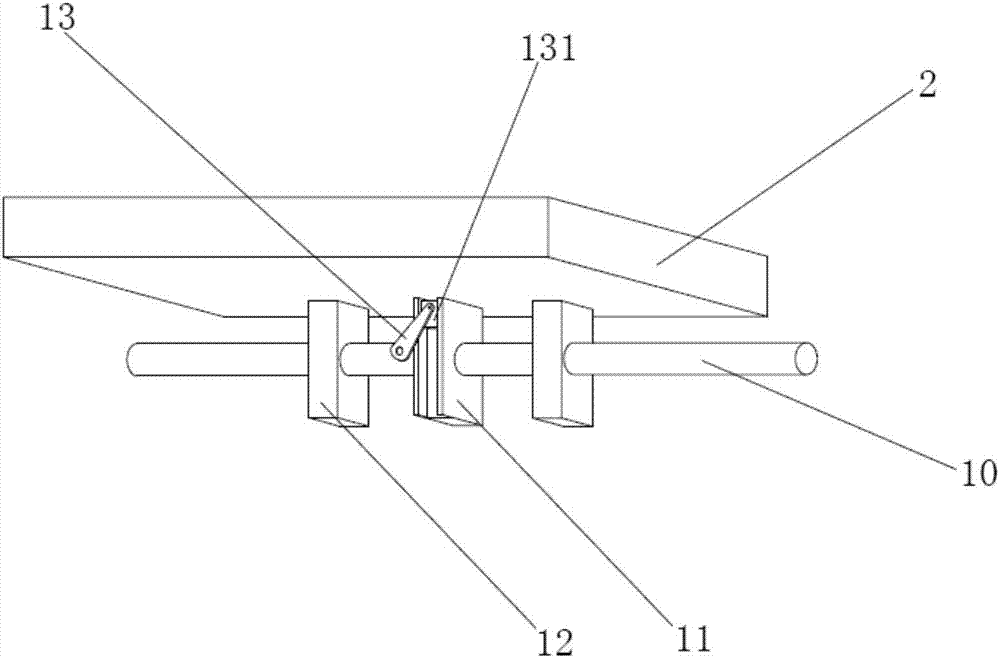

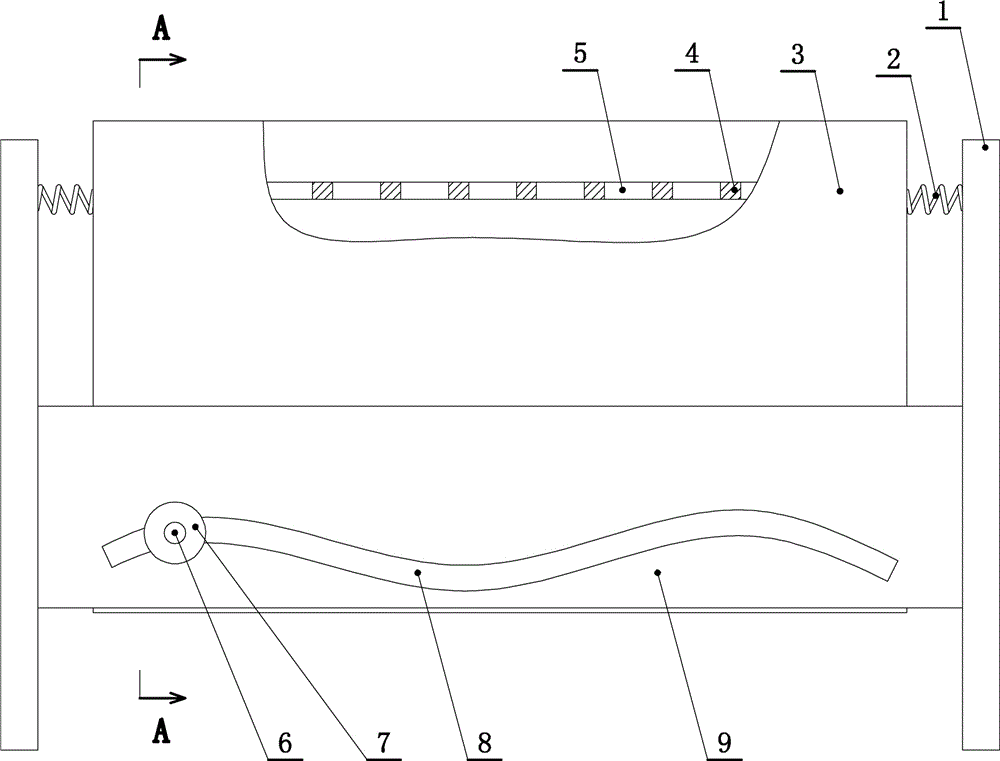

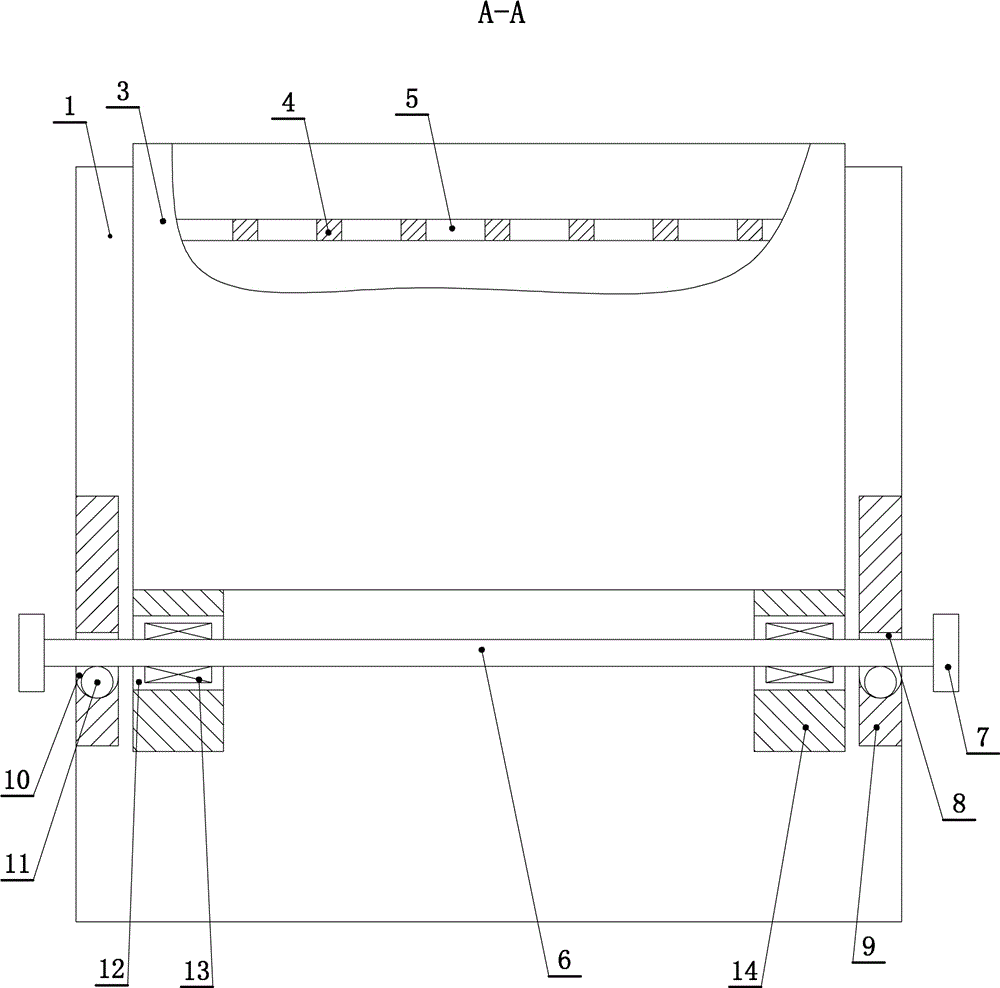

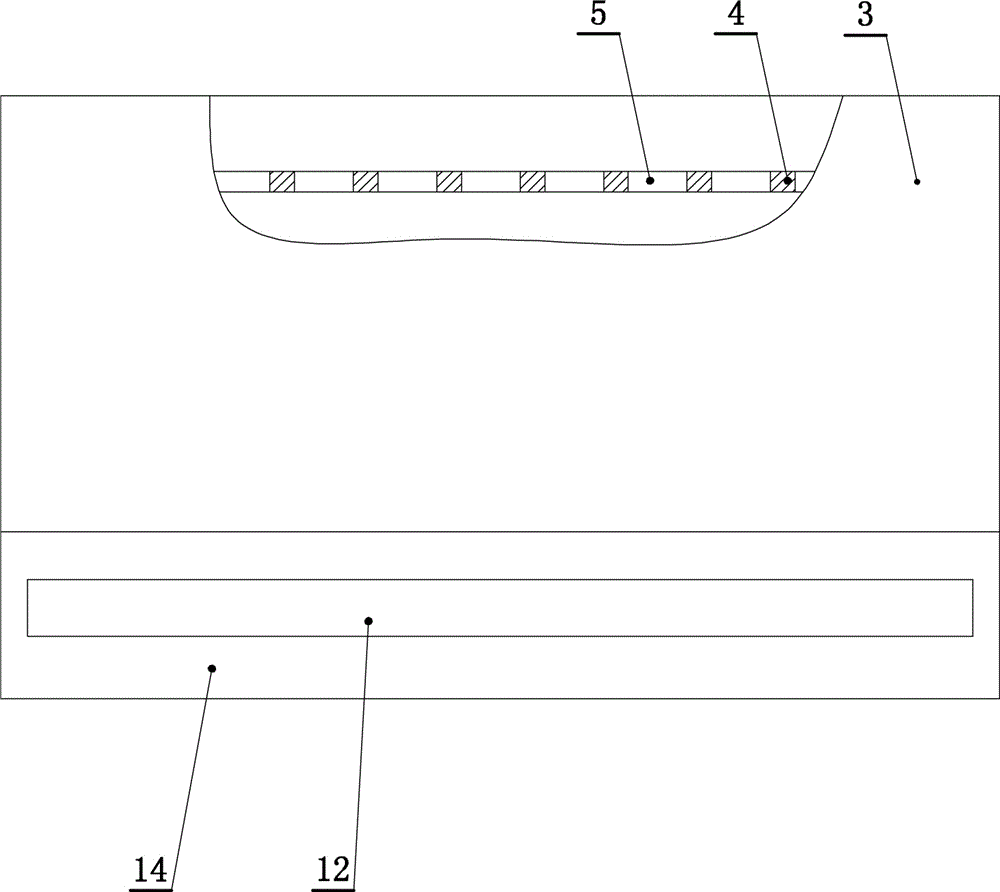

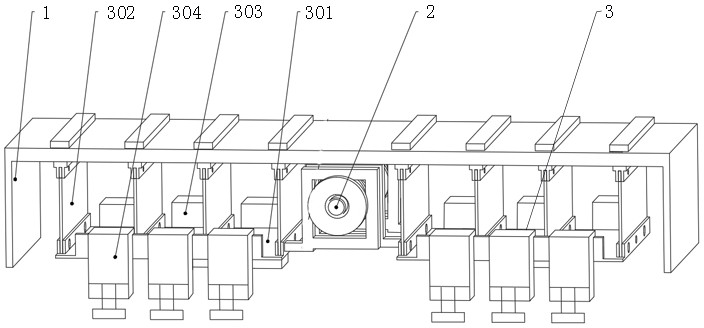

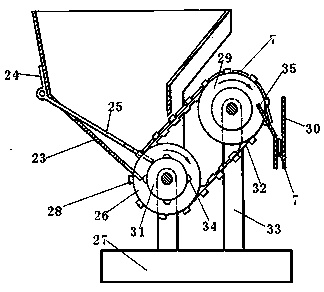

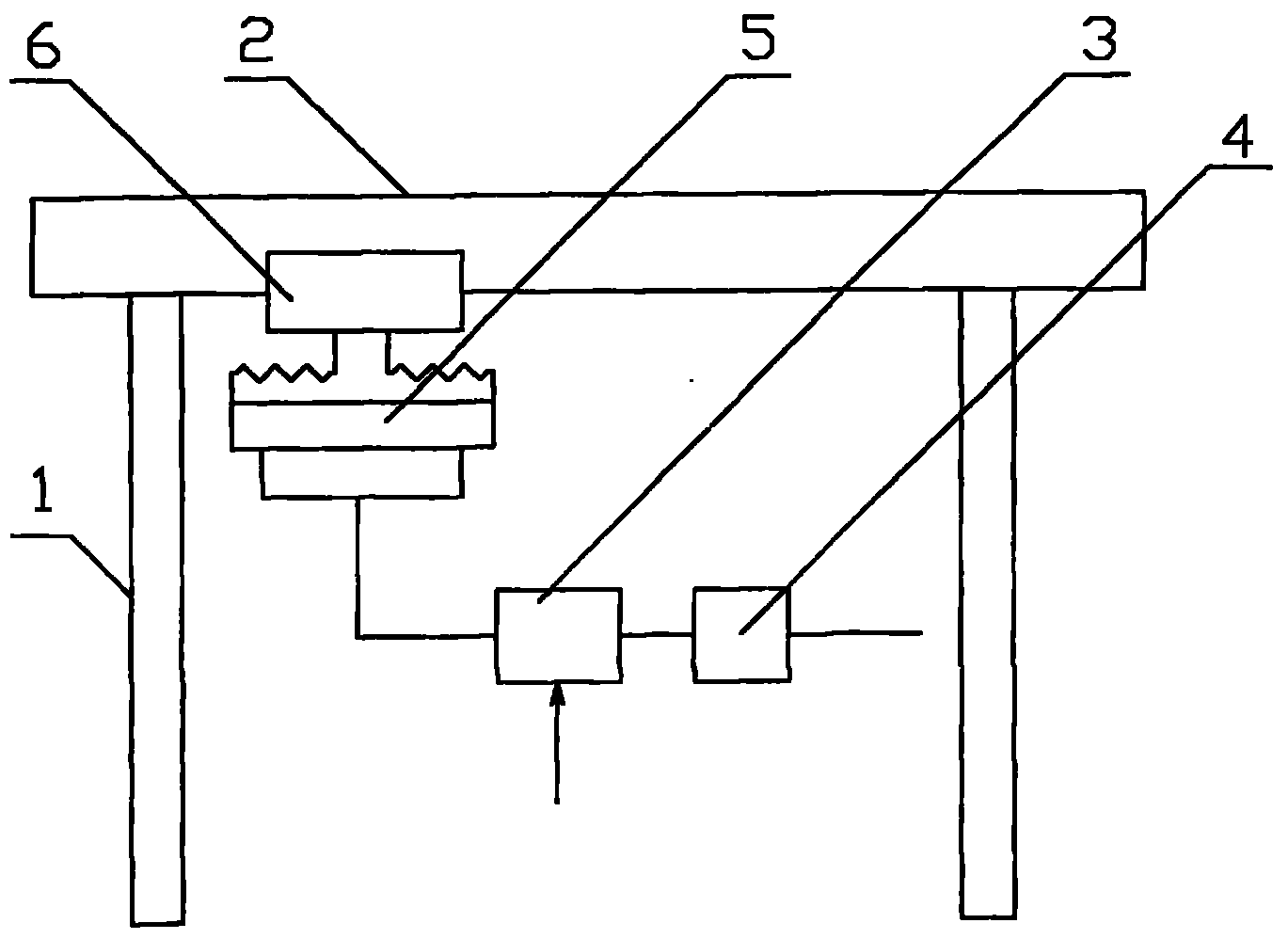

Oscillating shaking table

ActiveCN104069766AIncrease the operating areaImprove cultivation efficiencyShaking/oscillating/vibrating mixersAgricultural engineeringPulley

The invention discloses an oscillating shaking table. The oscillation shaking table comprises a rack, oscillating tanks, a motor, a belt, a belt pulley, a synchronizing wheel, a synchronizing belt, eccentric shafts, oscillating plates, pulley wheels, a guide rail and a main shaft, wherein the oscillating tanks are arranged below the rack, the motor is arranged on one side of the oscillating tanks, the main shaft is arranged in the center of the rack, the belt pulley and the synchronizing wheel are arranged below the main shaft, the belt is arranged on the belt pulley and connected with the motor, the synchronizing belt is arranged on the synchronizing wheel, and the other end of the synchronizing belt is connected with the eccentric shafts; the upper end of the main shaft is connected with the eccentric wheel, the oscillating plates are fixed on the eccentric wheel, the oscillation tank is fixed below the oscillating plates, and the guide rail and the pulley wheels are arranged below the oscillating tanks. According to above mode, the oscillating shaking table has reliable performance, compact structure and good oscillation, has large operation area due to two oscillating plates, is high in efficiency, small in noise and low in cost; meanwhile, the oscillating shaking table has wide market prospect on the biological culture market.

