Patents

Literature

216 results about "TOOTH IMPLANTATIONS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of porous structure with biological activity on surface of pure-titanium tooth implantation

InactiveCN1817319AImprove clinical successHas bone conductionDental implantsImpression capsBone tissueMedicine

A process for preparing the bioactive porous structure on the surface of Ti explant for tooth includes such steps as blasting sand, double acid treating, treating with H2O2 and heat treating. Its surficial TiO2 layer can induce the crystallization of hydroxy apatite, and has high compatibility to bone tissue and high successful rate.

Owner:ZHEJIANG UNIV

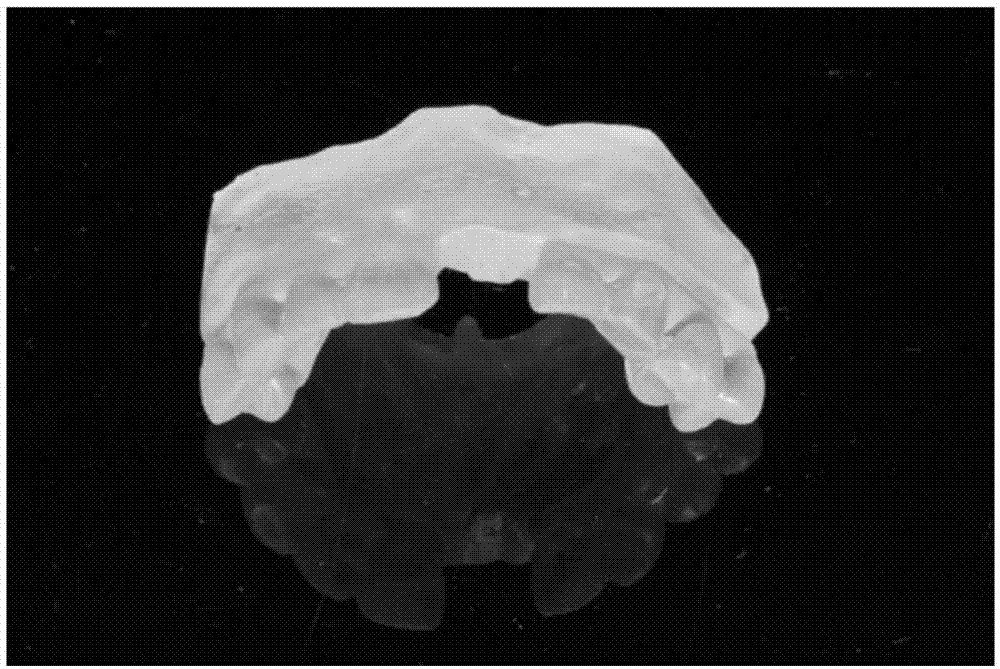

Method of making partial-anodontia tooth implantation surgical guide plate

InactiveCN101822575AReasonable adjustmentImprove practicalityDental implantsModel reconstructionBiomechanics

The invention discloses a method of making a partial-anodontia tooth implantation surgical guide plate, which comprises the following steps of: (1) acquiring CT data; (2) reconstructing a three-dimensional model of a skeleton; (3) designing an implantation scheme according to biomechanics and skeleton conditions of a patient; (4) designing an analog column for determining an implantation nest according to a position of an implant; (5) subtracting the analog column of the implant from the three-dimensional model of the skeleton by using Boolean subtraction to obtain a preliminary position of the implantation nest; (6) using a light-cured resin to form a skeleton model with a preliminary implantation nest through a rapid forming method; (7) adjusting the skeleton model with the preliminary implantation nest on the skeleton model; (8) inserting an analog implant into the implantation nest of the skeleton model; (9) making a gypsum model inside the oral cavity of the patient; (10) obtaining an analog soft tissue of an edentulous part; (11) repairing false teeth; and (12) making the surgical guide plate. The invention can be reasonably adjusted by an implantation doctor, and has accurate positioning and good practicability.

