Patents

Literature

64results about How to "Uniform cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

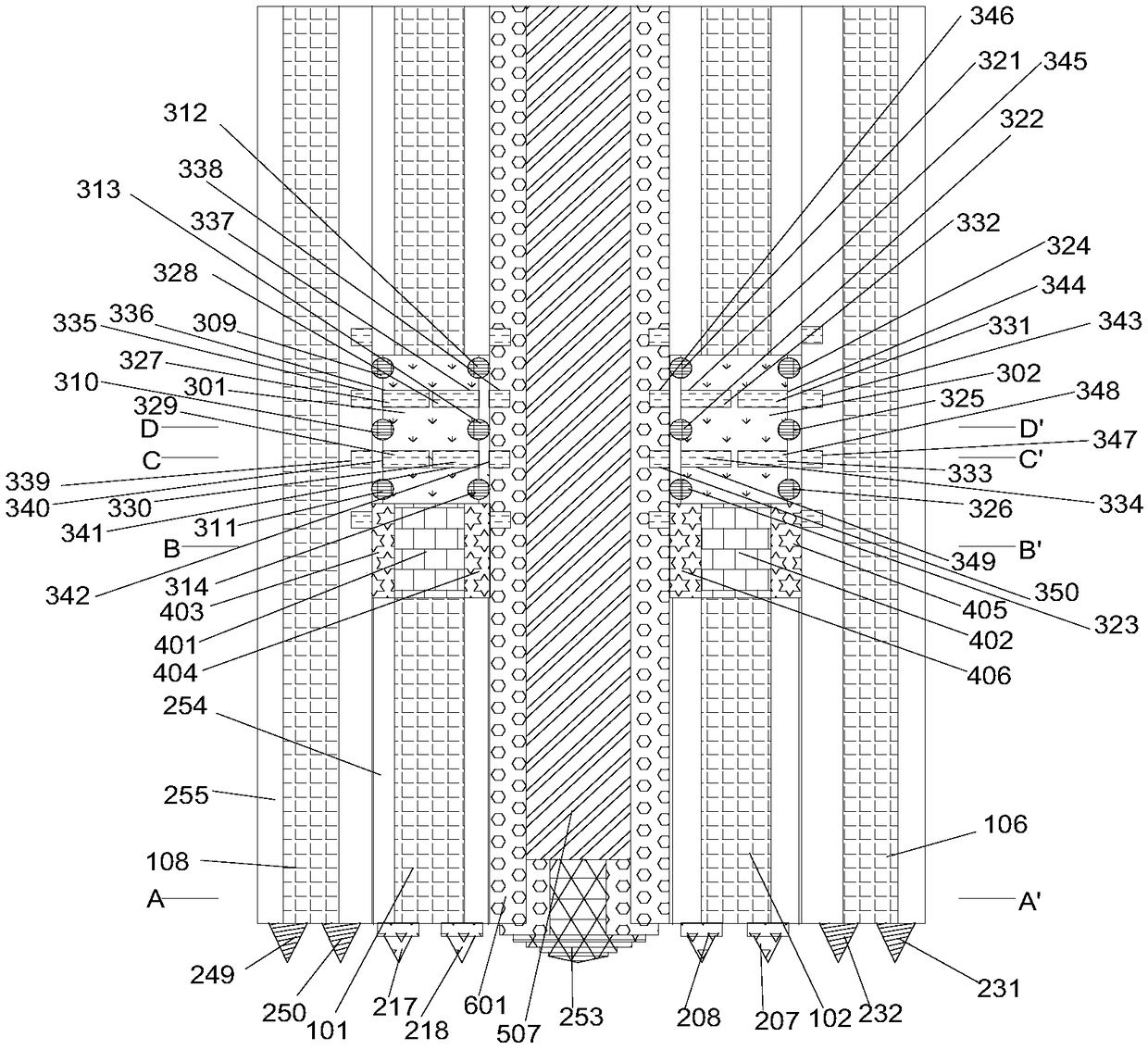

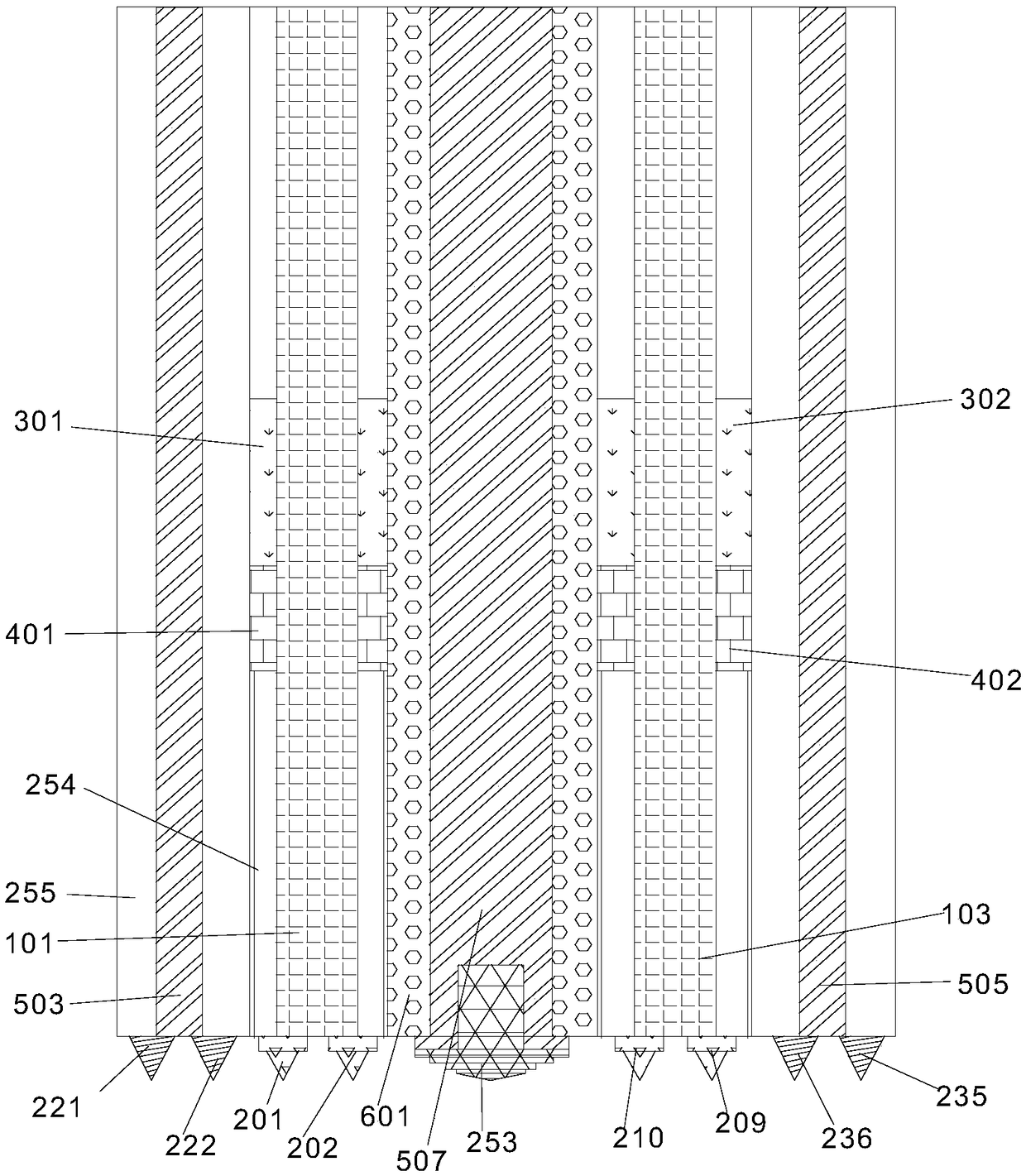

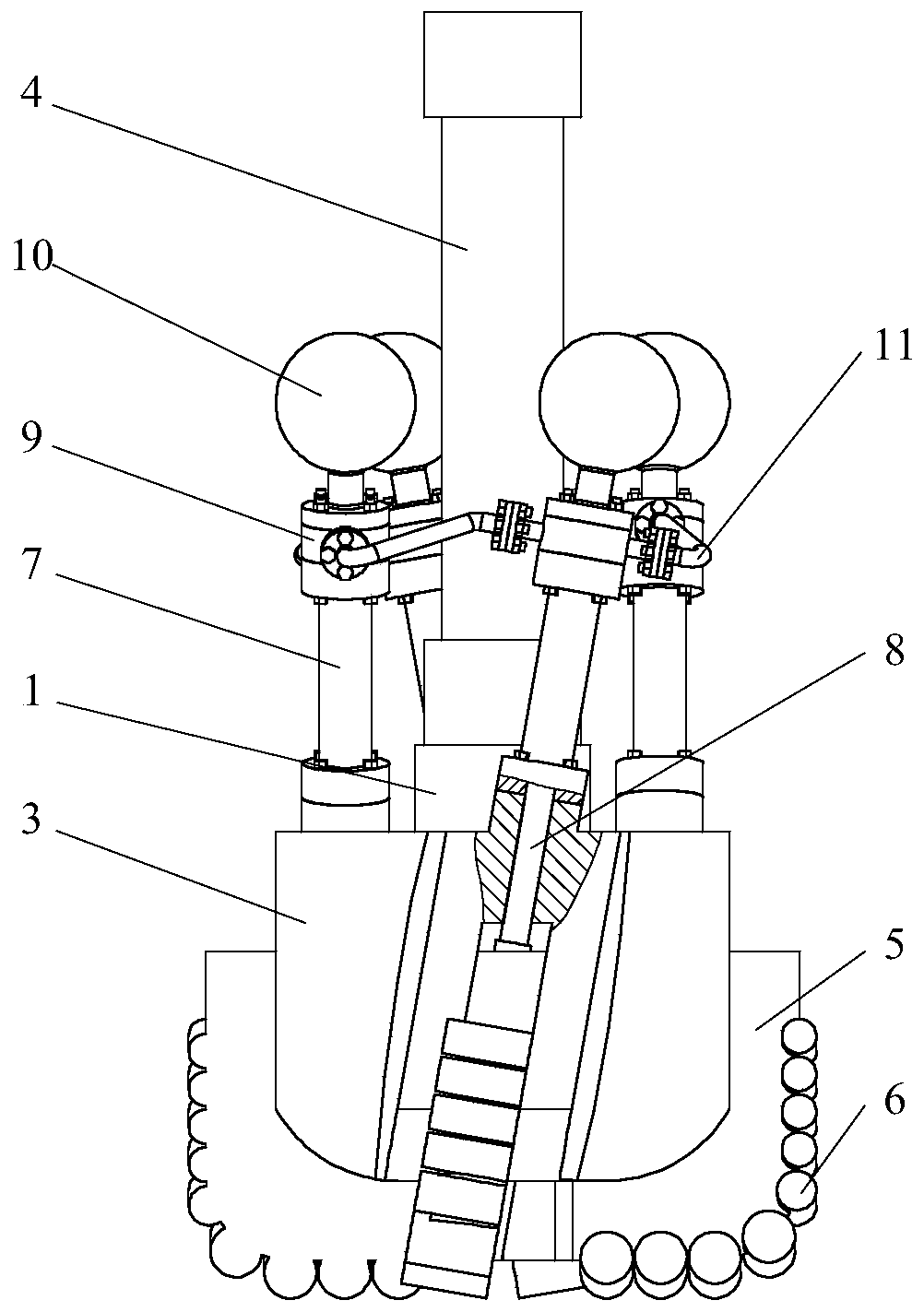

