Slim hole drilling friction reduction and resistance reduction speed increase tool

A technology for reducing friction and drag, and wellbore, which is applied in wellbore/well components, earthwork drilling, vibration generating devices, etc. The effect of few moving parts and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

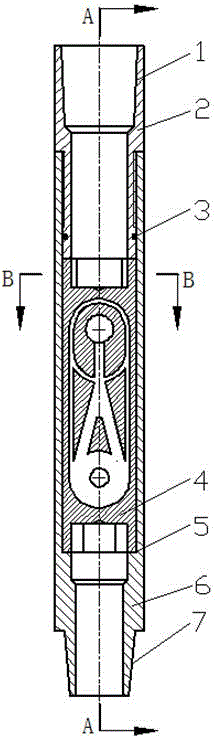

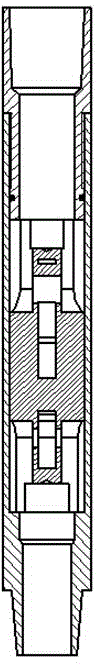

[0016] Such as figure 1 As shown, a slimhole drilling tool of the present invention for reducing friction and increasing speed includes an upper nipple 2, a casing 6, and an inner chamber 4; it is characterized in that: the casing 6 and the upper nipple 2 are connected by threads, The housing 6 is provided with an inner chamber 4 located on a step 5, and the lower part is provided with a male button 7 connected with other drilling tool assemblies; the upper end of the upper nipple 2 is provided with a female button 1 connected with the upper drill tool assembly or drill string , the lower end is provided with a sealing groove for installing a sealing ring 3; the inner chamber

[0017] There is a special flow channel 17 in the 4, and the special flow channel 17 is composed of the nozzle 9, the drilling fluid reversing channel I10, the drilling fluid reversing channel II16, the return chamber 13, the drilling fluid pressure feedback channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com