Owner:ZHEJIANG UNIV OF TECH

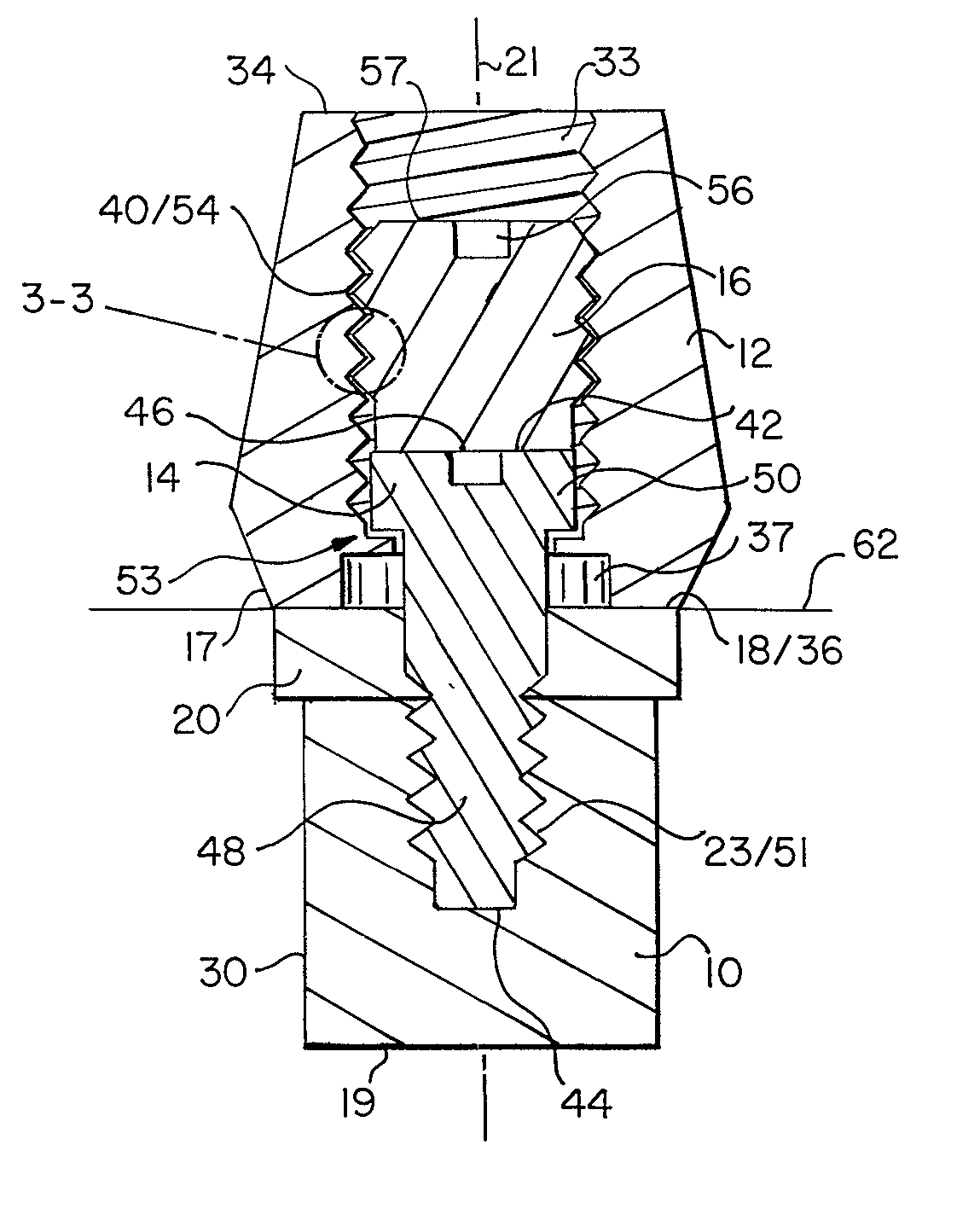

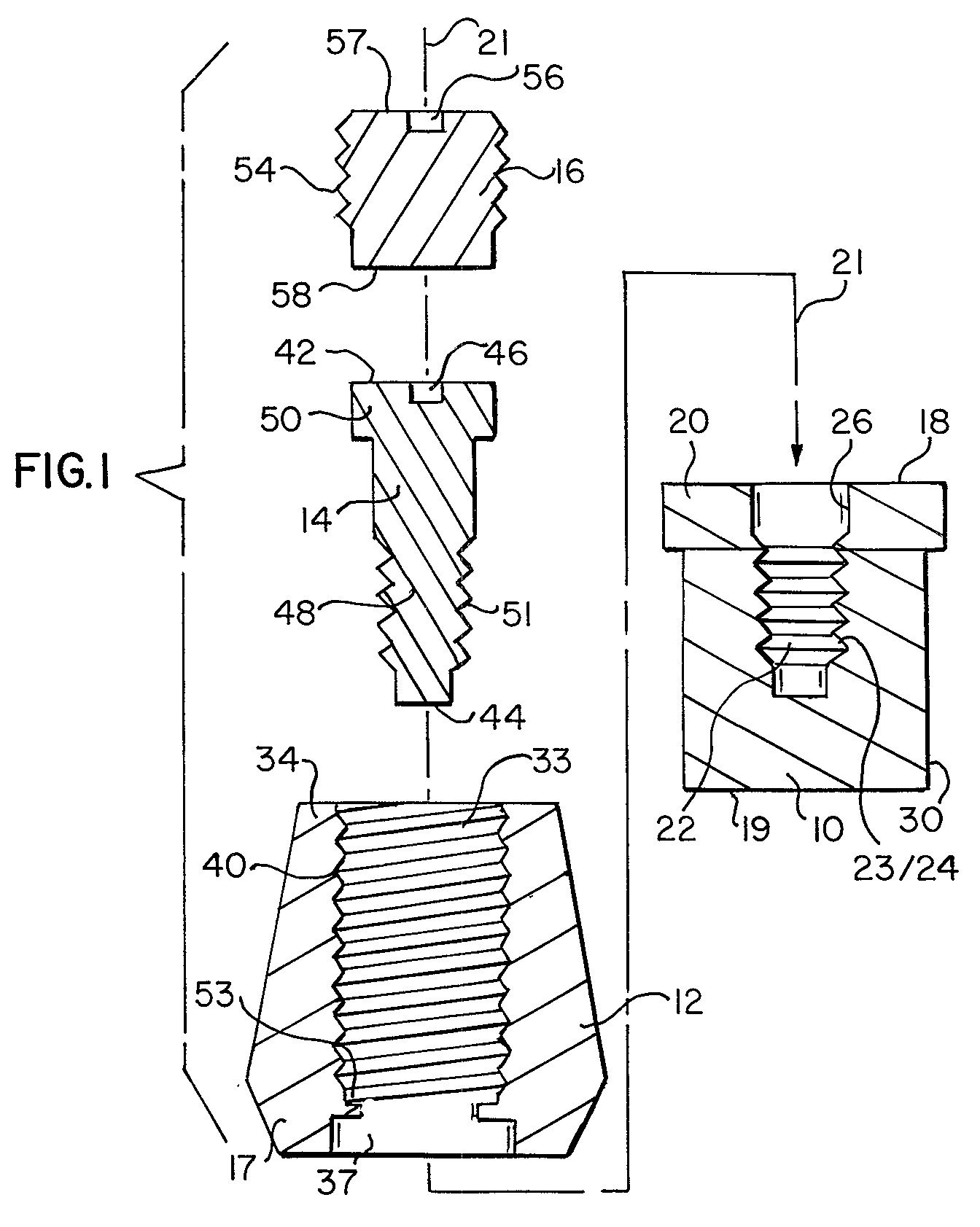

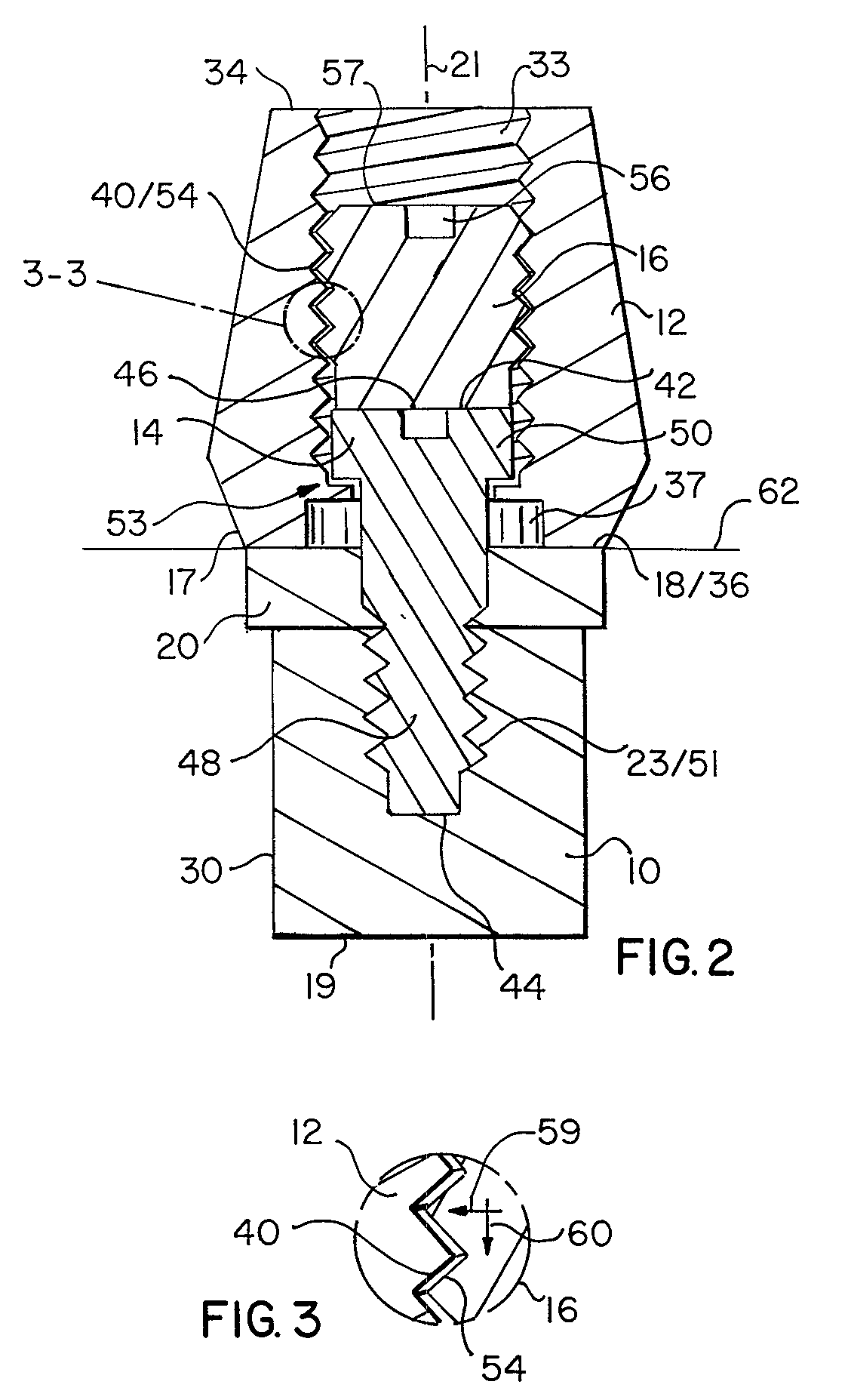

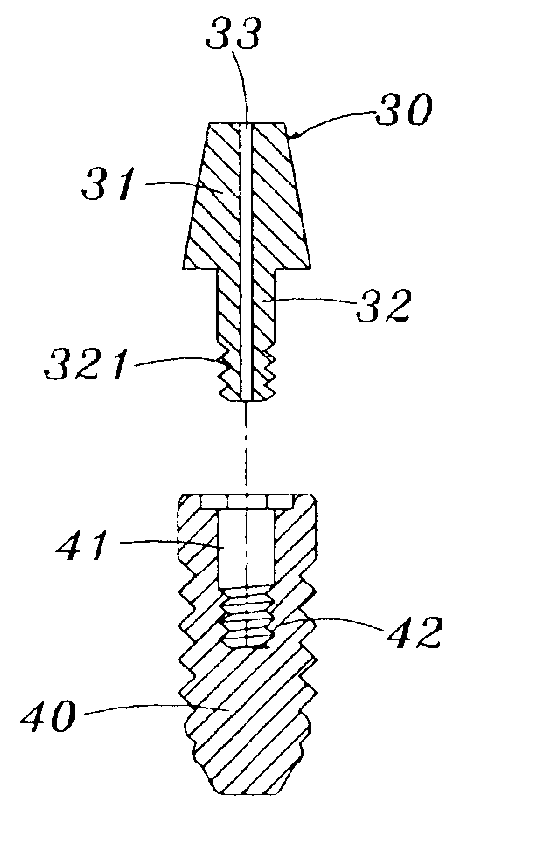

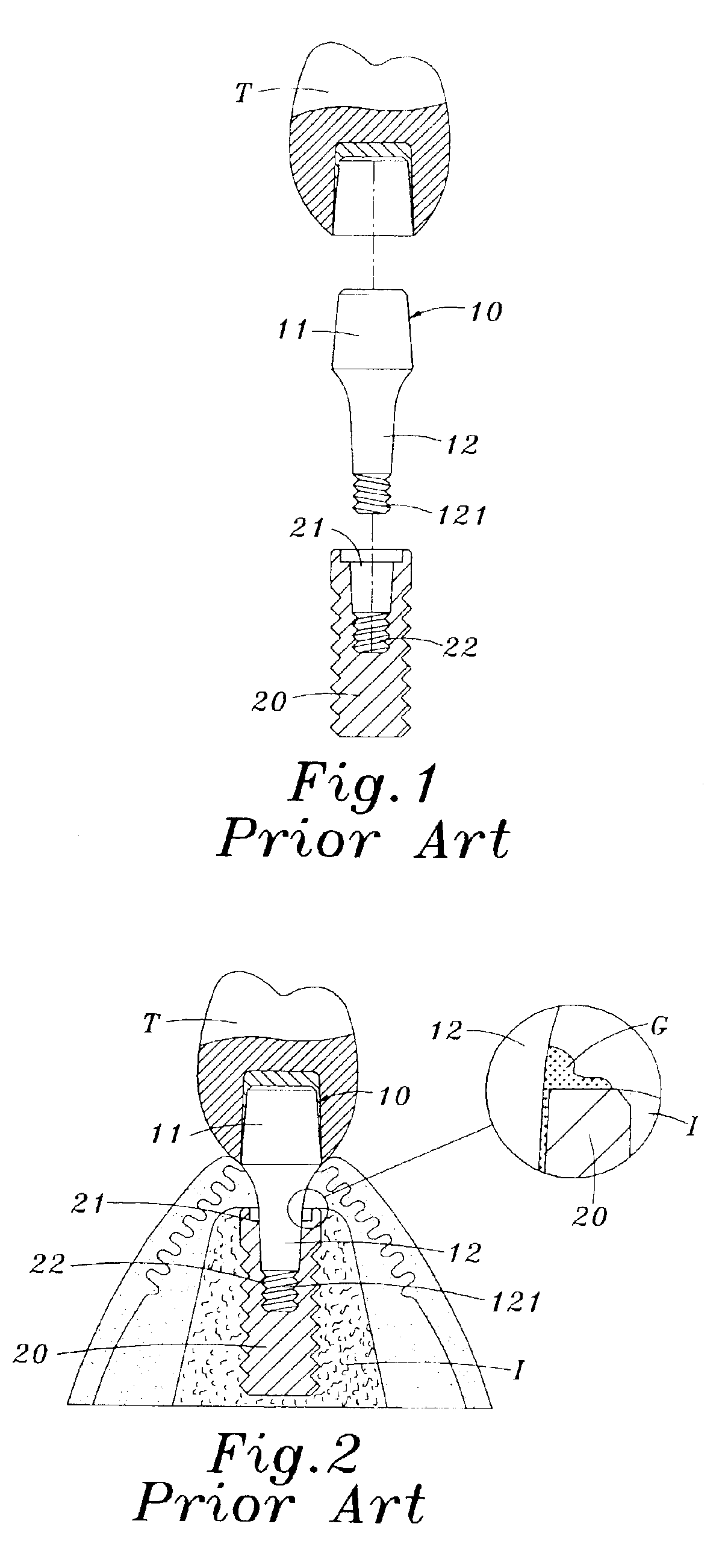

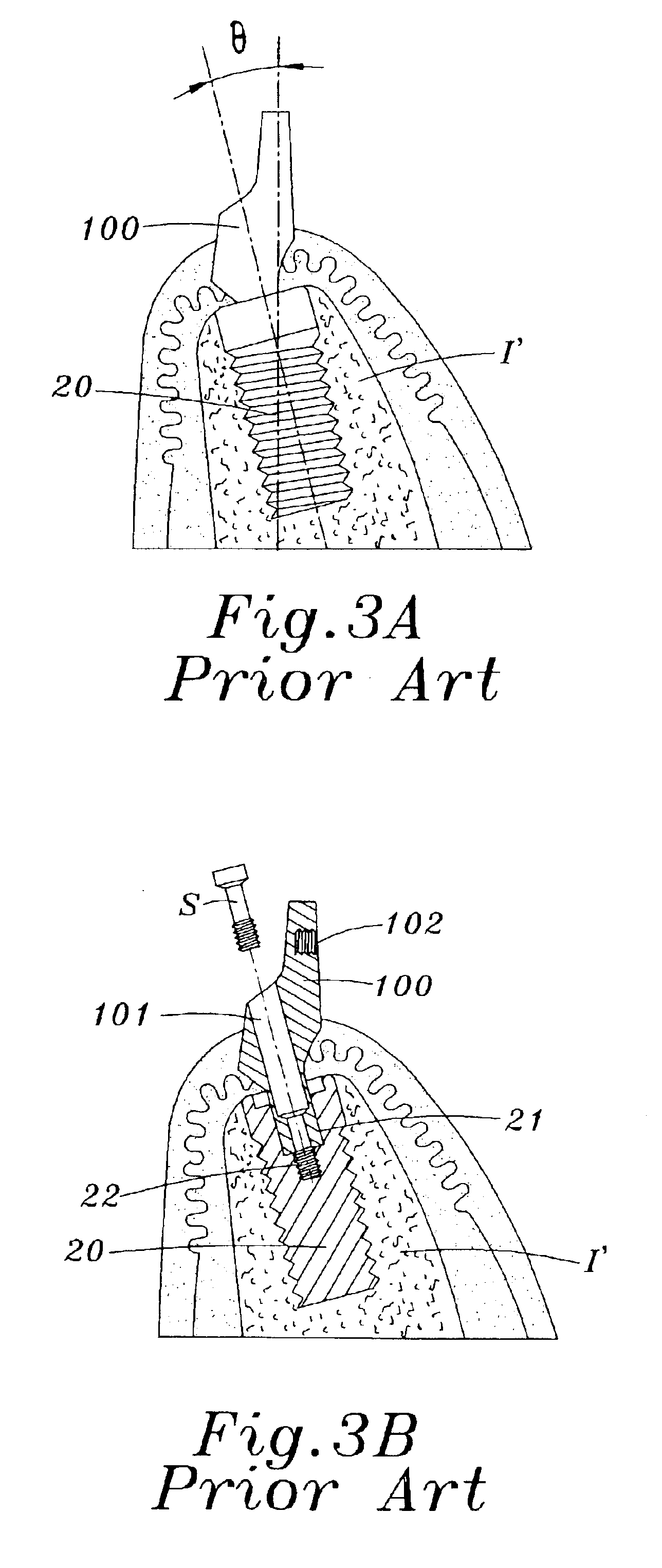

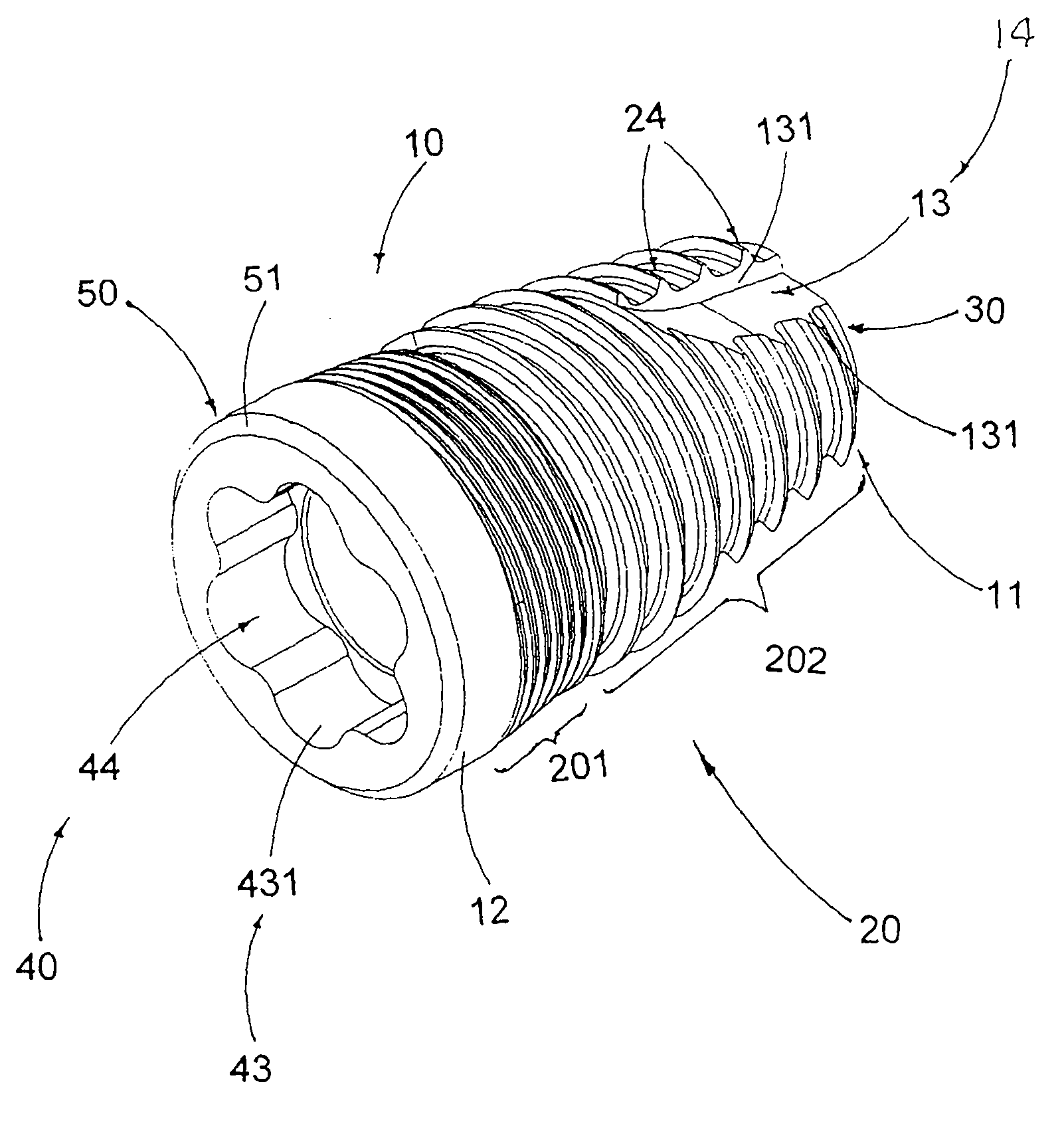

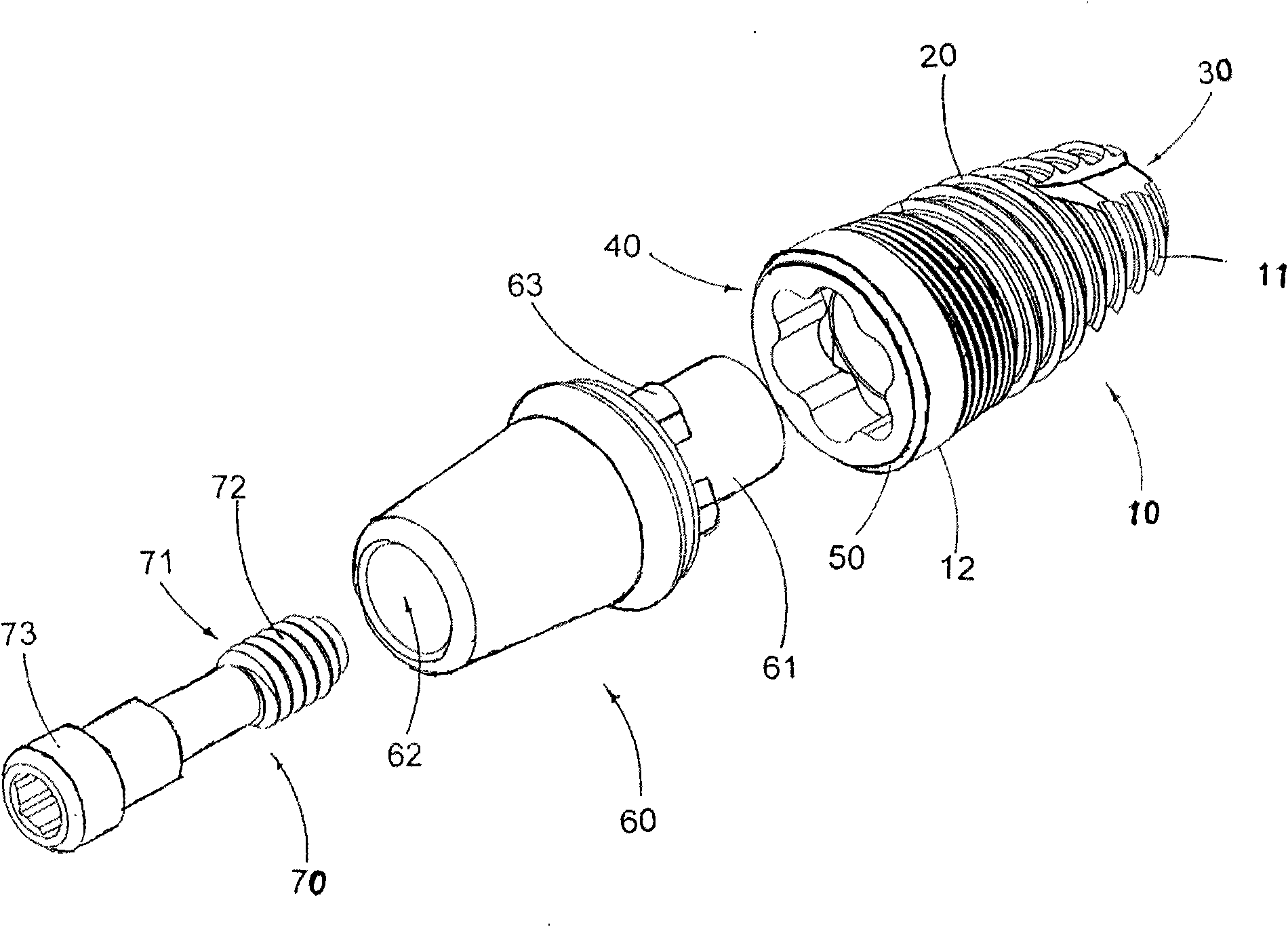

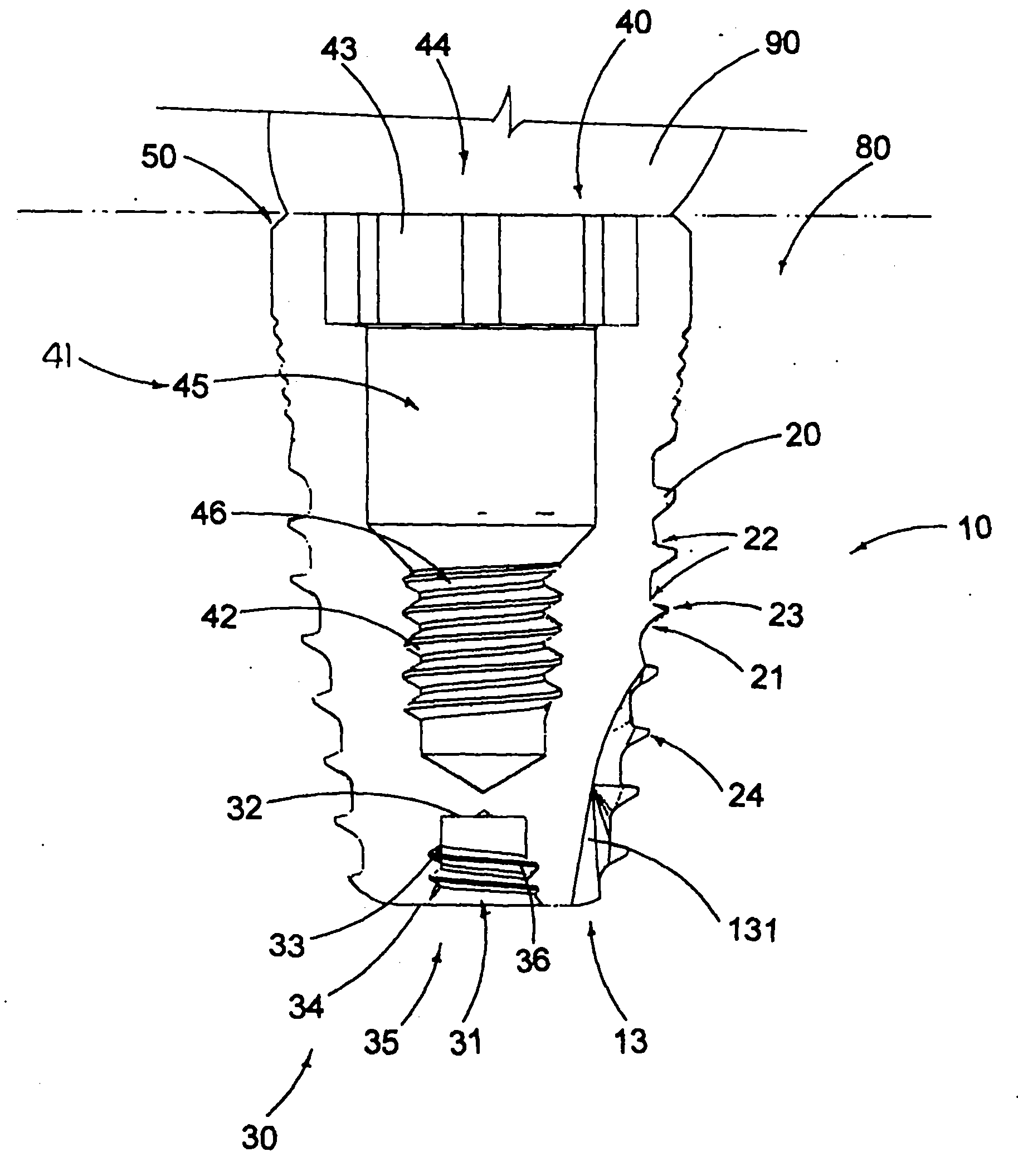

System of securement of dental abutments to dental implants

InactiveUS20020123022A1Long-term stability is assuredImprove comfortDental implantsFastening prosthesisEngineeringScrew thread

A system for tooth implantation having an implant part to be set into the jawbone, and an abutment part to which a tooth restoration is attached. The abutment part is screwed onto the implant part by an abutment screw, and a locking screw is disposed to lock the abutment screw to secure the abument part to the implant part to prevent loosening of the abutment. The threading interface between the lock screw and an abutment channel is matched in spiral direction but mismatched in thread timing with an interface between said abutment screw and an implant channel, thereby generating radial and axial locking forces.

Owner:PILLA NICOLA +3

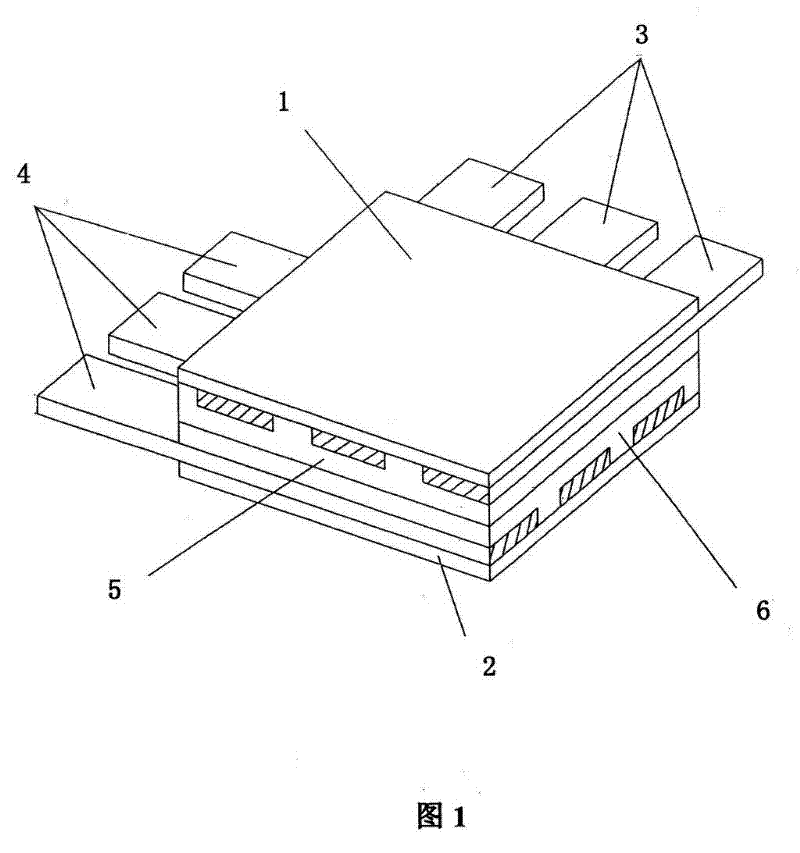

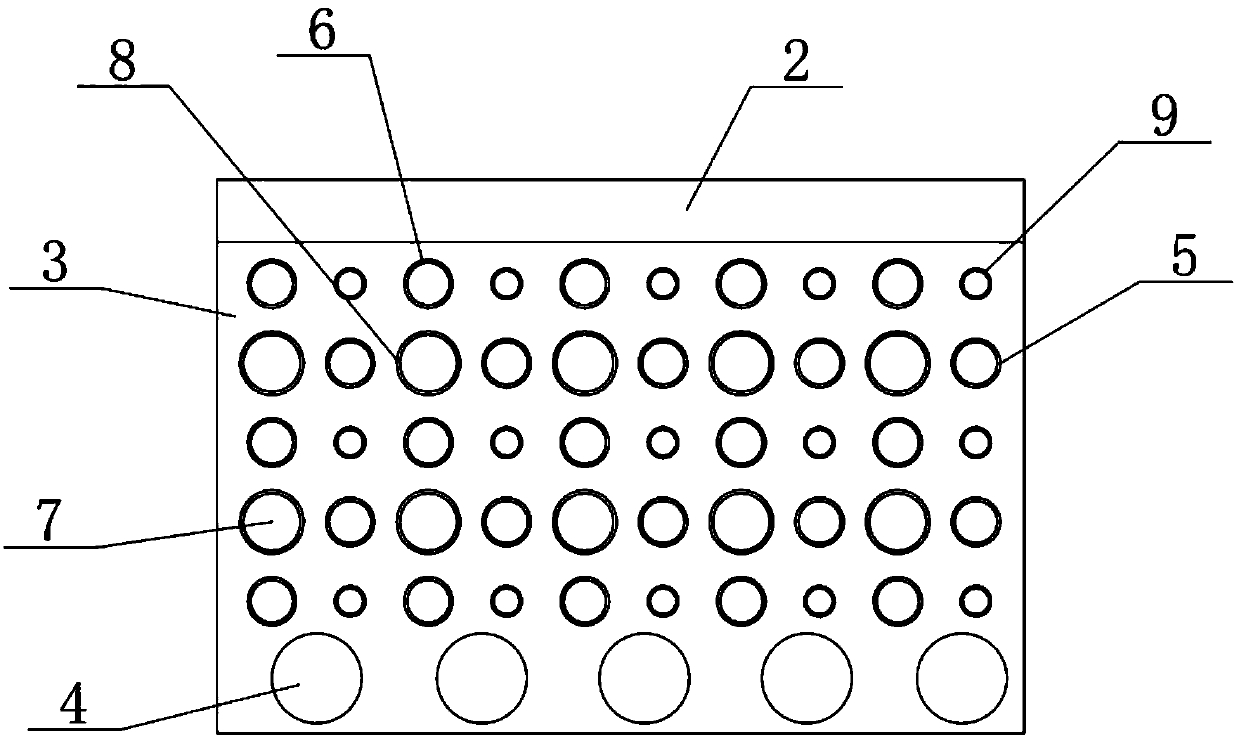

Dot matrix type pressure distribution sensor based on carbon nano tube and preparation method thereof

The invention provides a dot matrix type pressure distribution sensor based on a carbon nano tube and a preparation method thereof, which belongs to the technical field of sensing devices for dental clinical examination. The dot matrix type pressure distribution sensor comprises a first film substrate, a second film substrate, a group of first electrodes, a group of second electrodes, a first insulating layer and a second insulating layer, wherein the first and the second insulating layers are positioned between the first and the second film substrates; the first and the second film substrates are both polyester films; and the first electrodes, the second electrodes, first connecting wires, second connecting wires, first electrode terminals and second electrode terminals are all made of silver. The dot matrix type pressure distribution sensor has the advantages that the recoverability and the elasticity are outstanding, the occlusive service life reaches more than 300 times; the excellent clinical effects on tooth correction, false tooth implantation and health care are guaranteed; each imperceptible point on an end surface is guaranteed to be measured in the occlusal contact process of the upper and the lower teeth; and the processing steps are simple and not redundant, so not only can comprehensive reflection of the technical effects of the pressure distribution sensor be guaranteed, but the requirement of industrialized mass production can be satisfied.

Owner:江苏畅微电子科技有限公司

Preparation method of CAD/CAM personalized resin pre-formed crown and bridge

InactiveCN105616020ALess discomfortReduce the possibility of postoperative infectionDental implantsDesign softwareDentistry

The invention discloses a preparation method of a CAD / CAM personalized resin pre-formed crown and bridge. According to the method, data are acquired through oral clinical examination and oral CBCT, an implant scheme is designed by six-dimensional tooth implantation design software with repair as guide, implantation data are acquired, and a corresponding repair working model is obtained; a corresponding implantation replacement body is inserted into the repair working model, the position, the direction and the depth of the obtained replacement body and data of remaining teeth within a mouth are scanned with a scanner, a pre-formed crown and bridge module is designed with EXOCAD software according to the pre-designed upper repair body requirement by the combination of patient gingiva thickness, and a gap is reserved for placing a temporary drill base and a screw hole; finally, the CAD / CAM personalized resin pre-formed crown and bridge is obtained through cutting processing and finishing and polishing of a resin disc. According to the method, the immediate repair body can be put on at the same day after operation, modeling is not required in the patient mouth after the operation, the possibility of postoperative infection is reduced compared with the traditional technology, the time is saved, and the discomfort of the patient is effectively reduced.

Owner:杭州口腔医院集团有限公司

Layer casting molded graphene-nonmetal-metal composite material and preparation method

InactiveCN106745237AHigh hardnessHigh strengthTitanium dioxideZirconium oxidesMolecular rearrangementSensor materials

Owner:尹宗杰 +1

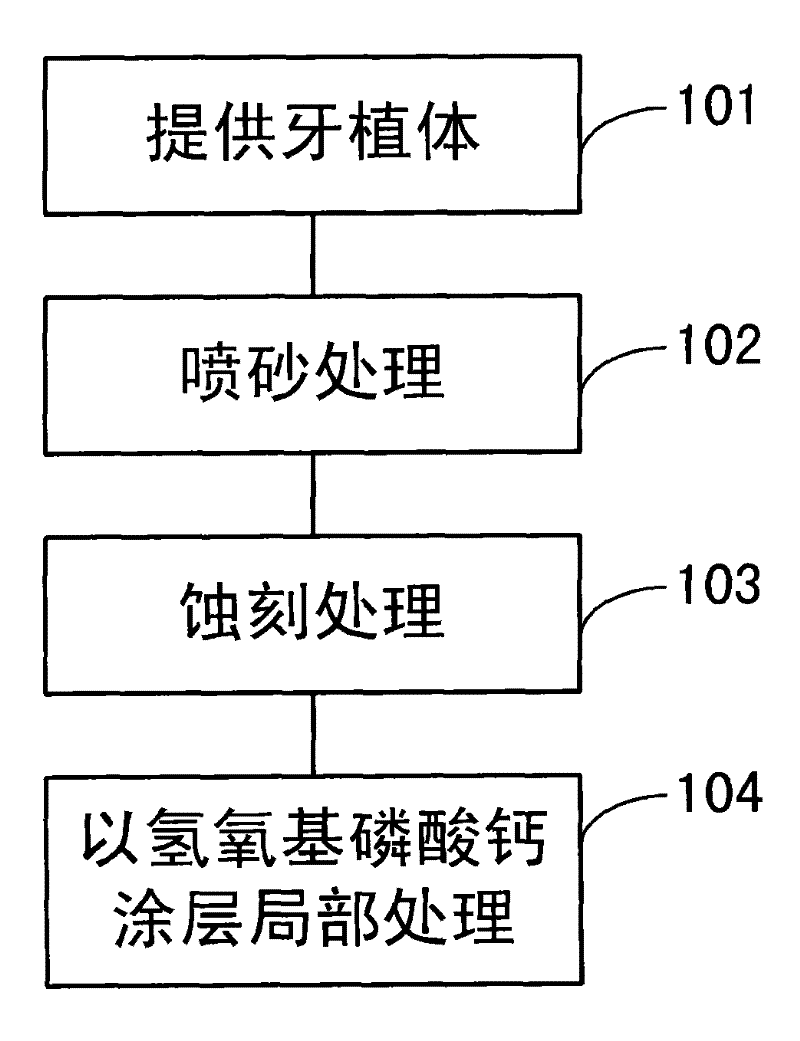

Surface treatment method of dental implant

InactiveCN102525673ASpeed up fusionShorten the duration of treatmentDental implantsCalcium biphosphateOsseointegration

The present invention discloses a surface treatment method of a dental implant, wherein a titanium or titanium alloy artificial implant is used. Through partial treatments which comprise sand spraying, acid pickling and coating hydroxyl calcium phosphate with biocompatibility, a specific porous structure is generated on the surface of the artificial dental implant, and the artificial dental implant is also provided with a partial porous hydroxyl calcium phosphate coating. Therefore osteoblast-like cell and bone integration speed can be increased, and furthermore the treatment period in artificial tooth implantation is reduced.