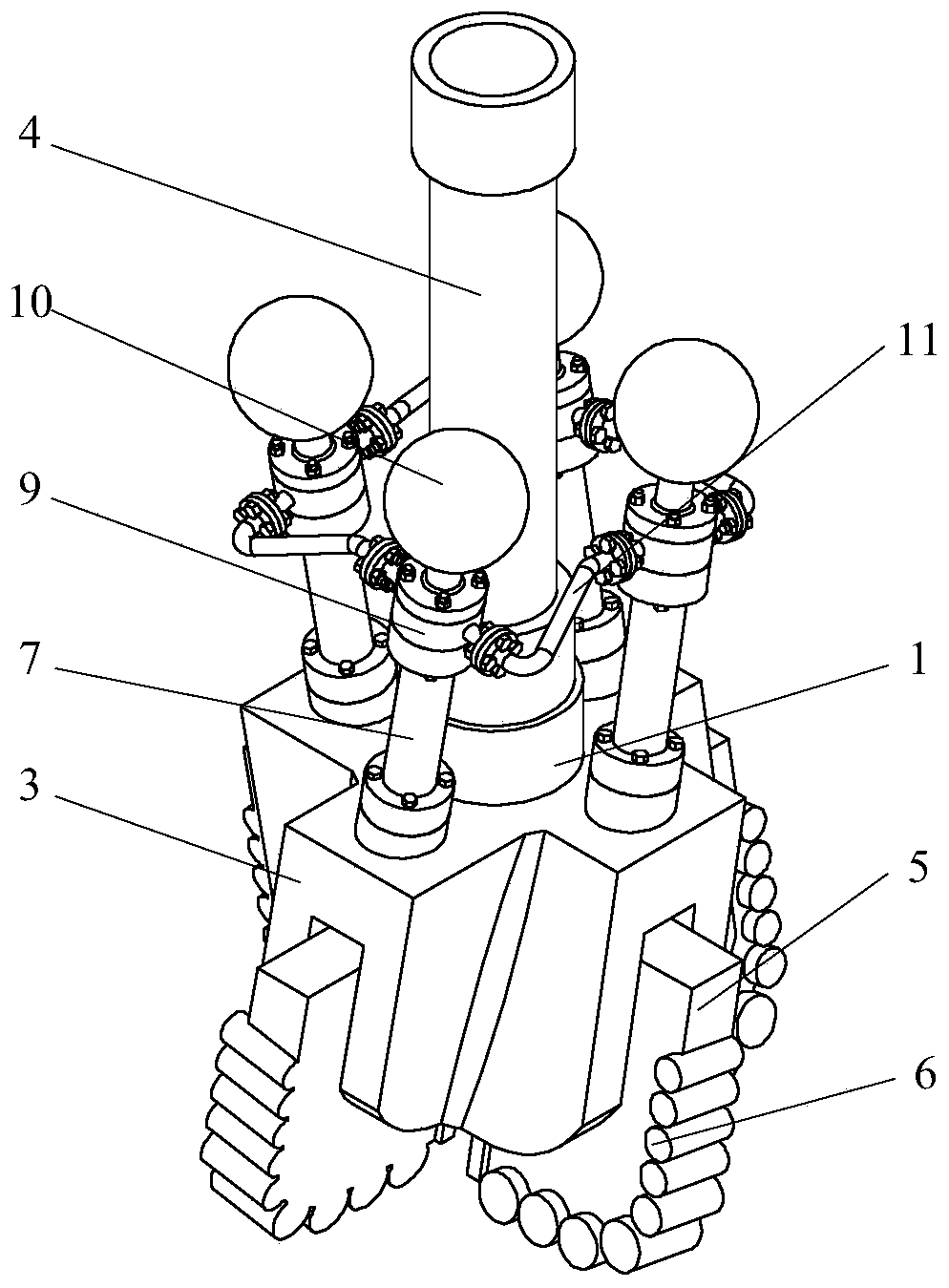

Full-cutterhead lifting-type composite drilling and cutting device for soft and hard strata

InactiveCN108643839AIncreased cutting forceCutting force reductionConstructionsLiquid/gas jet drillingAutomatic controlEngineering