Owner:苏州培英实验设备有限公司

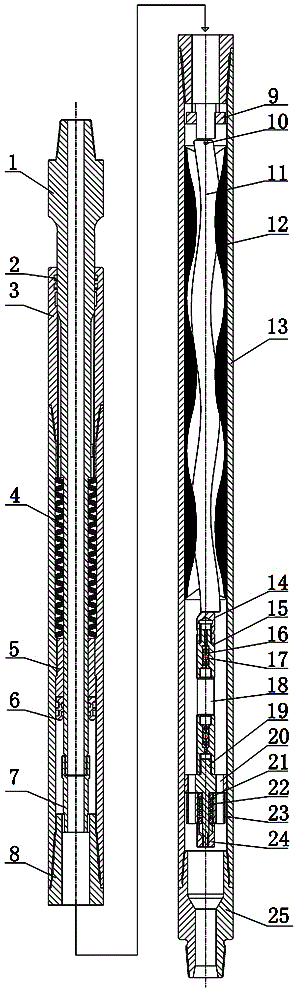

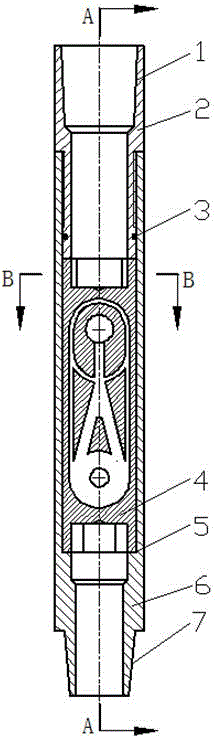

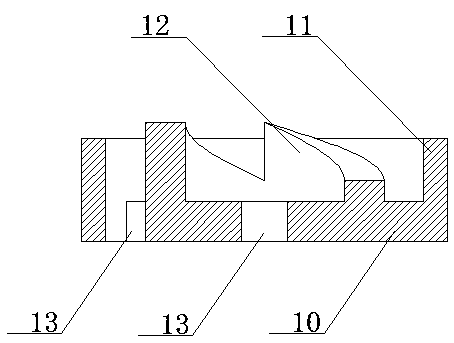

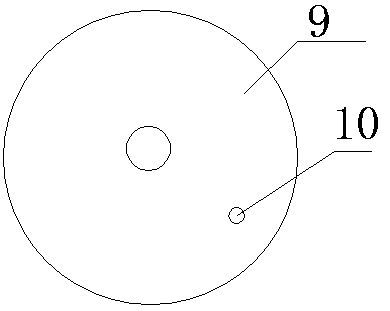

Slim hole drilling friction reduction and resistance reduction speed increase tool

InactiveCN104790894AReduce static frictionImprove drilling efficiencyVibration devicesFriction reductionScrew thread

The invention discloses a slim hole drilling friction reduction and resistance reduction speed increase tool which is formed by an upper nipple, an inner cavity and a shell. A female thread connected with a drilling string or other drilling assemblies is arranged at the upper end of the upper nipple, a special flow channel is formed in the inner cavity, and a male thread connected with other drilling assemblies or an adapter above a drill bit is arranged at the lower end of the shell. The inner cavity is located in the shell and is in transition matching connection with the shell. The upper nipple is connected with the shell through the corresponding thread, abuts against the inner cavity in the shell and prevents the inner cavity from moving axially. The slim hole drilling friction reduction and resistance reduction speed increase tool is used for reducing friction force of the drilling string and a borehole wall in the slim hole drilling process, thereby improving slim hole drilling efficiency.