Owner:CHANG GUNG MEDICAL TECH

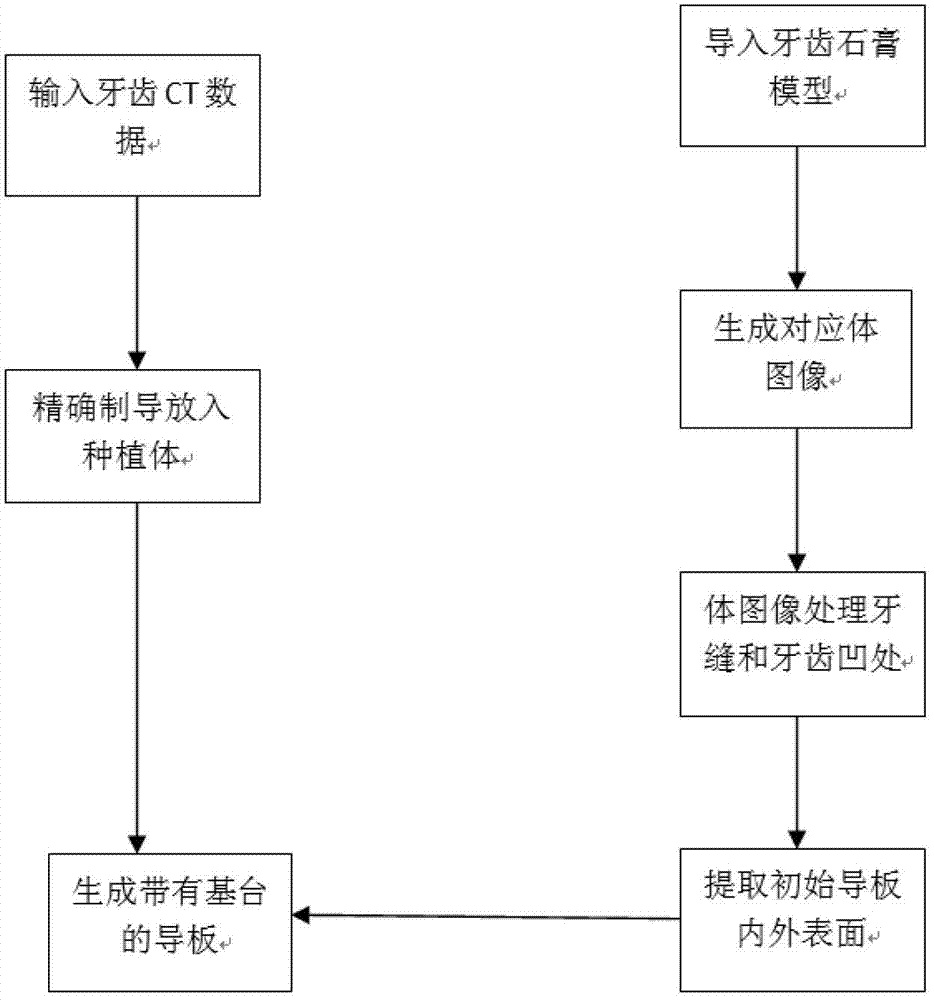

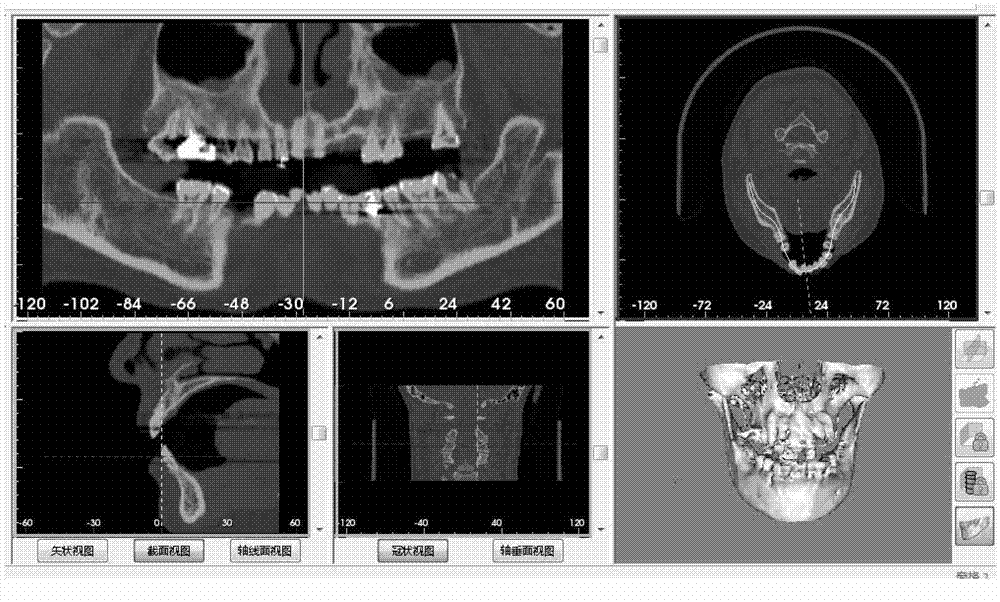

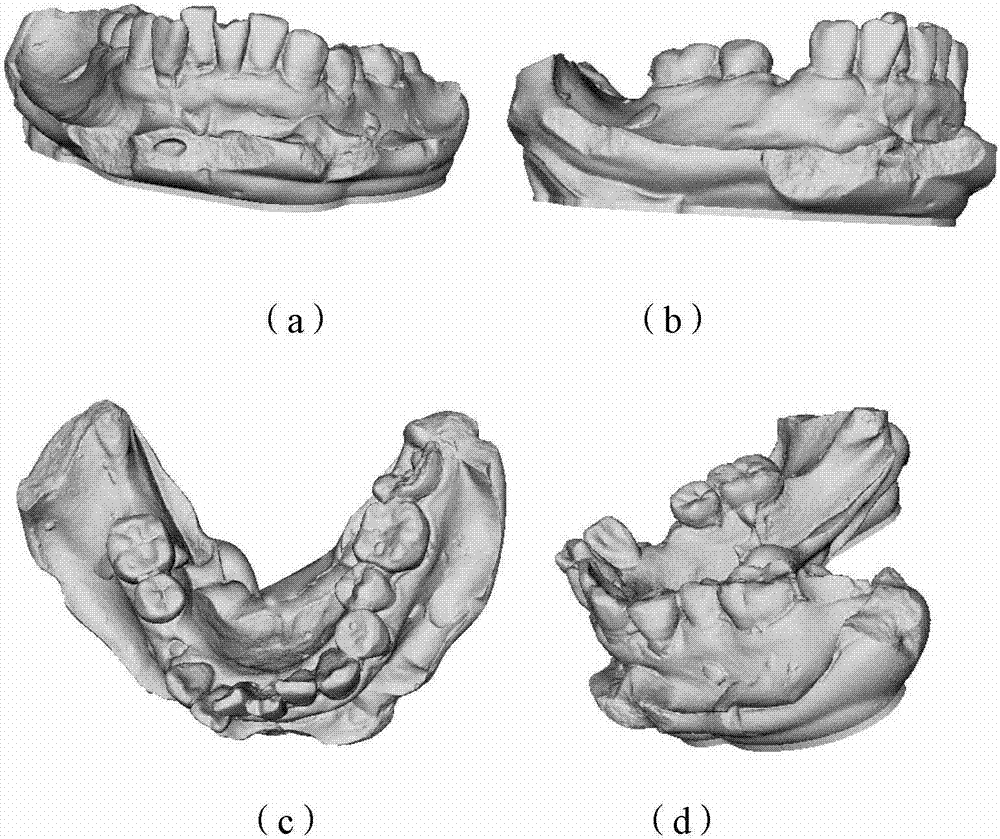

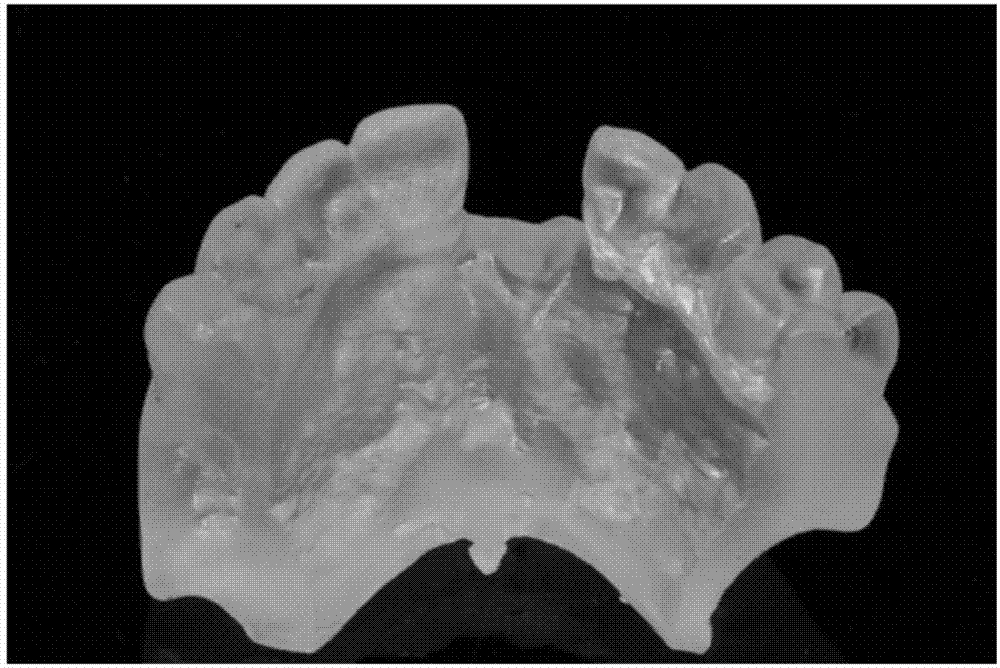

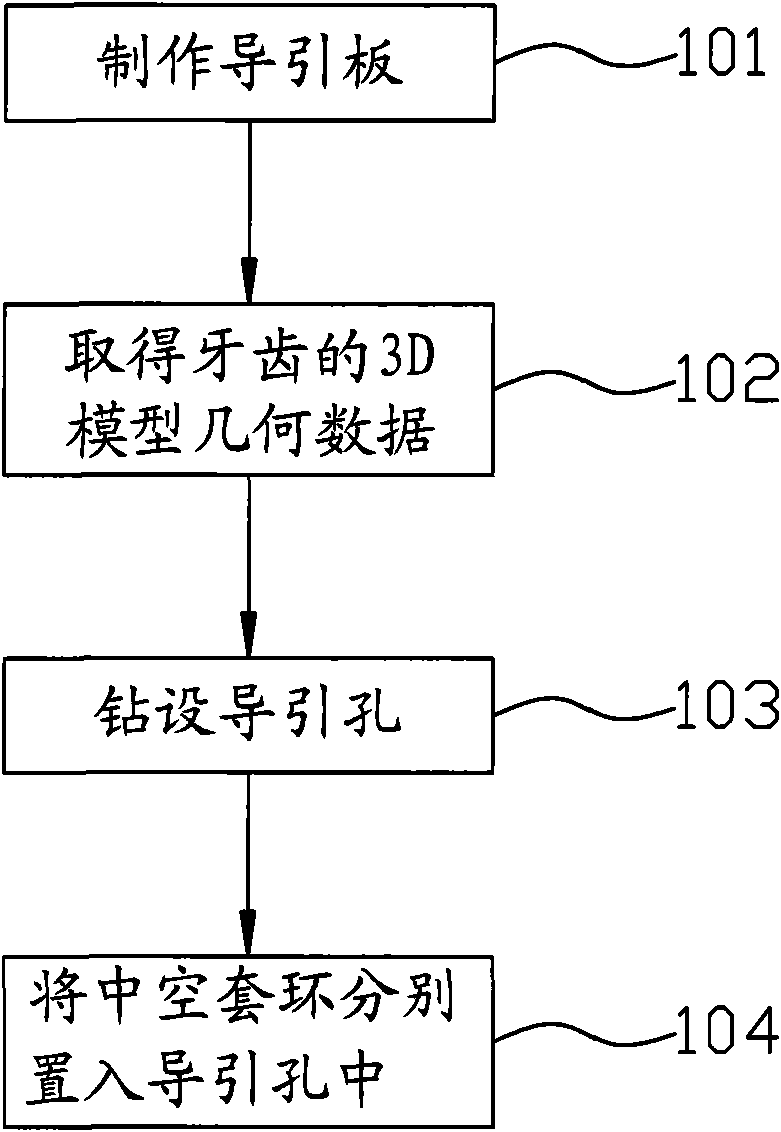

Manufacturing method of tooth implantation operation guide plate based on body image processing

ActiveCN103156693APrecise positioningEasy to operateDental implantsImage data processingComputing tomographyBody images

The invention discloses a manufacturing method of a tooth implantation operation guide plate based on body image processing. The manufacturing method of the tooth implantation operation guide plate based on body image processing includes the following steps: obtaining a plaster model of a tooth, scanning and generating a corresponding three-dimensional mesh model, and placing the three-dimensional mesh model into a stimulate implant through precision guidance according to a corresponding mouth cavity computed tomography (ct) model; sampling the three-dimensional mesh model of tooth gypsum and generating a corresponding body image; processing the body image and filling concave places in the teeth and extremely-narrow tooth slits; extracting the inner surface and the outer surface of an initial tooth guide plate; reading the position and the type of the implant, and generating an appropriate guide plate base table; defining a required guide plate range, taking out a tooth guide plate model, and obtaining the entity tooth implantation operation guide plate according to tooth guide plate model processing. The tooth implantation operation guide plate manufactured through the manufacturing method is capable of being successfully worn into the teeth, is not clamped, and meanwhile, can fit in with the teeth to the greatest extent, and is not prone to swaying when worn by a patient.

Owner:ZHEJIANG UNIV

Tooth implantation quick moulding system and tooth implantation quick moulding method based on 3D printing

InactiveCN105030350AReduce stress concentrationAvoid security issuesDental implantsAdditive manufacturing apparatusFlexural strengthEngineering

The invention provides a tooth implantation quick moulding system which is used for quickly preparing a human implant material on the basis of 3D printing and a moulding method which can accurately control position and angle of tooth implantation. During the preparation process, the material is dynamically added according to a preset scanning trace. The system is high in accuracy and is high in speed. A prepared tooth implantation body is strong in wear resistance and is high in bending strength. The 3D printing quickly moulding method can reduce rejection rate caused by flexural deflection or temperature, thereby greatly reducing production cost.

Owner:SUZHOU GUANGYING DENTAL MEDICAL TECH CO LTD

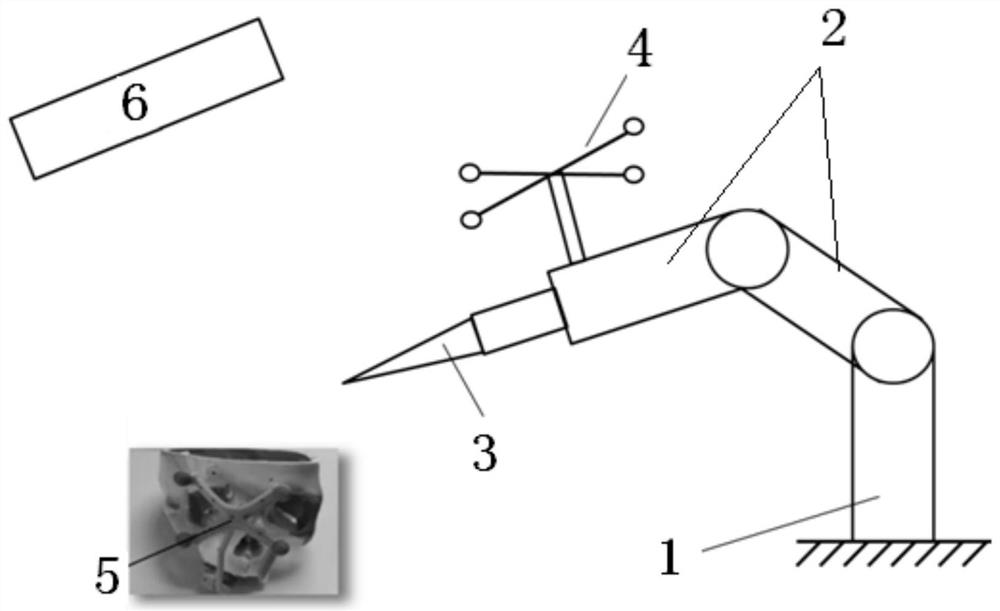

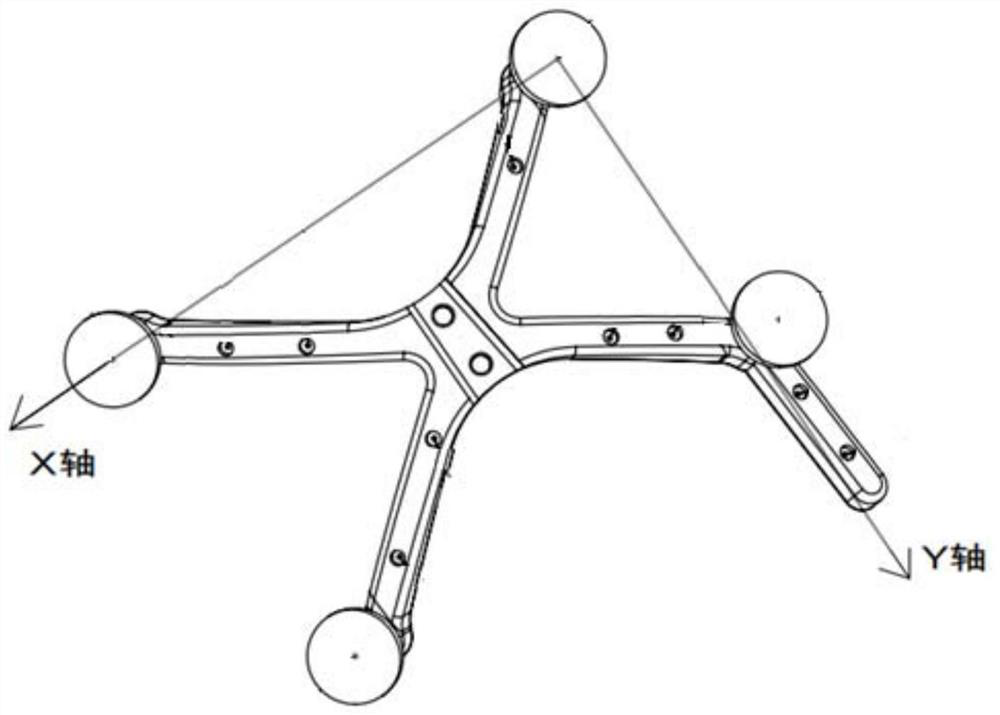

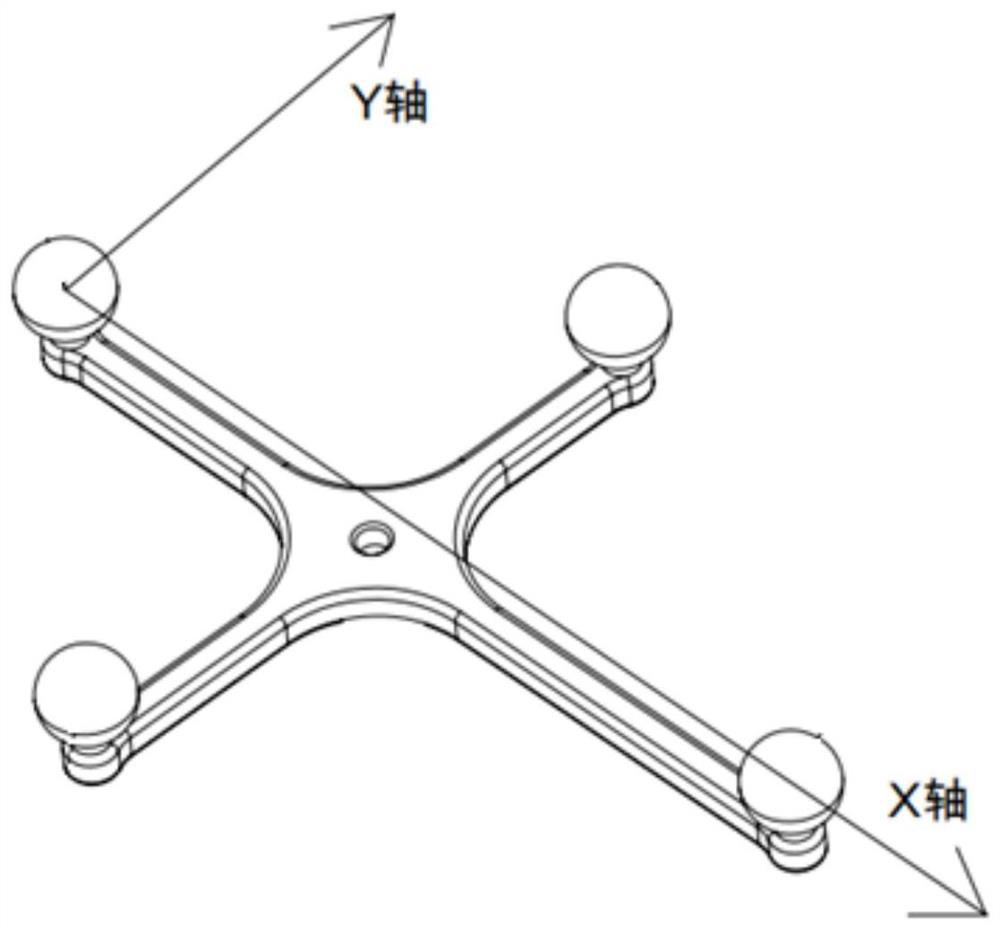

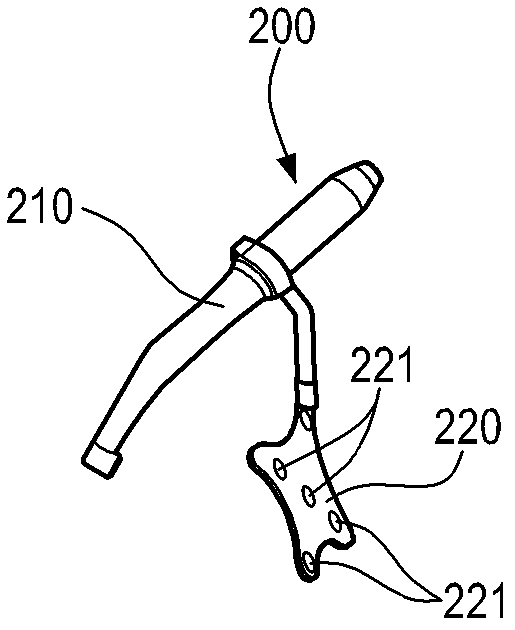

Navigation and positioning method for dental implant robot

ActiveCN113400325AReduce work intensitySimple and fast operationProgramme-controlled manipulatorDental implantsPhysical medicine and rehabilitationCt scanners

The invention provides a navigation and positioning method for a dental implant robot. The navigation and positioning method comprises the following steps of establishing a conversion matrix from a cutter target pose coordinate system to a mechanical arm base coordinate system; establishing a conversion matrix from a surgical knife coordinate system to a mechanical arm tail end TCP coordinate system; and calculating a conversion matrix from the mechanical arm tail end TCP coordinate system to the mechanical arm base coordinate system when the knife reaches the target pose, so as to generate a control instruction for each joint of a mechanical arm of the dental implant robot, so that each joint of the mechanical arm moves. According to the navigation and positioning method for the dental implant robot, a CT scanner and an optical locator are used for measuring, the coordinate system conversion relation between the patient tooth implantation path and the surgical knife is established, the mechanical arm is guided to move, the surgical knife is driven to reach the entering point position and direction of the target path, the mechanical arm is used for driving the surgical knife to move, the advantages of being easy and convenient to operate, safe and reliable are achieved, accurate positioning of the position and the direction of the surgical knife can be achieved, the working intensity of doctors is reduced, and the precision of dental implant surgery is effectively improved.

Owner:四川锋准机器人科技有限公司

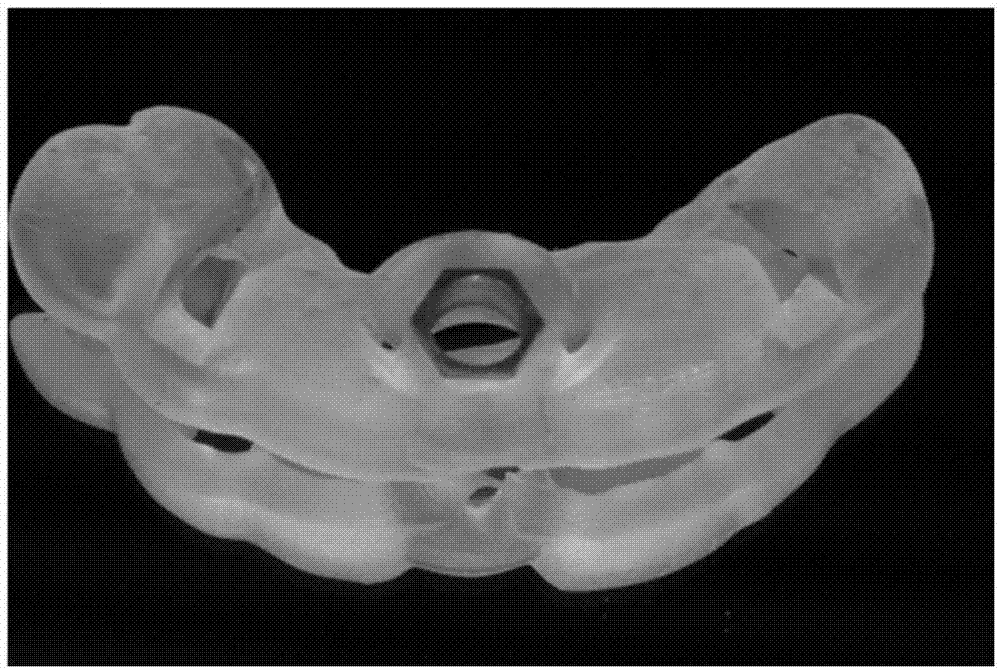

Manufacturing method for individual gingival aesthetic forming healing abutment

ActiveCN107260341AReduce the number of doctor visitsReduce stimulationDental implantsAdditive manufacturing apparatusTOOTH IMPLANTATIONSHealing abutment

The invention relates to a manufacturing method for an individual gingival aesthetic forming healing abutment. The method comprises the following steps: 1) preparing upper and lower jaw models of a patient before operation, shooting CBCT and acquiring Dicom data of upper and lower jaws; 2) scanning the upper and lower jaw models, fitting an acquired STL document with CBCT in a Dicom format and then importing into the implanting guide plate design software; 3) designing an implant three-dimensional position and guide plate and 3D printing the jaw model and guide plate; 4) treating the surface of an end product temporary abutment of a tooth implantation system, in vitro simulating implantation, placing the end product temporary abutment, using an optical scanner for scanning the implant three-dimensional position and importing into the abutment design software; and 5) adopting a CAD / CAM cutting abutment, in vitro splicing, manufacturing a condensate locator and utilizing adjacent teeth to confirm the position of the abutment in the oral cavity. Compared with the prior art, the manufacturing method disclosed by the invention has the advantages that the individual gingival aesthetic forming healing abutment is placed in the same period of implant surgery, the secondary cutting of the wound in the conventional implanting two-stage operation can be avoided, the stimulation to the soft tissues can be reduced, and the like.

Owner:TONGJI UNIV

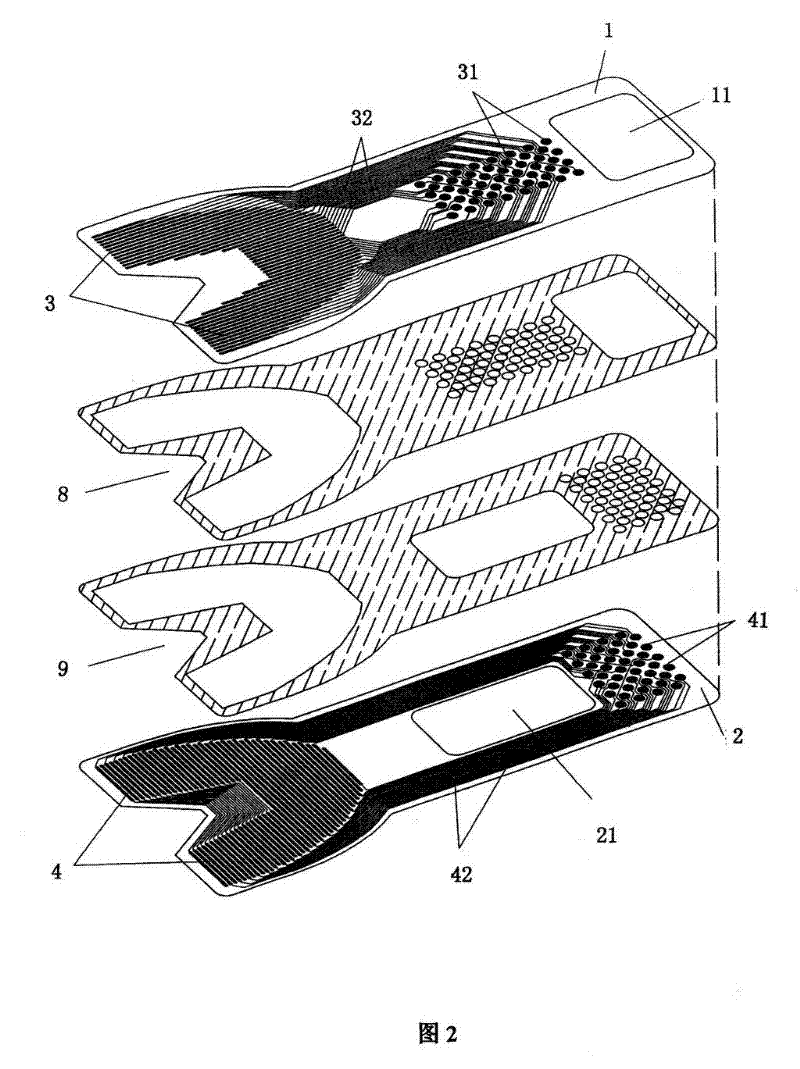

Zirconium oxide tooth implantation system

InactiveCN101810517AGood biocompatibilityNo side effectsDental implantsBite force quotientSide effect

The invention discloses a zirconium oxide tooth implantation system, and is characterized in that all devices are made of zirconium oxide. The system is divided into a one-stage type and a two-stage type. A one-stage type implantation body is provided with screw threads, the surface of a dentogingival part is smooth, and the body is combined with the base station integrally. The surface of the two-stage type implantation body has a smooth type and a screw-thread type, and the implantation body and the base station is embedded with each other by polyhedral angle and Moll's taper and is connected and fixed by the central screw nail. The invention has the following advantages that: the zirconium oxide implantation body without toxic side effect is capable of being integrated with alveolar bone; the total porcelain crown supported by the zirconium oxide base is attractive in appearance; and the zirconium oxide implantation teeth can resist the functionating of good occlusal force without influencing CT and nuclear magnetic imaging inspection.