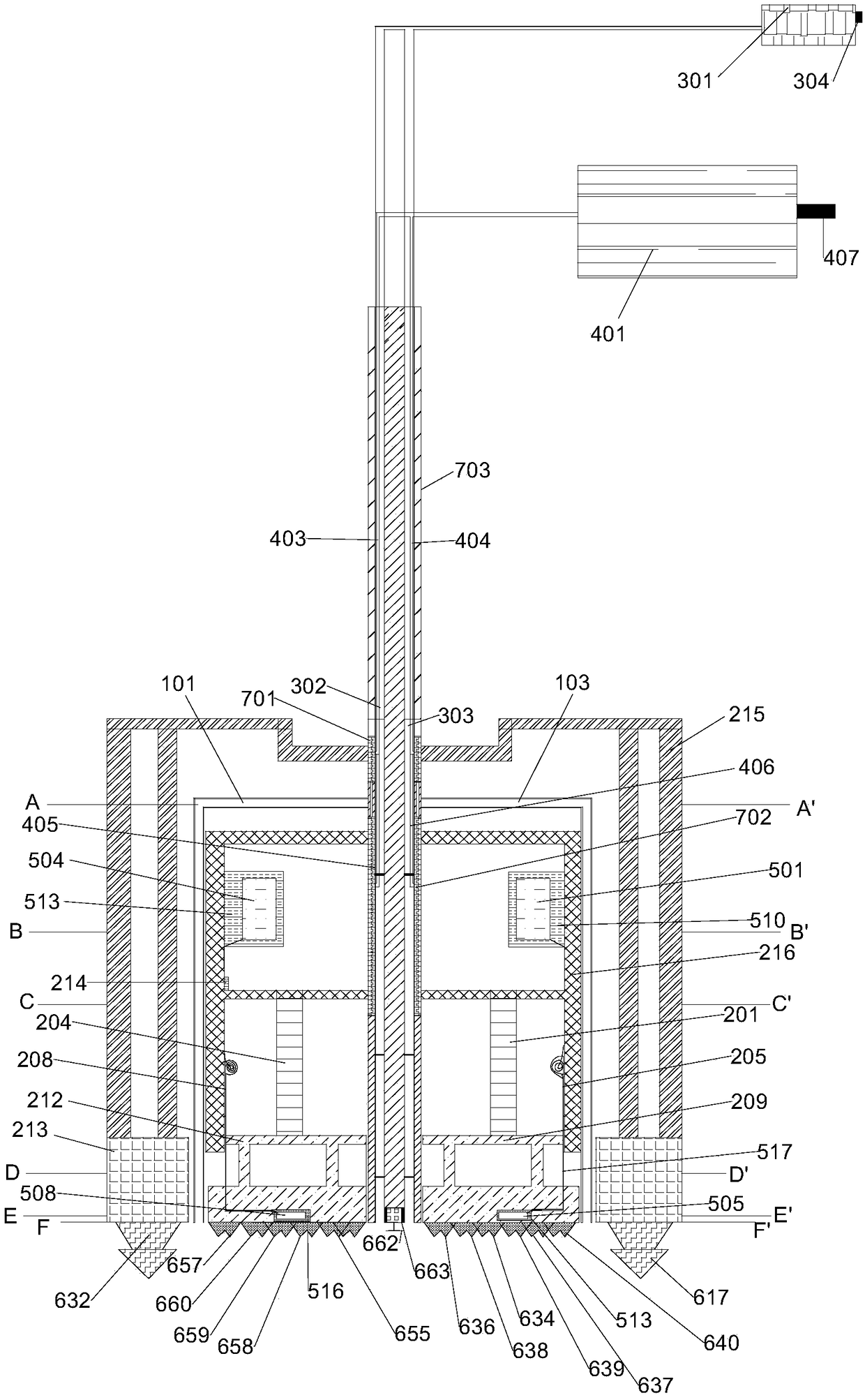

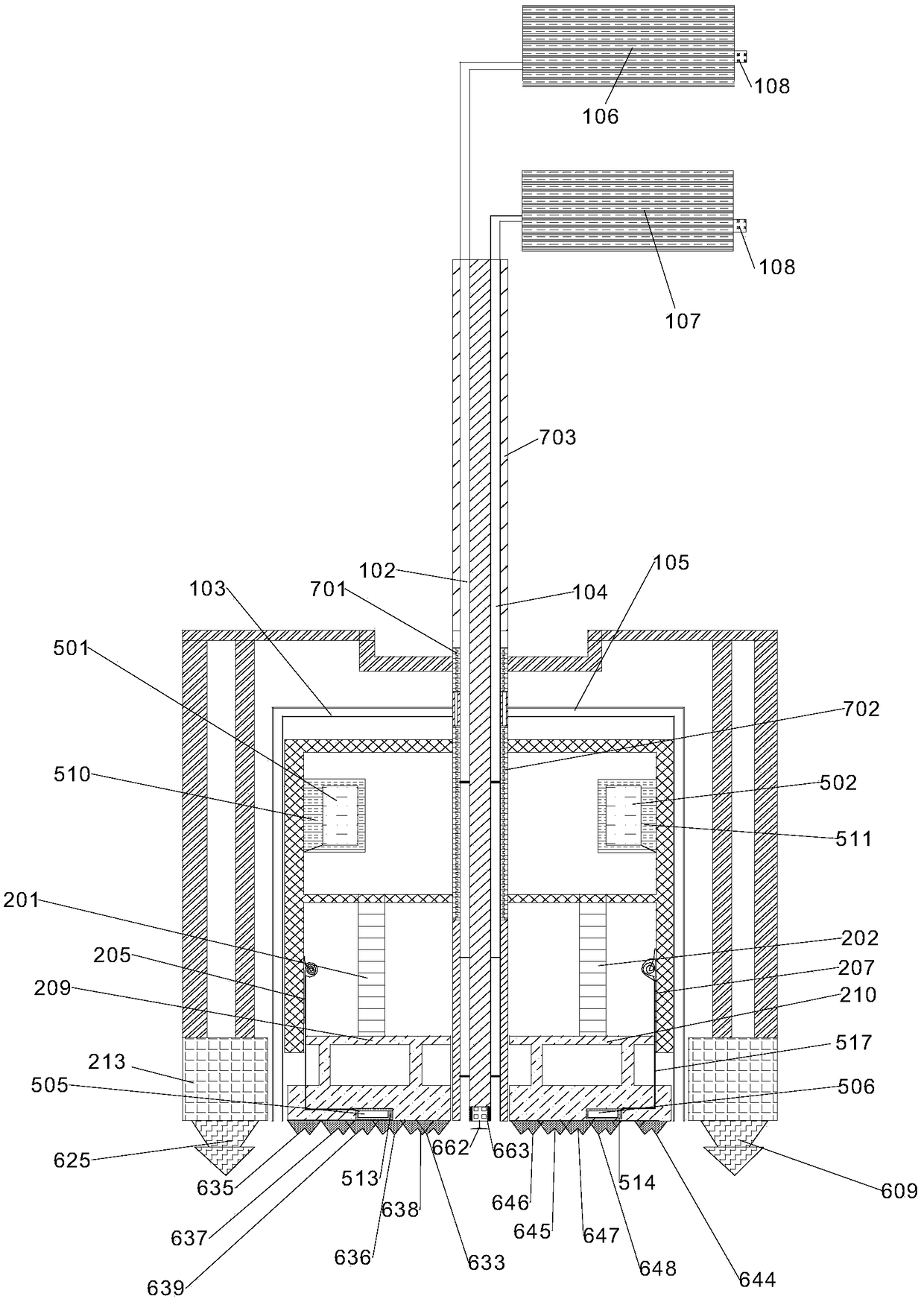

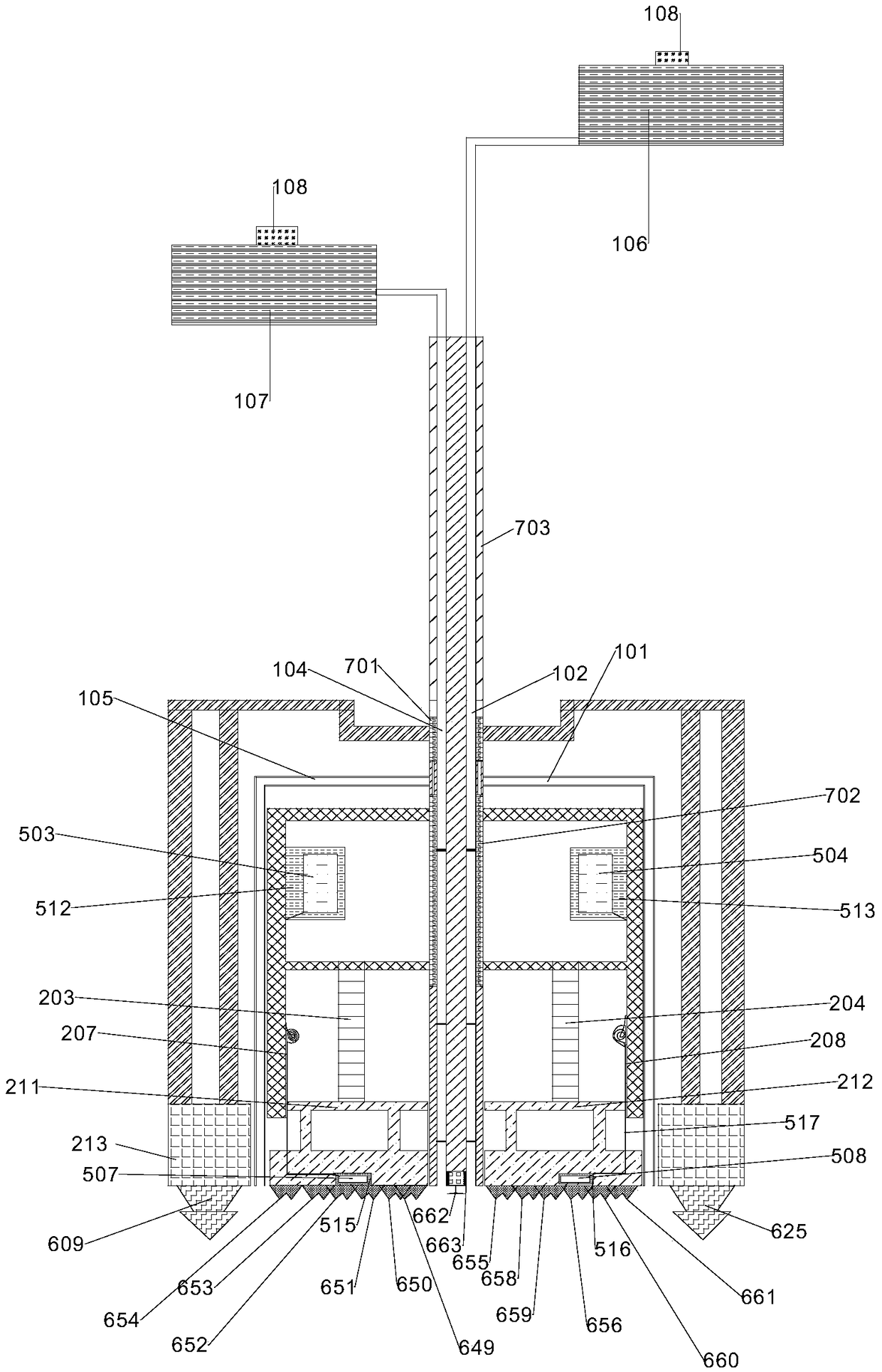

