Hydraulic oscillator

A hydraulic oscillator and power technology, applied in vibration generating devices, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increasing drilling tool friction, restricting drilling pressure, and easy deposition, etc., to improve friction Resistance, increase ROP, good vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

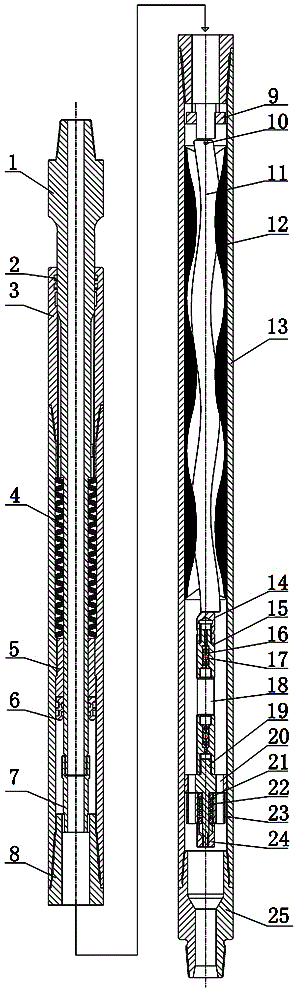

[0025] Such as figure 1 As shown, a hydraulic oscillator includes a mandrel 1, an upper joint 3, a disc spring 4, a mandrel middle joint 5, a mandrel lower joint 7, a screw pump, a disc valve group, an outer cylinder 13 and a lower joint 25, and the center The shaft 1 is a hollow cylinder structure, the mandrel 1 is inserted into the upper joint 3, the middle of the mandrel 1 is provided with a disc spring 4, the upper end of the disc spring 4 withstands the concave edge of the mandrel 1, and the lower end is pressed by the upper end of the mandrel joint 5 Tight, the joint 5 in the mandrel can move up and down, the lower end of the joint 5 in the mandrel is equipped with a piston 6, the lower joint 7 of the mandrel is arranged at the bottom of the mandrel 1, and the outer cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com