Owner:杨建军 +2

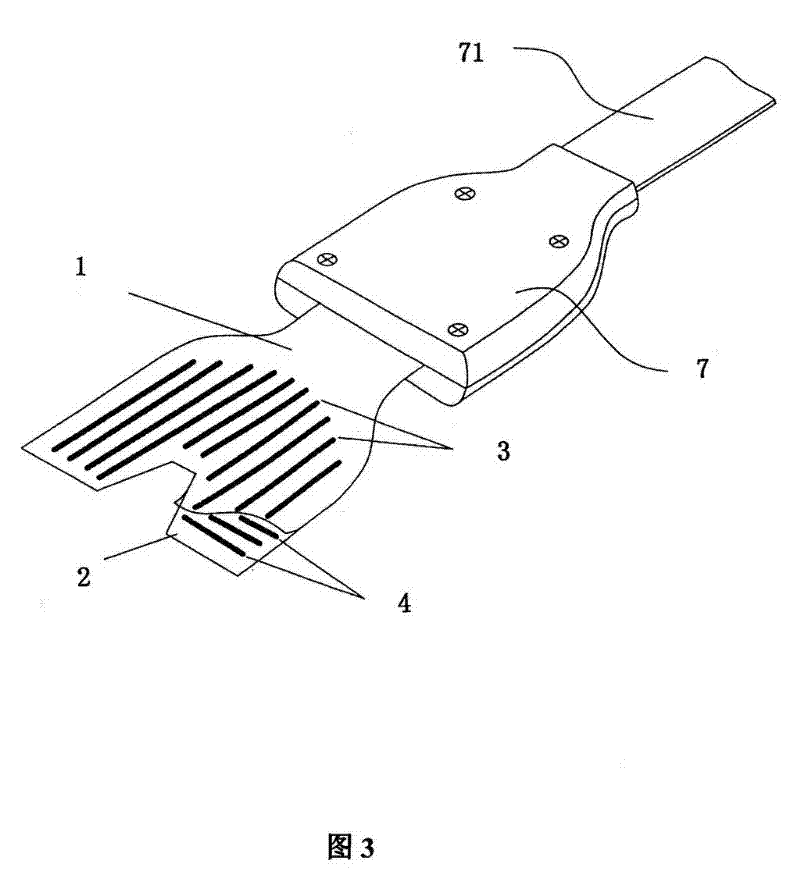

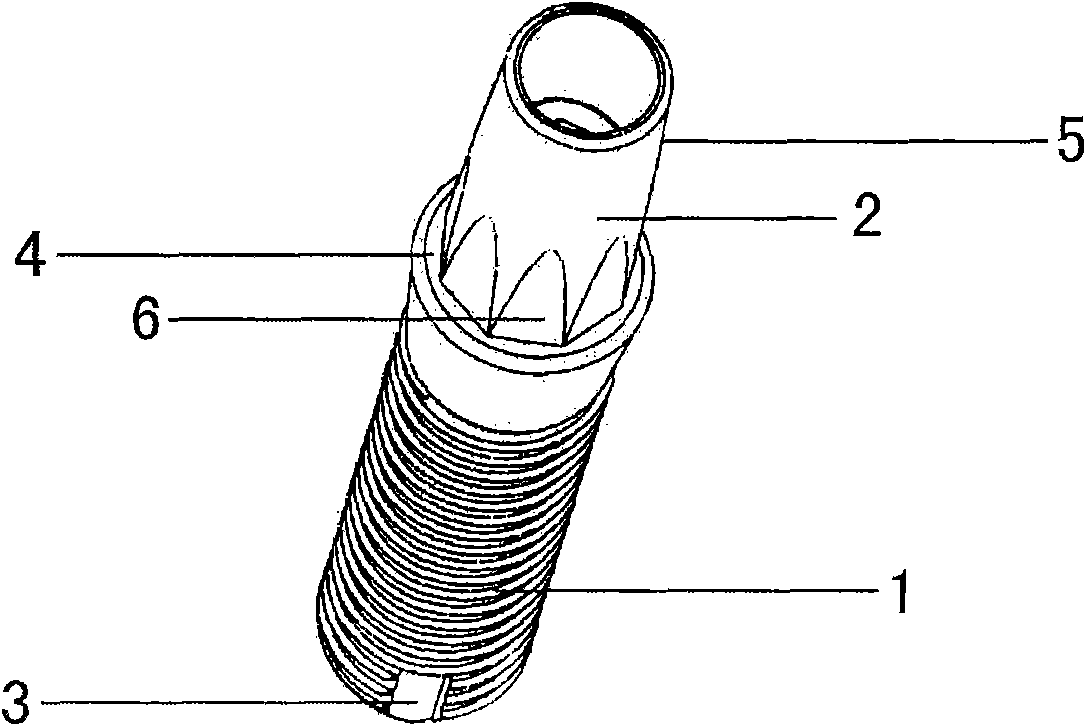

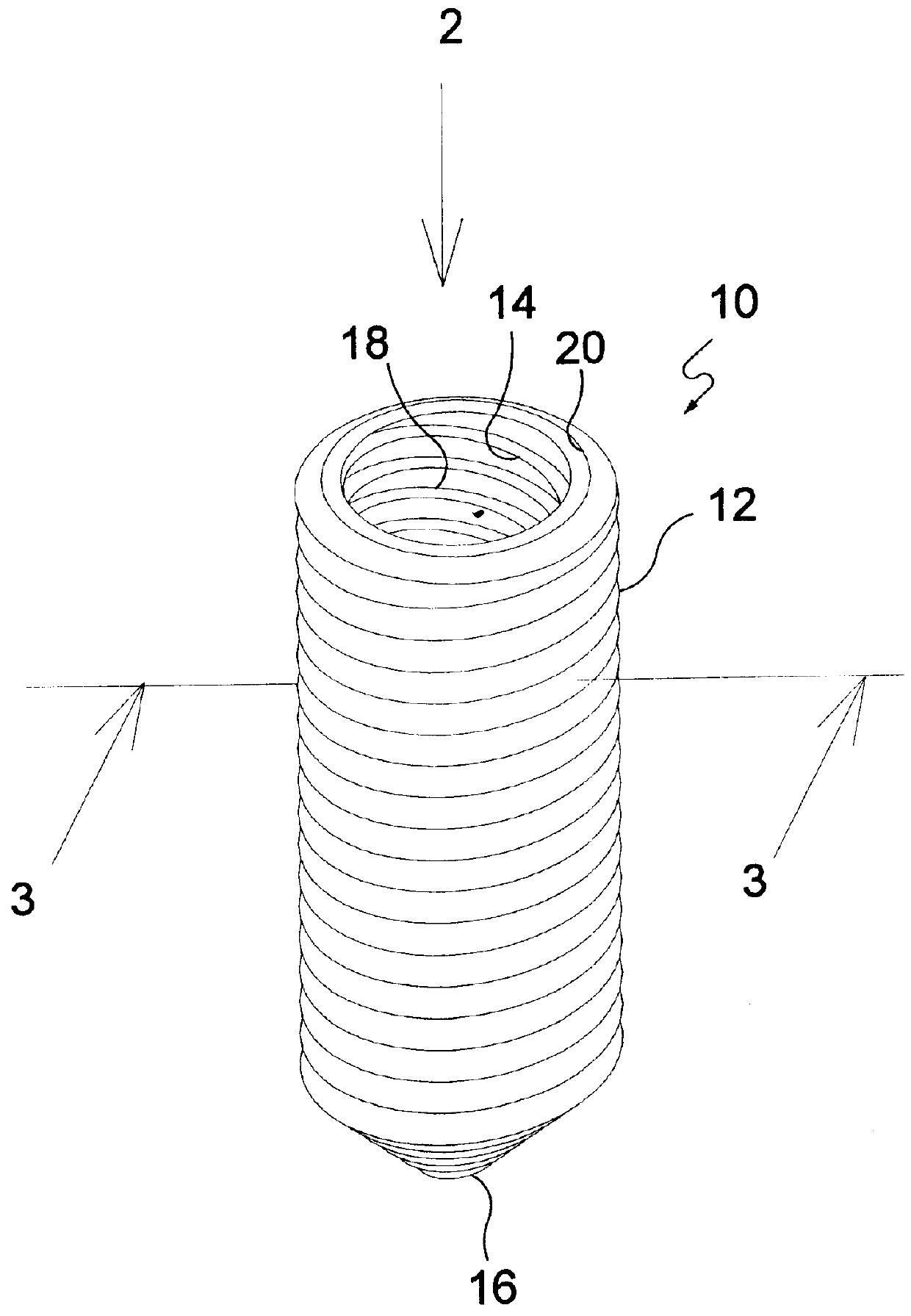

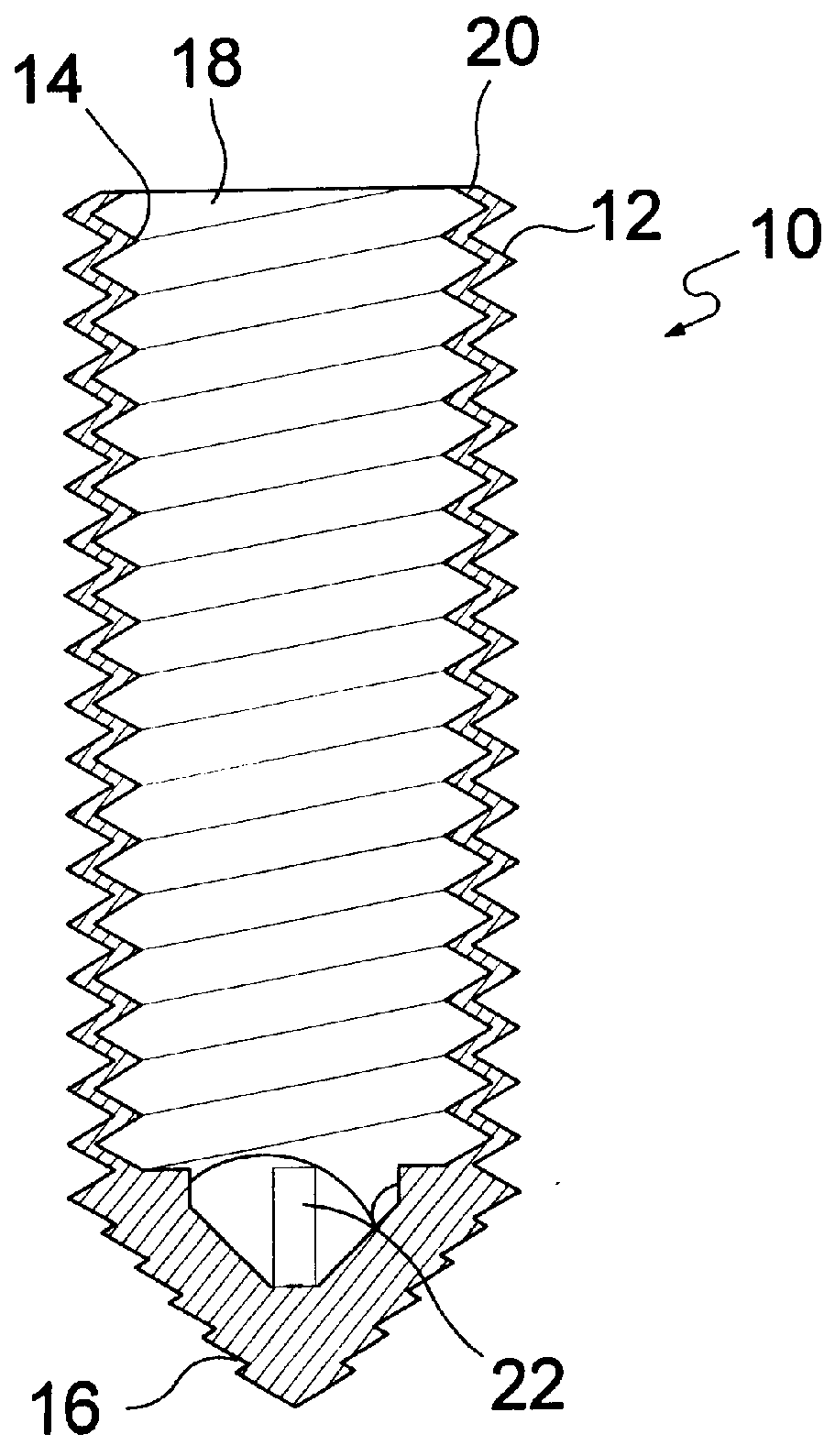

Method and apparatus for a prosthetic ligament

InactiveUS6152738ALow modulusLow elastic modulusDental implantsFastening prosthesisNatural toothProsthesis

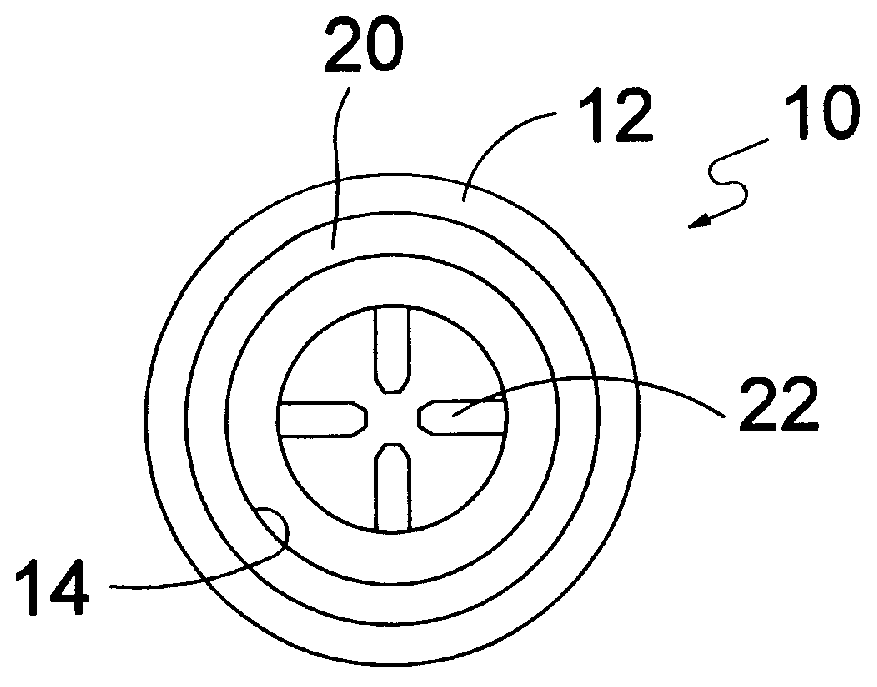

The present invention 10 discloses a method and apparatus for replicating the force absorption capabilities of natural teeth 28. Provided therein is a periodontal implant 10 which functions as a cup-like housing 10 for receiving an additional implant 32 or avulsed teeth. The implant 10 is externally threaded 12 for connection to the jaw bone 24 and internally threaded 14 for receiving the additional implant 32. The periodontal ligament 10 is fabricated from materials having a low modulus of elasticity, without causing deformation of the periodontal ligament implant. Materials of construction may include natural, synthetic, biological or genetically engineered materials.

Owner:AKER FR

Tooth implant with a primary and a secondary crown

InactiveUS20090155745A1Easy to installSimple featuresDental implantsFastening prosthesisProsthesisBiomedical engineering

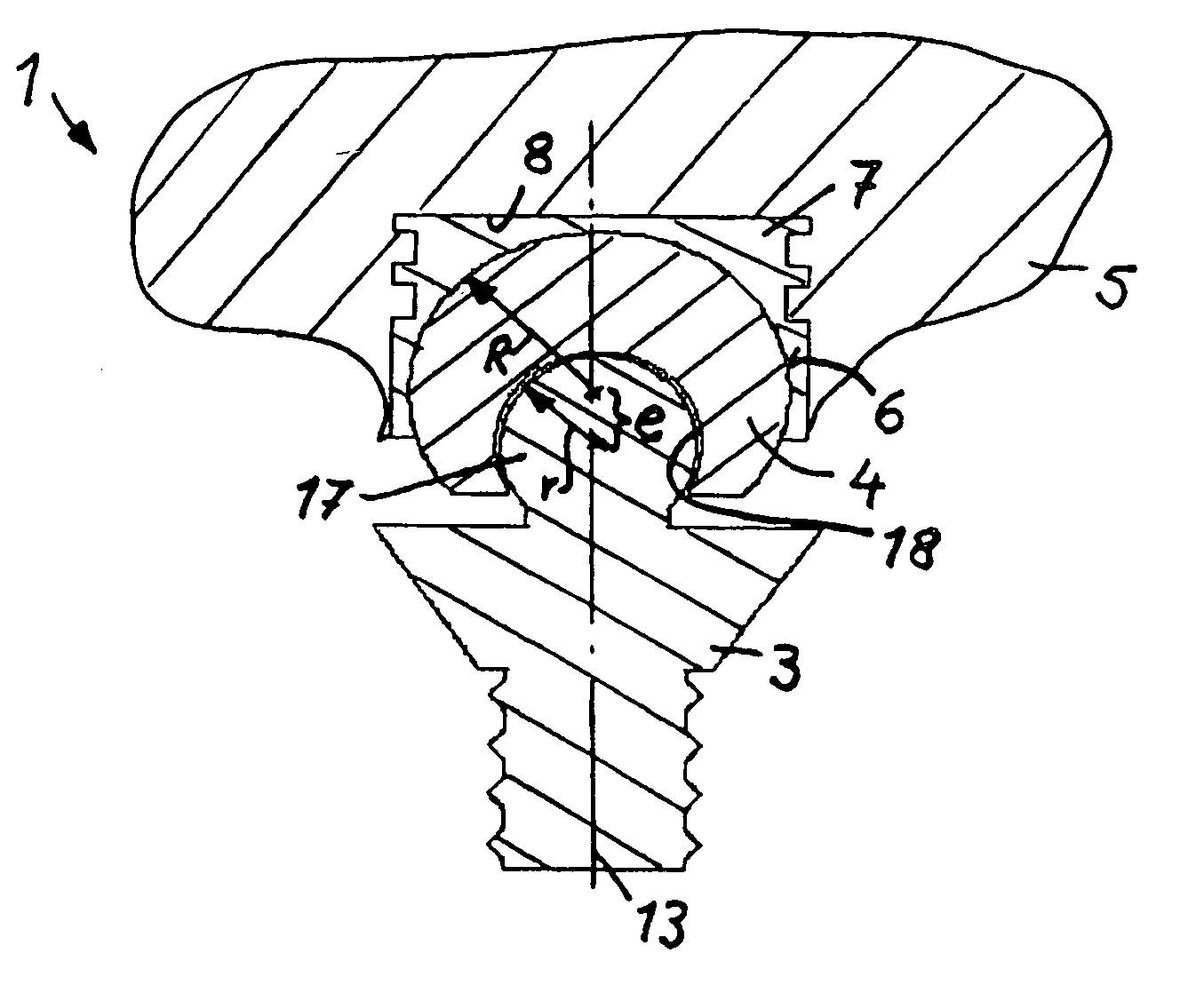

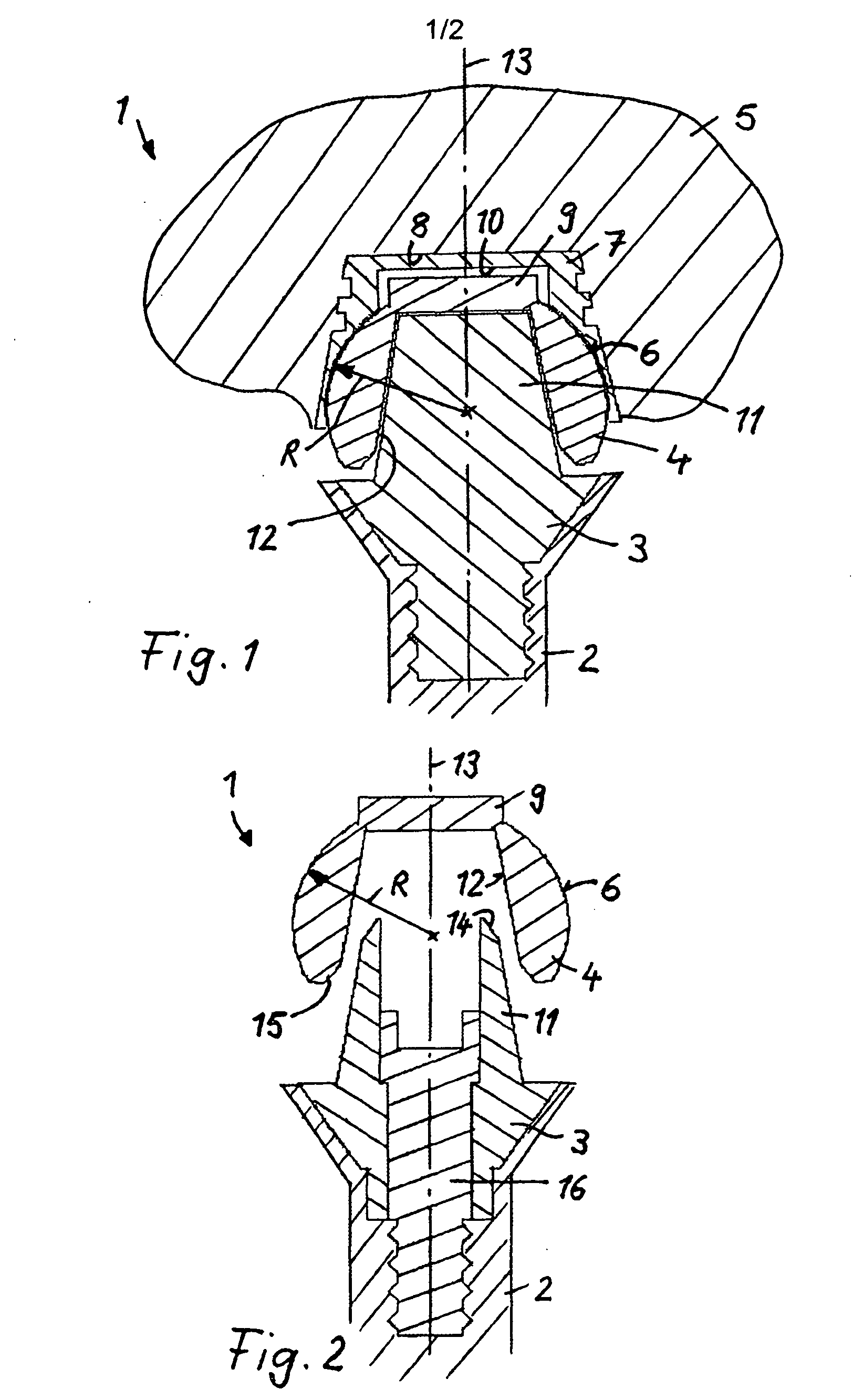

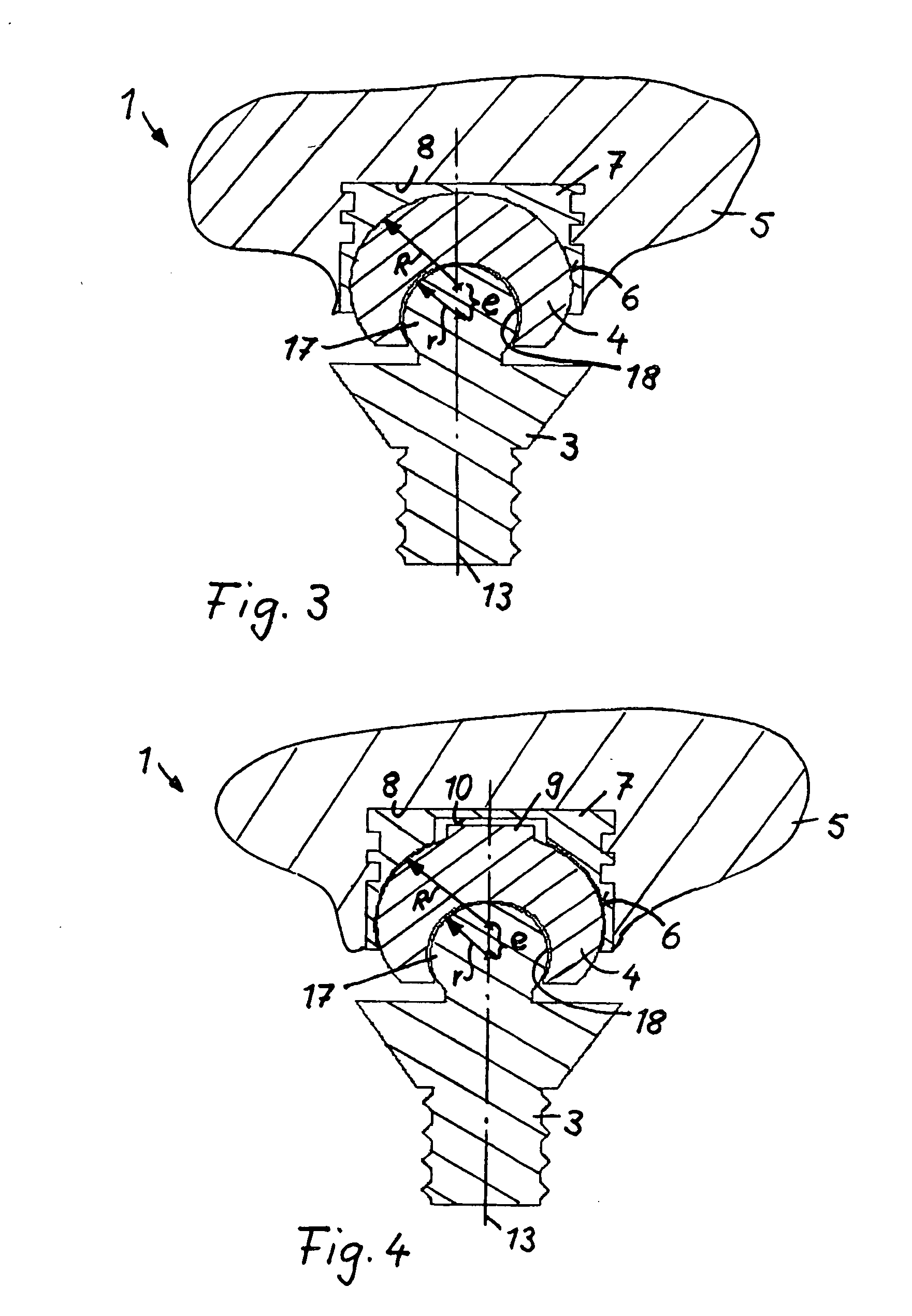

In a tooth implant comprising a primary crown for mounting on a base carrier implanted into a patient's jaw and a secondary crown mounted onto the primary crown for supporting a bridge or prosthesis, the primary crown has a circular or ball-shaped projection and the secondary crown has a recess of a complementary configuration receiving the projection of the primary crown so that the secondary crown is pivotally supported by the primary crown for permitting adjustments during installation of the prosthesis or bridge onto the secondary crown.