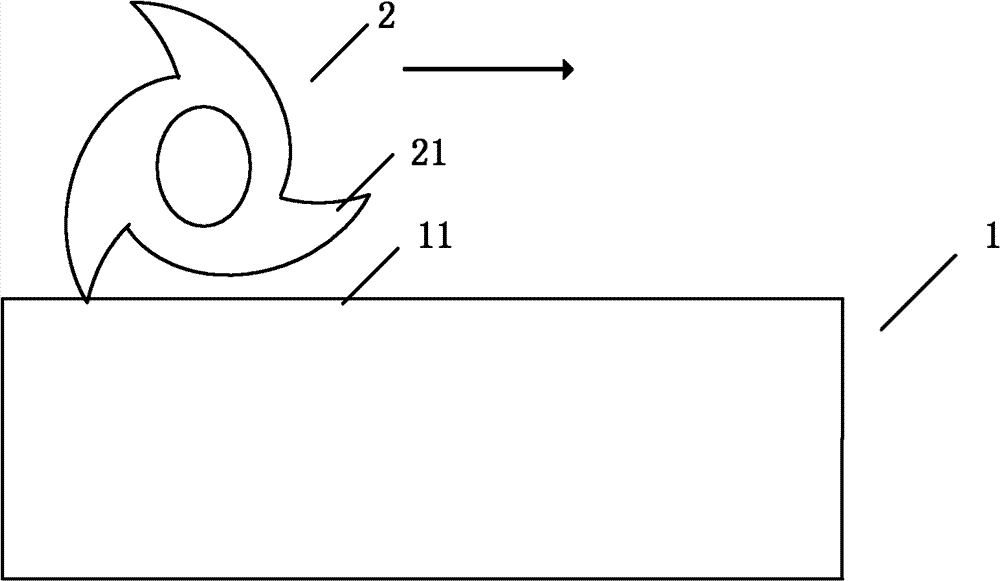

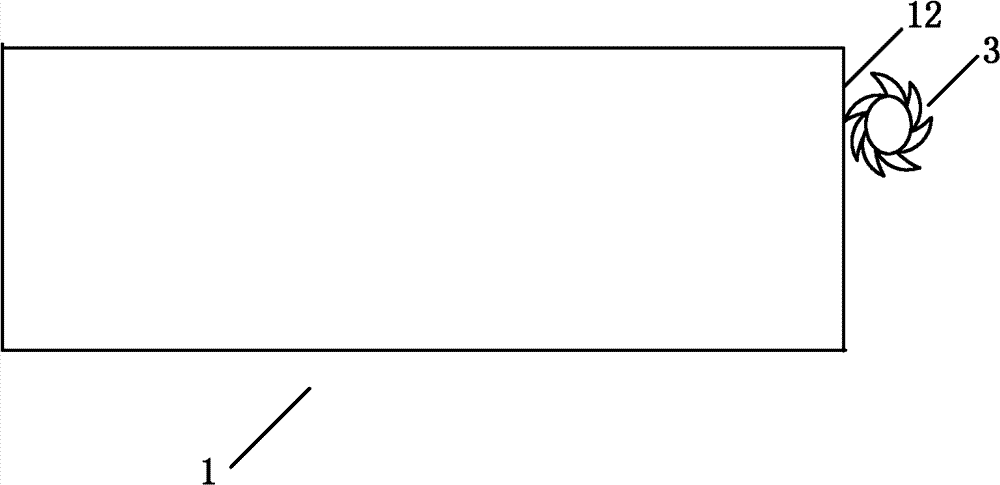

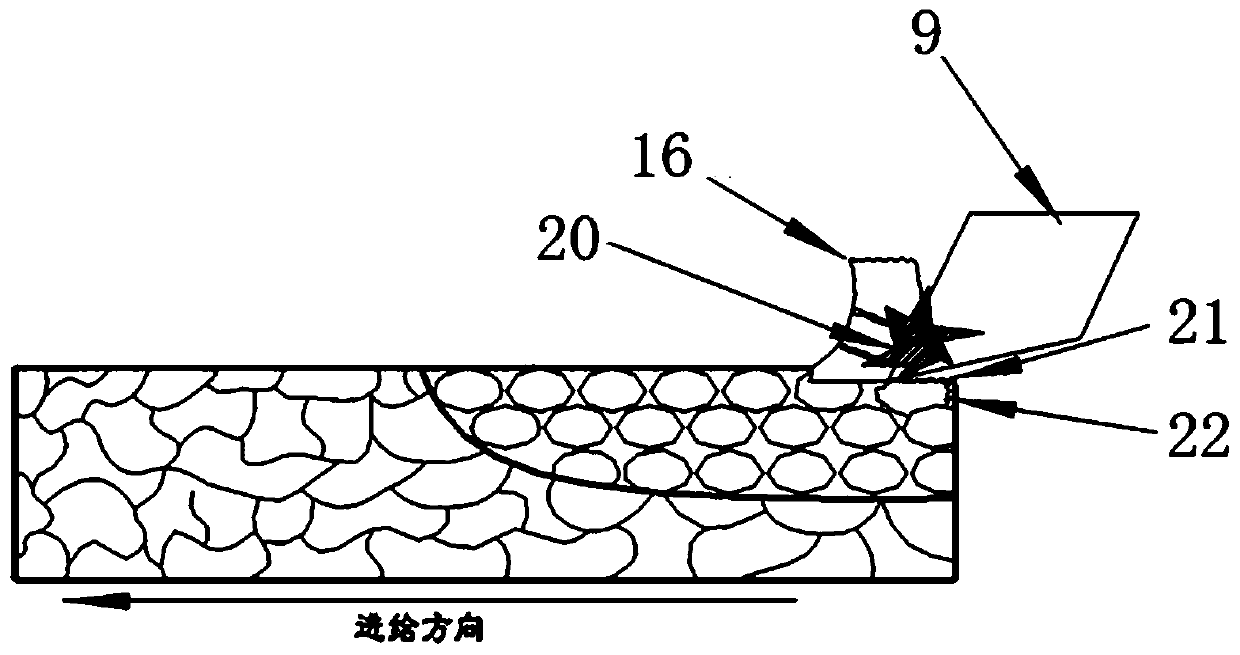