Owner:SOUTHWEST PETROLEUM UNIV

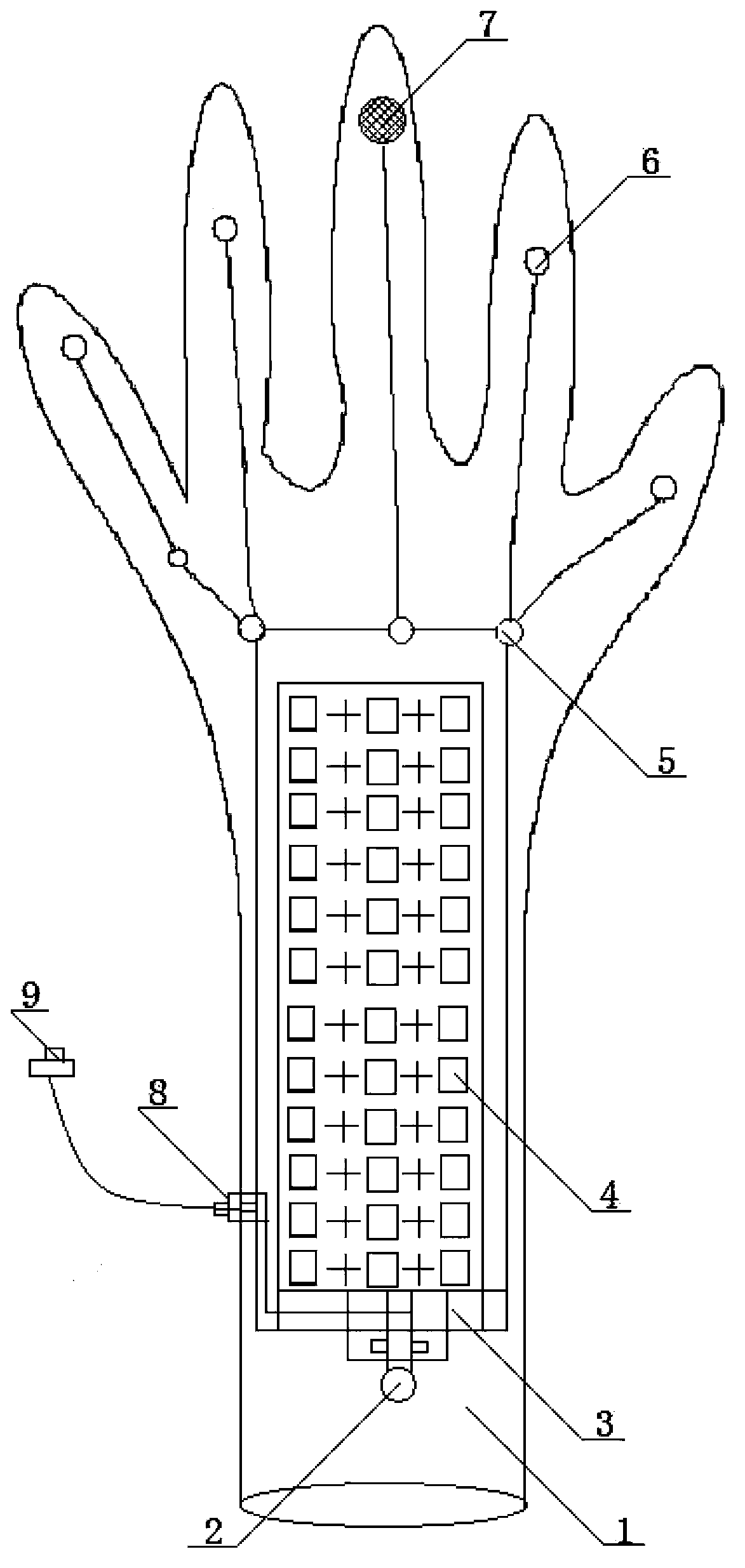

Ultrasonic oscillation and massage arm cover

InactiveCN104248501AHealth massage is convenientGentle massageDevices for pressing relfex pointsVibration massageElectricityMassage

The invention discloses an ultrasonic oscillation and massage arm cover. An ultrasonic oscillation module is arranged in the inner layer of an arm cover body; the ultrasonic oscillation module is respectively connected with a switch, an electricity transmission device and a plug; the ultrasonic oscillation module is provided with an ultrasonic oscillation circuit, an electromagnetic oscillation module and a finger oscillation module; the finger oscillation module is provided with a fingerprint oscillator, so, as long as a power supply is plugged and the switch is opened, corresponding acupoint massage can be performed on arms and hands to achieve the health-care goal.

Owner:赵旭

Test tube oscillator

InactiveCN105617918ASimple structureLow costShaking/oscillating/vibrating mixersTransportation and packagingWave formEngineering

The invention discloses a test tube oscillator. A test tube placement box is fixedly connected between two vertical plates front and back via springs, is hollow and is provided with an upward opening; a test tube positioning plate is fixedly connected into the test tube placement box, a plurality of test tube through holes are formed in the test tube positioning plate, baffles which are correspondingly arranged on the left and right sides are respectively fixedly connected between two vertical plates on the left and right sides of the test tube placement box, a push groove is transversely formed in each baffle and is of a wave form, a push rod is movably inserted into the left and right push grooves, and the test tube placement box is erected on the push rod; support plates are fixedly connected to the lower part of the test tube placement box, support grooves are formed in the support plates along the length direction of the support plates, and the push rod passes through the support grooves; inner bearings are in transmission connection to the outside of the push rod in the support grooves; the two support plates are fixedly connected to the lower part of the test tube placement box, and the push rod passes through the left and right support grooves; a plurality of connected pits are formed in the lower sides of the push grooves in a downward sinking manner, balls are arranged in the pits in a rolling manner, and the push rod is in rolling contact with the balls.

Owner:于红艳

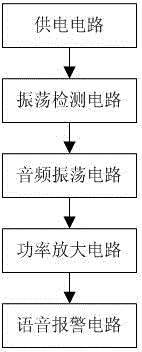

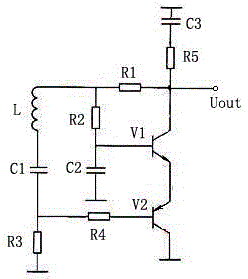

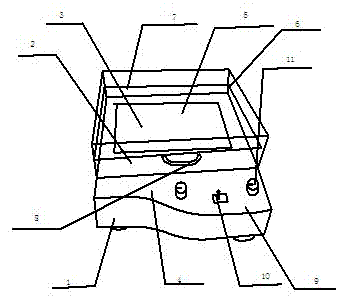

Oscillation detection-based metal detector

InactiveCN105607132AImprove the detection effectOscillation effect is goodOscillations generatorsElectric/magnetic detectionPhysicsInductor

The invention discloses an oscillation detection-based metal detector. The metal detector includes a power supply circuit, an oscillation detection circuit, an audio oscillation circuit, a power amplification circuit, a filtering circuit and a voice alarm circuit; the oscillation detection circuit includes an inductor, a first resistor, a second resistor, a third resistor, a first capacitor, a second capacitor, a first transistor and a second transistor; one end of the inductor is connected in series with the first capacitor and the third capacitor, and then, the third capacitor is grounded; the other end of the second resistor is connected with the second capacitor, and then, the second capacitor is grounded; the other end of the second resistor is connected with the base of the first resistor; the emitter of the first resistor is connected with the collector of the second transistor; the collector of the first transistor is grounded; the base of the second transistor is connected with one end of the third resistor; the emitter of the second transistor is grounded; and the other end of the first resistor is connected with a voltage output end. The oscillation detection-based metal detector responds timely when detecting a metal object, and the practicability of the metal detector in detection can be improved.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Thermostatic oscillator

InactiveCN103084231ACutting costsMeet temperature requirementsHeating or cooling apparatusShaking/oscillating/vibrating mixersPhysics

Owner:刘海源

Novel hydraulic oscillator for downhole operations in oil field

The invention discloses a novel hydraulic oscillator for downhole operations in an oil field. The hydraulic oscillator comprises a sleeve, wherein the bottom of the sleeve is connected with a containing cylinder, the containing cylinder is a round table shape, a movable terminal is arranged in the sleeve, and the bottom of the movable terminal is provided with a group of arc-shape through groovesaround the circumference; two ends of the arc-shape through grooves are provided with openings, the arc-shape through grooves penetrate through opening elastic sleeves, two ends of the opening elasticsleeves are connected with clamping plates, the opening elastic sleeves penetrate through springs, the springs are connected with oscillating balls, and the clamping plates are fixed through bolts; the springs are sleeved with soft sleeves, the tops of the soft sleeves are provided with a group of top connecting holes around the circumference, the top connecting holes are connected with top metalwires, the top metal wires are bound to the tops of the springs, the bottoms of the soft sleeves are provided with a group of bottom connecting holes around the circumference, the bottom connecting holes are connected with bottom metal wires, and the bottom metal wires are bound to the bottoms of the springs. The hydraulic oscillator is used for downhole operations in an oil field.

