Sawing and drilling combined production line

A production line, saw-drilling technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low machining accuracy and many times of reverse transportation of workpieces, and achieve the effects of simple clamping, efficient and reliable positioning, and simple positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

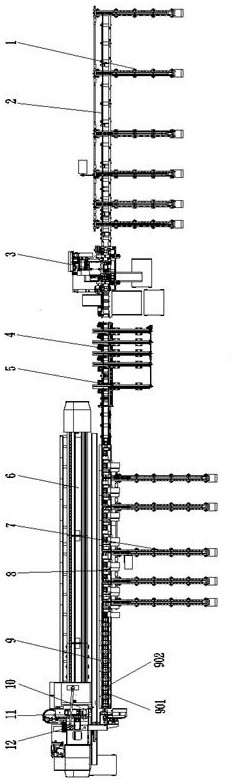

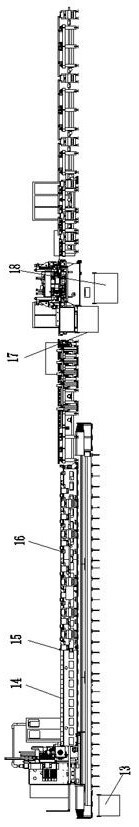

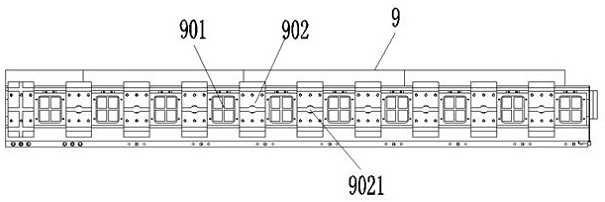

[0029] Attached below Figure 1-6 Specific examples of the present invention are described.

[0030] Saw-drilling combined production line, including upper feed rack 1, longitudinal feeding roller table 2, sawing unit 3, intermediate power roller table 4, horizontal lower residual material device 5, longitudinal workbench I8, longitudinal workbench II9, drilling unit, Horizontal blanking rack 7.

[0031] (Such as figure 1 As shown) the combined saw-drilling production line includes a horizontal feeding frame 1, and the horizontal feeding frame 1 is vertically connected to the vertical feeding roller table 2. The horizontal feeding frame 1 is used to convey the rails horizontally to the vertical feeding roller table 2. After the rails are conveyed to the vertical feeding roller table 2, the horizontal feeding frame 1 stops conveying, and the rails are transferred from the horizontal feeding frame 1 to the vertical feeding rollers. Automatic feeding of lane 2. Save manpower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com