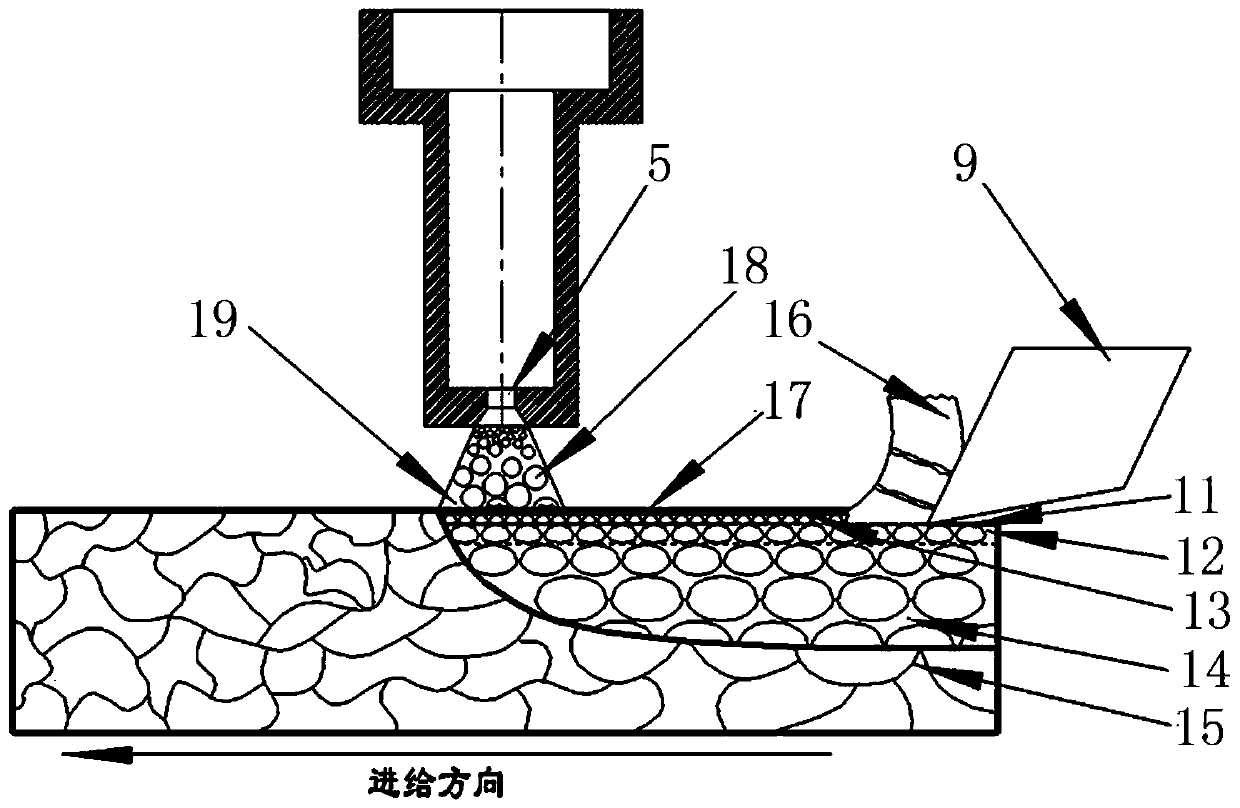

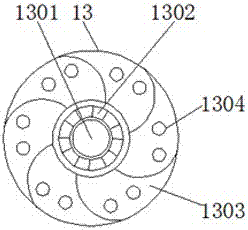

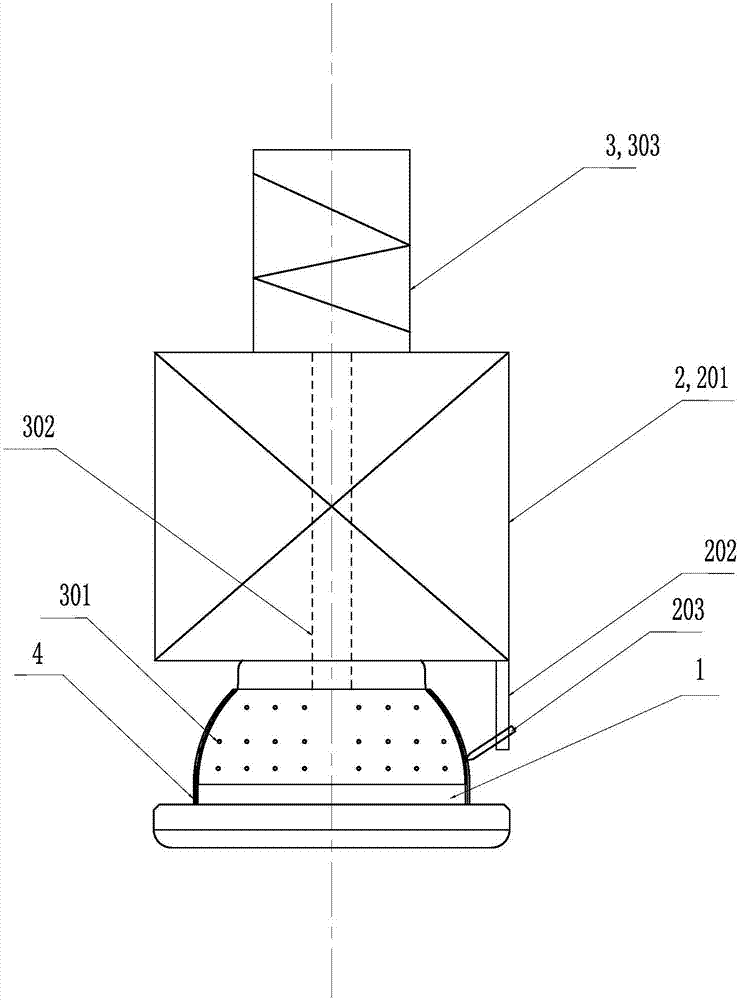