Owner:陈玉

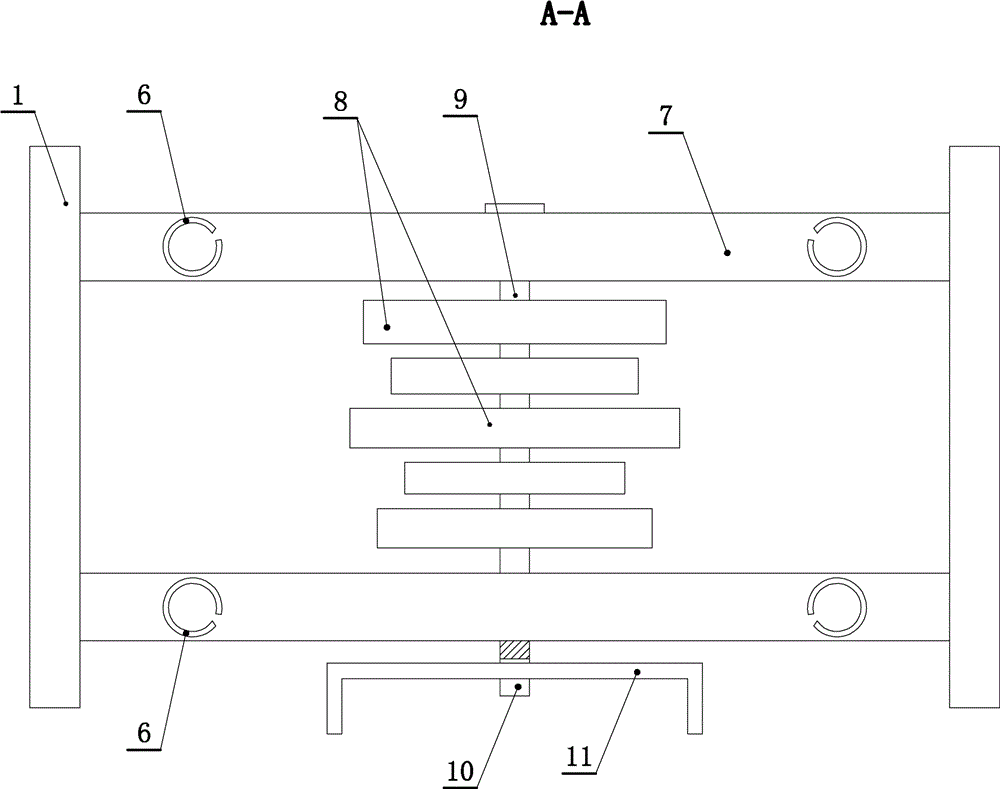

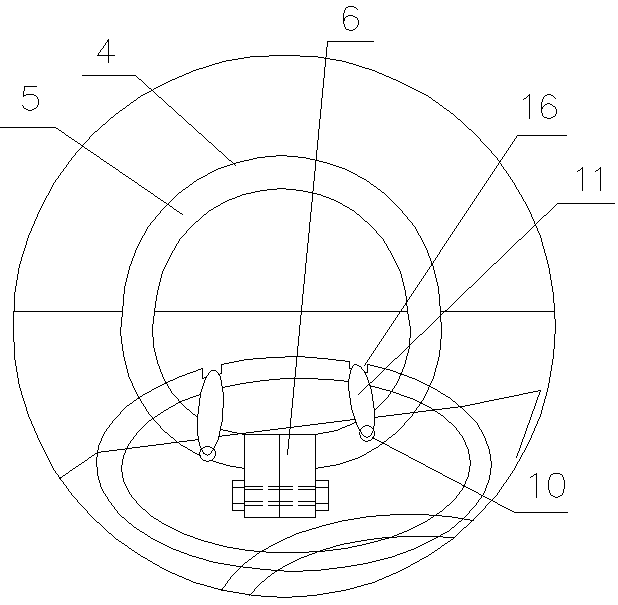

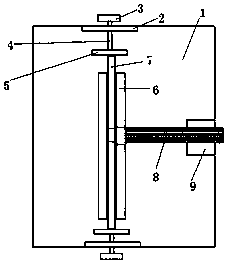

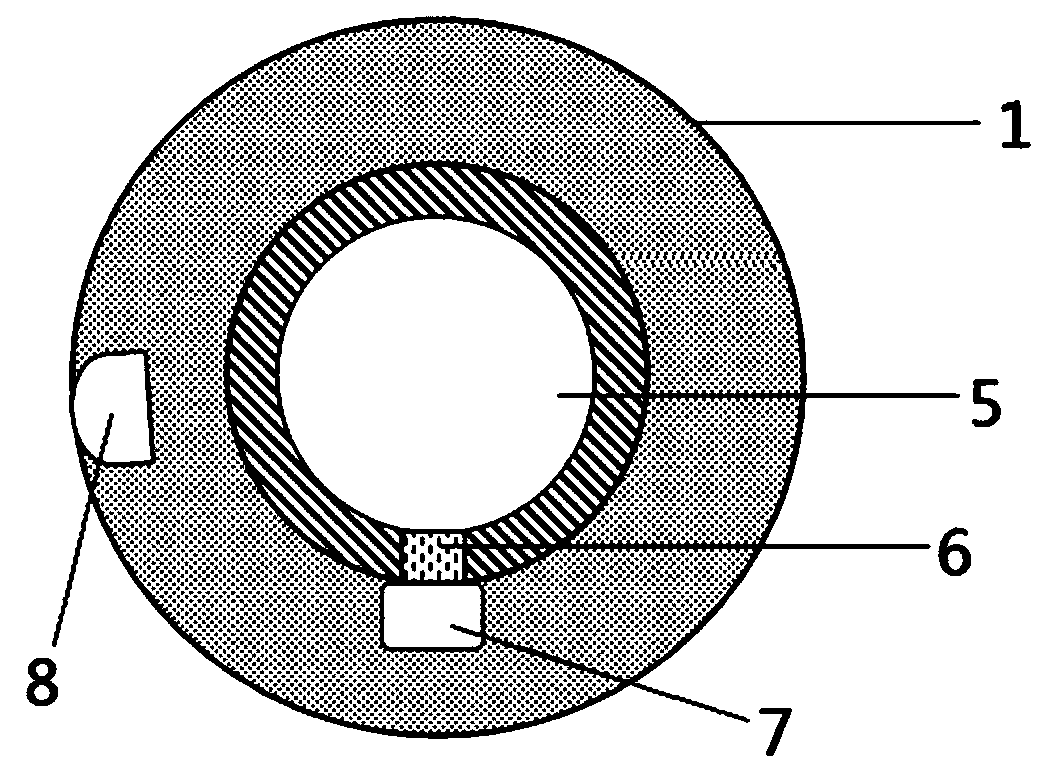

Inclined block eccentric type three-dimensional hydroscillator

PendingCN110145235AOscillation effect is goodFix security issuesVibration drillingClamp connectionUpper joint

The invention relates to hydroscillators, in particular to an inclined block eccentric type three-dimensional hydroscillator. The inclined block eccentric type three-dimensional hydroscillator is composed of a shell, an axial oscillation part and a radial oscillation part. An upper joint is arranged in a port in one end of an upper shell in a threaded manner, the axial oscillation rod is movably arranged at the position, below the upper joint, in the upper shell, the axial oscillation part is connected with the upper joint through a spring, the other end of the upper shell is provided with a lower shell in a threaded manner, the radial oscillation part is movably mounted in the lower shell through a thrust bearing, the radial oscillation part and the axial oscillation part are in clamped connection, and a lower joint is arranged on the bottom end of the lower shell in a threaded manner. The inclined block eccentric type three-dimensional hydroscillator has the advantages of being safe,reliable and good in oscillation effect. The problem that an existing oscillator is single in safety and oscillation effect is solved, and the oil and gas development needs can be met.

Owner:YANGTZE UNIVERSITY

Table self with acoustics function

InactiveCN101091607ASave spaceOscillation effect is goodTransducer detailsTablesEngineeringSurface plate

The present invention provides a table whose self-body has acoustic function. It is characterized by that it includes a table body, in the described table body interior a plane horn is mounted, the described plane horn is connected with an audio-frequency power amplification circuit, and the described audio-frequency power amplification circuit is connected with a power supply circuit. The described plane horn includes a drive ring capable of producing audio-frequency oscillation, and the described drive ring is mounted on the back surface of tabletop, and said plane horn adopts NXT plane horn, so that said table can produce good audio effect.

Owner:郭海生

Oscillator capable of automatically controlling temperature

InactiveCN107983233AImprove work efficiencyImprove securityShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMoisture sensor

The invention provides an oscillator capable of automatically controlling temperature and relates to the technical field of oscillation equipment. The oscillator comprises a machine box, a shaking table and a sealing cover, wherein a heating tube and a mist nozzle are arranged on the sealing cover; the inner wall of the machine box is fixedly connected with a temperature sensor and a humidity sensor; a transverse rod is arranged in the machine box; the middle position of the transverse rod is sleeved with a main sliding block with a vertical groove in the middle part; secondary sliding blocksidentical in number are arranged on two sides of the main sliding blocks and are sleeved with the transverse rod; the top end surfaces of the main sliding block and the secondary sliding blocks are fixedly connected with the lower end surface of the shaking table; the main sliding block is in sliding connection with a square block at one end of a rotating mechanism; the other end of the rotating mechanism is fixedly connected with a motor; a plurality of heat dissipation tubes are also arranged at the lower end of the machine box; a muffler is arranged in each heat dissipation tube. The oscillator has the beneficial effects of high safety and low production cost, and is capable of effectively reducing the noise generated by operation of the constant-temperature oscillator and adjusting theoperation temperature of the reactant in the shaking table.

Owner:佛山市高明区生产力促进中心

Test tube shaker

InactiveCN105617918BSimple structureLow costShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMaterial Perforation

A test tube oscillator, a test tube placement box is fixedly connected by springs between the front and rear vertical plates, the test tube placement box is hollow and has an upward opening, a test tube positioning plate is fixedly connected to the test tube positioning box, and a test tube positioning plate is set There are multiple test tube perforations; the two vertical plates on the left and right sides of the test tube storage box are respectively fixedly connected with left and right corresponding baffles, and each baffle is provided with horizontal push grooves, and the push grooves are wavy. A push rod is plugged in the left and right push grooves, and the test tube placement box is erected on the push rod. A support plate is fixedly connected to the bottom of the test tube placement box, and the support plate is provided with a support groove along its length direction, and the push rod passes through the support groove. The outer transmission of the push rod in the support groove is connected with an inner bearing. Two support plates are fixedly connected to the bottom of the test tube placement box, and the push rod passes through the left and right support grooves. The lower side wall of the push groove is recessed downwards and provided with a plurality of connected pits, balls are rollingly arranged in the pits, and the push rod is in rolling contact with the balls.

