UVLED light curing composition and application thereof in floor coating

A technology of floor coatings and compositions, applied in the direction of epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., which can solve the problems of large difference in continuous emission spectrum, incompleteness, poor absorption of UVLED light source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

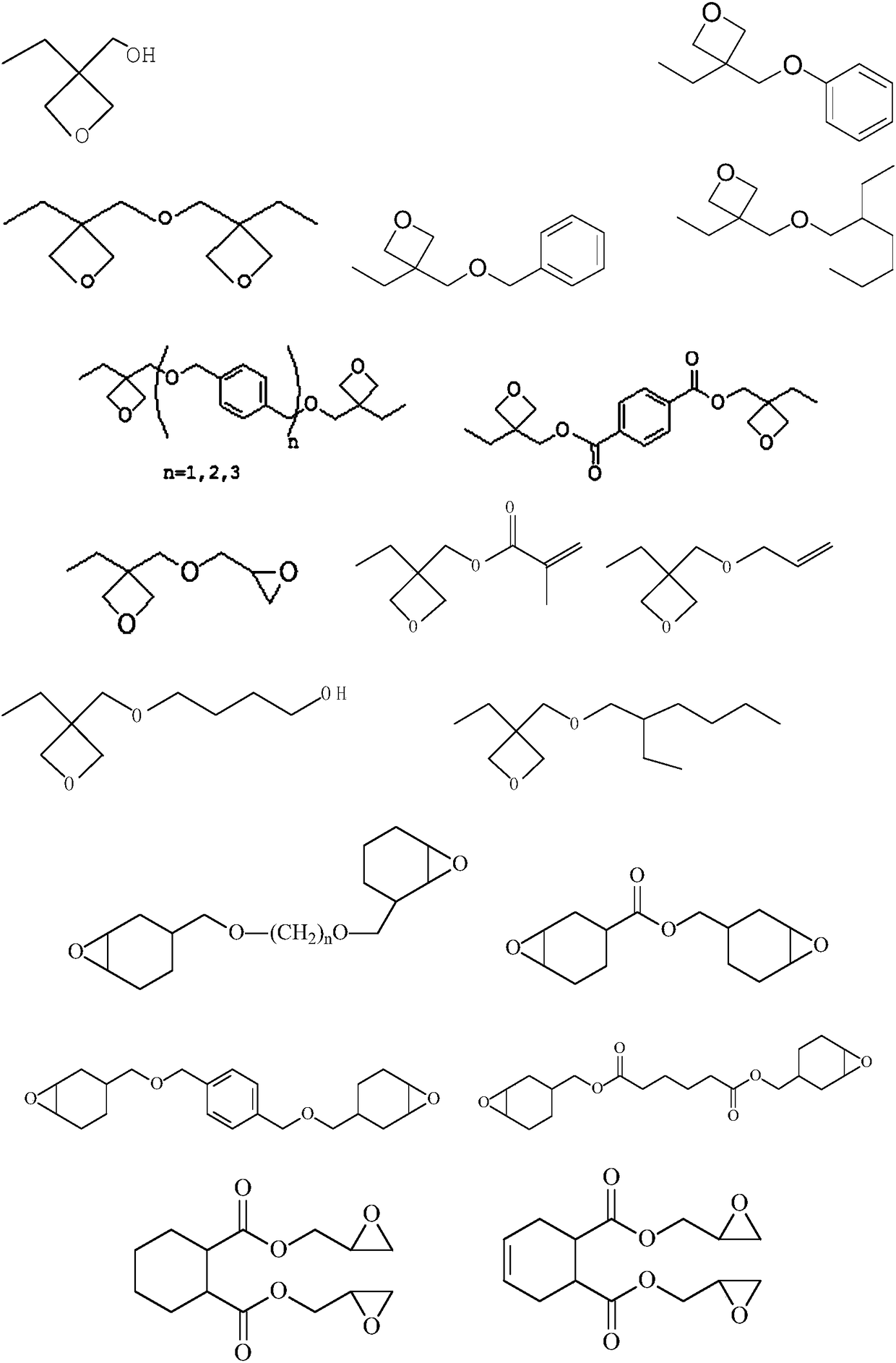

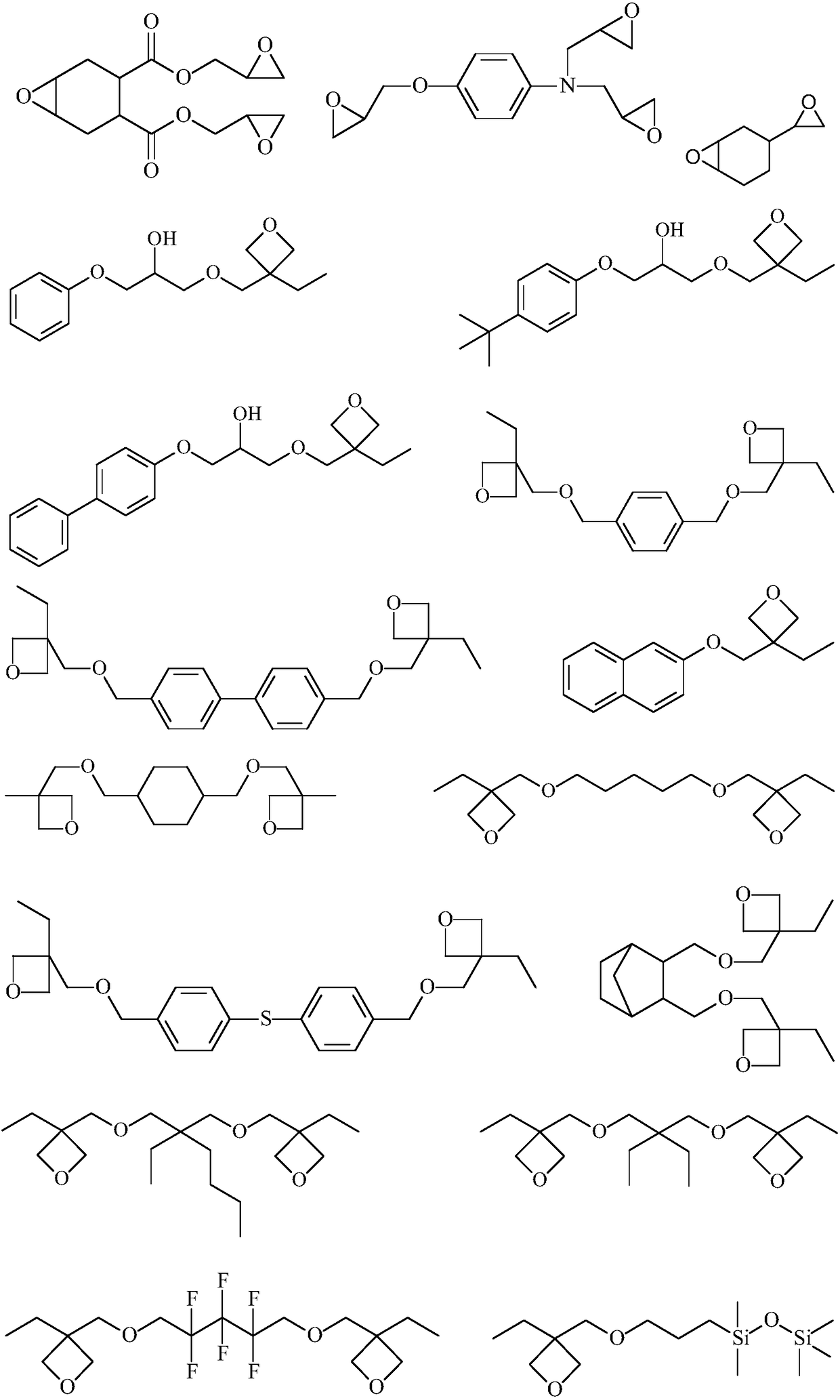

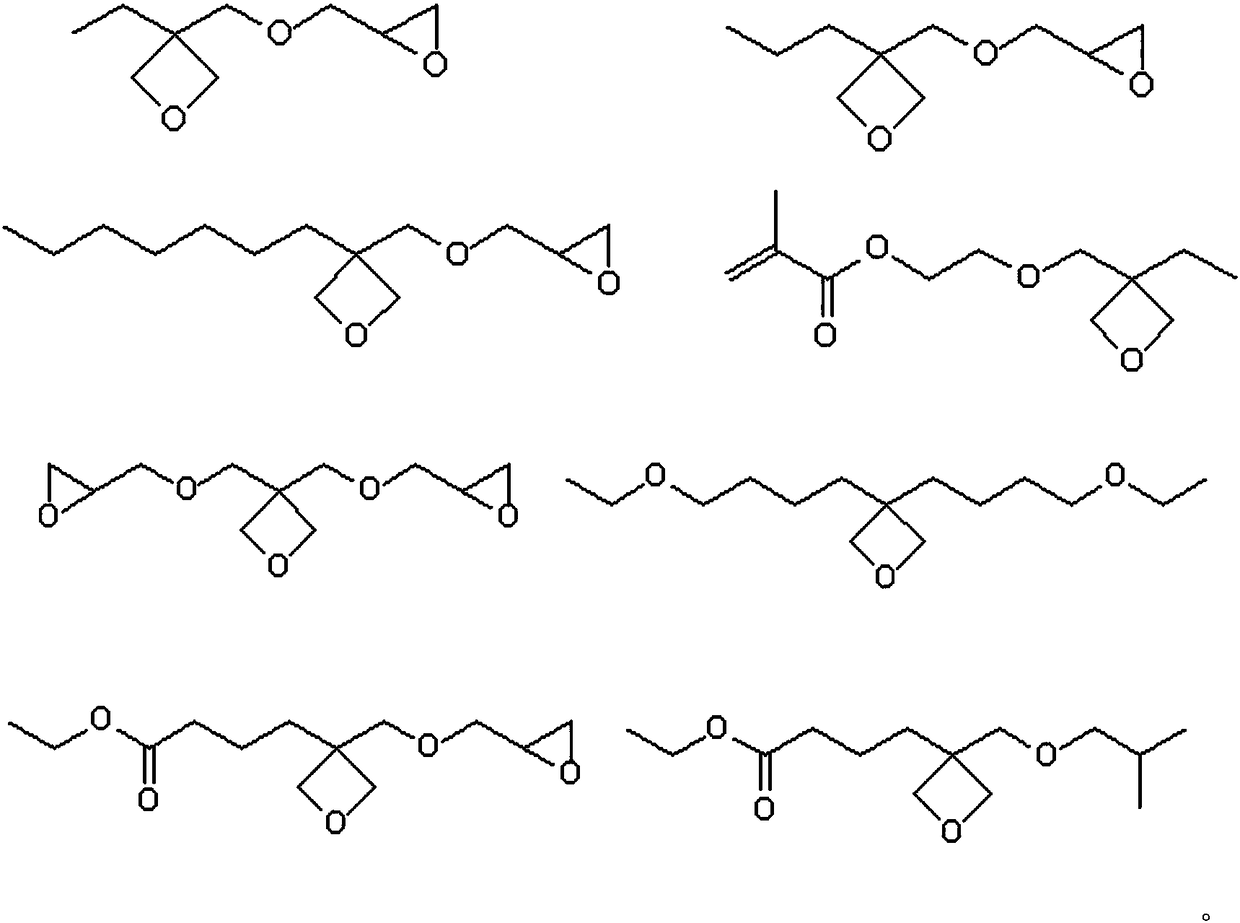

Image

Examples

preparation example Construction

[0080]

[0081] The UVLED light-curing composition used for floor coatings of the present invention can be prepared by conventional methods in the field of light-curing compositions, and the raw materials are usually mixed uniformly with a stirring device. If it is necessary to further improve the