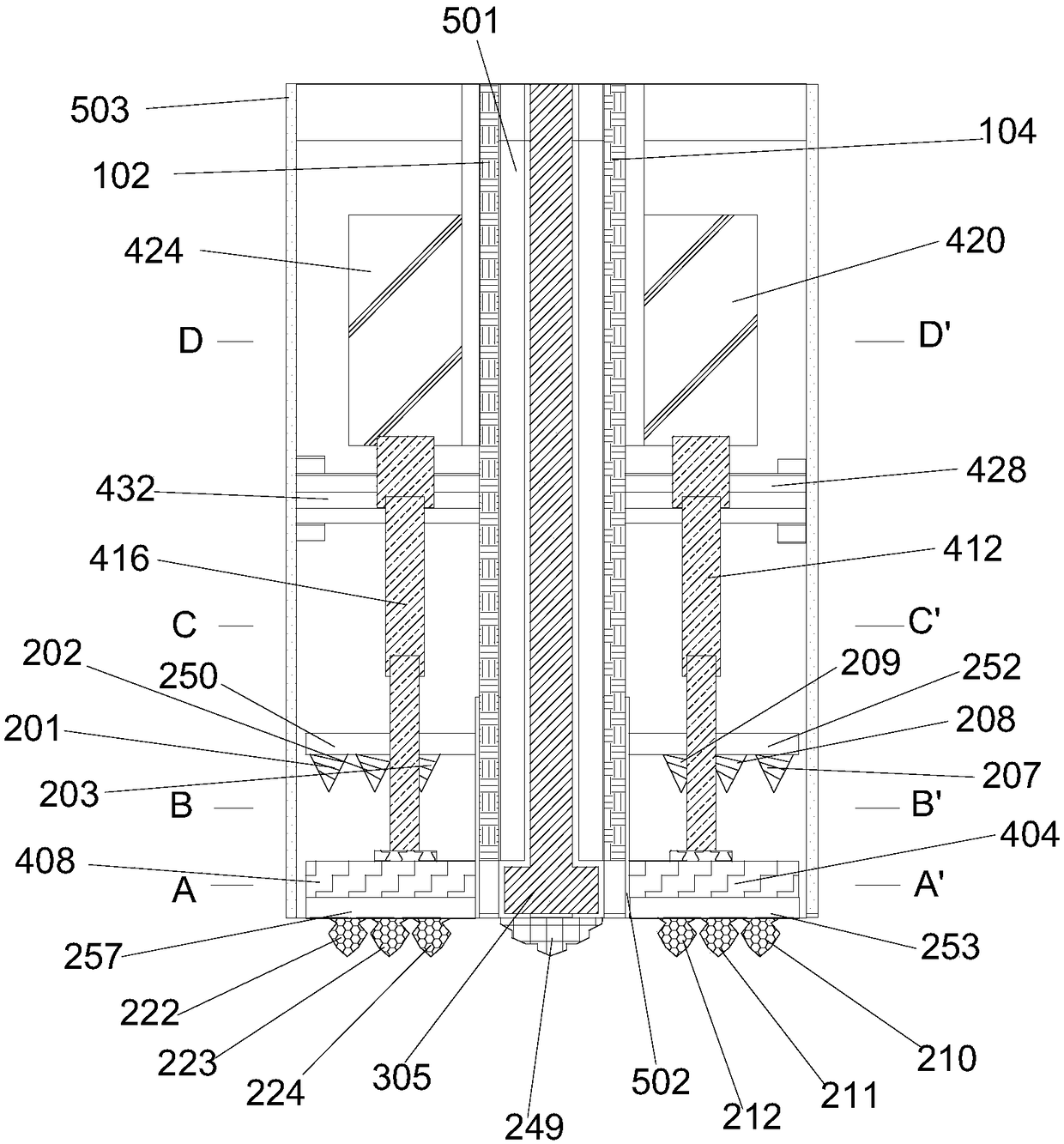

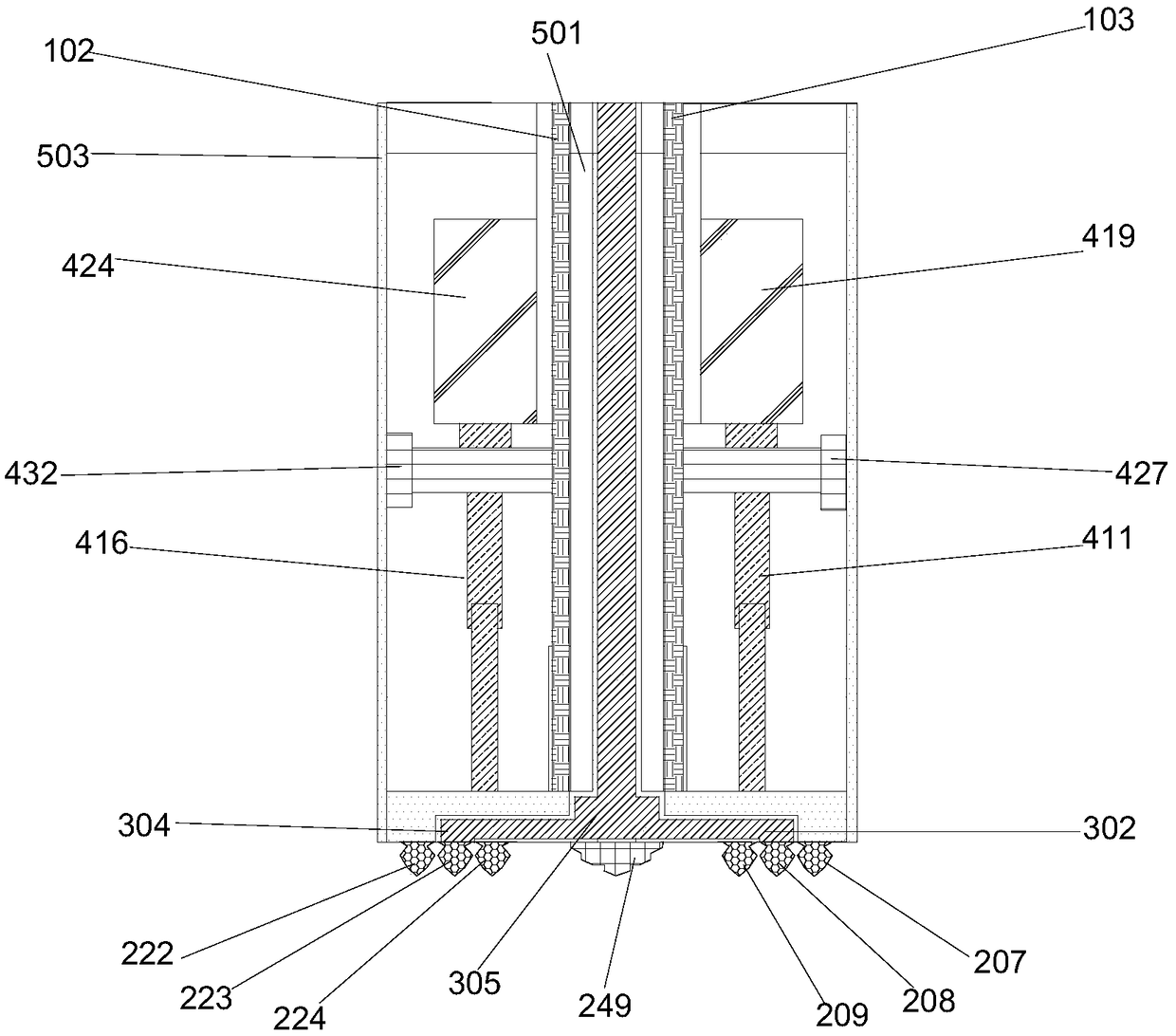