Owner:于红艳

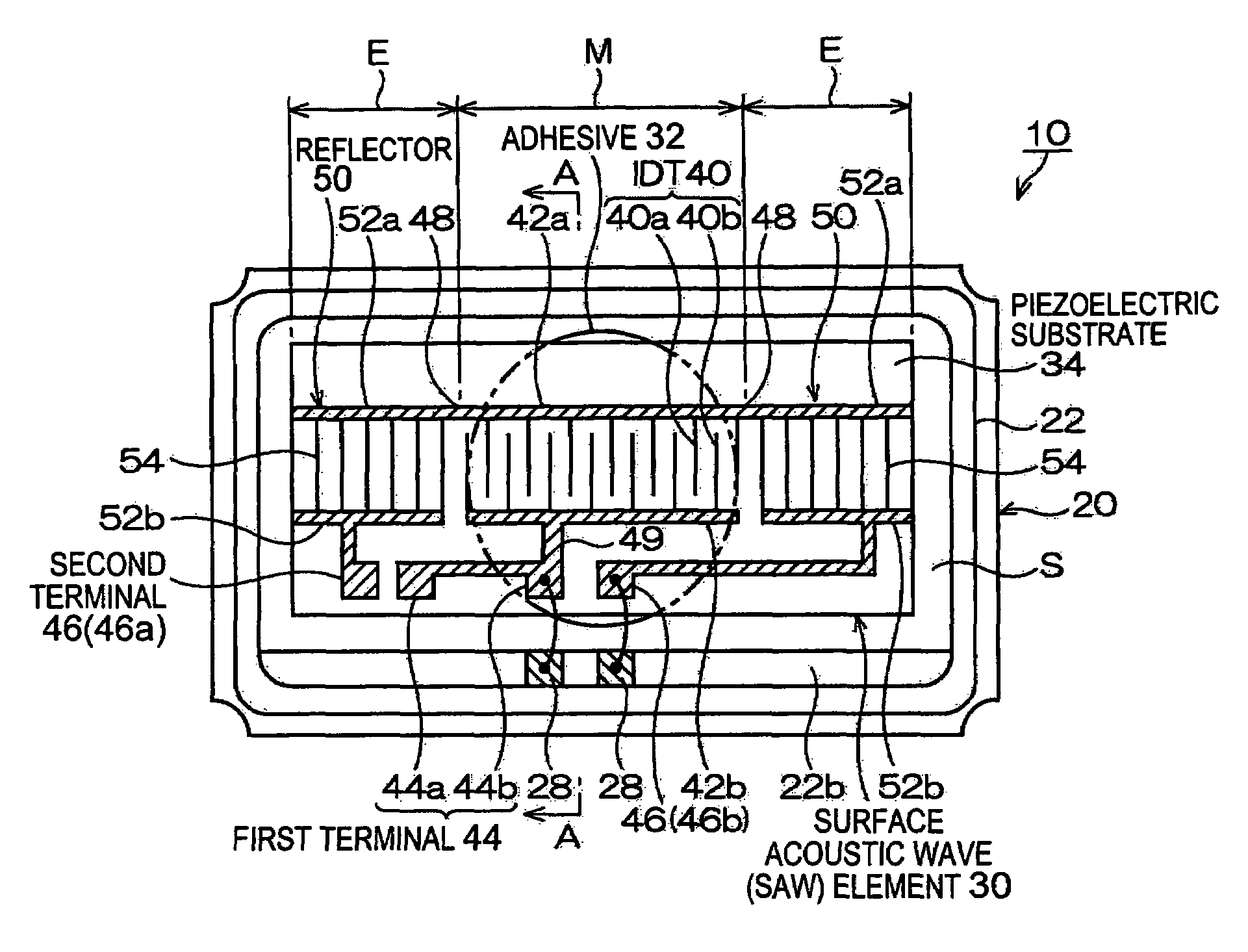

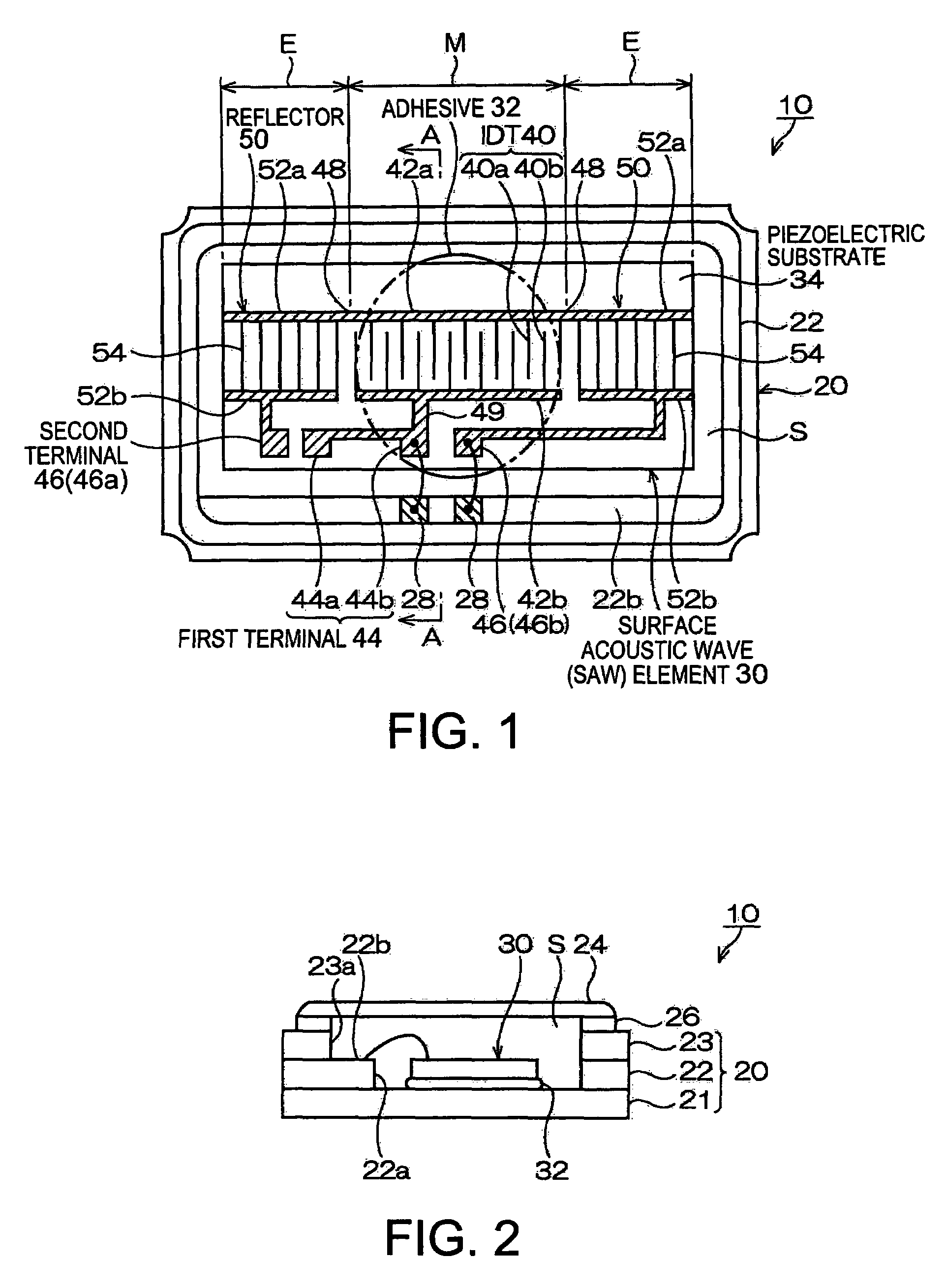

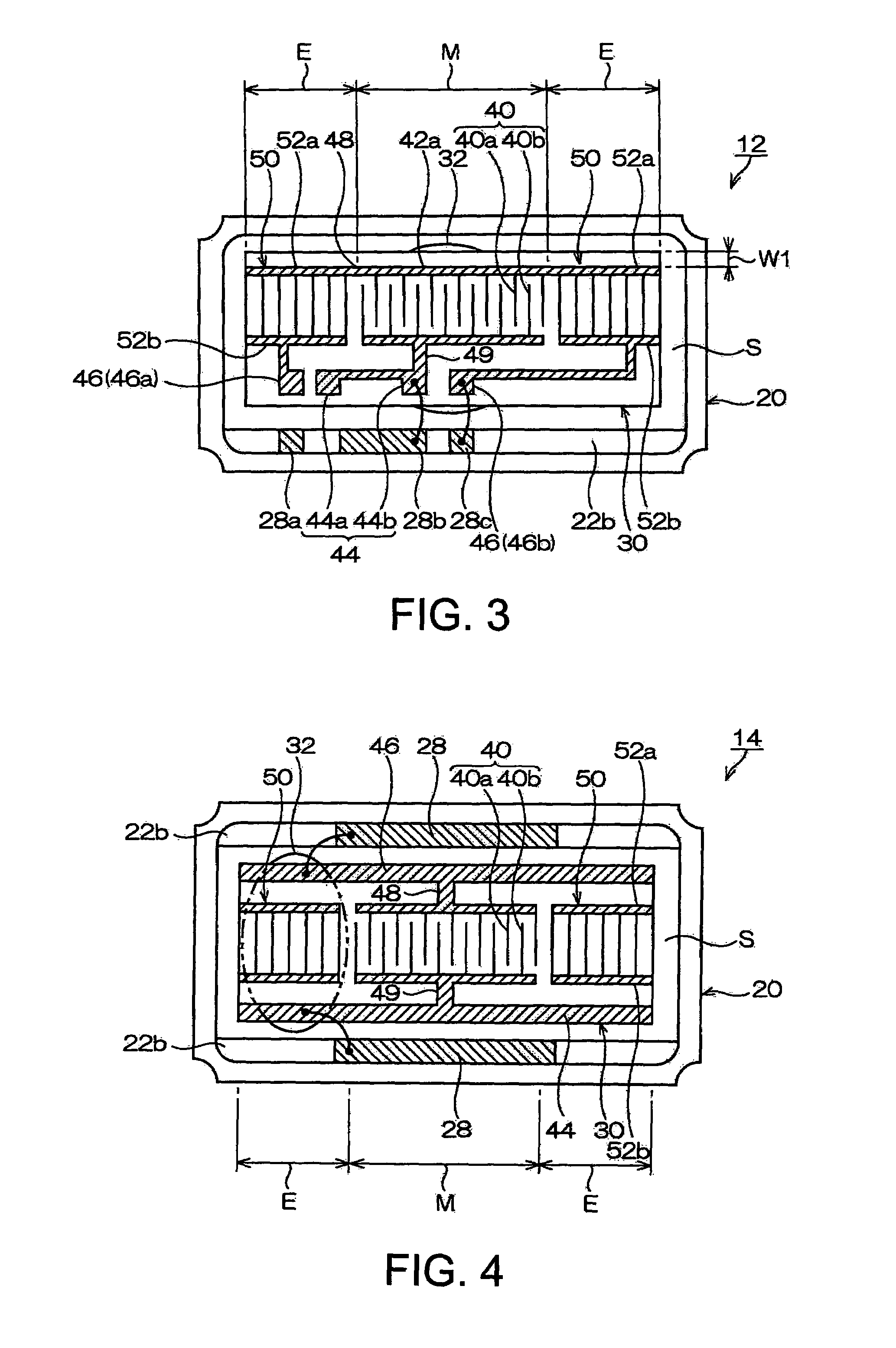

Surface acoustic wave element and surface acoustic wave device using the same

InactiveUS7474034B2Low priceOscillation effect is goodPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface acoustic wave sensorAdhesive bonding

A surface acoustic wave element includes a piezoelectric substrate, an IDT composed of a pair of first and second comb-like electrodes, formed around a center of the piezoelectric substrate, and formed on a surface of the surface acoustic wave element, and a pair of first and second terminals electrically connected to the IDT, formed at central and peripheral areas of the piezoelectric substrate, respectively, in which a package is bonded with an adhesive to a surface of the surface acoustic wave element, opposite to the surface formed with the IDT.