Owner:ACCURA HLDG

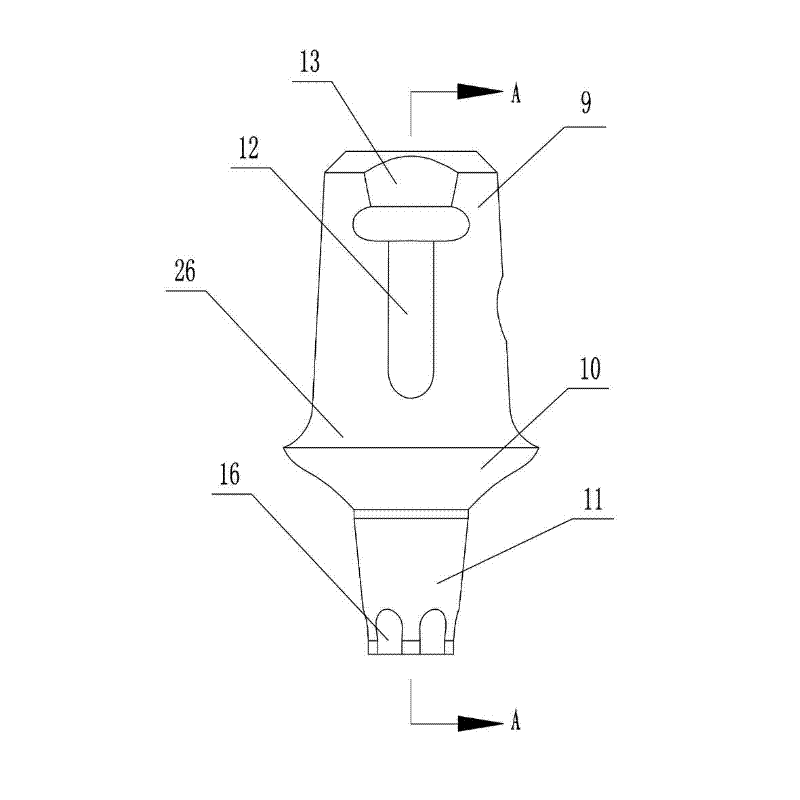

Abutment structure used exclusively in tooth implantation

InactiveUS7059854B2Easy to disassembleInhibit inflammationDental implantsFastening prosthesisGum inflammationMaterials science

A dental abutment is provided with an axial through hole and is fastened at a lower segment thereof with an implant in conjunction with a cement which is infected into a threaded hole of the implant. An excess amount of the cement is forced out via the axial through hole of the abutment such that the cement is deposited on a flat top of the abutment to facilitate the removing of the cement residue and to minimize the likelihood of a gums inflammation which may be resulted from an incomplete removal of the cement residue.

Owner:WU WEN YUEN

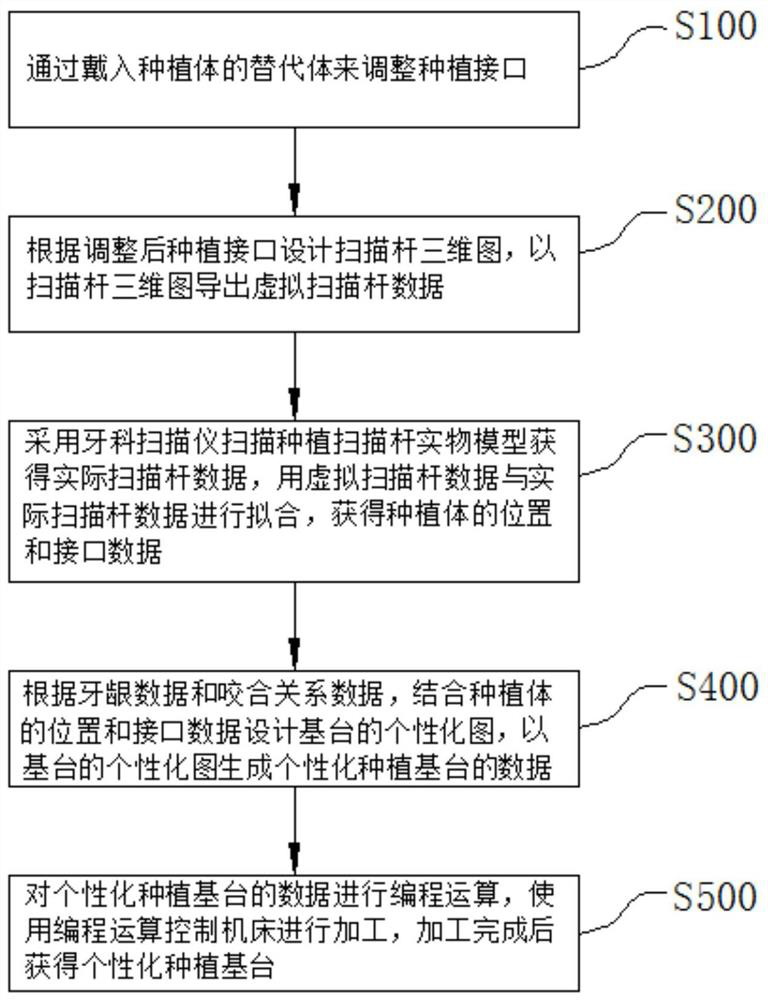

Digital three-dimensional construction and manufacturing method of personalized planting base station

ActiveCN111616821APersonalizeAvoid discomfortDental implantsAdditive manufacturing apparatusDental scanningDentistry

The invention relates to the technical field of artificial tooth implantation, and discloses a digital three-dimensional construction and manufacturing method of a personalized implant abutment, whichcomprises the following steps: s100, adjusting an implant interface by wearing a substitute of an implant; s200, designing a scanning rod three-dimensional diagram according to the adjusted plantinginterface, and exporting virtual scanning rod data according to the scanning rod three-dimensional diagram; s300, scanning the implant scanning rod physical model by adopting a dental scanner to obtain actual scanning rod data, and fitting the virtual scanning rod data with the actual scanning rod data to obtain the position of the implant and interface data; s400, designing a personalized map ofthe base station according to the gingival data and the occlusion relationship data in combination with the position of the implant and the interface data, and generating data of the personalized implant base station according to the personalized map of the base station; and S500, carrying out programming operation on the data of the personalized planting base station, controlling a machine tool to carry out processing by using the programming operation, and obtaining the personalized planting base station after the processing is completed. The individuation of the planting base station can berealized.

Owner:北京联袂义齿技术有限公司

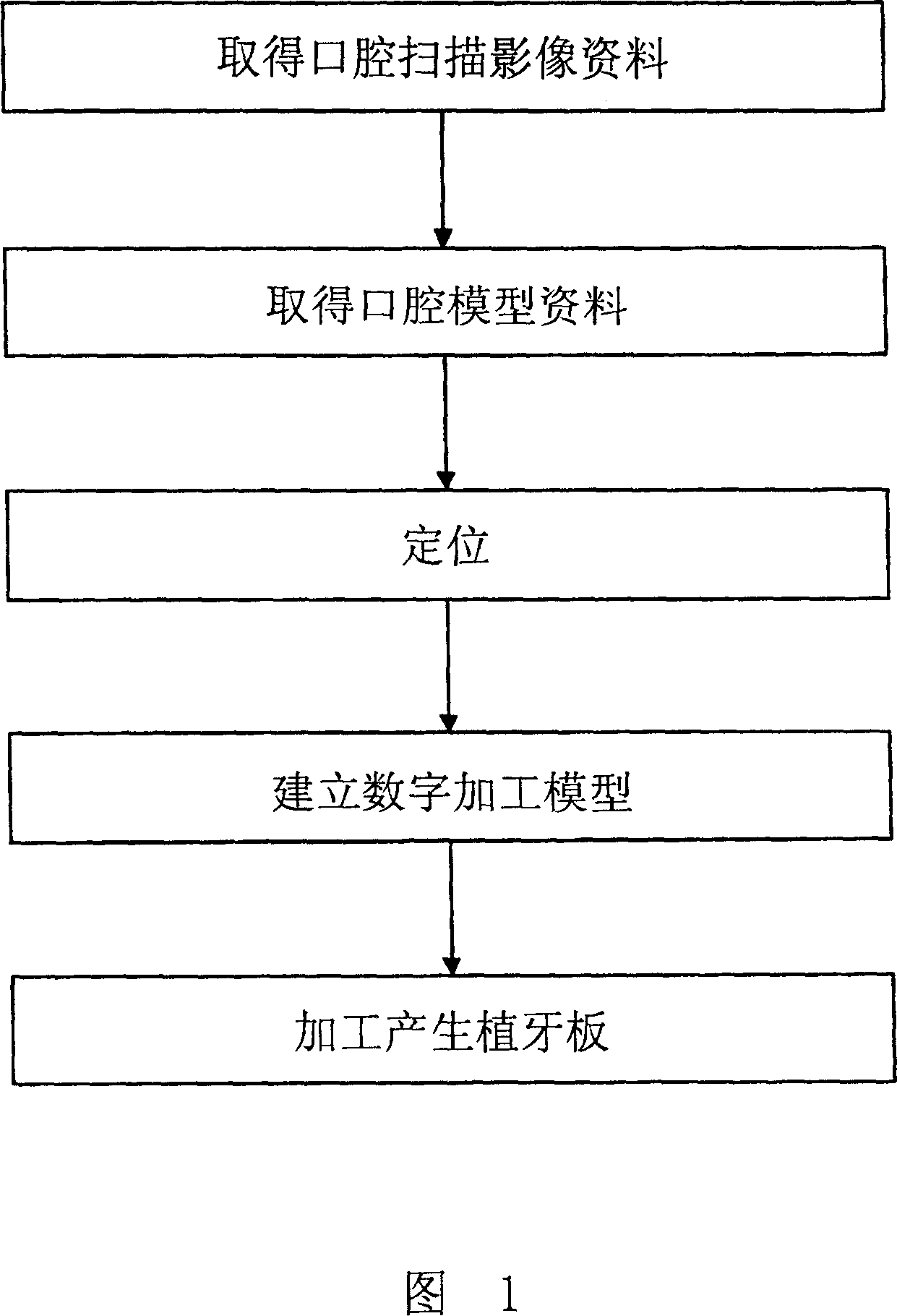

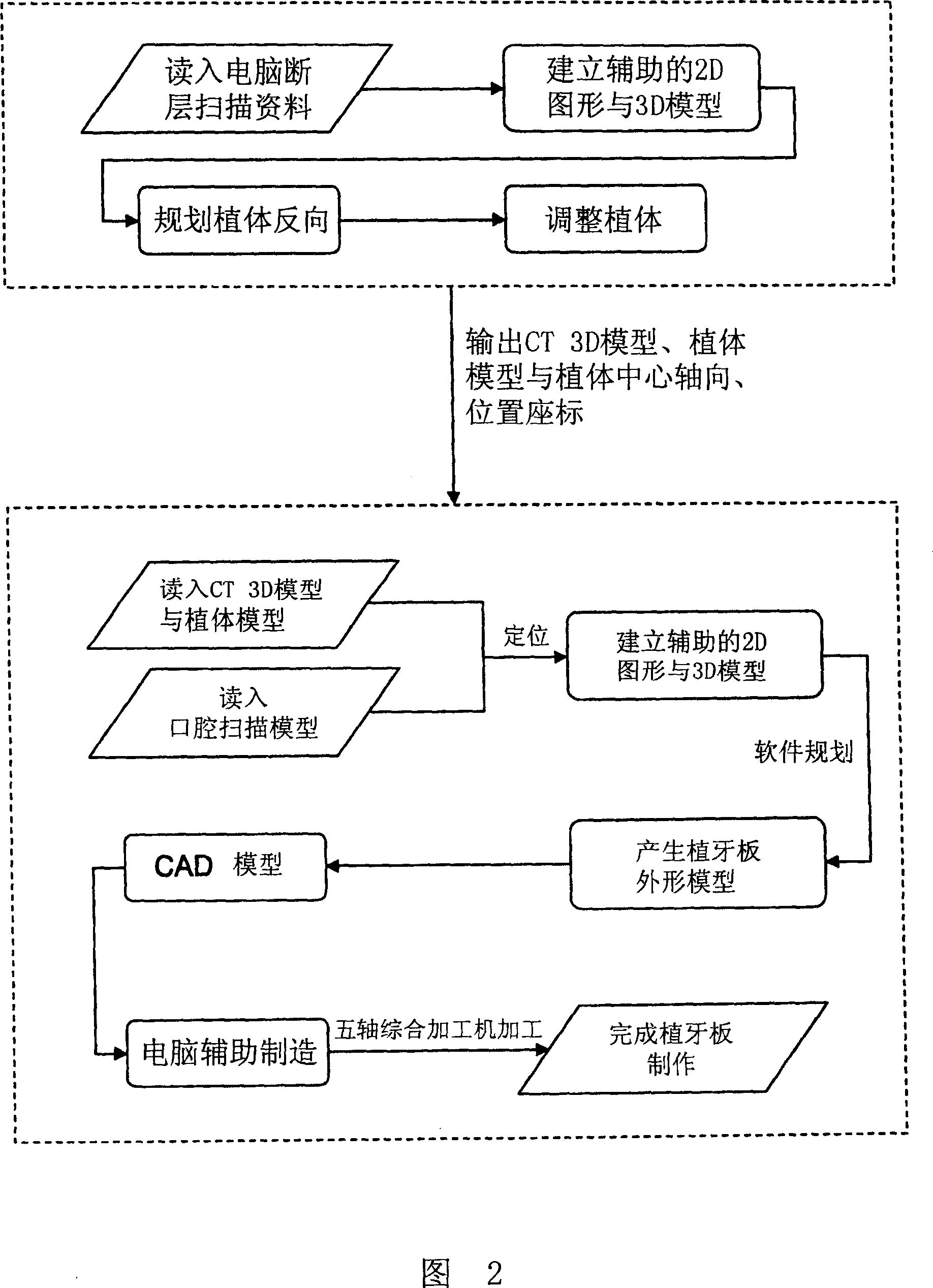

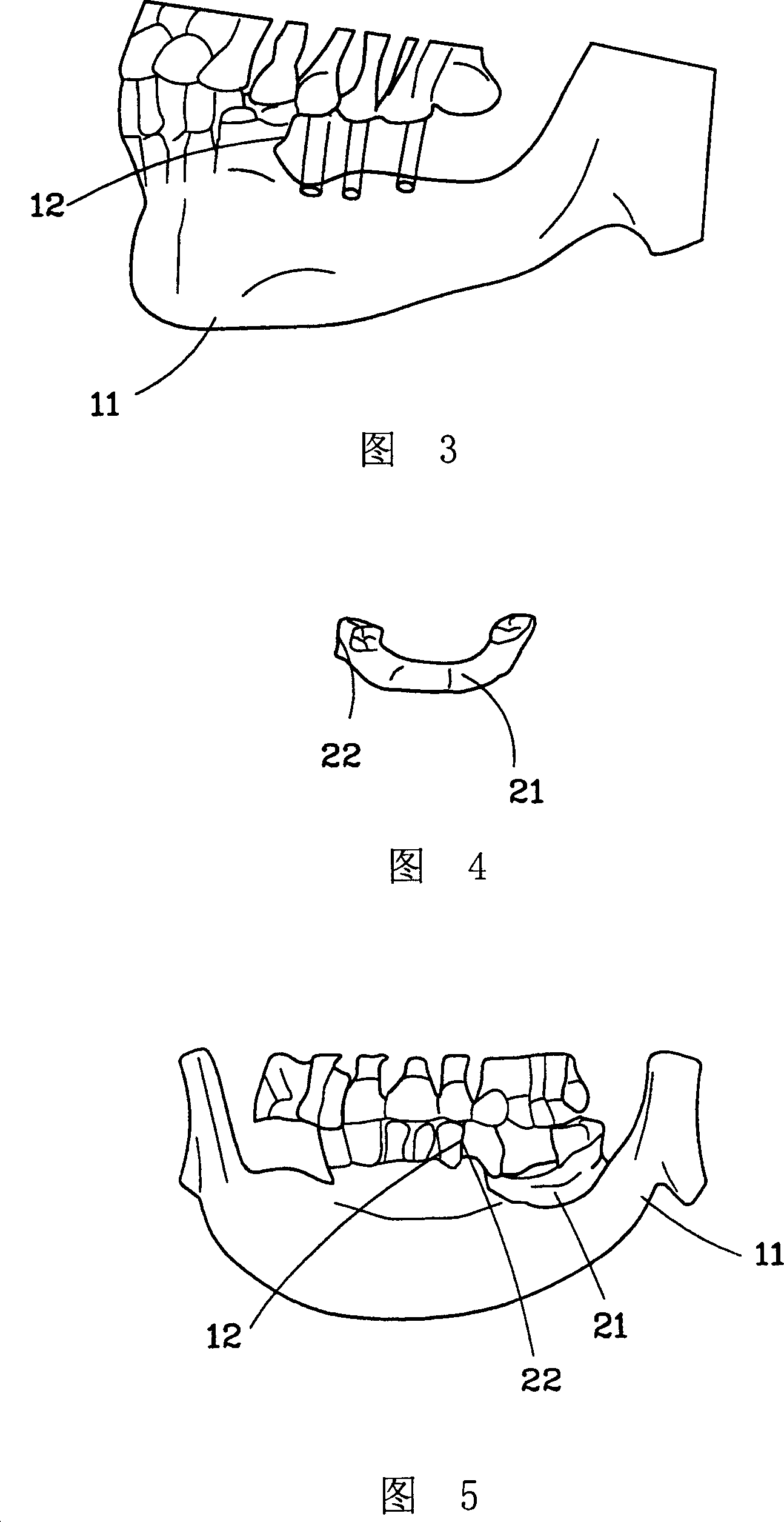

Method for making dental implant

A method for manufacturing a tooth implantation plate includes such steps as using CT to obtain scanned oral cavity image data as reference object, copying a stereo model of oral cavity to obtain the shape of oral cavity, scanning the stereo model to obtain the model data of oral cavity as locating object, taking at least one relative characteristic from said reference object and locating object, locating the characteristic for locating said model data in said scanned image data, creating a digital model, using CAM to plan a machining route to obtain a digital manufacture model, and manufacturing tooth implantation plate.

Owner:POU BIOTECH

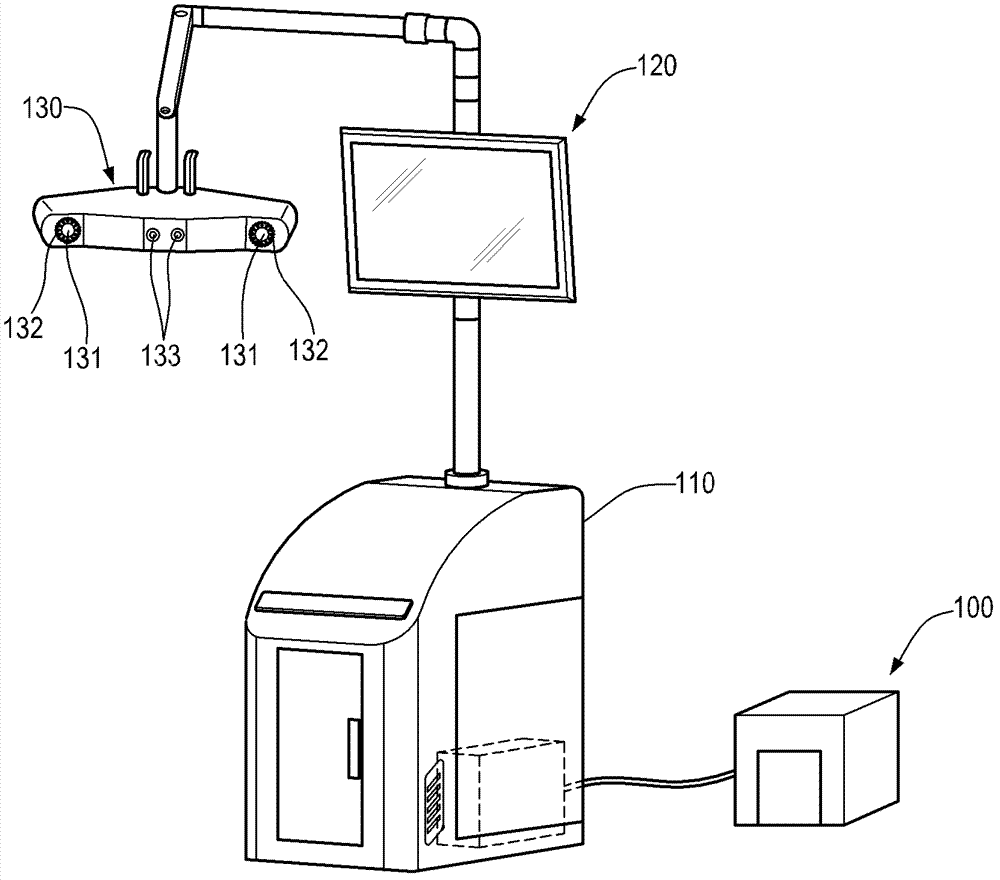

Tooth implantation guidance system

The invention discloses a tooth implantation guidance system. The tooth implantation guidance system comprises 1, a scanning and storage device which is used for scanning a tooth model of a patient, carrying out digitization and storing the digitized tooth model information, 2, an optical positioning device which is used for acquiring spatial data of a tooth implantation tool, 3, a biteplate which is arranged in the oral cavity and carries out coordinate registration of images and entities, and 4, a tooth implantation planning device which is connected to the scanning and storage device and the optical positioning device and carries out analysis comparison of the digitized tooth model information stored in the scanning and storage device and the spatial data obtained by the optical positioning device. The tooth implantation guidance system provides tracking orientations of a tooth implantation hand tool and a tooth model by a positioning algorithm thereby estimating if a tooth implantation orientation is correct so that patient discomfort or an accident risk is reduced to the lowest degree.

