A removable partial denture and its manufacturing process

A denture and partial technology, which is applied in the field of removable partial denture and its manufacturing process, can solve the problems of fracture, splitting or falling off, unsuitable denture tissue surface, complicated processing technology, etc., so as to reduce the number of visits, improve the wearing effect, and simplify the The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

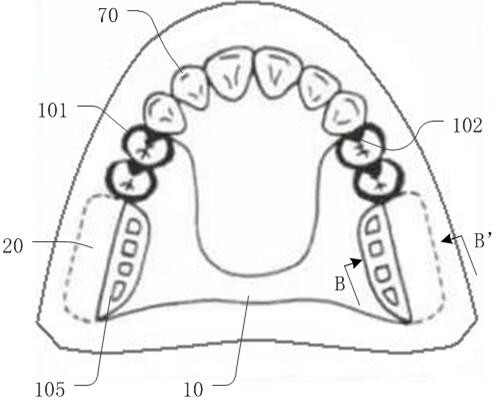

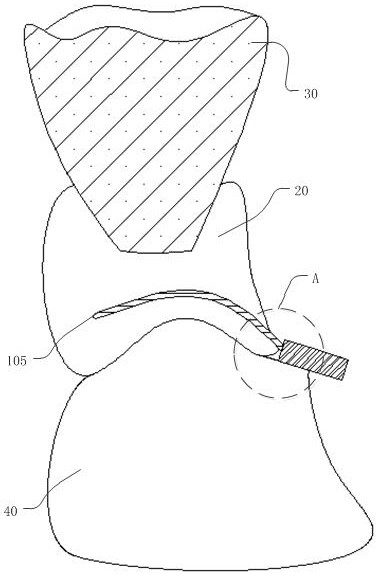

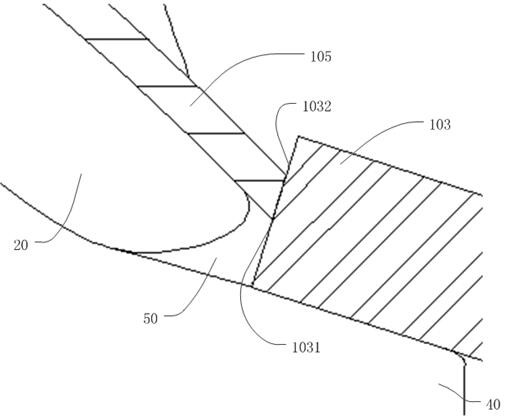

[0049] Such as Figure 7-11 As shown, this embodiment discloses a removable partial denture, which includes a bracket 10A, an artificial tooth 30 and an artificial gingiva 60, and the bracket 10A includes a clasp 101, a rest 102, a large connecting body 103, a small connecting body and Smoothly connect the saddle base plate 104 of the large connecting body 103; the effect of smooth connection is equivalent to the saddle base plate 104 being a plate-shaped body extending from the large connecting body 103 to both sides; the saddle base plate 104 is plate-shaped and tightly covered on the patient The surface of edentulous gingiva 40 forms the substrate 104 of artificial gingiva 60 ;

[0050] Such as Figure 11 with 12 As shown, the bracket 10A, the artificial tooth 30 and the artificial gingiva 60 are integrated, that is, the three parts are processed as a whole. Such as Figure 1-6 It is the structural diagram of the removable partial denture in the existing design, and the ...

Embodiment 2

[0052] Such as Figure 8 As shown, this embodiment specifically discloses the structure of the artificial gingiva 60 in the above-mentioned embodiment: the shape of the artificial gingiva 60 is consistent or similar to that of the patient's gingiva 40 . Specifically, the convexity of the root of the artificial gingiva 60 is consistent with the convexity of the root of the patient's oral cavity. This makes the shape of the denture 1 consistent with the patient's oral cavity, more like the patient's "native" teeth 70, and the use experience is better. The artificial gingiva 60 is provided with a gingival papilla 601 between every two adjacent artificial teeth 30 , or at both ends of the artificial gingiva 60 . Whether to take the end depends on the location of the artificial gingiva. If it is at the non-gum end, it includes both ends. If it is at the end, the gingival papilla may not be involved at the end. This makes no gaps are left between the artificial teeth, preventing f...

Embodiment 3

[0054] Such as Figure 13 As shown, this embodiment discloses a method for manufacturing an integral removable partial denture, comprising the following steps:

[0055] A. The step of collecting oral data of the patient, the oral data includes oral model data and occlusal relationship data;

[0056] B. A step of constructing an overall denture model through the oral cavity data, the overall denture model is an overall model including three parts of the bracket 10A, the artificial tooth 30 and the artificial gingiva 60;

[0057] C. Based on the constructed integral denture model, the disc-shaped PEEK material was cut to obtain an integral (one-piece) removable partial denture.

[0058] This embodiment discloses a method for collecting oral data of a patient, that is, obtaining an impression of the patient clinically, or scanning the oral cavity of the patient to collect the oral data of the patient. Dental data are also used in the determination of orthodontic solutions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com