Manufacturing method for individual gingival aesthetic forming healing abutment

A technology of healing abutment and manufacturing method, applied in dentistry, dental implants, medical science and other directions, can solve problems such as poor healing, prolong crown wearing period, increase patient cost, etc., to avoid soft tissue retraction, shorten treatment period, and reduce the number of visits to the doctor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

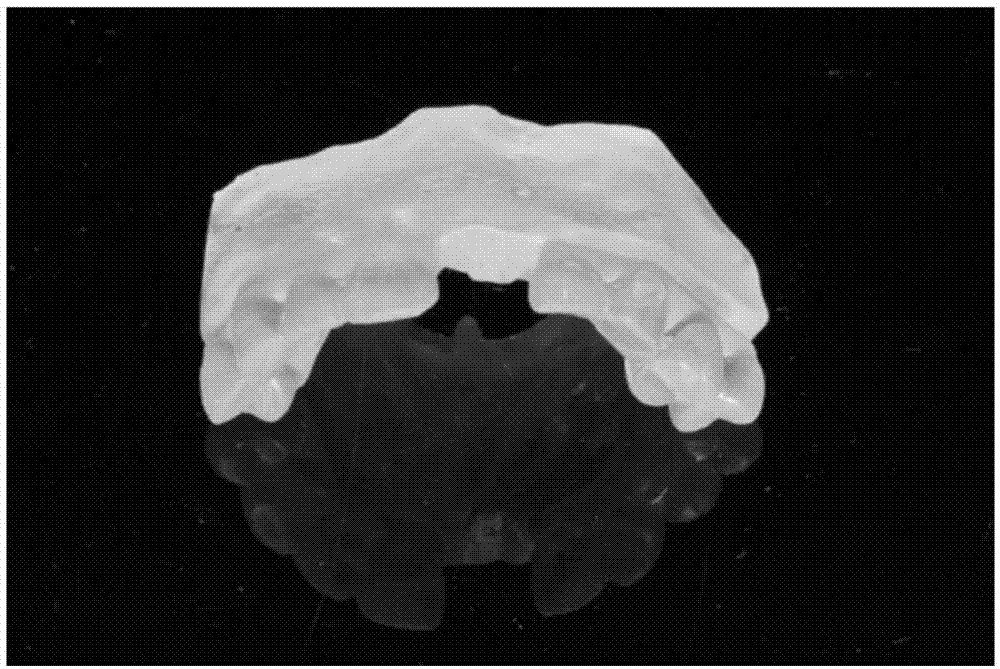

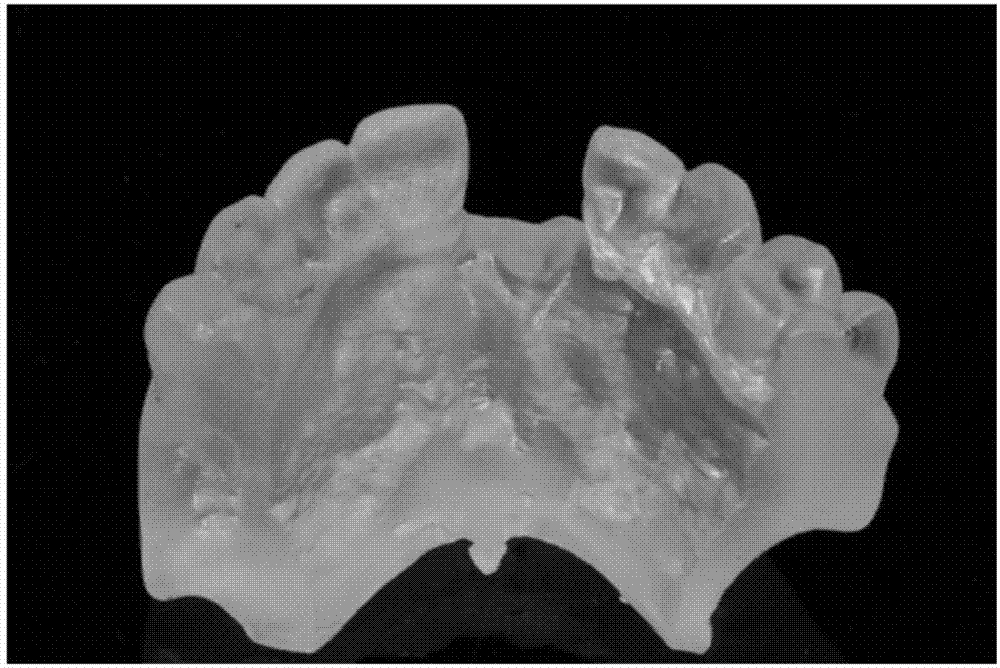

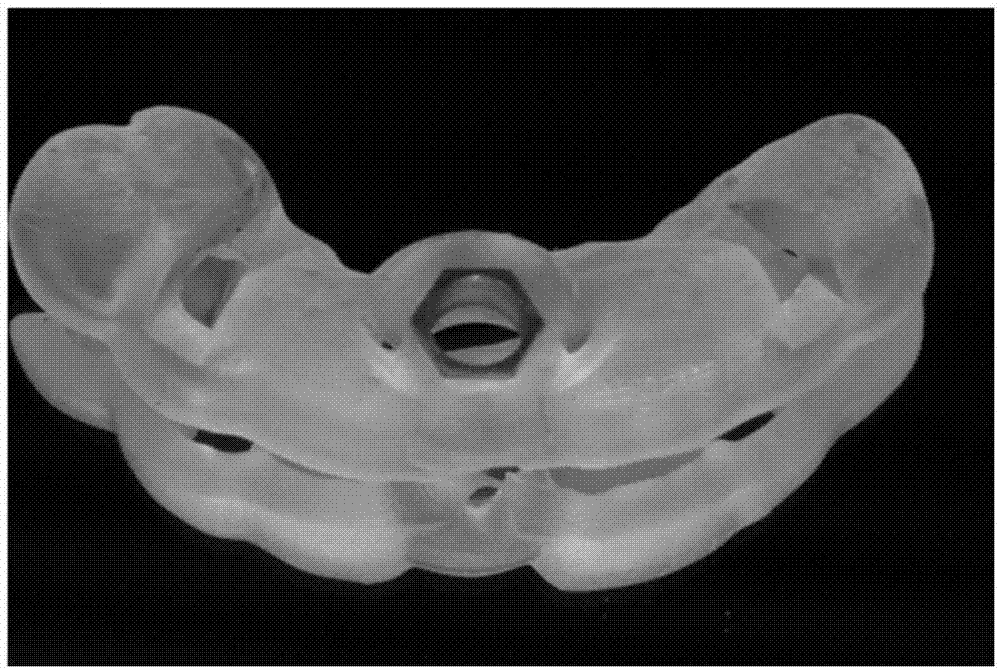

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

[0038] Patients with missing maxillary or mandibular left / right central incisors or lateral incisors were selected and implanted, and the patients to be restored in the upper part were included in the experiment. Inclusion criteria: good health, no systemic diseases. Normal occlusion, no obvious misaligned teeth; the lateral incisors in areas A and B are teeth with vital pulp, and there are no restorations or fillings in the neck of the teeth; the appearan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com