Digital three-dimensional construction and manufacturing method of personalized planting base station

A manufacturing method and abutment technology, which are used in dental implants, design optimization/simulation, special data processing applications, etc., can solve the problems of complete conformation of gingival contours, different implant deflection angles, and inability to realize finished abutments, etc. Improves fit, avoids interference and patient discomfort, and enhances the effectiveness of combination tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] Personalized abutment refers to the three-dimensional measurement and construction of the implant interface and screw channel of the finished abutment according to the implant system in the patient's mouth, and the personalized design of the implant abutment to penetrate the gingiva according to the position of the implant, gingiva and occlusal relationship information The connecting part of the head and the prosthesis is cut and formed with a machine tool.

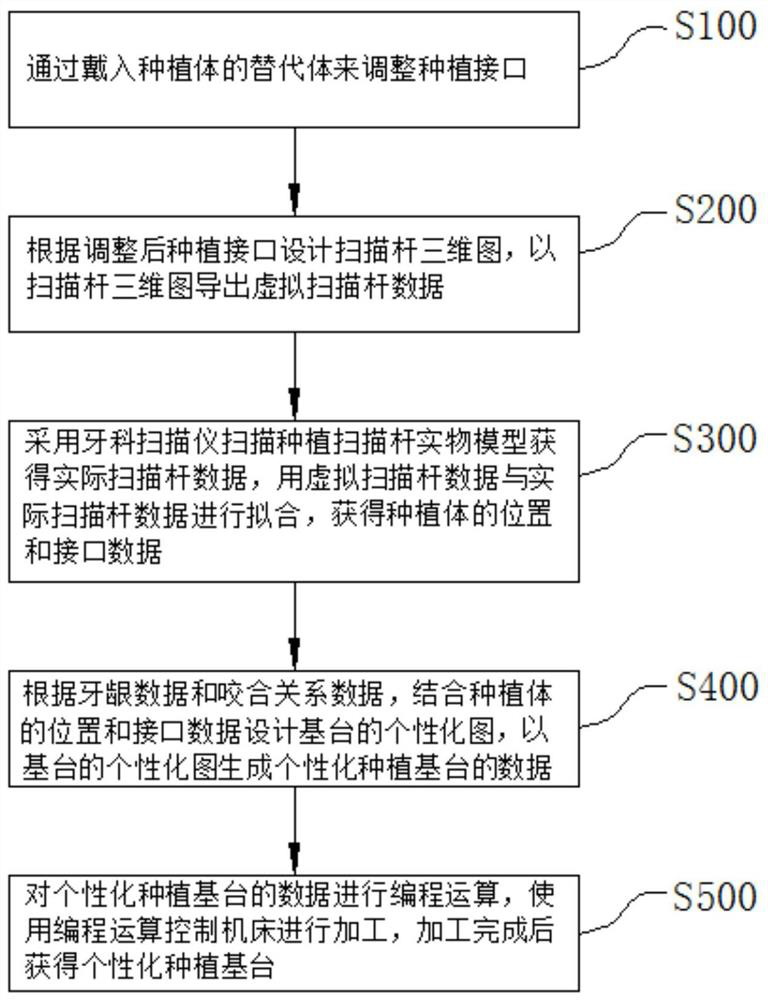

[0030] like figure 1 The flow of an optional embodiment of the digital three-dimensional construction and manufacturing method of the personalized implant abutment includes the following steps:

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com