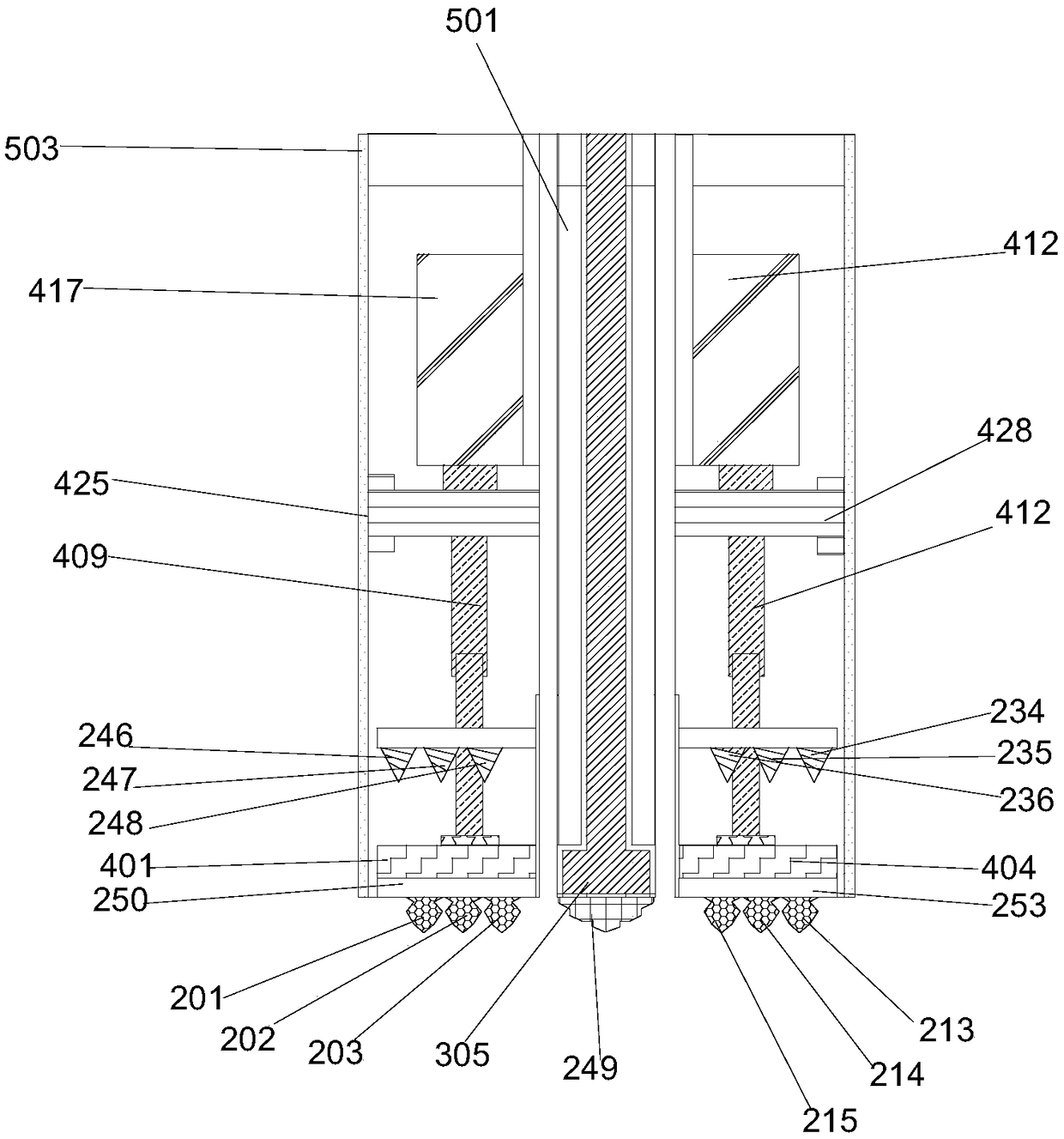

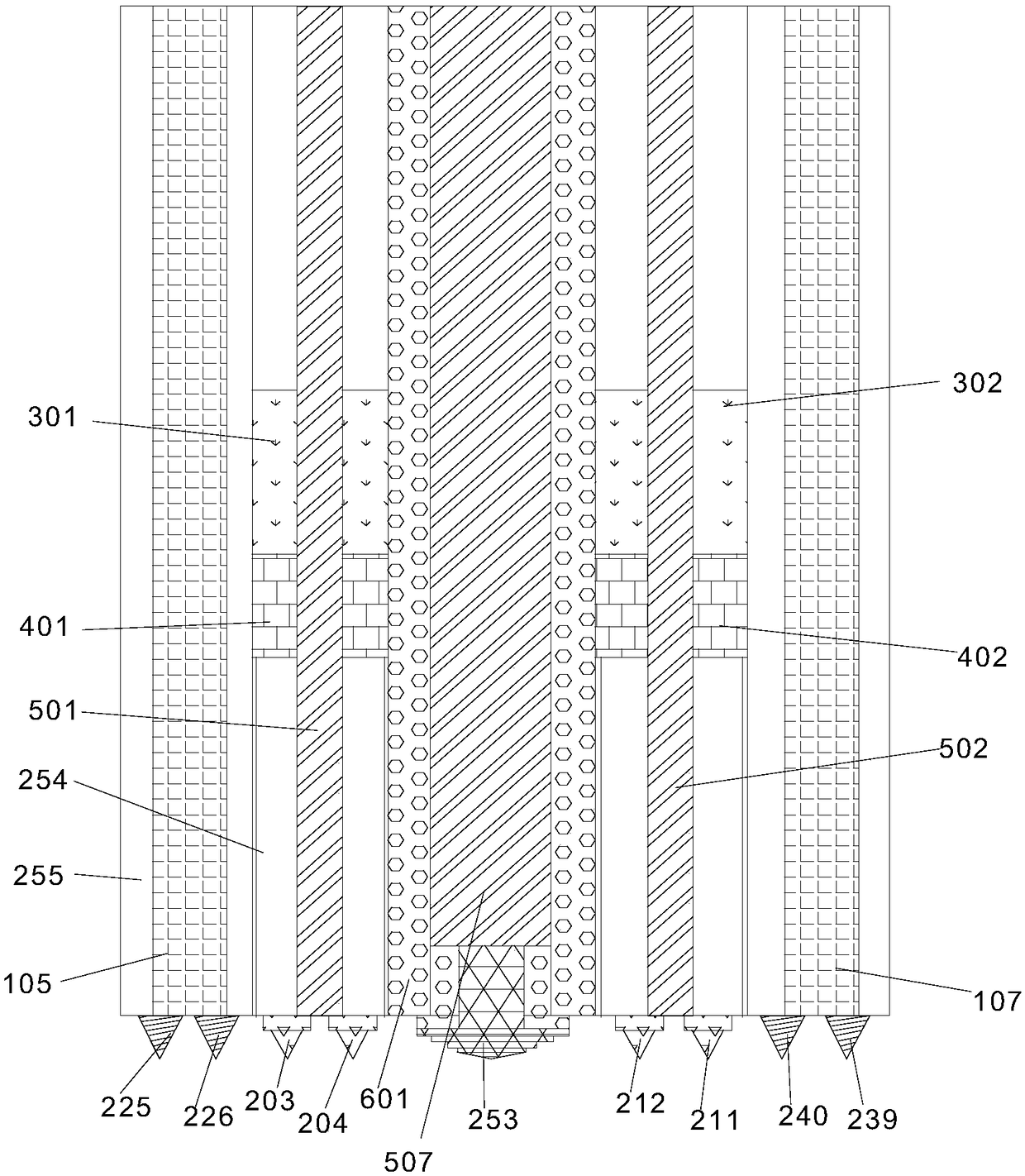

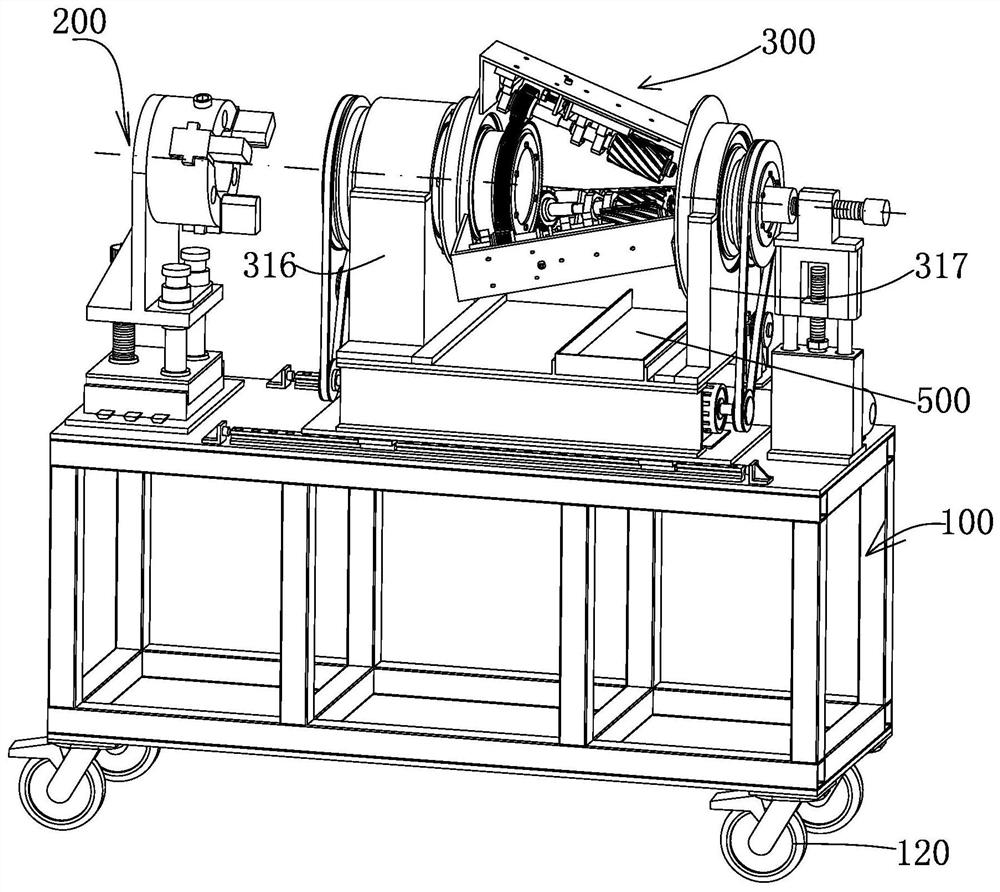

