Immediate full denture or half denture manufacturing method based on 3D printing technology

A complete denture and 3D printing technology, applied in the field of oral materials, can solve problems such as difficult heating speed and holding time, cumbersome production process, uneven pressure, etc., to improve production efficiency and accuracy, reduce production costs, Create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

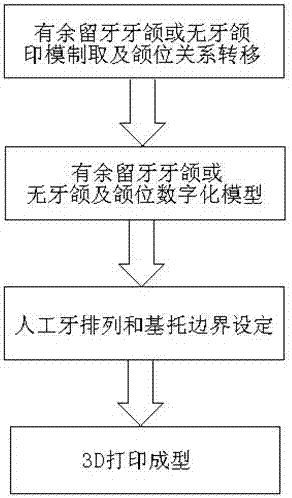

[0053] Method content of the present invention comprises the following steps: below with the embodiment of toothless state

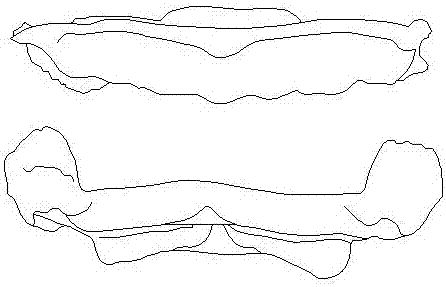

[0054] 1. Impression taking of edentulous jaw and transfer of jaw position

[0055] It is one of the important steps to determine the jaw position relationship type complete denture restoration. It not only coordinates the occlusal relationship after restoration with the temporomandibular joint and masticatory muscles, but also enables the occlusal position in this position to better play the chewing function. The position relationship includes the establishment of the neutral zone, the measurement of the vertical distance and the establishment of the horizontal relationship.

[0056] There are three steps (1) to take the maxillary and maxillary impression, (2) to determine the neutral zone, (3) to determine the vertical distance and horizontal relationship.

[0057] (1) Take the maxillary and maxillary impression

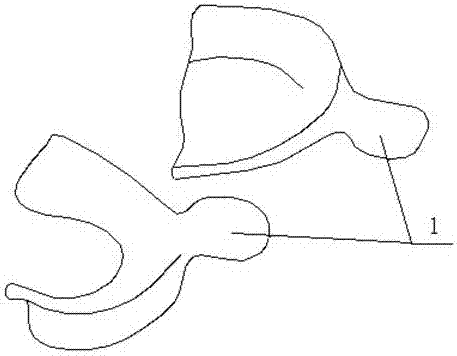

[0058] Customized self-curing acryli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com