Owner:EPED

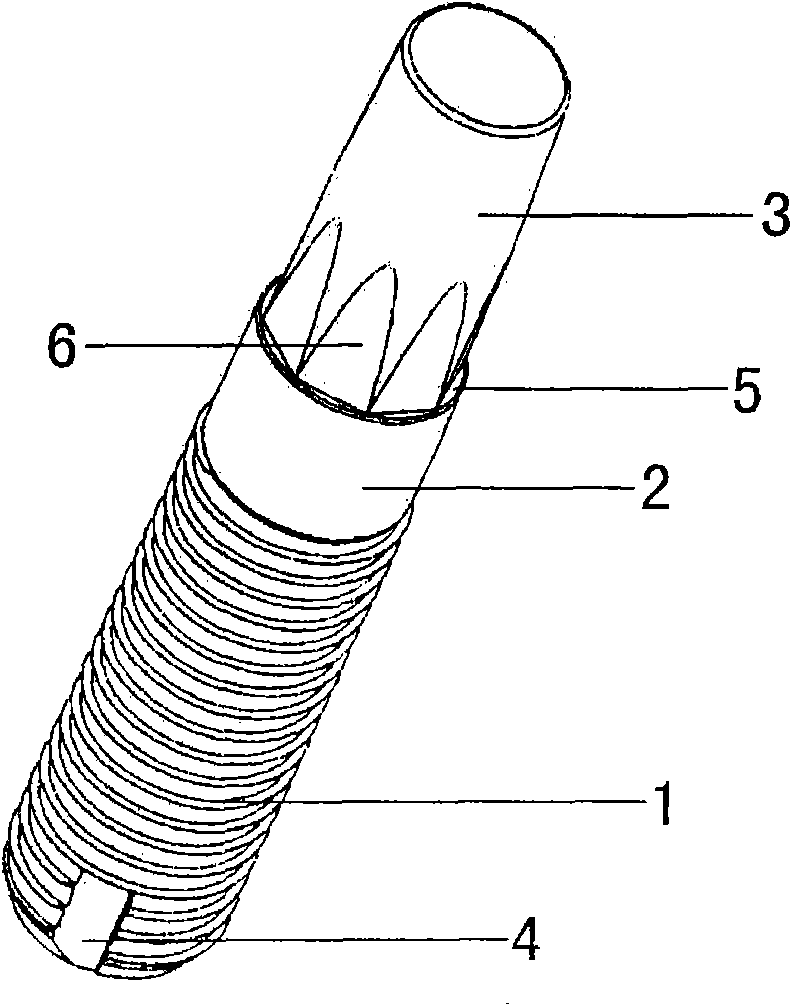

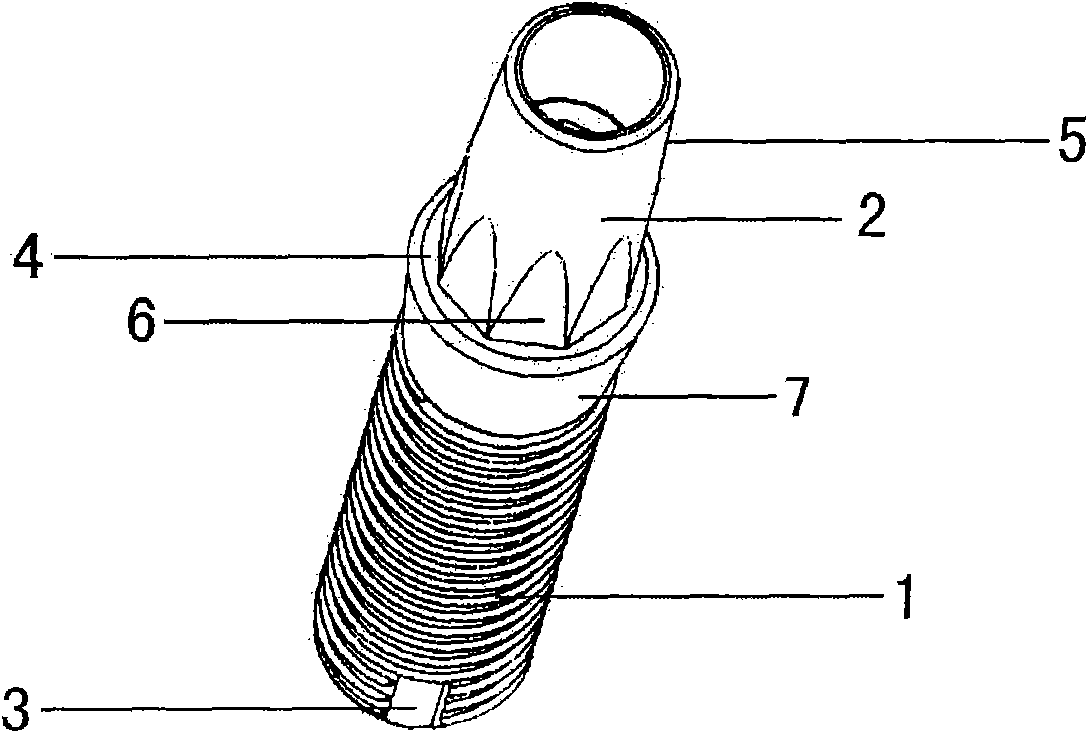

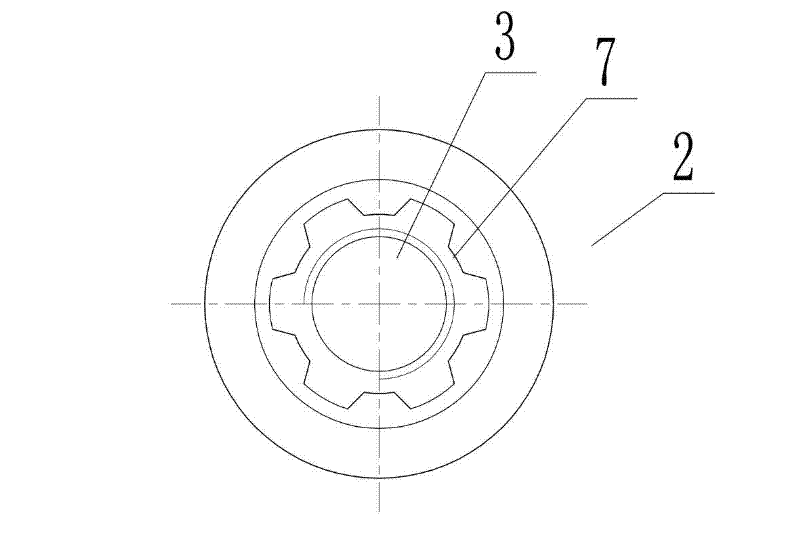

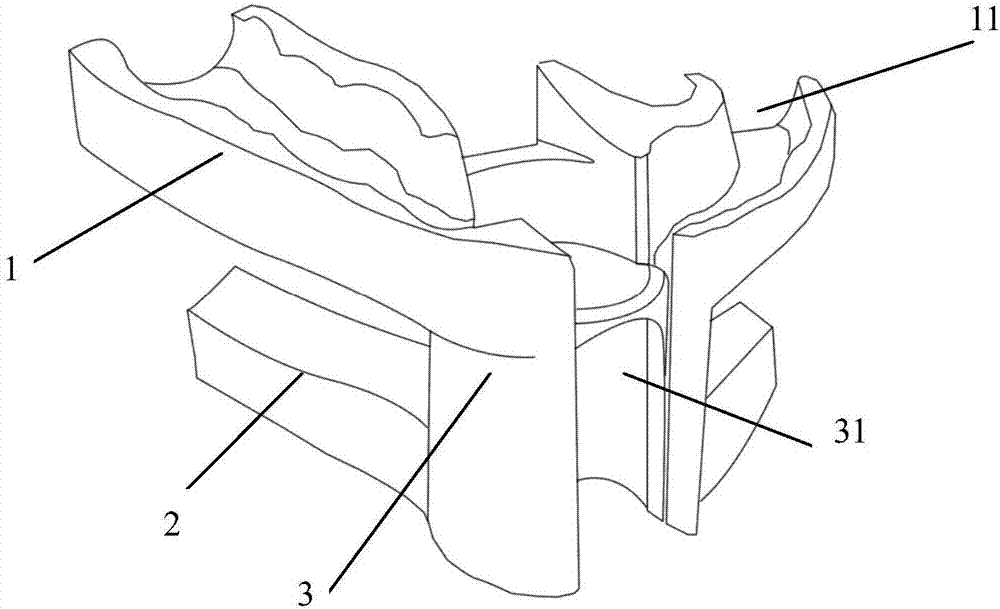

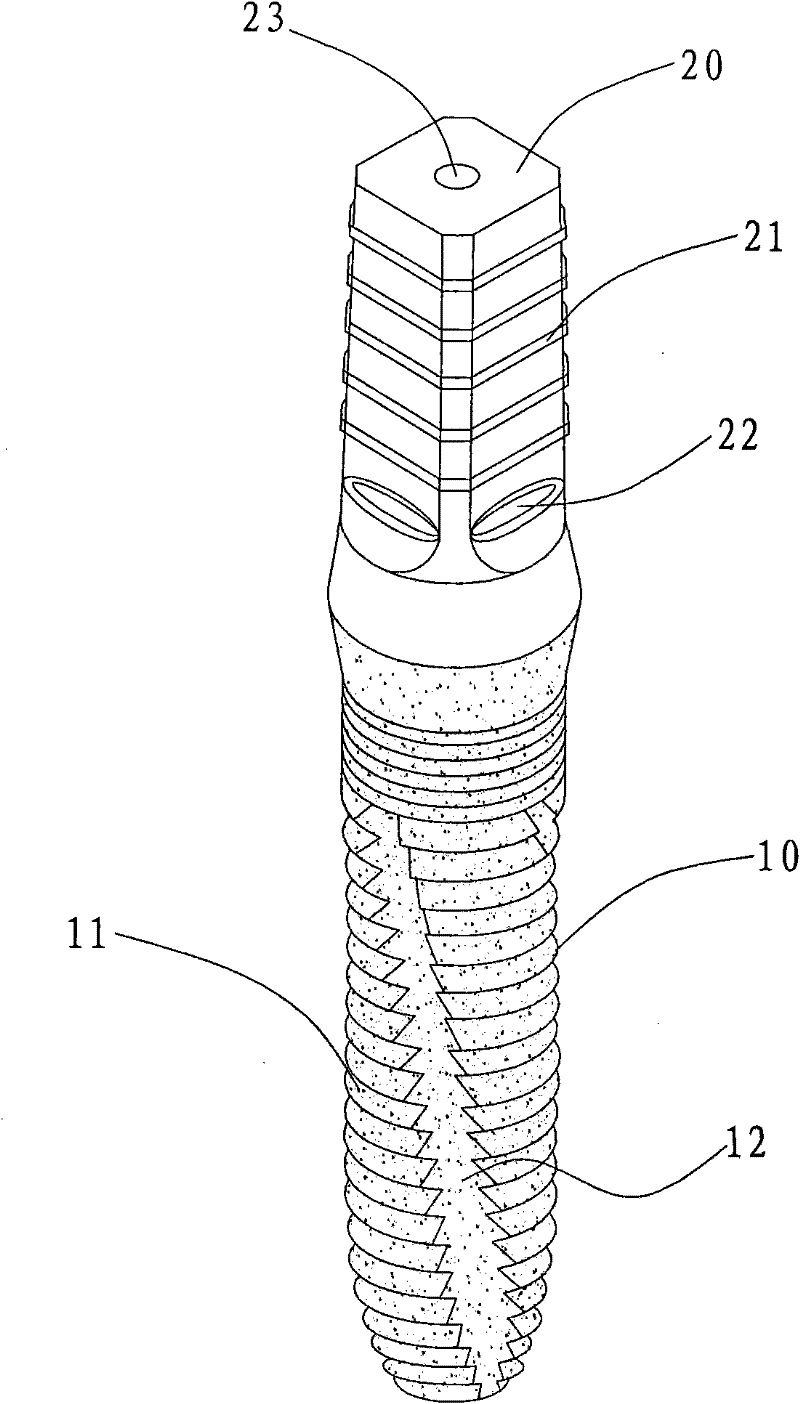

Assembled Dental Implants

The invention relates to an assembled dental implant which is particularly suitable for artificial tooth implantation for filling gaps after teeth are pulled out through operative treatment, in particular to a dental artificial body which can improve osseointegration, gripping and fixation effects. The assembled dental implant comprises an implanting screw and an assembled base platform and is assembled by the implanting screw and the assembled base platform; a thread section is formed outside the implanting screw, the upper part in the implanting screw is provided with an inner conical hole,the lower part of the inner conical hole is provided with positioning bulges, and an inner thread of the implanting screw is formed below the positioning bulges; the assembled base platform comprisesa base platform body, a connecting screw and a thread bushing, the upper part of the base platform body is provided with an artificial tooth connection part, the middle part of the base platform bodyis provided with a transgingival part, the lower part of the base platform body is provided with an implanting screw connection part, and the assembled base platform is arranged in the implanting screw; a step through hole is formed in the base platform body, and a connecting rod is arranged in the step through hole; and the thread bushing is matched with the inner thread of the implanting screw.

Owner:常州百康特医疗器械有限公司

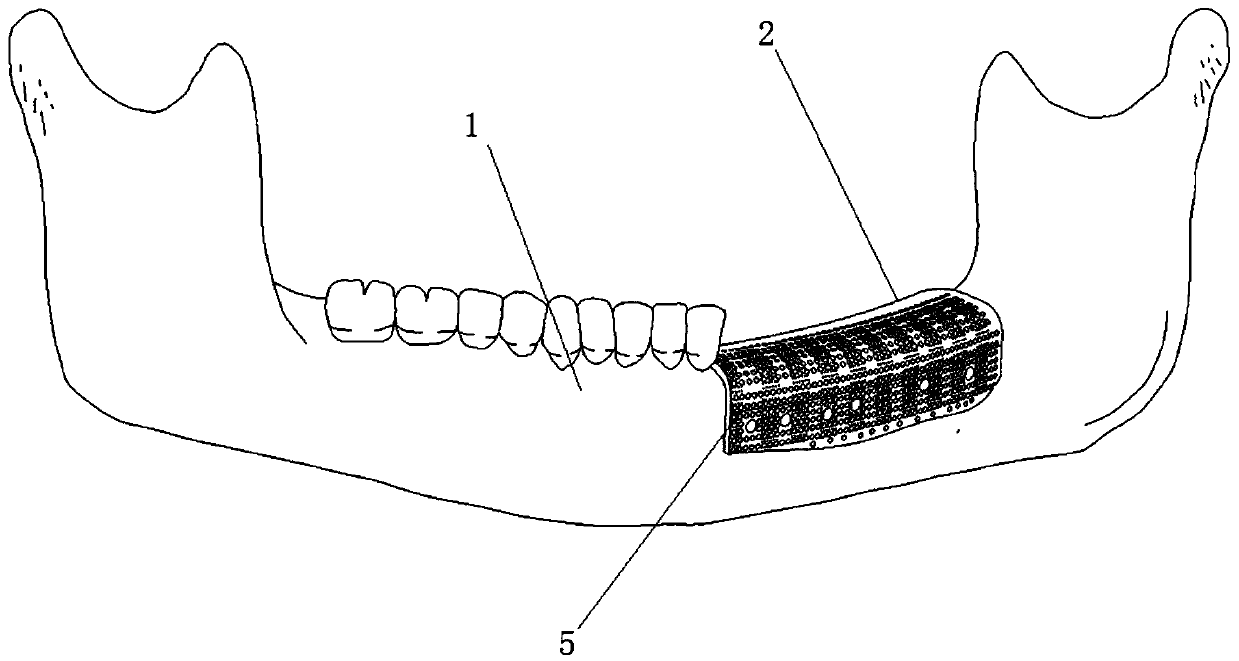

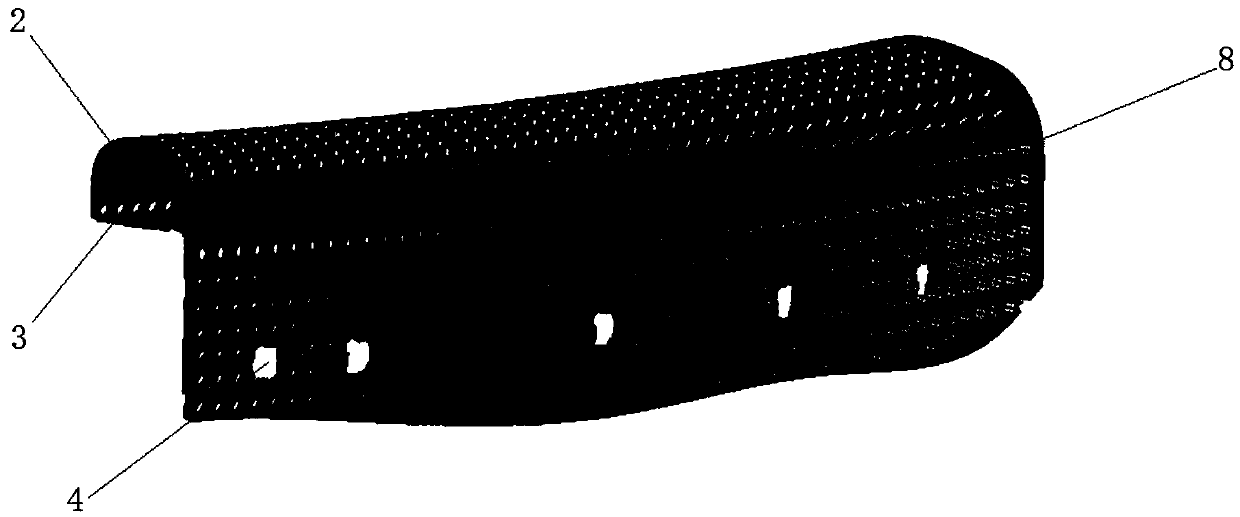

Three-dimensional printed titanium mesh implant with osteogenic induction coating

PendingCN109646714AOvercome prebendingImprove fitDental implantsAdditive manufacturing apparatusTitaniumBone defect

The invention relates to the field of dental implants, in particular to a three-dimensional printed titanium mesh implant with an osteogenic induction coating. The three-dimensional printed titanium mesh implant with the osteogenic induction coating can achieve optimal osteogenic induction according to an optimal repair effect after reconstruction of the alveolar bone through an accurately printedcontour of a titanium mesh body. The unpredictability of the shape after the alveolar bone ossifies is avoided, an optimal shape is guided to be formed after the alveolar bone ossifies, and latter tooth implantation is facilitated. Pre-bending of the titanium mesh body before implantation is overcome, it can be achieved that the edge of the titanium mesh body accurately fits the shape of remaining bone mass. A three-dimensional printing technology can accurately print the titanium mesh body with good fitting performance according to the bone shape of the position, in contact with the titaniummesh body, around a bone defect, and the bent titanium mesh body does not need to be adjusted during an operation at all; and the fitting performance of the titanium mesh body with the alveolar boneis far more precise than manual bending.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

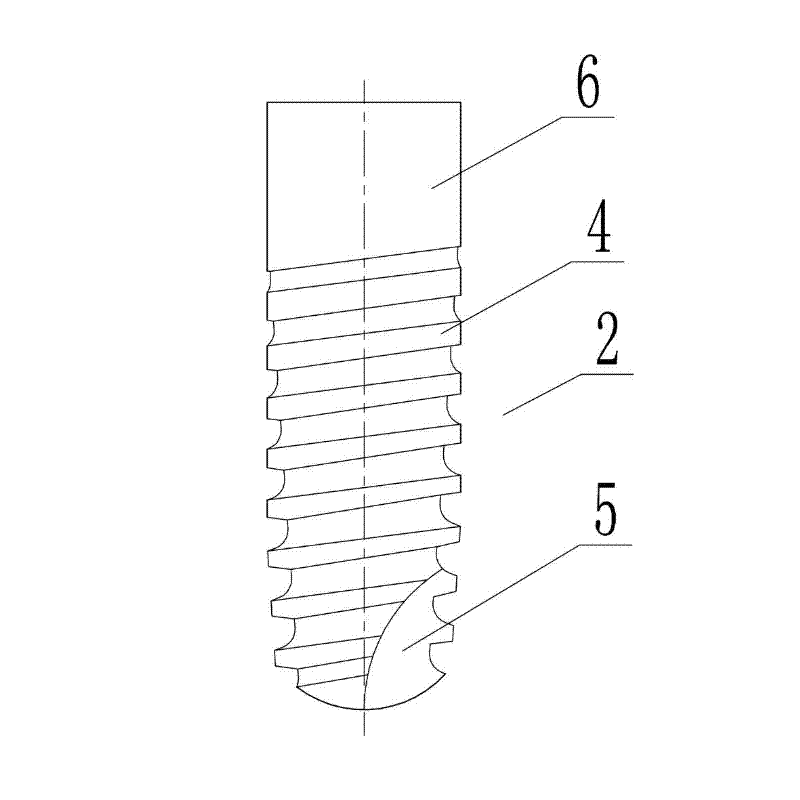

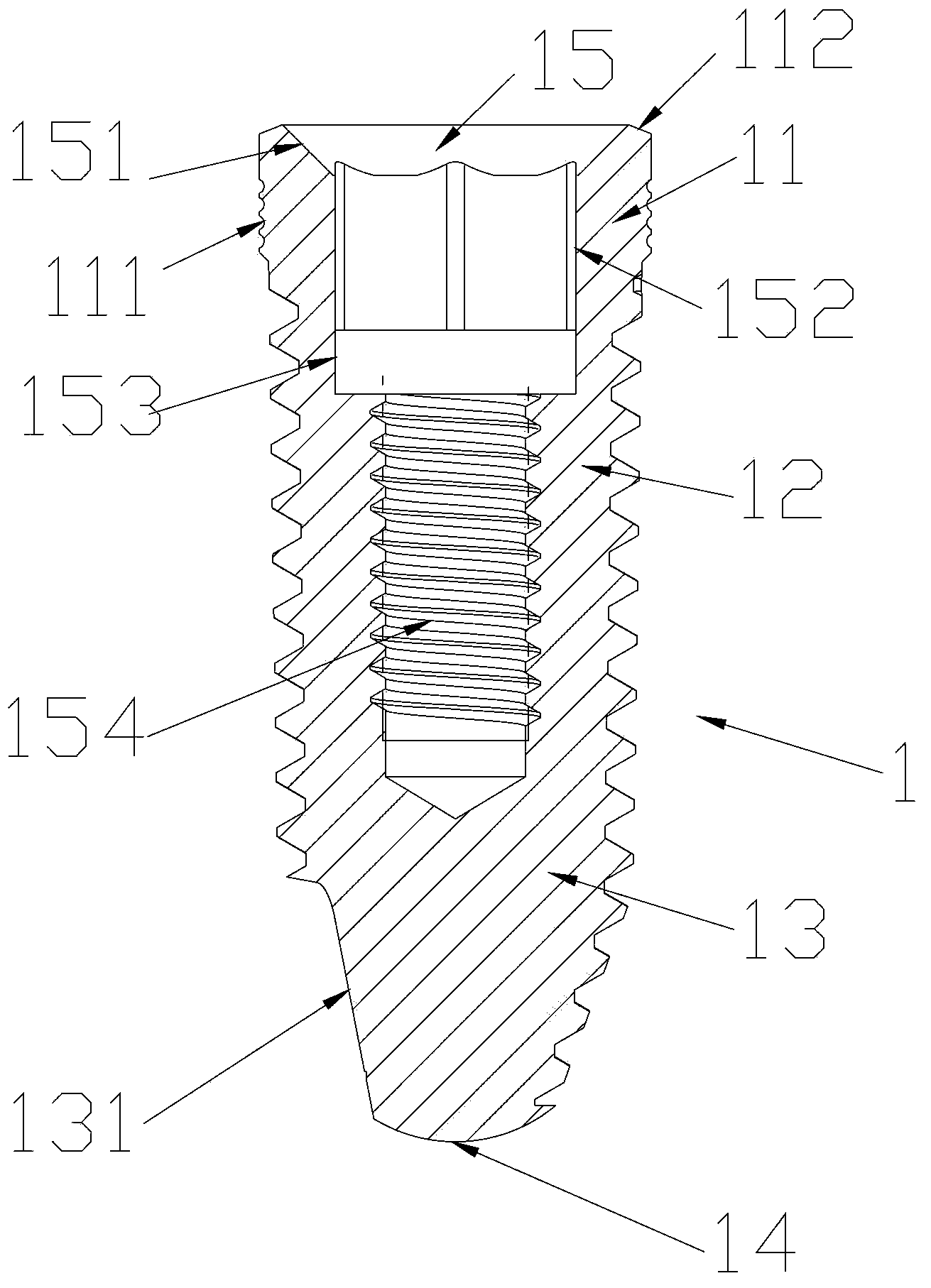

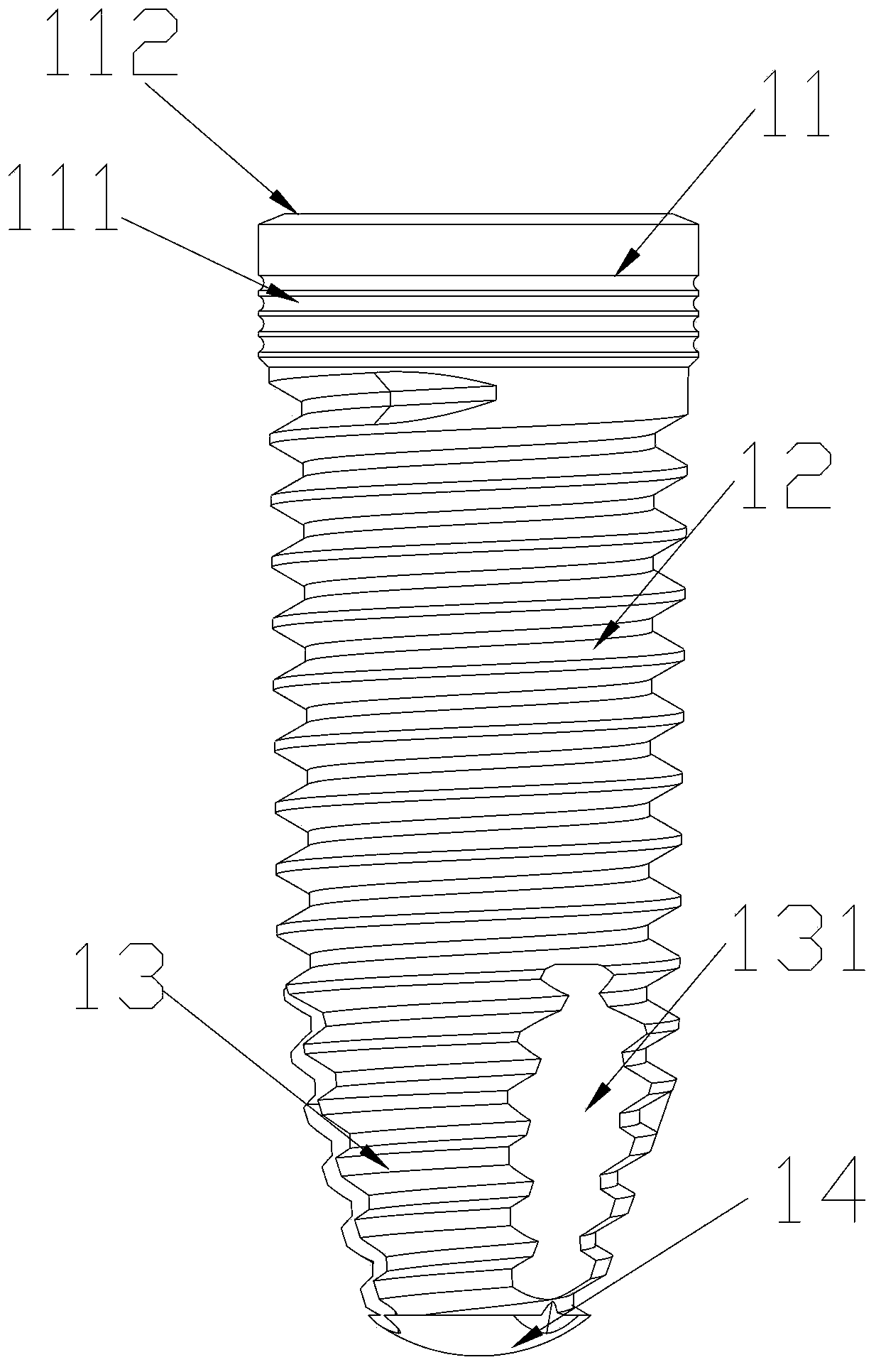

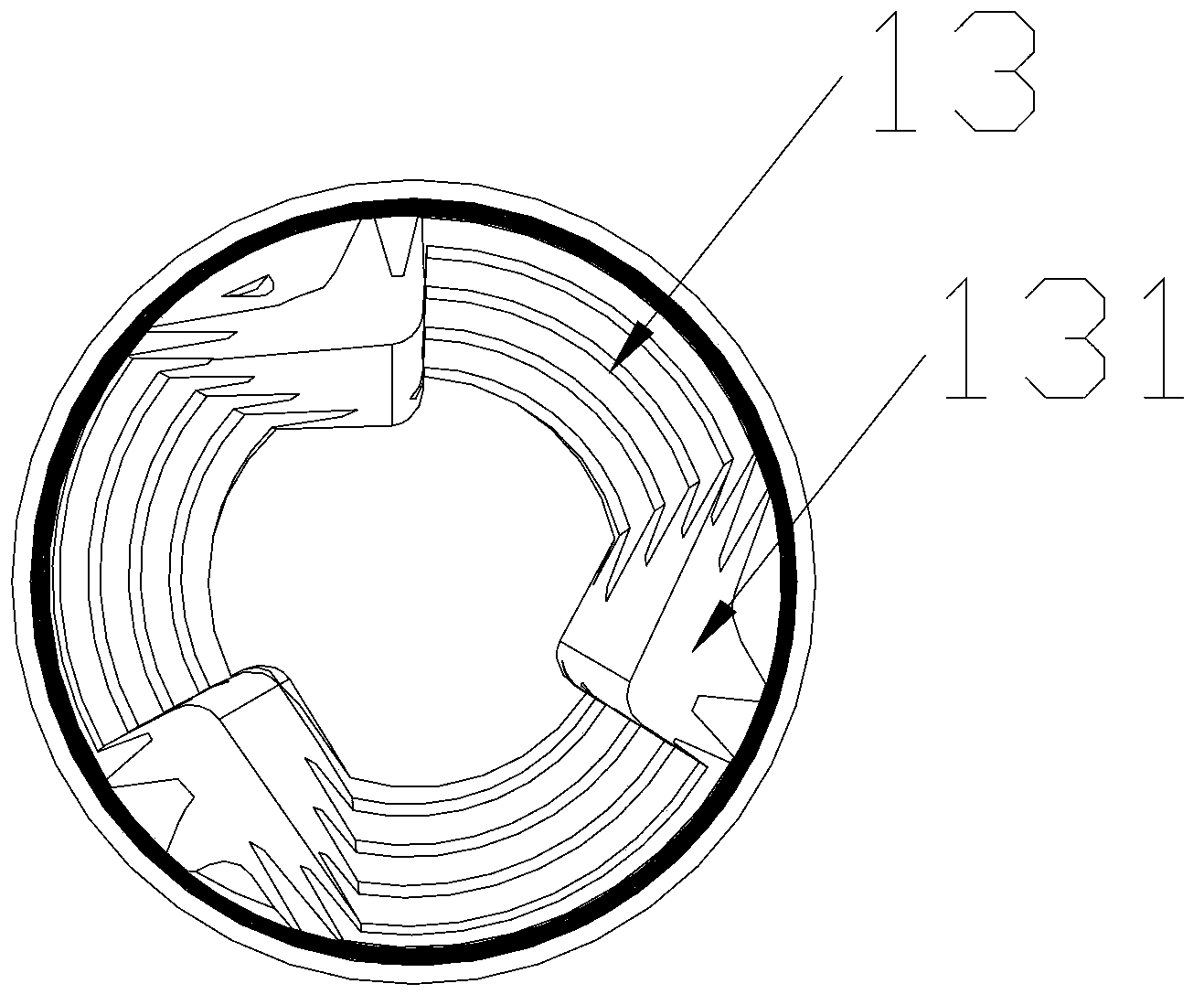

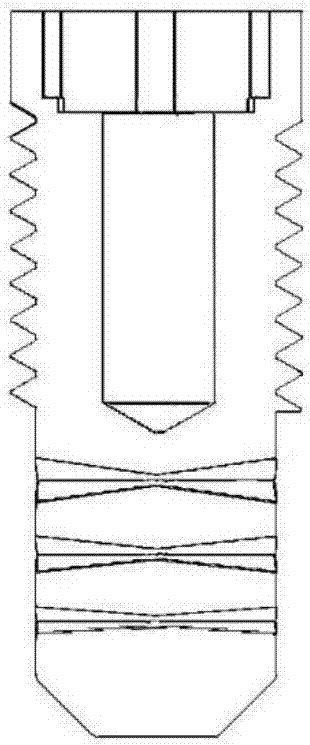

Self-tapping dental implant

InactiveCN104068941AImprove initial stabilityRealize the transfer functionDental implantsNeck partsDental implant

The invention provides a self-tapping dental implant. The self-tapping dental implant comprises a body, wherein the body is successively provided with a neck part, a body part, a root and a bottom from top to bottom in an adjoining manner; the neck part is a cylinder; the outer surface of the neck part is provided with a four-ring circular groove; the body part is a first tapered thread section; the root is a second tapered thread section; the thread tapers of the first tapered thread section and the second tapered thread section are different; three slant self-tapping cutting grooves are uniformly distributed in the periphery of the outer surface of the root; the bottom is a sphere; an open inner cavity is vertically formed in the radial middle part of the body; the inner cavity is successively provided with reverse tapered bores, regular polygon bores, cylindrical bores and inner threaded bores from top to bottom in an adjoining manner; the diameter of each cylindrical bore is the same as that of an inscribed circle of each regular polygon bore. The self-tapping dental implant has the function of platform transferring; due to the design of double tapers and arrangement of cutting grooves, implanting operation can be performed more easily, the initial stability of tooth implantation is improved, and the bone loss is reduced to the maximum extent. The matching of inner conical surfaces and the base station achieves the sealing effect to prevent micro leakage.