storage stability, the active components (A), (B) and (C) can be mixed as the first part, and the other remaining components can be mixed as the second part, and then mixed in the actual use Mix the two parts together.

[0082]

[0083] The present invention also relates to the application of the above-mentioned UVLED photocurable composition in floor coatings. There is no special limitation on the specific application form, and the conventional method of photocuring floor coating can be used.

[0084] The invention has excellent response to UVLED light sources in the wavelength range of 200-500nm, and has the advantages of fast curing speed, excellent coating film performance, ...

specific Embodiment approach

[0085] The present invention will be described in further detail below in conjunction with specific examples, but they should not be construed as limiting the protection scope of the present invention.

[0086] 1. Preparation of UVLED light-curing composition (ie floor coating)

[0087] According to the formulation shown in Table 1, the UVLED photocurable floor coatings of Examples 1-5 were prepared. Unless otherwise specified, the quantities stated in each embodiment are parts by weight.

[0088] Table 1

[0089]

[0090]

[0091] Unless otherwise specified, the raw materials in Table 1 are commercially available paint industrial grades.

[0092] In Table 1, the meanings of the trade names in each component are as follows.

[0093] E201: 80wt% standard bisphenol A epoxy acrylate and 20wt% TPGDA mixture, Changzhou Qiangli Electronic New Material Co., Ltd.;

[0094] SR9010: polyurethane acrylate, Sartomer (Guangzhou) Chemical Co., Ltd.;

[0095] Celloxide2021: 3,4-ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com