Piezoelectric ceramic atomizer plate

A piezoelectric ceramic sheet, piezoelectric ceramic technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of affecting the atomization amount and atomization effect of the product, unstable atomization process, low sensitivity to water cut, etc. The effect of gathering energy, avoiding the phenomenon of dry burning, and improving the sensitivity of water cut off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and example the present invention will be further described:

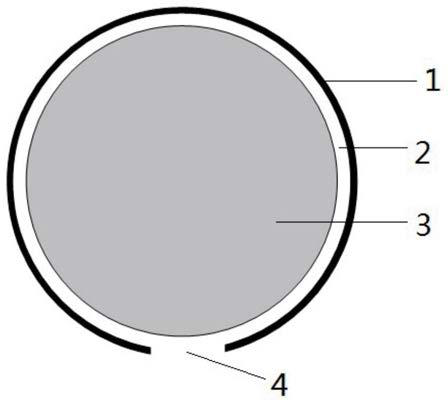

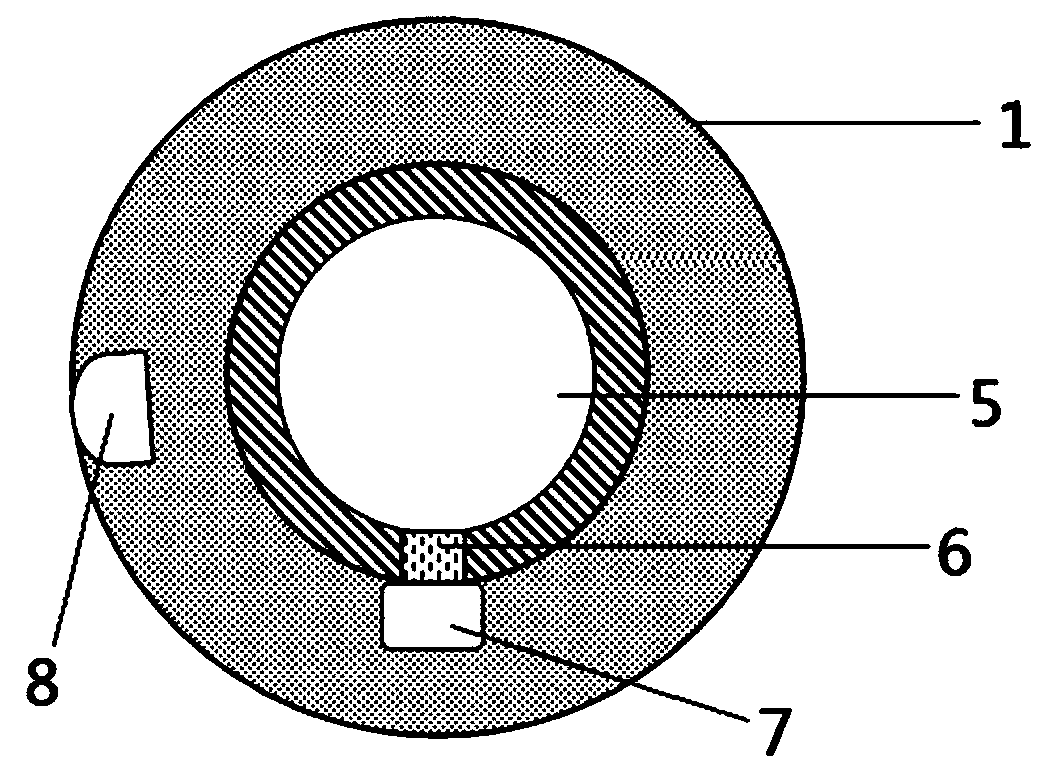

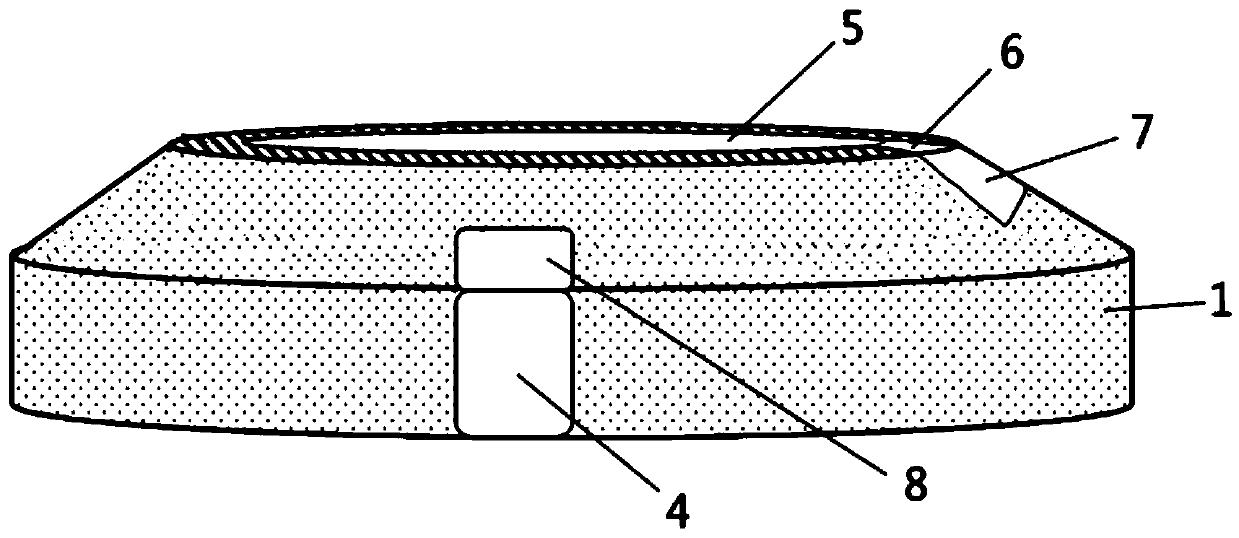

[0025] An example of the present invention is figure 1 , figure 2 , image 3 As shown, the piezoelectric ceramic sheet 1 is included. The upper part of the piezoelectric ceramic sheet 1 is in the shape of a truncated cone and the lower part is cylindrical in shape. The bottom surface of the electric ceramic sheet 1 is provided with a front circular electrode 2; the top surface of the piezoelectric ceramic sheet 1 is provided with a reverse circular electrode 5 and a reverse electrode connection line 6; There are reverse electrode welding areas 7 and reverse welding areas 8, and side connection lines 4 are arranged on the cylinder side of the piezoelectric ceramic sheet 1; The back welding area 8 is connected to the front circular electrode 2 through the side connection line 4 to form a conduction. Since the reverse electrode welding zone 7 and the reverse s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com