Three-dimensional hydraulic oscillator

A hydraulic oscillator, three-dimensional technology, applied in the direction of vibration drilling, vibration generating device, fluid using vibration, etc., can solve the problems of affecting drilling speed, reducing drilling efficiency, sticking drill, etc., to improve drilling efficiency and vibration effect Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

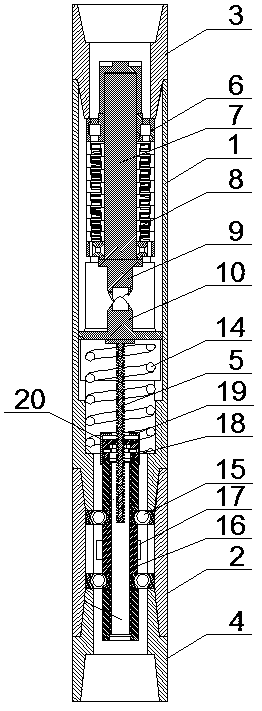

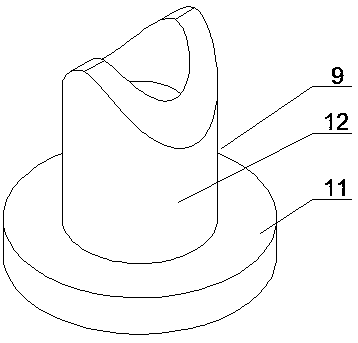

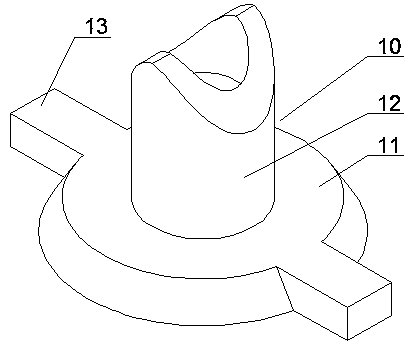

[0023] This three-dimensional hydraulic vibrator is made up of upper shell 1, lower shell 2, upper joint 3, lower joint 4 and screw rod 5 by it, threaded connection between upper shell 1 and lower shell 2; The center of upper shell 1 The hole is a stepped hole; one end of the upper shell 1 is threaded with an upper joint 3; one end of the lower shell 2 is threaded with a lower joint 4 . The upper rotating shaft 7 is installed through the centralizing bearings 6 arranged symmetrically in the upper casing 1, and the upper rotating shaft 7 between the centralizing bearings 6 is equipped with a turbine group 8; the turbine group 8 includes a rotor and a stator. The lower end of the upper rotating shaft 7 is fixedly equipped with an upper cam 9 , and a lower cam 10 is movably installed in the upper housing 1 below the upper cam 9 . The upper cam 9 and the lower cam 10 are T-shaped respectively, and the upper cam 9 and the lower cam 10 are respectively composed of a cam disc 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com