Owner:SEIKO EPSON CORP

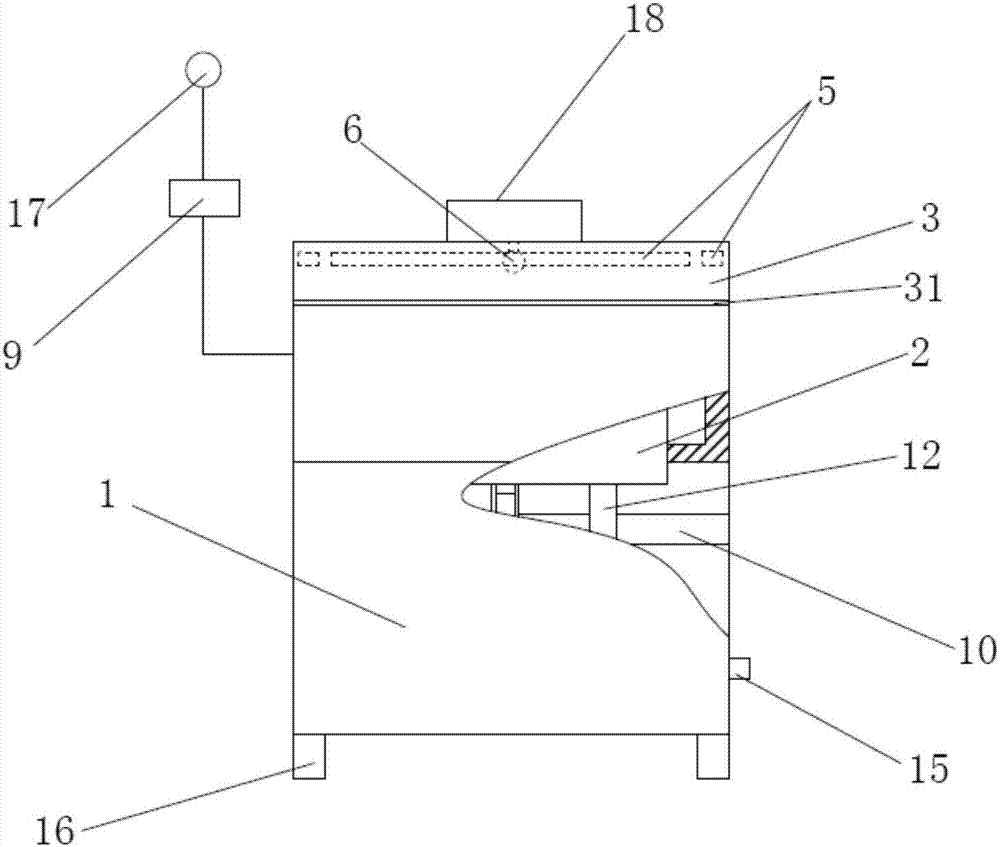

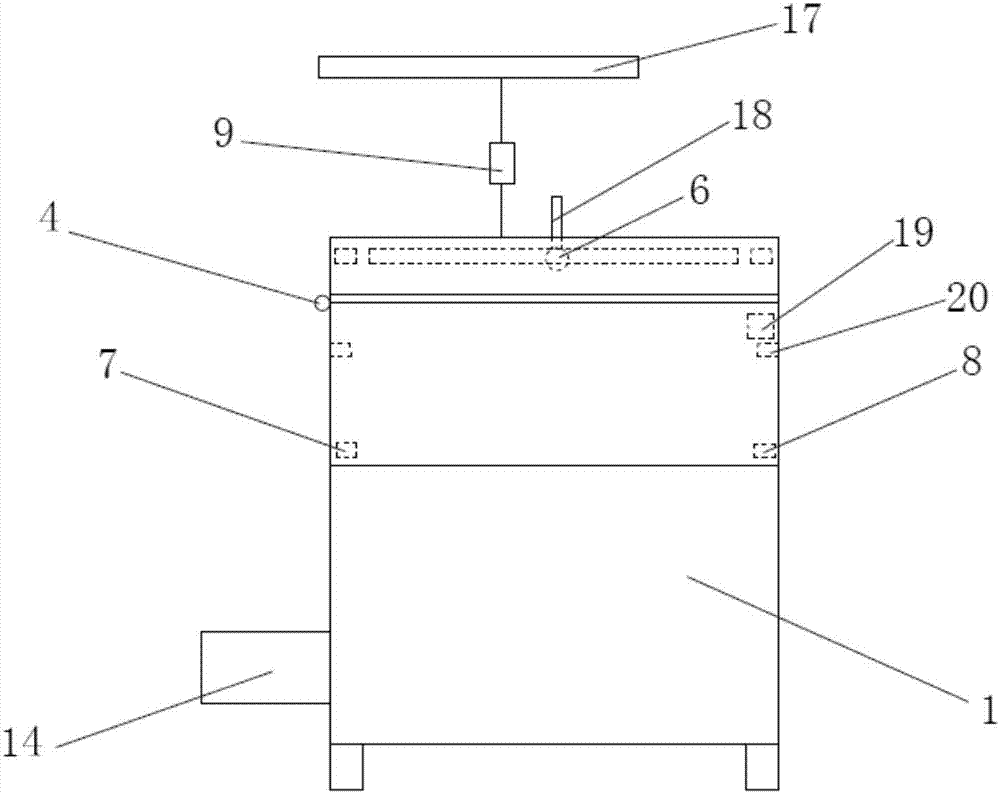

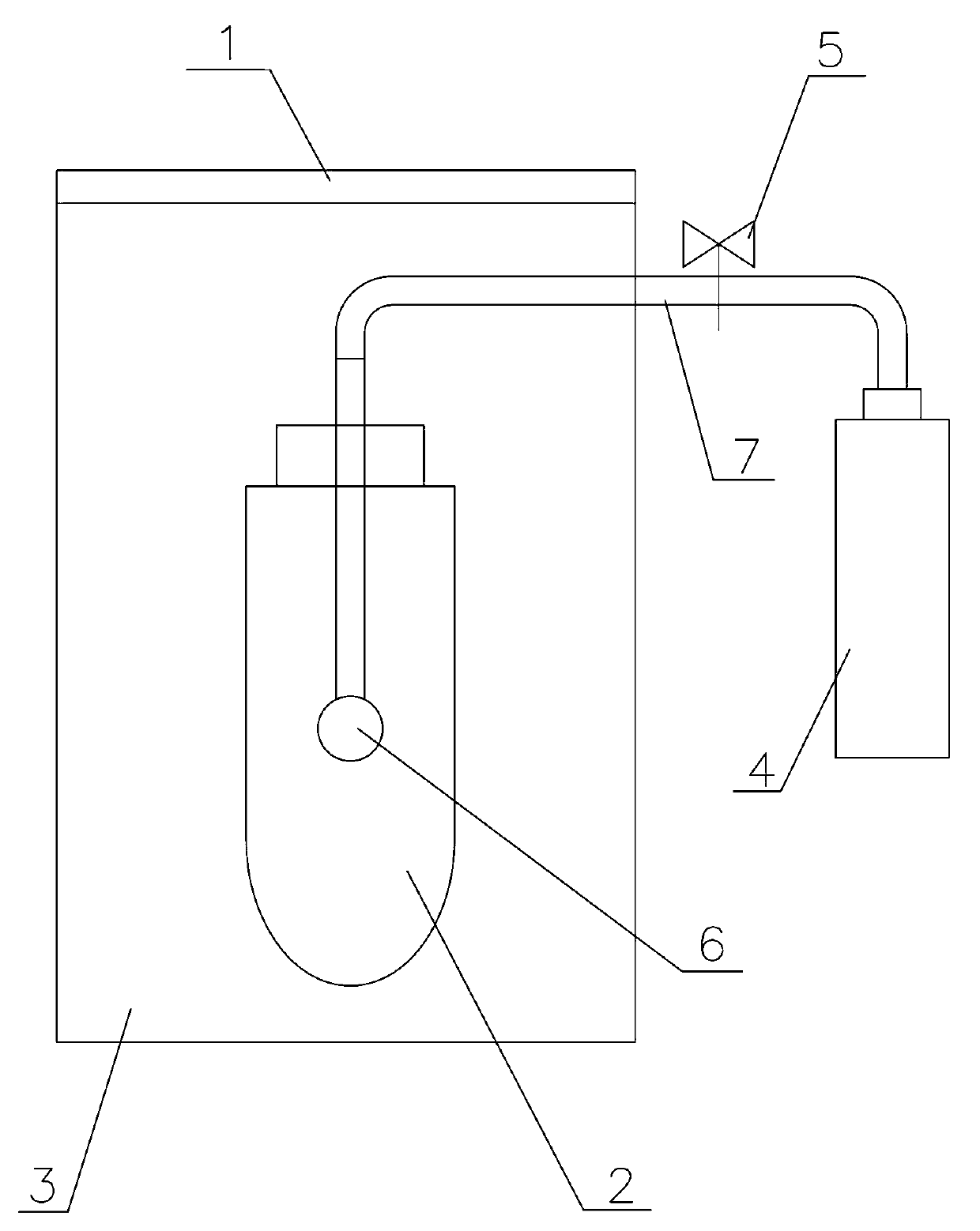

Pneumatic oscillatory type cell culture system

InactiveCN102337212BCause damageIngenious structureTissue/virus culture apparatusWater bathsCulture fluid

The invention discloses a pneumatic oscillatory type cell culture system which comprises a constant temperature water bath box, wherein a culture bottle is arranged in the constant temperature water bath box and the culture bottle is internally provided with an air pump device. According to the invention, since the air pump device is arranged in the culture bottle, after the culture bottle is full filled with culture liquid containing experiment cells, the constant temperature water bath box can provide constant temperature water bath, the air pump device can pump air in the culture liquid, the pumped air naturally drives the culture liquid to turn over and oscillate, and because the oscillation is not forced oscillation caused by a mechanical stirring device, the cells can not be damaged. The pneumatic oscillatory type cell culture system has the advantages of simple and ingenious structure and good oscillation effect, can be widely applied to experiments of cell culture, fermentation, hybridization, biochemistry, enzyme and cell tissue and the like.

