Four-eccentric-wheel drive forced oscillation device for super-finishing machining and using method

An oscillating device and four-wheel drive technology, which is applied in the field of machining and manufacturing, can solve the problem that the use performance is difficult to meet the needs, and achieve the effects of improving the stability of oscillation, the retention of oscillation performance, good linearity, and the stability of oscillation frequency and amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

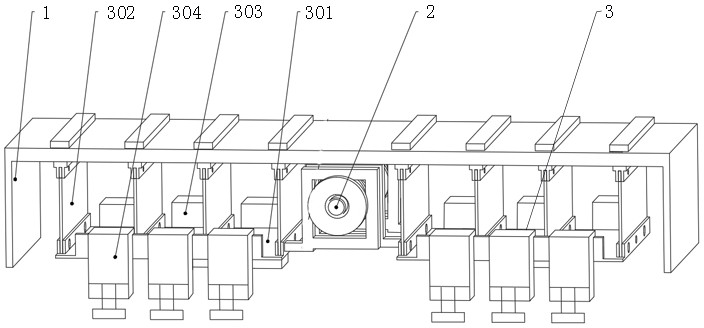

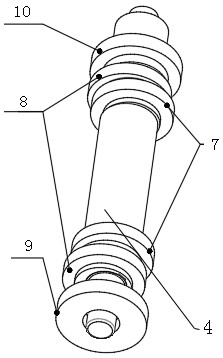

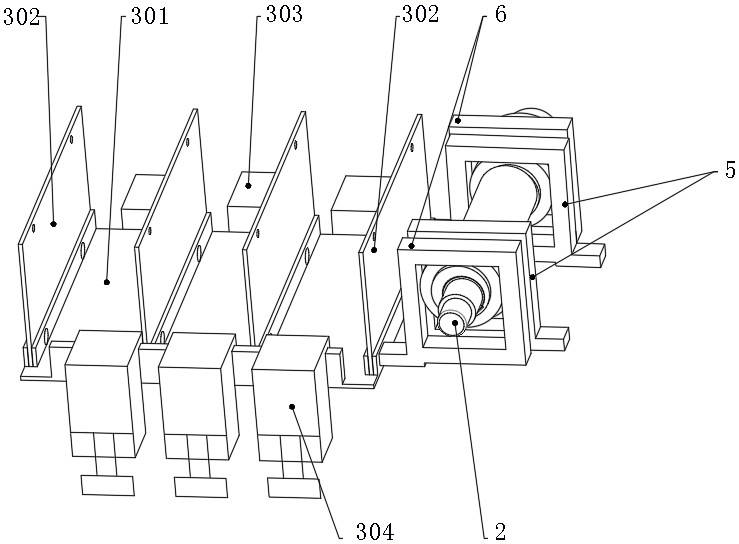

[0025] Four eccentric wheels drive the forced oscillation device for ultra-finishing processing, which has excellent performances such as better linearity of oscillation, stable oscillation frequency and amplitude, more stable oscillation, and small driving torque, and can maintain good oscillation accuracy and performance for a long time, such as figure 1 As shown, it includes a frame 1, a four-wheel drive shaft system 2 and an oscillation mechanism 3. The four-wheel drive shaft system 2 is installed in the center of the frame 1 through the bearings at both ends of the shaft, and the oscillation mechanism 3 includes two groups ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com