Owner:广东健齿生物科技有限公司

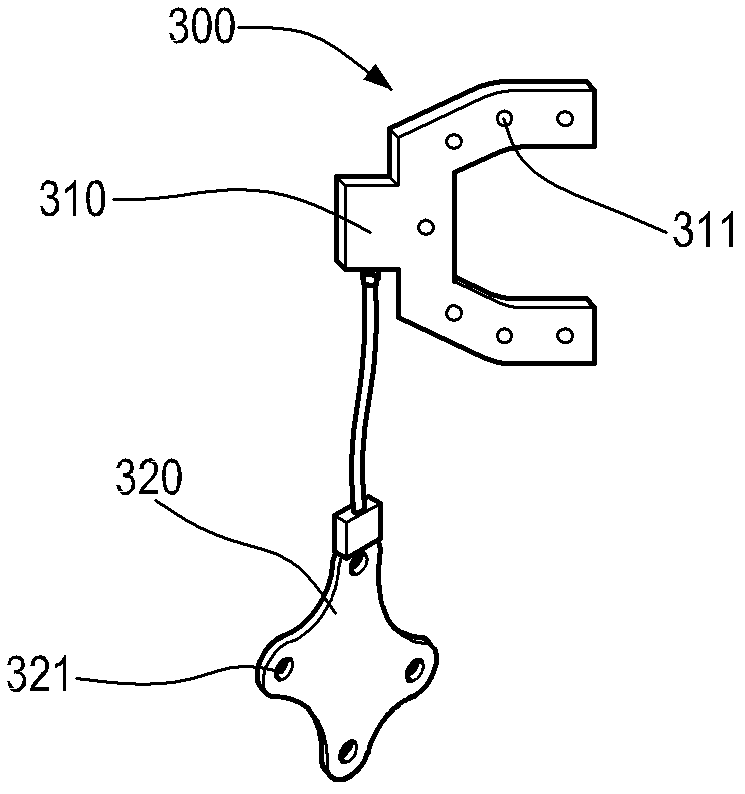

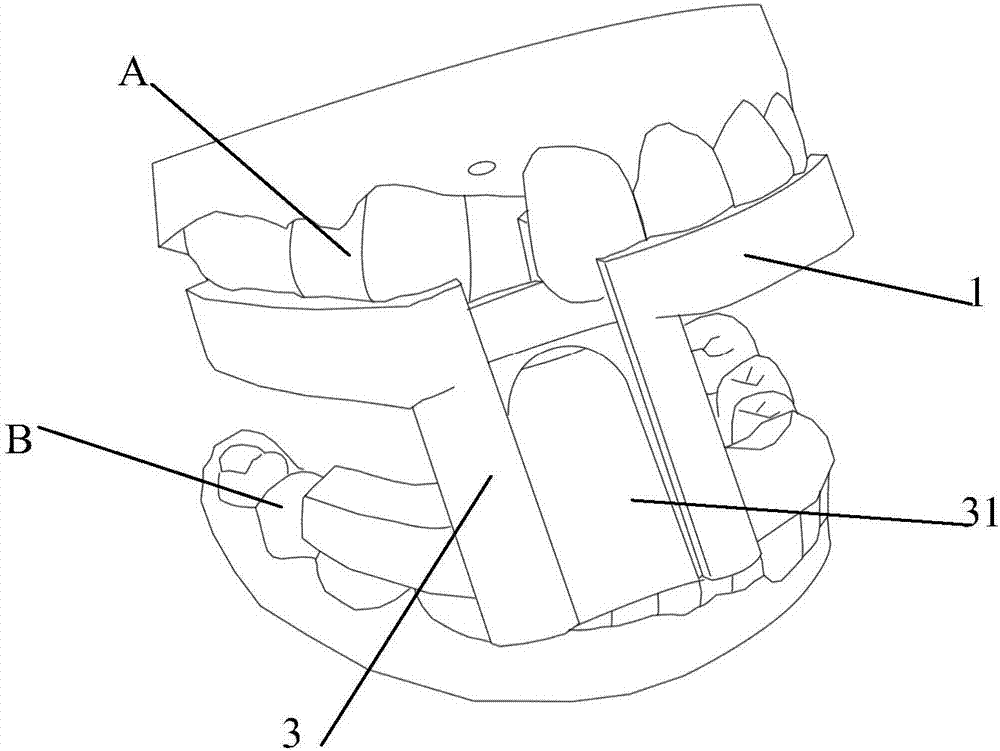

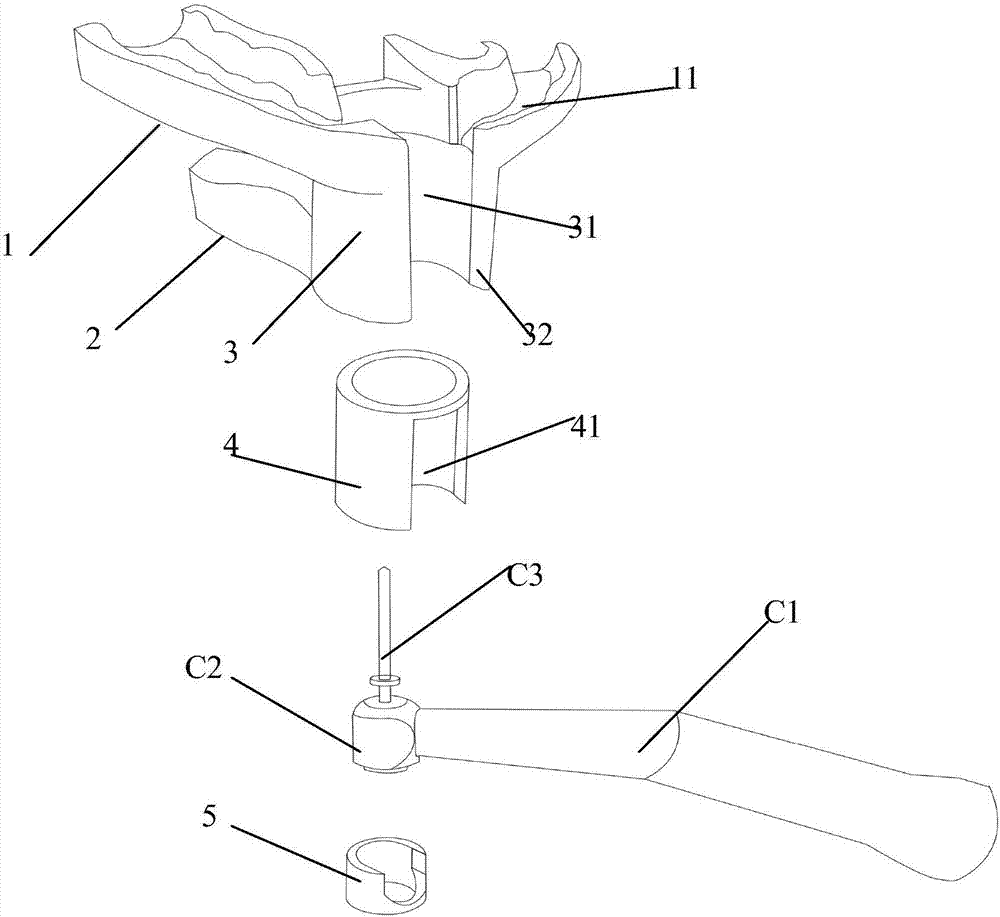

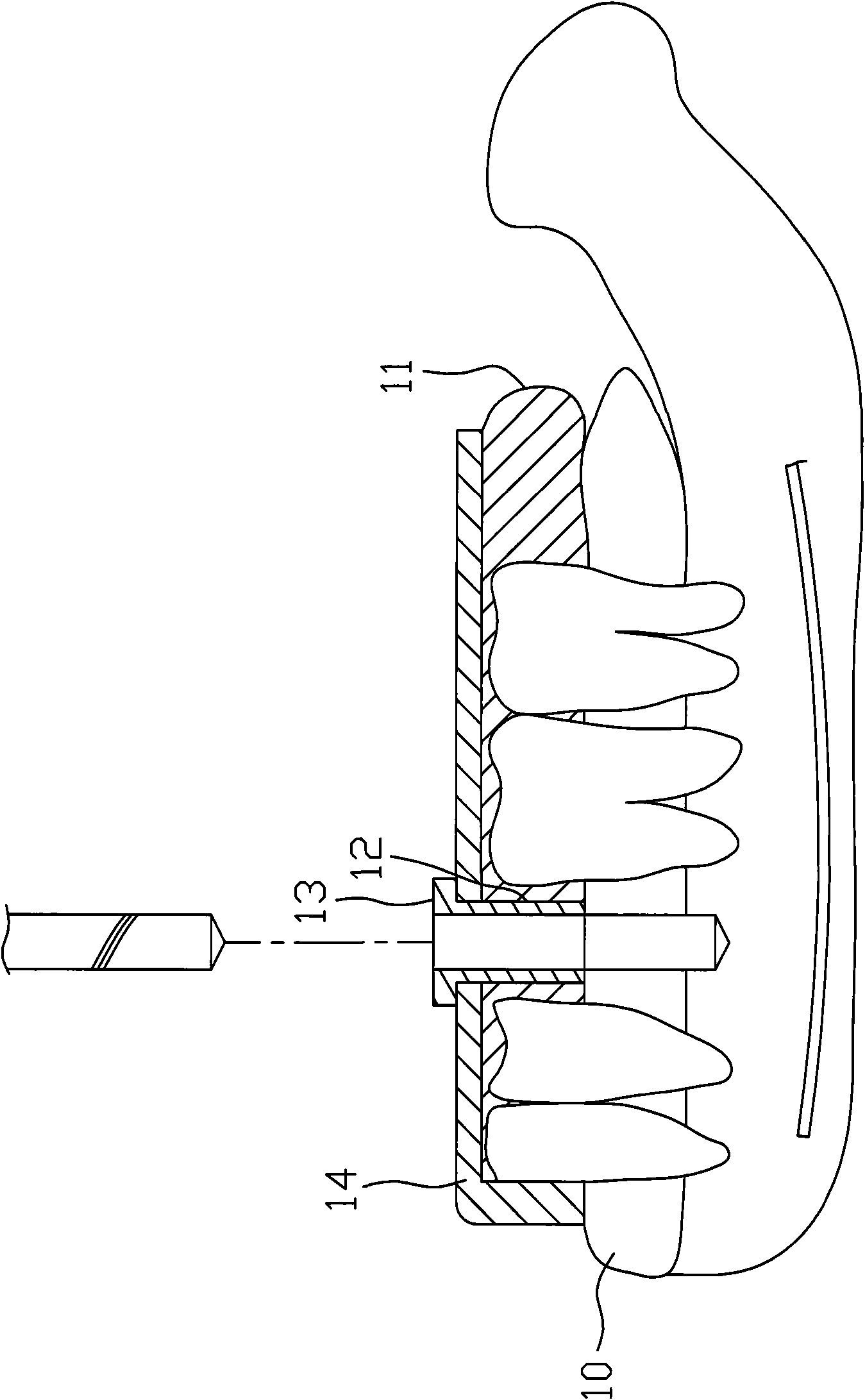

Tooth articulation control machine head guide plate and a production method thereof

InactiveCN107157601ANo extra heatReduce difficultyDental implantsImpression capsEngineeringMucous membrane

The present invention discloses a tooth articulation control machine head guide plate and a production method thereof. The guide plate comprises an upper base body controlled by superior teeth, upper alveolar bone or mucous membrane and a lower base body controlled by inferior teeth, lower alveolar bone or mucous membrane, wherein a supporting body is arranged between the upper base body and the lower base body, and a control mechanism for positioning and guiding an implantation machine head on the supporting body, the upper base body or the lower base body. During the use, the guide plate is placed between the superior teeth and the inferior teeth of a patient, and is subjected to articulation fixation respectively with the upper base body and the lower base body through the superior teeth and the inferior teeth, the machine head is placed the control mechanism arranged according to the implantation data, the machine head moves to the alveolar bone along the control mechanism direction during the implantation drilling, and the guide plate performs guiding positioning on the machine head, such that the positioning guiding precision is improved, the direct contact between the guide and the high-speed rotating drill bit is avoided, and the heat generation of the drill bit cannot be additionally increased; and the guide plate can be fixed only through the articulation action of the patient, such that the multi-person operation is not required during the tooth implantation operation, and the tooth implantation difficulty is reduced.

Owner:SHENZHEN AHEAD FIT TECH CO LTD

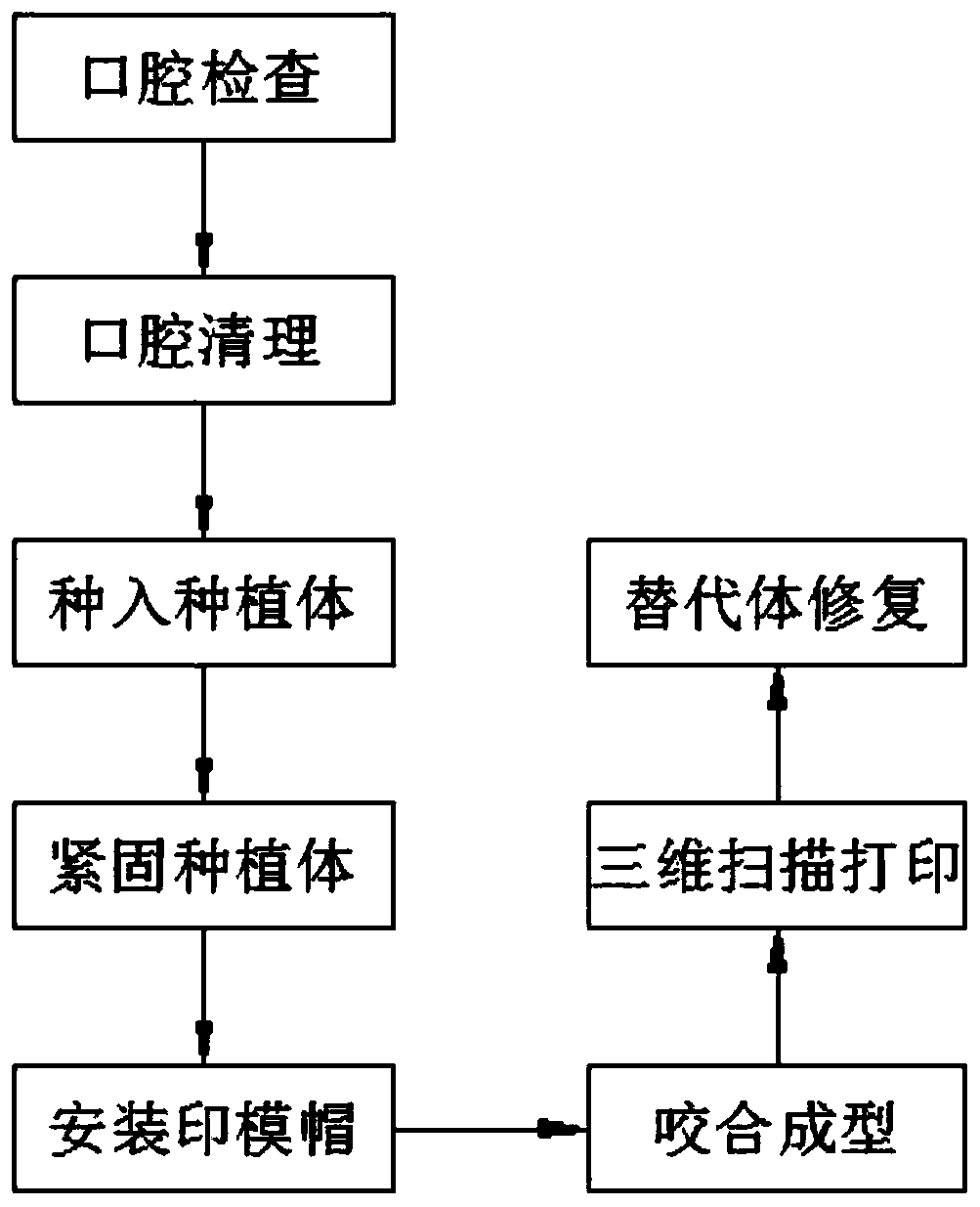

Digital model taking technology for tooth implantation

The invention discloses a digital model taking technology for tooth implantation. The technology specifically comprises the following steps that firstly, oral cavity examination is performed on a patient; secondly, the oral cavity of the patient is cleaned; thirdly, a doctor embeds an implant into a position where the patient lacks a tooth, and an impression cap is placed at the cuff of the implant in the oral cavity of the patient; fourthly, an occlusal tray is placed in the oral cavity of the patient; fifthly, three-dimensional scanning is carried out through a three-dimensional scanner, a 3D model is printed, and finally a suitable denture is made. According to the invention, the special digital impression cap is fixed to the cuff of the implant in the mouth of the patient, and then thedoctor can take a model according to a conventional model taking method without a transfer rod, a substitution or a healing cap; after the model is taken, the tray is sent to a technician for scanning and printing the resin model, and then the resin model is machined according to a normal repair body manufacturing flow. The technology has the advantages that the operation is simple, the accuracyis high, the patient feels no pain, and particularly digital repairing can be carried out.

Owner:QINGDAO HUAXINHUA DENTAL

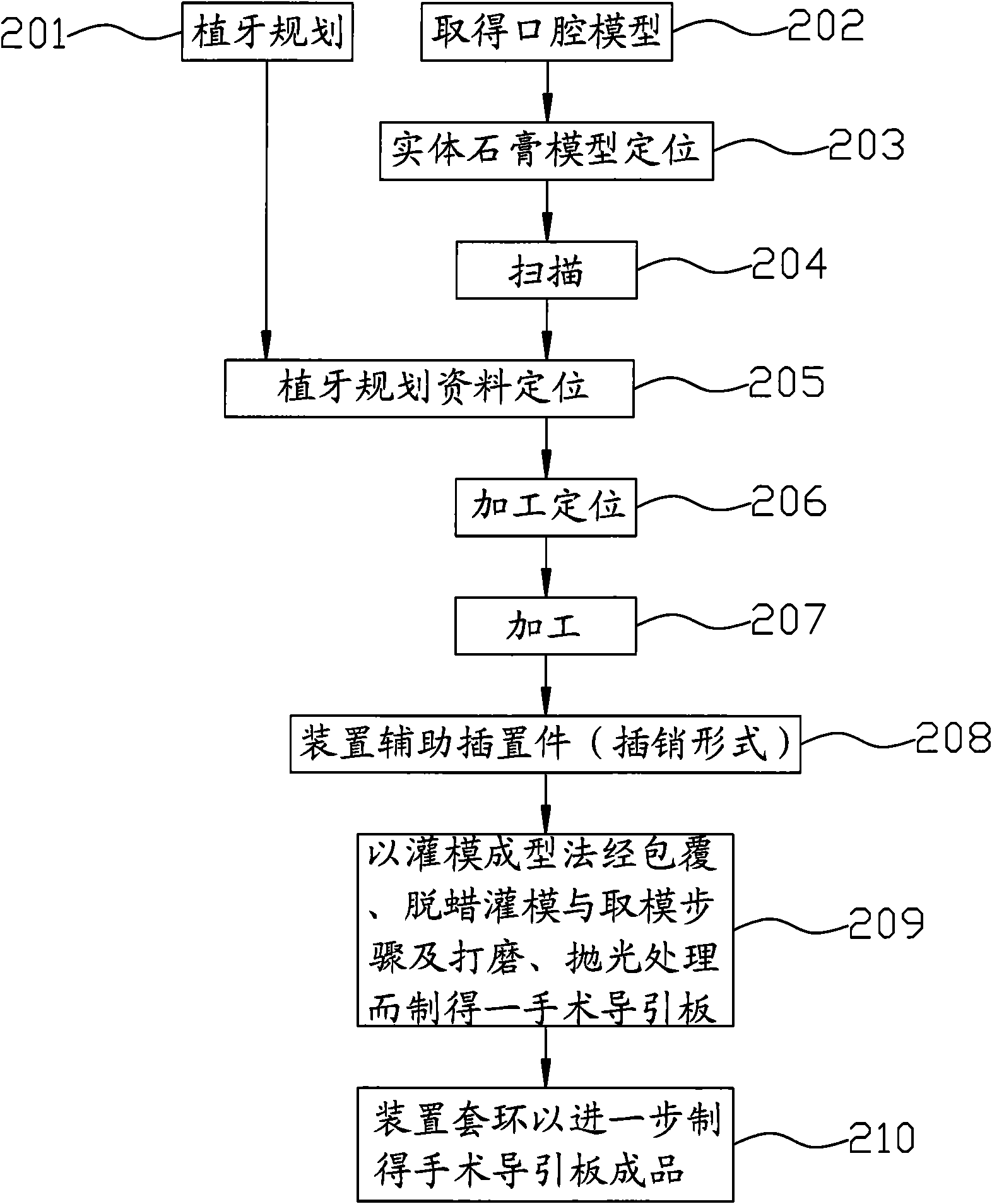

Method for producing tooth implantation surgical guide stent

InactiveCN101642386AAccurate presentationReduce iterative stepsDental implantsDental prostheticsRolloverInsertion stent

The invention relates to a method for producing a tooth implantation surgical guide stent, which comprises the following steps: performing a tooth implantation plan; obtaining an oral entity plaster model; positioning and scanning the entity plaster model; positioning information of the tooth implantation plan on a digital plaster model obtained by scanning; positioning the digital plaster model in a scheduled processing position by processing software; putting the entity plaster model in the processing position to perform drilling processing and present the information of the tooth implantation plan on the entity plaster model; installing an auxiliary implanting piece; and forming the surgical guide stent with a plurality of guide holes on the processed entity plaster model by thermoplastic materials in fit with a rollover forming method or a vacuum forming method. Thus, the method can be used for producing more precise surgical guide stents, and has the characteristics of time saving, labor saving and production cost reduction.

