Manufacturing method of tooth implantation operation guide plate based on body image processing

A production method and volumetric image technology, applied in image data processing, dental implants, dental restorations, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings.

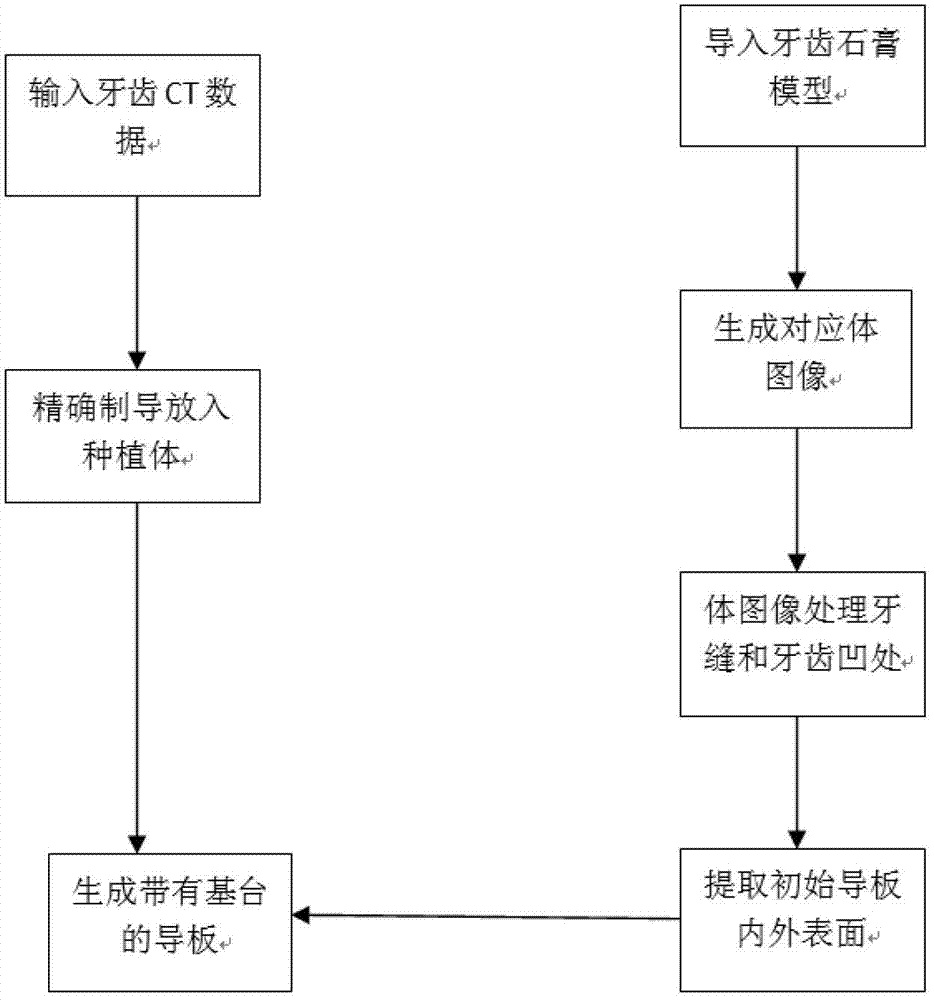

[0082] by such as figure 1 As shown in the flow chart of the generation of the guide plate with the abutment, it can be known that the production method of the guide plate with the abutment is as follows:

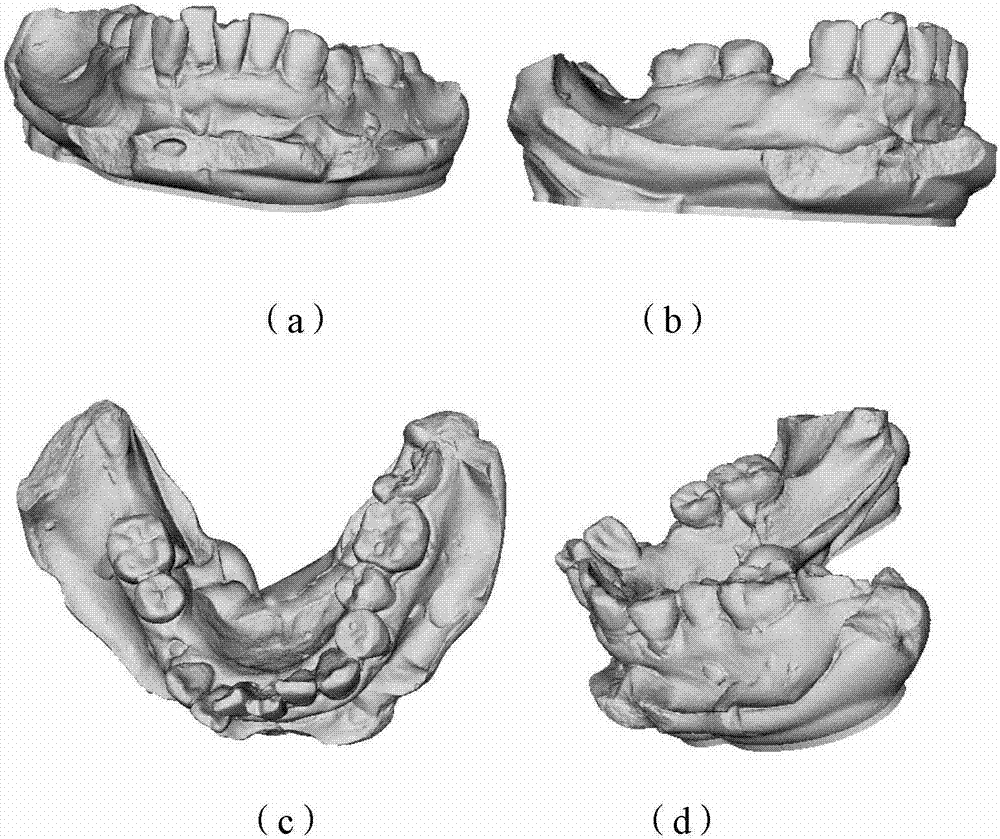

[0083] 1) Obtain a plaster model of teeth, and scan the plaster model to generate a corresponding three-dimensional mesh model of plaster, wherein, image 3 is a three-dimensional model of tooth plaster, image 3 Among them, a, b, c, and d are screenshots viewed from different directions.

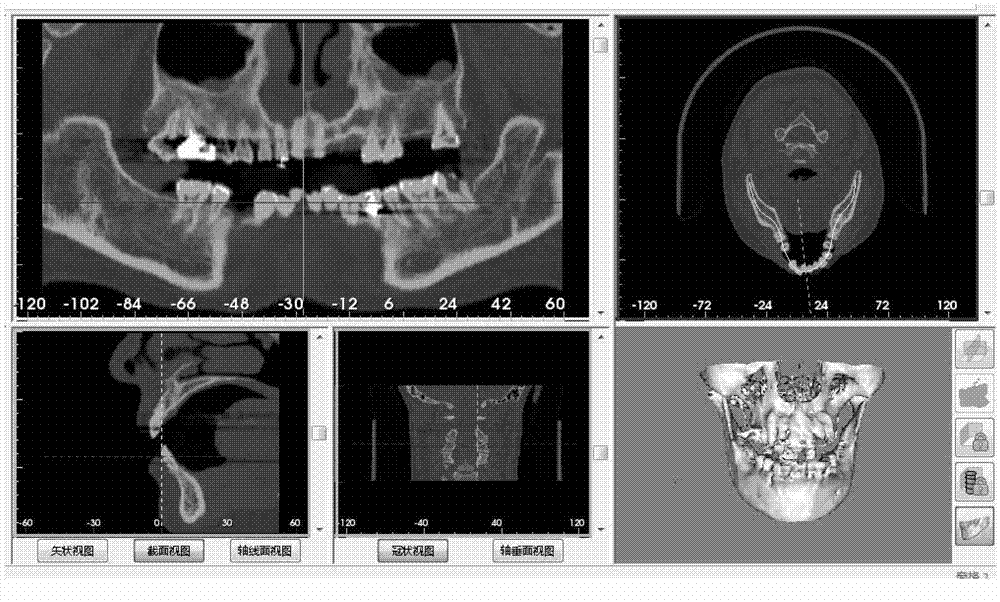

[0084] 2) Putting simulated implants into the plaster three-dimensional mesh model in combination with the corresponding oral cavity ct model, wherein, figure 2 It is the CT image of the tooth, and each interface displays various interfaces of the internal information of the oral cavity; in addition, after placing the simulated implant, import the plaster model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com