Overflow valve with magneto-rheological pilot valve

A technology of magnetorheological and pilot valves, which is applied in the direction of valve operation/release devices, valve details, safety valves, etc., which can solve the problems of easy heating, increased viscosity of magnetorheological fluids, and high cost, and achieve rapid reset action response , expand the scope of application, enhance the effect of working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

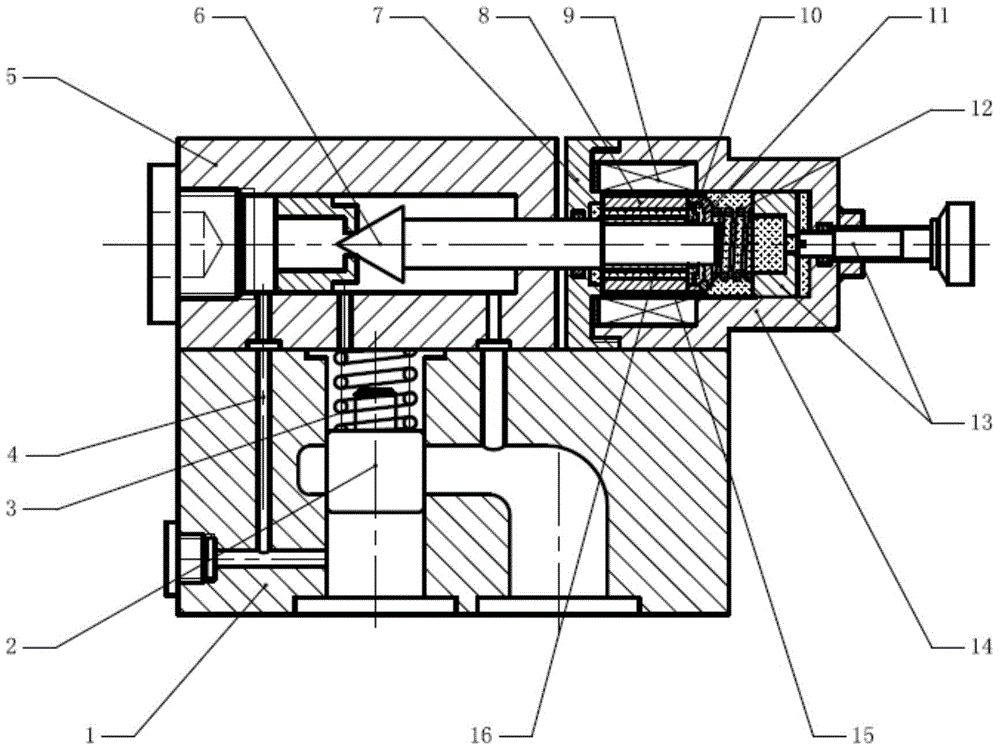

[0019] refer to figure 1 , a relief valve using a magneto-rheological pilot valve. The working medium in the relief valve is ordinary hydraulic oil. The working medium inside is magnetorheological fluid, and the volume of magnetorheological fluid is 30-150ml.

[0020] The overflow valve using a magnetorheological pilot valve includes a relief valve body 1, an upper cover plate 5 of the overflow valve, a main valve core 2, a main valve core spring 3, and a magnetorheological pilot valve cone valve 6 , Magnetorheological pilot valve front cover 7, magnetorheological pilot valve body 14, magnetorheological pilot valve piston 8, electromagnetic coil 9, pressure regulating spring 12, pressure regulating block and pressure regulating screw 13.

[0021] The upper cover plate 5 of the overflow valve, the front cover plate 7 of the magneto-rheological...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com