Owner:POU BIOTECH

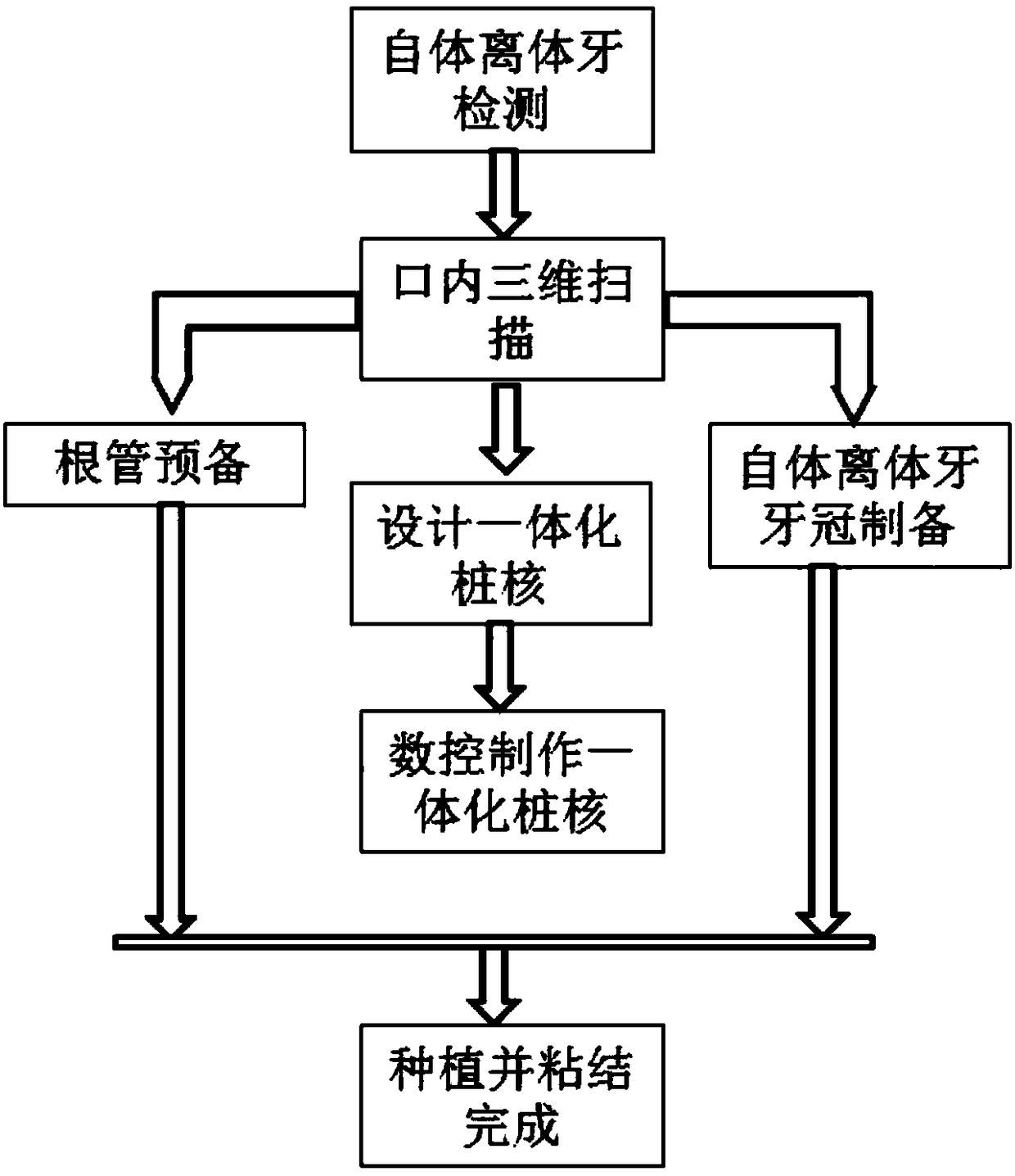

Customized dental implant, and preparation method thereof

InactiveCN108338847AGood compatibilityImprove experienceDental implantsDental prostheticsPersonalizationExtracted tooth

The invention relates to a customized dental implant, and a preparation method thereof. The preparation method comprises following steps: 1, it is determined whether an autogenous extracted tooth dental crown is prepared; 2, an oral cavity optical digital impression is obtained; 3, a routine post-core root canal tooth is prepared; 4, if the bone mineral density data detected in step 1 is relatively high, and an extracted tooth is preserved, an integrated post-core and the autogenous extracted tooth dental crown are prepared, and a post-core three dimensional design matching the autogenous extracted tooth dental crown is formed; 5, if the bone mineral density data detected in step 1 is relatively high, and the extracted tooth preservation is qualified, an integrated post-core provided witha dental crown is prepared; 6, numerically controlled machining is adopted to prepare the customized integrated post-core; and 7, the prepared integrated post-core, or the integrated post-core and theautogenous extracted tooth dental crown are implanted into a prepared root canal using a binder. The preparation method is capable of realizing effective utilization of autogenous extracted teeth, and improving tooth implantation experience greatly.

Owner:苏州口腔医院(集团)有限公司

Dental implant

The invention discloses a dental implant, which comprises a cylindrical dental implant body part, a first tail end and a second tail end, wherein the dental implant body part is encircled by unsymmetrical screw, a top-end lock is positioned at the first tail end of the dental implant body part; a lock for inserting into a proper position of nasal sinuses and maximizing internal contact design is located at the second tail end of the dental implant body part, and then is tightly connected with supporter teeth by a bolt; the top-end lock positioned at the first tail end of the dental implant body part is provided with a concave space to allow bones of the nasal sinuses to grow into the top end lock from the opening (i.e. the concave space), and provides a locking mechanism for tightly integrating the dental implant and the bones; and the lock for maximizing the internal contact design is provided with a lock hole at the second tail end of the dental implant body part to contain the rootpart of the supporter teeth. The invention is easy to be used, provides biggest tooth implantation stability, improves the success rate of an implant surgery, and avoids multiple surgical procedures.

Owner:艾迪生物医学有限责任公司

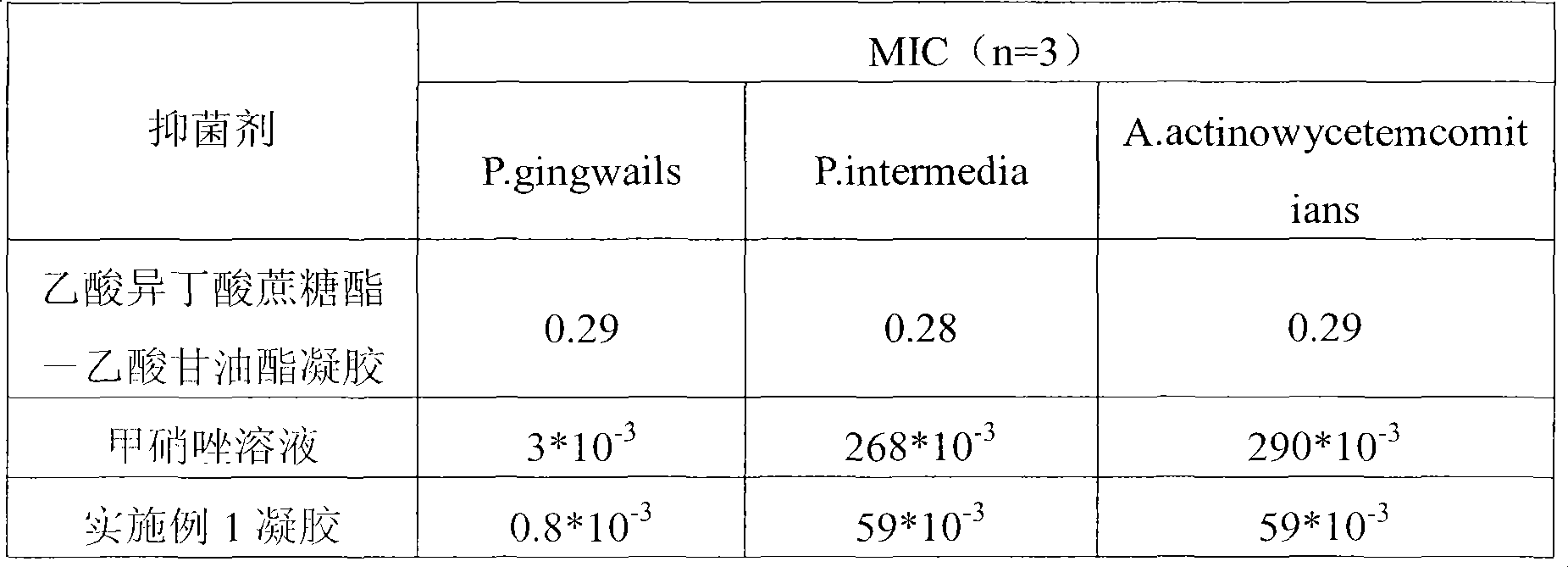

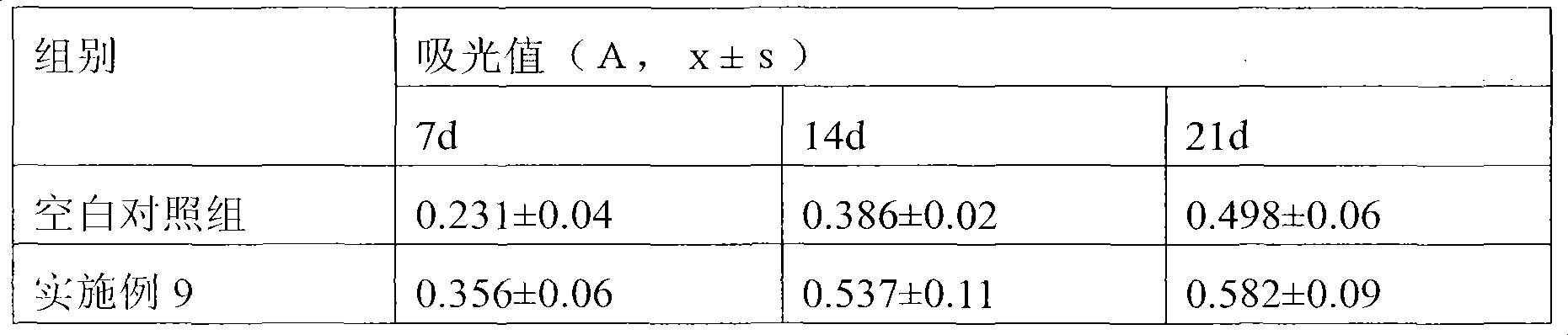

Sucrose acetate isobutyrate gel and application thereof

InactiveCN103830767AInduced formationEvenly distributedImpression capsSurgeryColloidal particleNew Bone Formations

The invention relates to a gel material which comprises 3-80 wt% of sucrose acetate isobutyrate colloidal particle, 0.1-30 wt% of pharmaceutical active component, 0-60 wt% of assistant and the balance of water. The gel material is applicable to promoting bone healing and new bone formation in tooth cavities after implementation of tooth extraction. The bone healing is wound healing after implementation of tooth extraction; and the new bone formation is new bone formation in a tooth implantation process. The gel material can also be used for temporary sealing after cavity preparation and during dental pulp disease treatment in the tooth disease treatment process.

Owner:韩冰

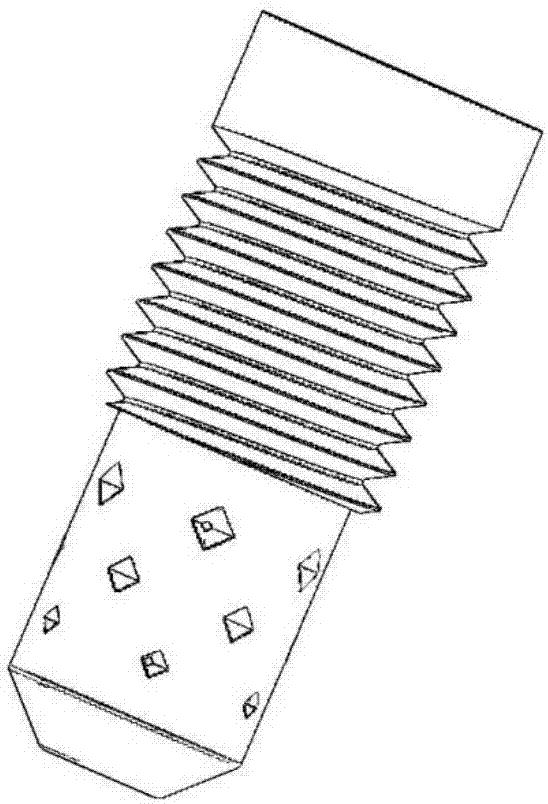

Multistage through-hole porous tooth implantation body

ActiveCN106859792AEasy accessPromote growth and proliferationDental implantsSolid structurePore diameter

The invention discloses a multistage through-hole porous tooth implantation body. The multistage through-hole porous tooth implantation body comprises a gingiva passing through segment and a screw thread segment; the gingiva passing through segment is of a smooth solid structure, and is arranged on the upper part of the screw thread segment; the multistage through-hole porous tooth implantation body also comprises a porous structure segment; the porous structure segment is arranged on the lower part of the screw thread segment; the hole diameter of transverse through holes on the porous structure segment from the lower part to the upper part is increased successively; the transverse through holes with the same hole diameter are arranged in a radiation manner along the periphery of the porous structure segment. The multistage through-hole porous tooth implantation body is capable of increasing combination strength, increasing combination speed, and is provided with the porous structure conveniently.

Owner:ZHEJIANG UNIV OF TECH

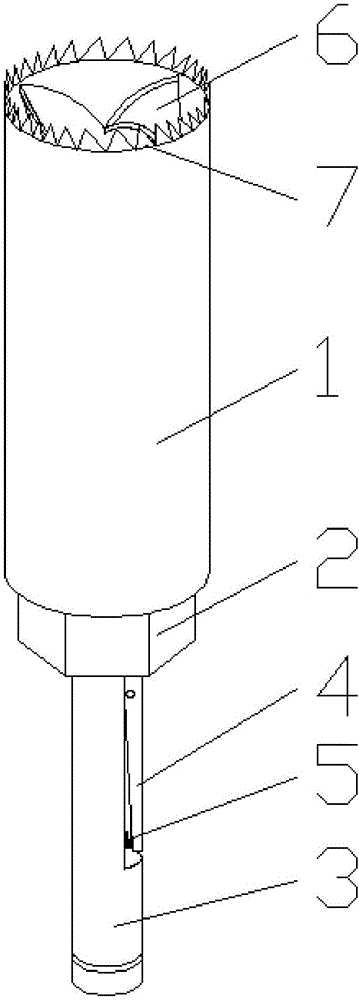

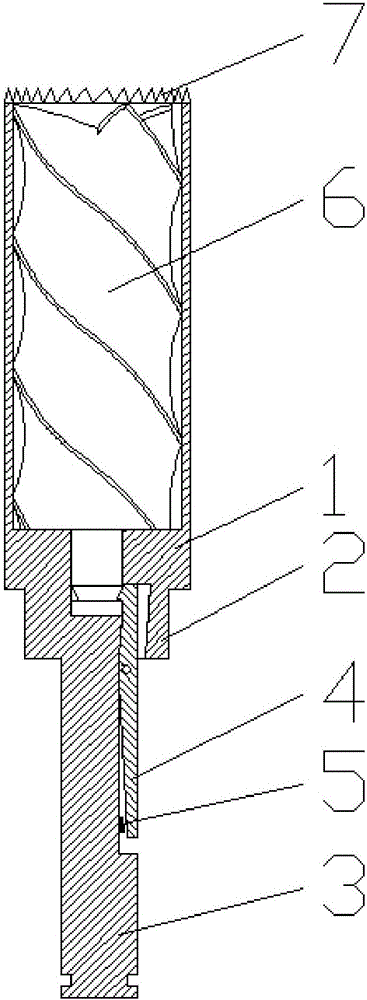

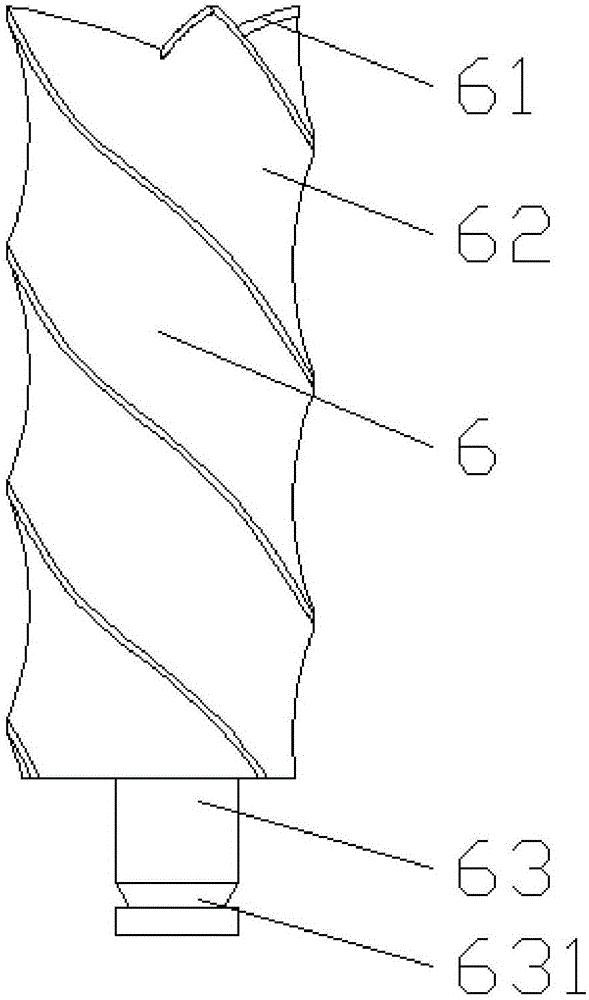

Crushed bone collection drill

The invention discloses a crushed bone collection drill, and belongs to the technical field of tooth implantation. The crushed bone collection drill comprises a cylindrical hollow barrel, an external hexagonal connector, a handle and a crushed bone drill bit, annular saw teeth are arranged at the upper end of the hollow barrel, the lower end of the hollow barrel is fixedly connected with the external hexagonal connector, the lower end of the external hexagonal connector is fixedly connected with the handle, the hollow barrel, the external hexagonal connector and the handle are coaxial, the crushed bone drill bit is detachably embedded into the hollow barrel, and a spiral crumb guide channel is formed in the side wall of the crushed bone drill bit. The crushed bone collection drill can be connected with a manual drill, can be also connected with an electric drill, radial stress cannot be applied to bones with drilling holes, bones cannot be fractured when holes are drilled, drilled bone crumbs are conveniently collected in the collection drill, and healing of soft tissues cannot be affected.

Owner:吴大怡

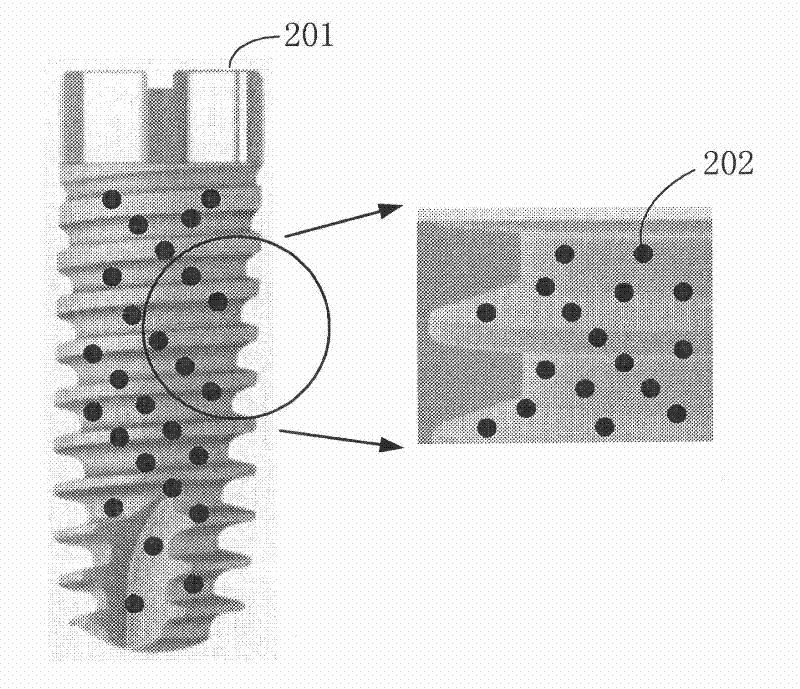

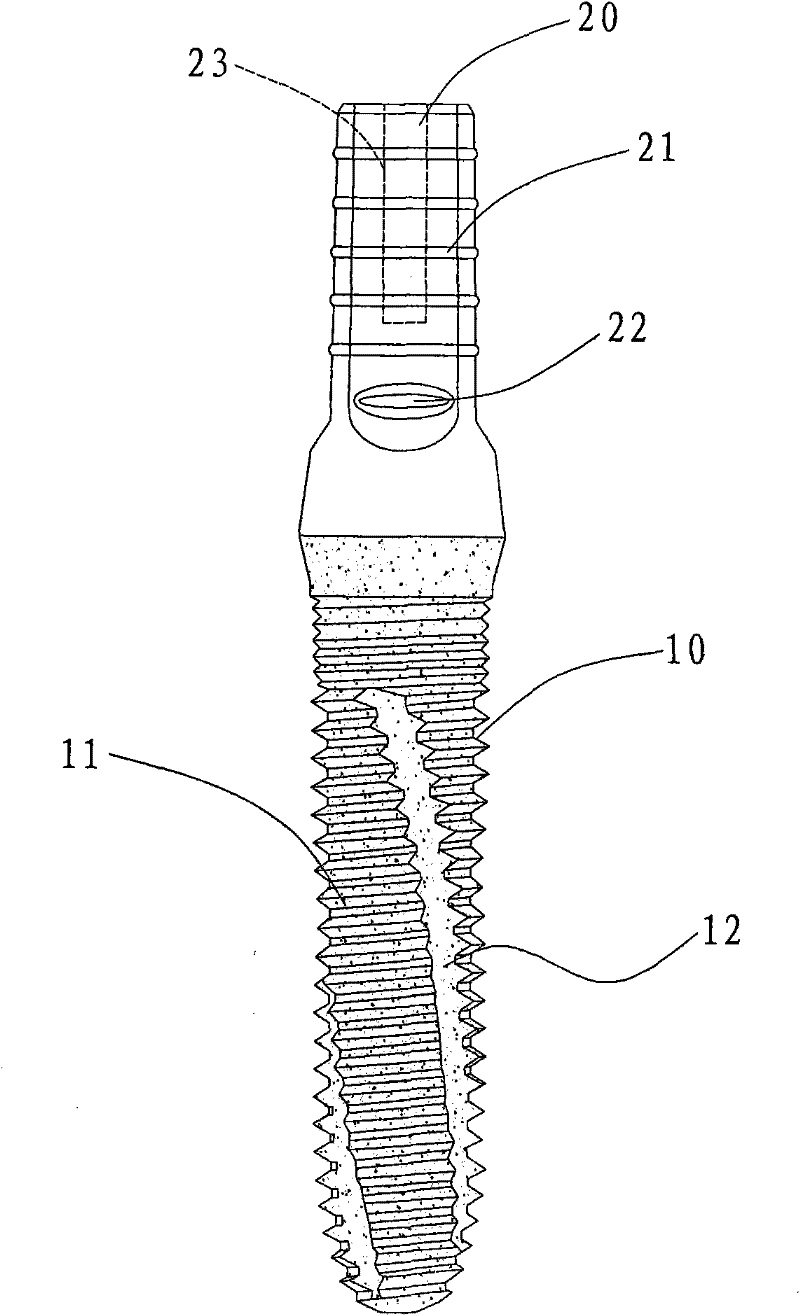

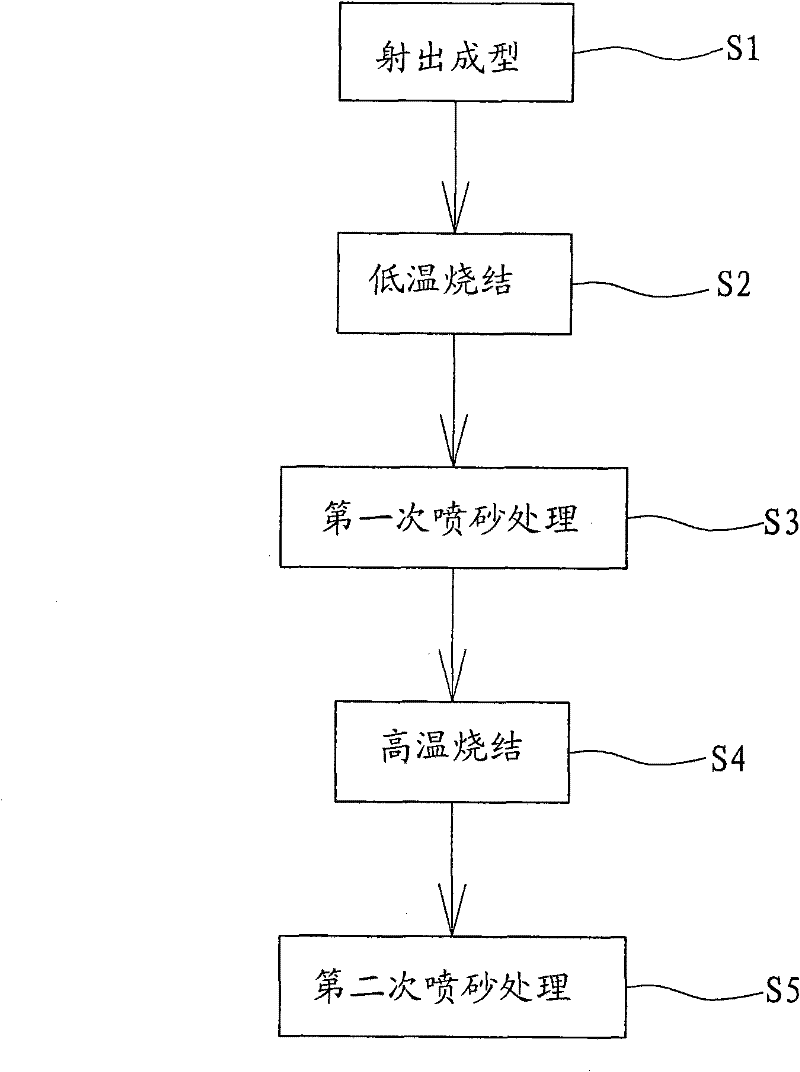

Dental artificial implant and production method thereof

InactiveCN102475578AIncreased mutual gripEasy to integrateDental implantsArtificial teethBone tissueScrew thread

The invention discloses a dental artificial implant and a production method thereof. The dental artificial implant comprises a tooth root and a tooth column, wherein the tooth root is a columnar body, the outer edge of the columnar body is provided with a screw thread part, the surface of the tooth root is processed by sandblasting to form a plurality of first pores and second pores on the surface of the tooth root, the tooth column stretches from the top of the tooth root, one or more mark parts and tabling grooves are formed at the outer edge, and a supported hole is arranged in the top of the tooth column. According to the invention, by carrying out sandblasting on the surface of the tooth root, a plurality of pores are formed on the surface of the tooth root, so that after tooth implantation, bone cells in the body bone tissue can be allowed to effectively penetrate into the first pores and the second pores and can generate radial grasping effect with the first pores and second pores, and then mutual grasping effect between the artificial implant and the bone tissue is strengthened.

Owner:阎京如

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com