Owner:广州市尤德生物科技有限公司

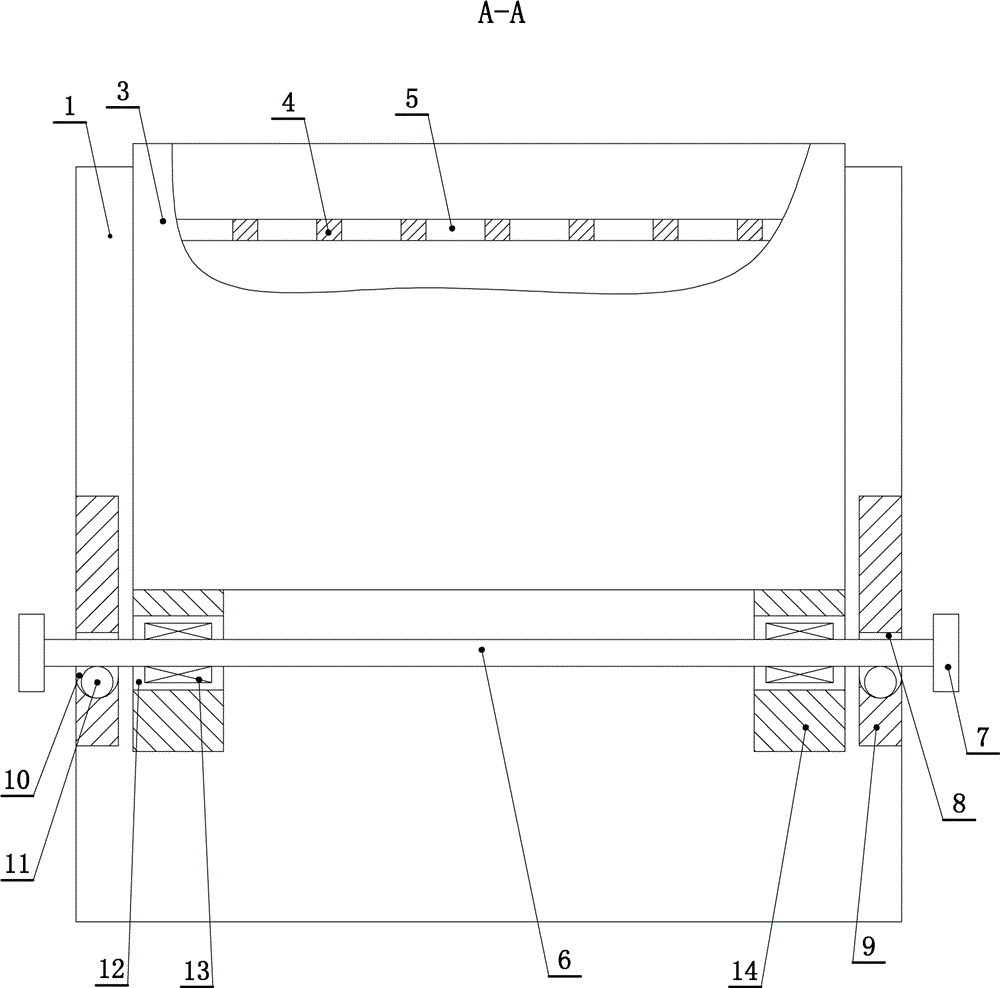

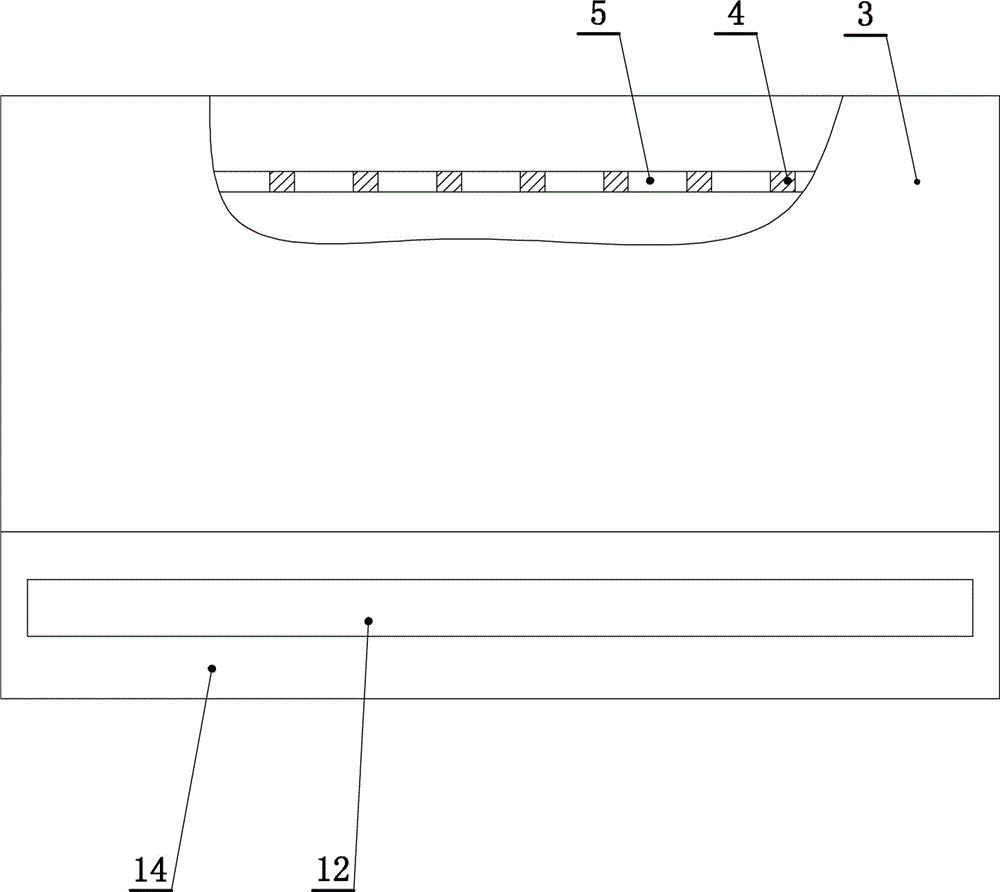

Four-eccentric-wheel drive forced oscillation device for super-finishing machining and using method

PendingCN112192328AGood linearityOscillation frequency and amplitude are stableGrinding machine componentsSuperfinishing machinesForced oscillationFour-wheel drive

The invention discloses a four-eccentric-wheel drive forced oscillation device for super-finishing machining. The device comprises a rack, a four-wheel drive shaft system and oscillation mechanisms, wherein the four-wheel drive shaft system comprises an eccentric shaft, a right oscillation frame assembly, a left oscillation frame assembly, a right drive eccentric wheel pair, a left drive eccentricwheel pair, an eccentric shaft front supporting bearing and an eccentric shaft rear supporting bearing, two eccentric wheels of the right driving eccentric wheel pair are installed on the inner sideof the eccentric shaft front supporting bearing and the inner side of the eccentric shaft rear supporting bearing respectively, two eccentric wheels of the left driving eccentric wheel pair are installed on the inner side of the right driving eccentric wheel pair, two eccentric wheels of the right driving eccentric wheel pair are framed in two oscillating frames of the right oscillating frame assembly respectively, and two eccentric wheels of the left driving eccentric wheel pair are framed in two oscillation frames of the left oscillation frame assembly respectively. The device has the advantages of better oscillation linearity, stable oscillation frequency and amplitude, more stable oscillation, small driving torque and the like, and can keep good oscillation precision and performance for a long time.

Owner:HENAN UNIV OF SCI & TECH

A brush automatic embedding machine

ActiveCN108199245BThread embedding processing speed is fastImprove automationDynamoelectric machine connectorsBrushes manufactureEngineeringBrush

Owner:江苏民威电碳科技有限公司

Traction type oscillator for inspection

InactiveCN107812487AAchieve left and right movementSimple structureShaking/oscillating/vibrating mixersTransportation and packagingEngineeringTransverse mode

Owner:梁艳

Table tool with sounding function

The invention provides a table tool with a sounding function. The table tool comprises a table body, wherein a plane loudspeaker is arranged in the table body and is connected with an audio amplifying circuit; the audio amplifying circuit is connected with a power supply circuit; the plane loudspeaker comprises a driving ring which generates audio oscillation; the driving ring is arranged on the back surface of a table tool panel of the table body; the plane loudspeaker is the plane loudspeaker of NXT company; the table tool panel is a wooden panel with a good oscillating effect; the driving ring is stuck to the back surface of a table tool panel. Due to the fact that the table tool adopts the plane loudspeaker of England NXT company, the driving ring which can generate audio oscillation and the wooden table panel with the good oscillating effect are fully combined, the table tool panel oscillates and excites air, the table tool becomes a uniform sounding body and is good in sounding effect and outstanding in tone, and the whole structural design is ingenious, the table tool is very convenient to use, and the space of a table top is saved.

Owner:TIANJIN FENGCAI TECH

Lifting Rocking Oscillator

ActiveCN105478044BSimple structureLow costShaking/oscillating/vibrating mixersTransportation and packagingJoystickEllipse

A lifting and swinging oscillator, the left and right brackets are fixedly connected with the front and rear corresponding beams, and the front and rear beams are connected with a plurality of non-circular turntables arranged side by side through the relative rotation of the rotating shaft, and the rotating shaft and the beam rotate relatively connection, the rotating shaft is fixedly connected with the turntable, and one end of the rotating shaft is connected with a rocker; the upper end of the beam is fixedly connected with a vertical spring, and the upper end of the spring is fixedly connected with a hollow test tube holding box with an upward opening. The box is erected on the turntable, and the test tube box is located between the left and right brackets. The test tube box is fixedly connected with a shelf, and a plurality of test tube perforations are arranged vertically and horizontally on the shelf. The turntable is one or more of ellipse, triangle or rectangle. The intersection point of the turntable and the rotating shaft deviates from the center of the turntable. A baffle is fixedly connected to the inner side of the support, and the test tube holding box is located in the area surrounded by the baffle. The baffle is triangular, rectangular or trapezoidal.

