Surface treatment method of dental implant

A technology of surface treatment and dental implants, applied in dentistry, dental implants, dental repairs, etc., can solve the problems of not getting clear conclusions, shorten the treatment time and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

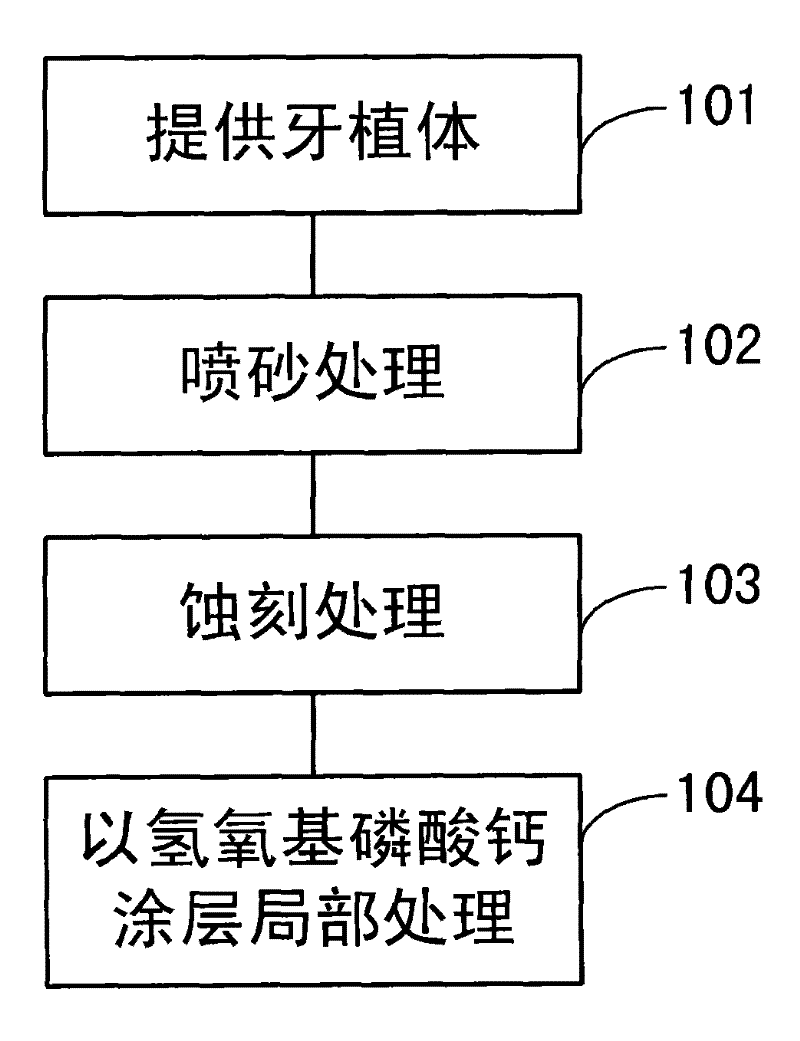

[0017] A method for surface treatment of a dental implant of the present invention, the embodiment is as follows figure 1 As shown in the flow chart, it includes the following steps:

[0018] first as figure 1 As shown in step 101, a dental implant is provided, and the dental implant is made of titanium or titanium alloy.

[0019] Then as figure 1 As shown in step 102, sandblasting is performed on the dental implant. Usually, sandblasting, also known as shot peening, uses hard sand particles to fly out at high speed with external power to hit the material on the object to be treated, so that the surface produces a set bite. Sprayed surfaces, or to remove stains and oxides, as well as to eliminate scratches and clean surfaces. The mechanism of sandblasting is divided into two types: dry type and wet type. Generally speaking, the wet type is more suitable for sandblasting with a particle size of about 15 microns (um). The materials used for sandblasting generally include st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com