Dot matrix type pressure distribution sensor based on carbon nano tube and preparation method thereof

A carbon nanotube and pressure distribution technology, applied in the fields of instruments, measuring force, medical science, etc., can solve the problems of difficult to comprehensively reflect the fine condition of the occlusal surface, lack of electrical conductivity, uneven dispersion, etc., and meet the requirements of industrialized large-scale production. , The process steps are simple but not complicated, and the effect of the technical effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

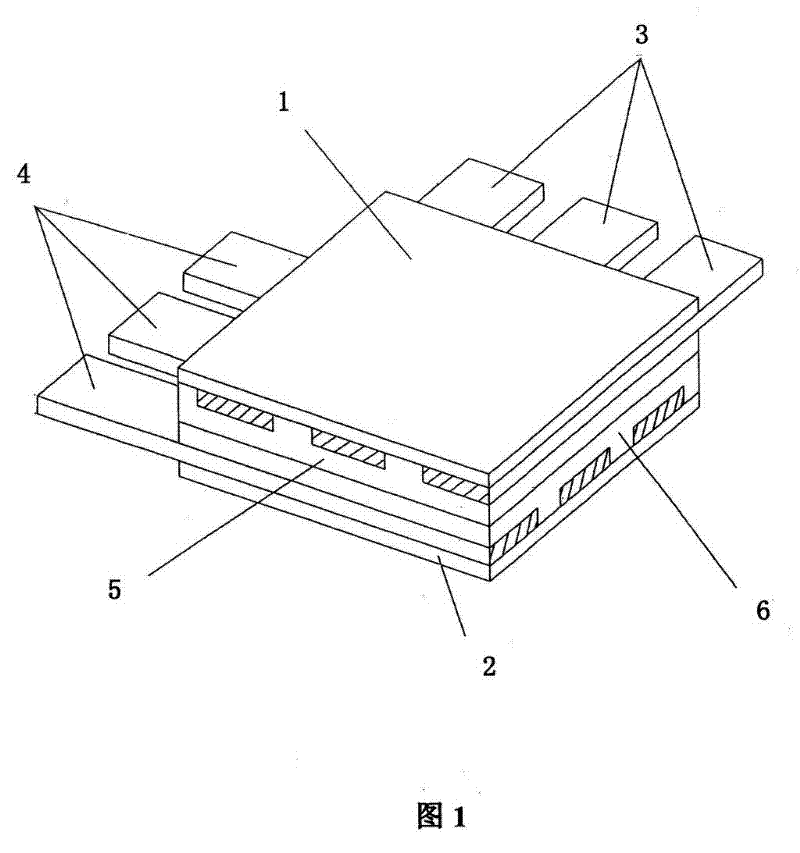

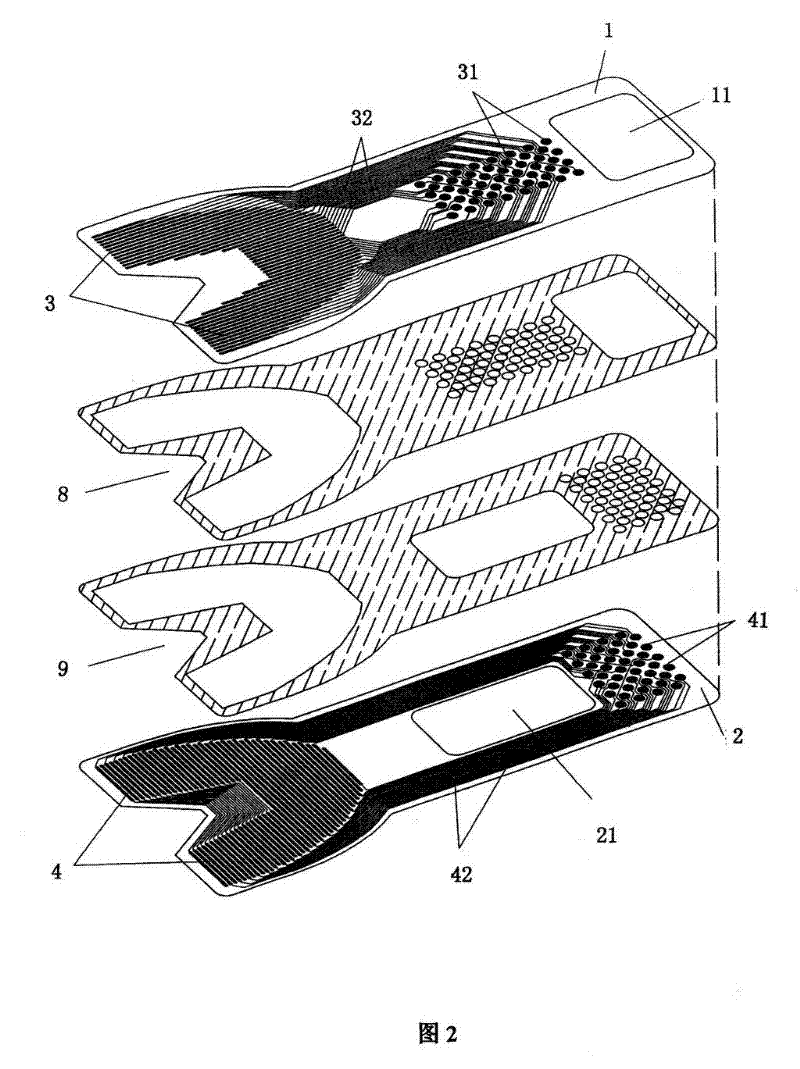

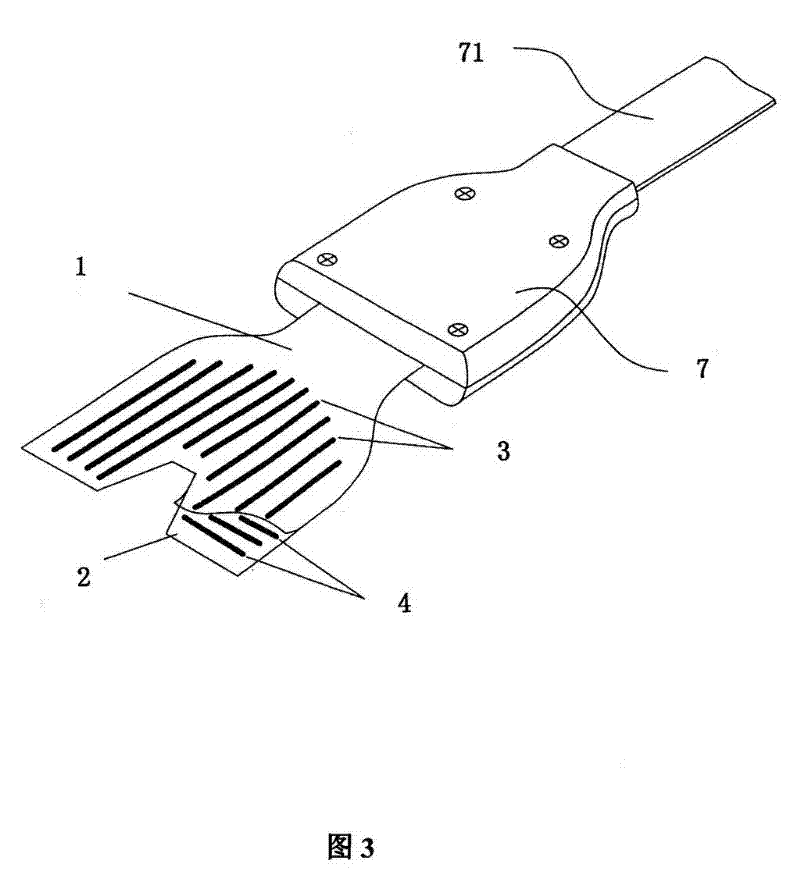

[0038] A) Raw material preparation, select the first and second film substrates 1 and 2, carbon nanotubes, resin and solvent, and reserve them for later use, wherein: the first and second film substrates 1 and 2 are all polyester films, and pre-processed become figure 2 The schematic geometric shape is processed into a shape that tends to match the gums of the human oral cavity. Specifically, the heads of the first and second film substrates 1 and 2 are figure 2 , image 3 The left end of the shown position state is designed to be U-shaped, the first film substrate 1 is formed with a first cavity 11, and the second film substrate 2 is formed with a second cavity 21, and the carbon nanotubes are 10-60nm in diameter. carbon nanotubes, the resin is a phenoxy resin, and the solvent is a ketone or glycol ether organic polymer solvent. In this embodiment, a ketone organic polymer solvent is used such as acetone, methyl ethyl ketone and cyclohexane Any one of ketones, but doe...

Embodiment 2

[0051] Only change the parts by weight of the organic polymer solvent in step B) to 4 parts by weight of ethylene glycol methyl ether, change the parts by weight of carbon nanotubes to 0.2; change the width of each electrode in step C) to 0.7mm, change the distance between adjacent electrode lines to 0.4mm; change the thickness of the silver paste in step D) to 0.1mm, and the rest are the same as the description of embodiment 1.

Embodiment 3

[0053] Only change the parts by weight of the organic polymer solvent in step B) to 2.2 parts by weight of cyclohexanone, change the parts by weight of carbon nanotubes to 0.083; change the width of each electrode in step C) to 0.9 mm , change the spacing distance between adjacent electrode lines to 0.6mm; change the thickness of the silver paste in step D) to 0.075mm, and the rest are the same as the description of Example 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com