Owner:陈晓熠

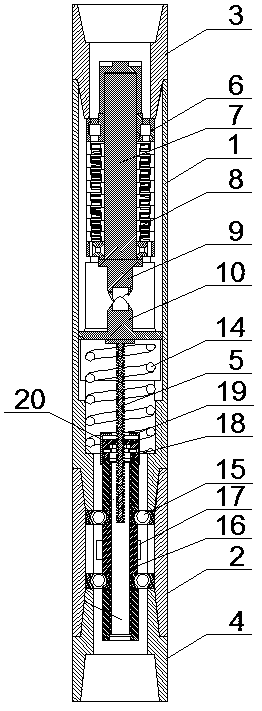

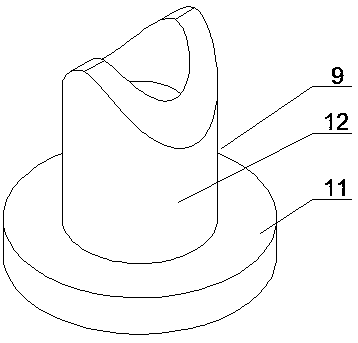

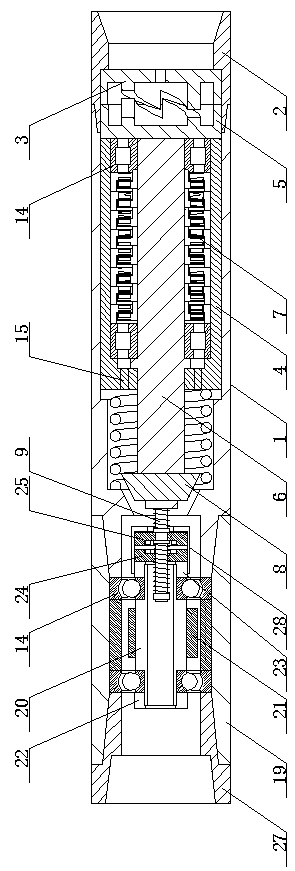

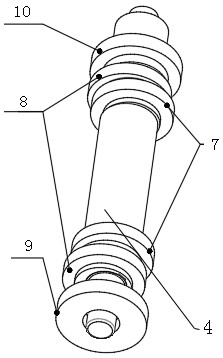

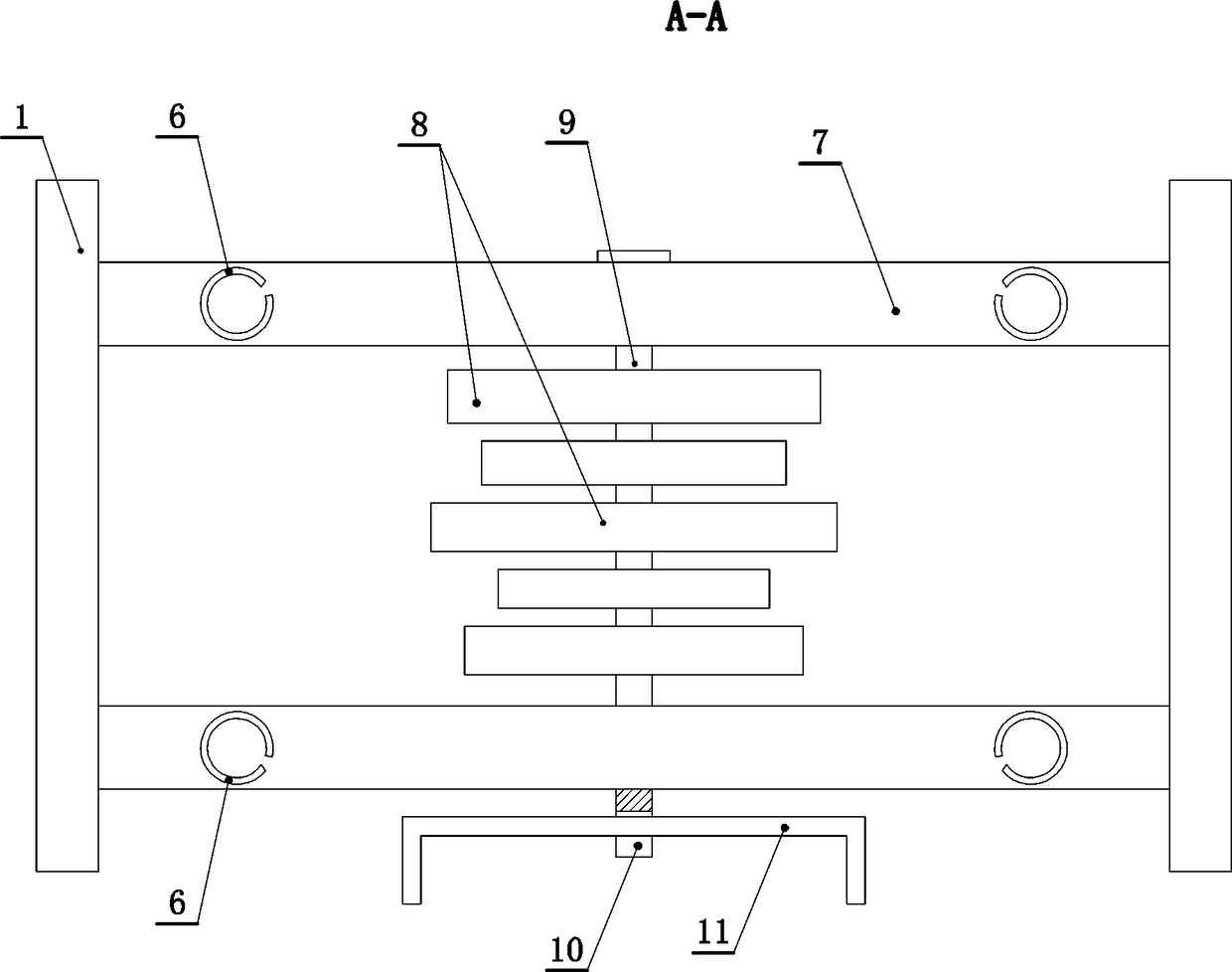

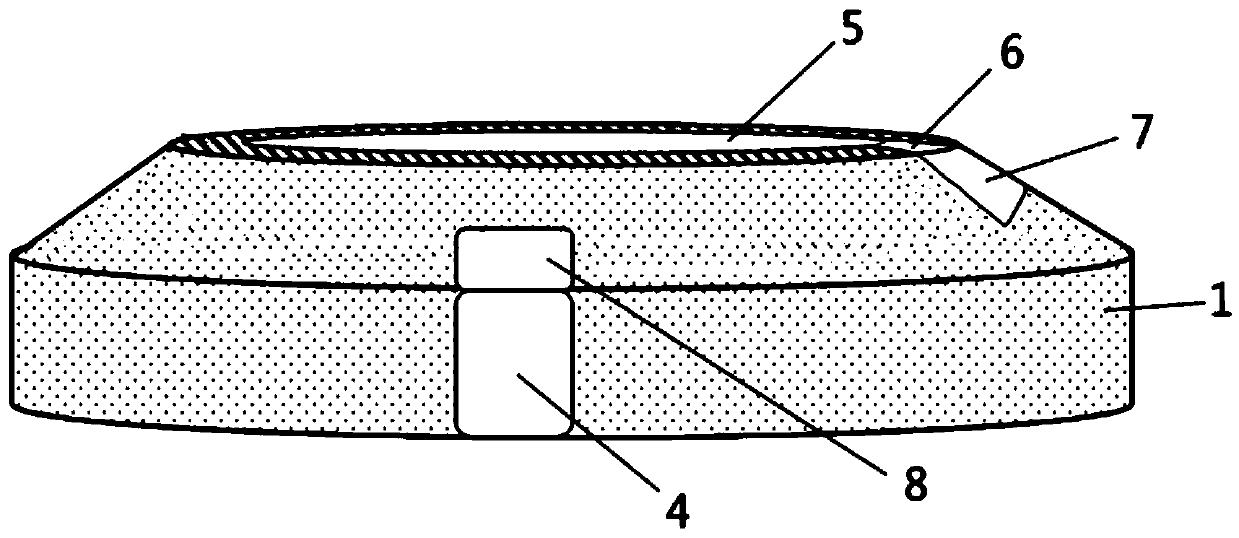

Push rod type three-dimensional hydraulic oscillator

ActiveCN111021961AOscillation effect is goodIncrease the oscillation frequencyVibration devicesVibration drillingBall bearingUpper joint

The invention relates to a hydraulic oscillator, in particular to a push rod type three-dimensional hydraulic oscillator. The push rod type three-dimensional hydraulic oscillator is composed of a shell, an upper joint, a lower joint, a one-way valve, a transmission part and an oscillating part. The upper joint is mounted at the end of one end of the shell in a threaded mode. The lower joint is mounted at the end of the other end of the shell in a threaded mode. The transmission part is arranged in the shell on one side of the upper joint. The one-way valve is mounted in the shell between the transmission part and the upper joint. The oscillating part is mounted in the shell between the transmission part and the lower joint through symmetrically arranged ball bearings, and is connected withthe transmission part. The push rod type three-dimensional hydraulic oscillator has the characteristics of good oscillation effect and high oscillation frequency, solves the problems of the simplex oscillation mode and low oscillation frequency of an existing oscillator, and meets requirements of petroleum drilling.

Owner:YANGTZE UNIVERSITY

Piezoelectric ceramic atomizer plate

PendingCN111185340APrevent proliferationSolve the phenomenon that the amount of atomization is too smallLiquid spraying apparatusSolderingCeramic

The invention relates to a piezoelectric ceramic atomizer plate which comprises a piezoelectric ceramic chip, wherein the upper portion of the piezoelectric ceramic chip is in a circular truncated cone shape, and the lower portion of the piezoelectric ceramic chip is cylindrical. A front round electrode is arranged on the bottom face of the piezoelectric ceramic chip, and a reverse round electrodeand a reverse electrode connecting wire are arranged on the top face of the piezoelectric ceramics chip. A reverse electrode welding area is connected with the reverse round electrode through the reverse electrode connecting wire to achieve conduction. A reverse welding area is connected with the front round electrode through a side face connecting wire to achieve conduction. The welding areas are arranged on circular truncated cone slopes of the piezoelectric ceramics chip, direct influence of the welding areas on electrode oscillation can be effectively avoided, the atomizing effect has noloss and is not affected, and meanwhile, soldering tin can be prevented from diffusing to the surface of the round electrode. In addition, due to the fact that the upper portion of the piezoelectric ceramic chip is in a circular truncated cone shape, and the lower portion of the piezoelectric ceramic chip is cylindrical, the effect gathering effect of products can be effectively motivated, and a good atomizing effect can be achieved.

Owner:HUNAN JIAYEDA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com