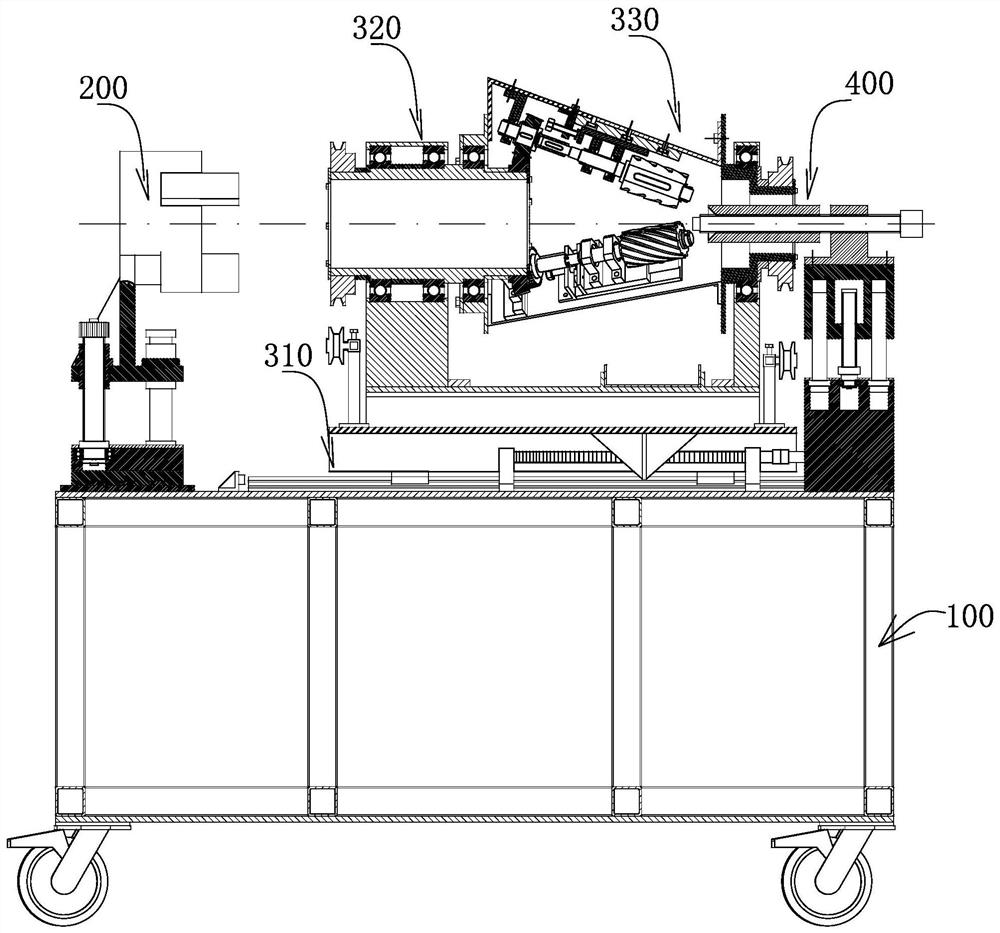

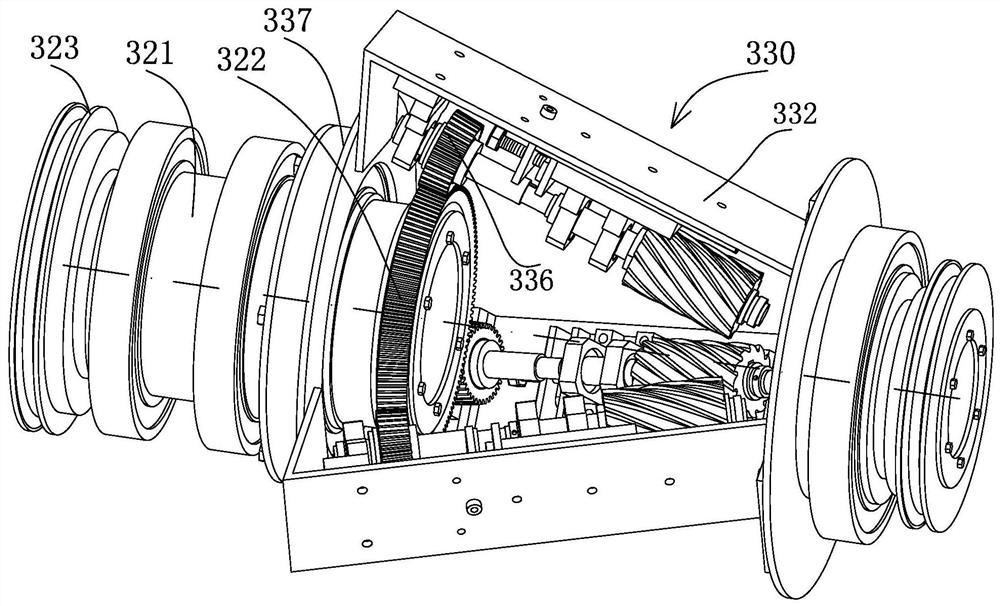

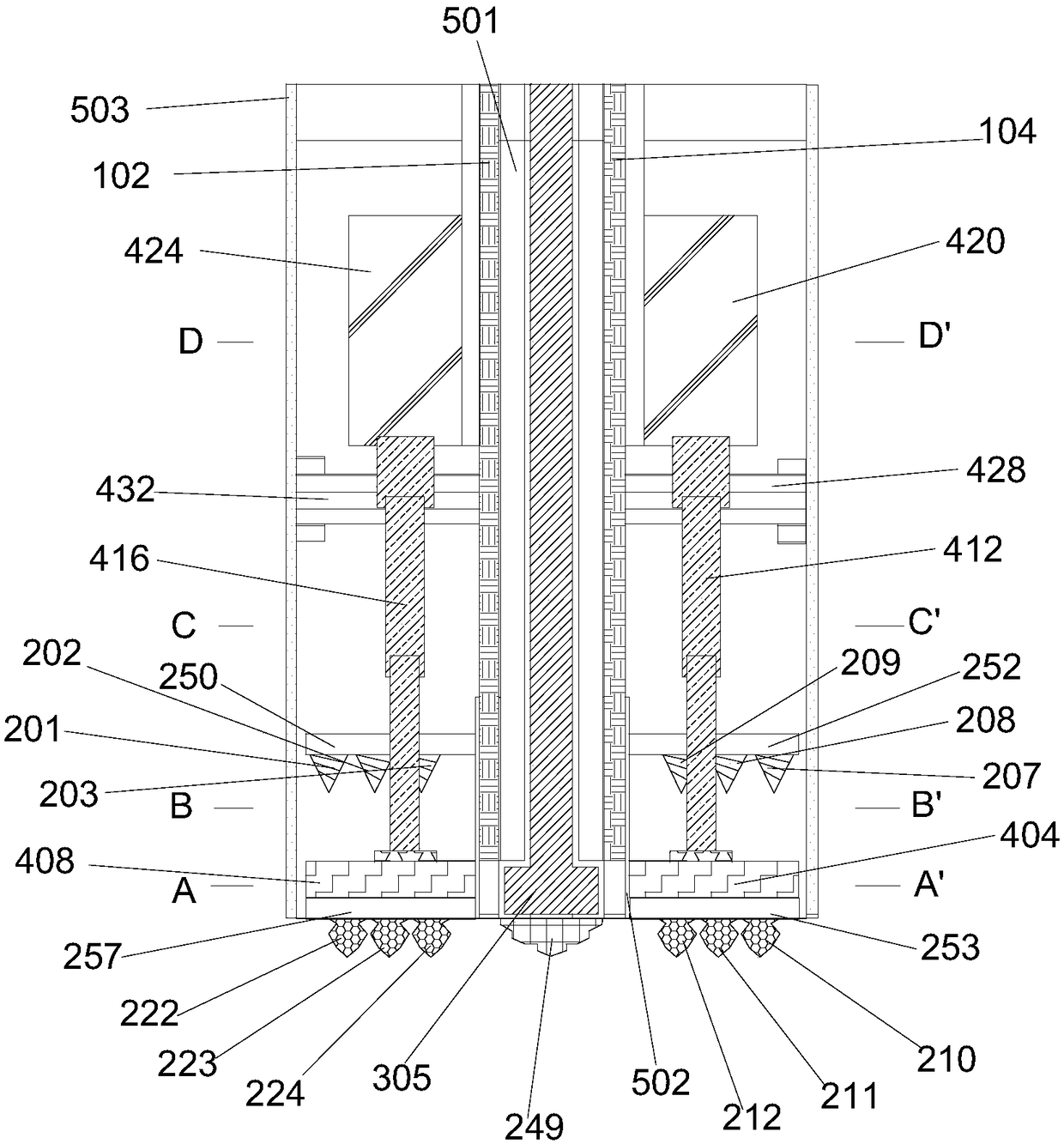

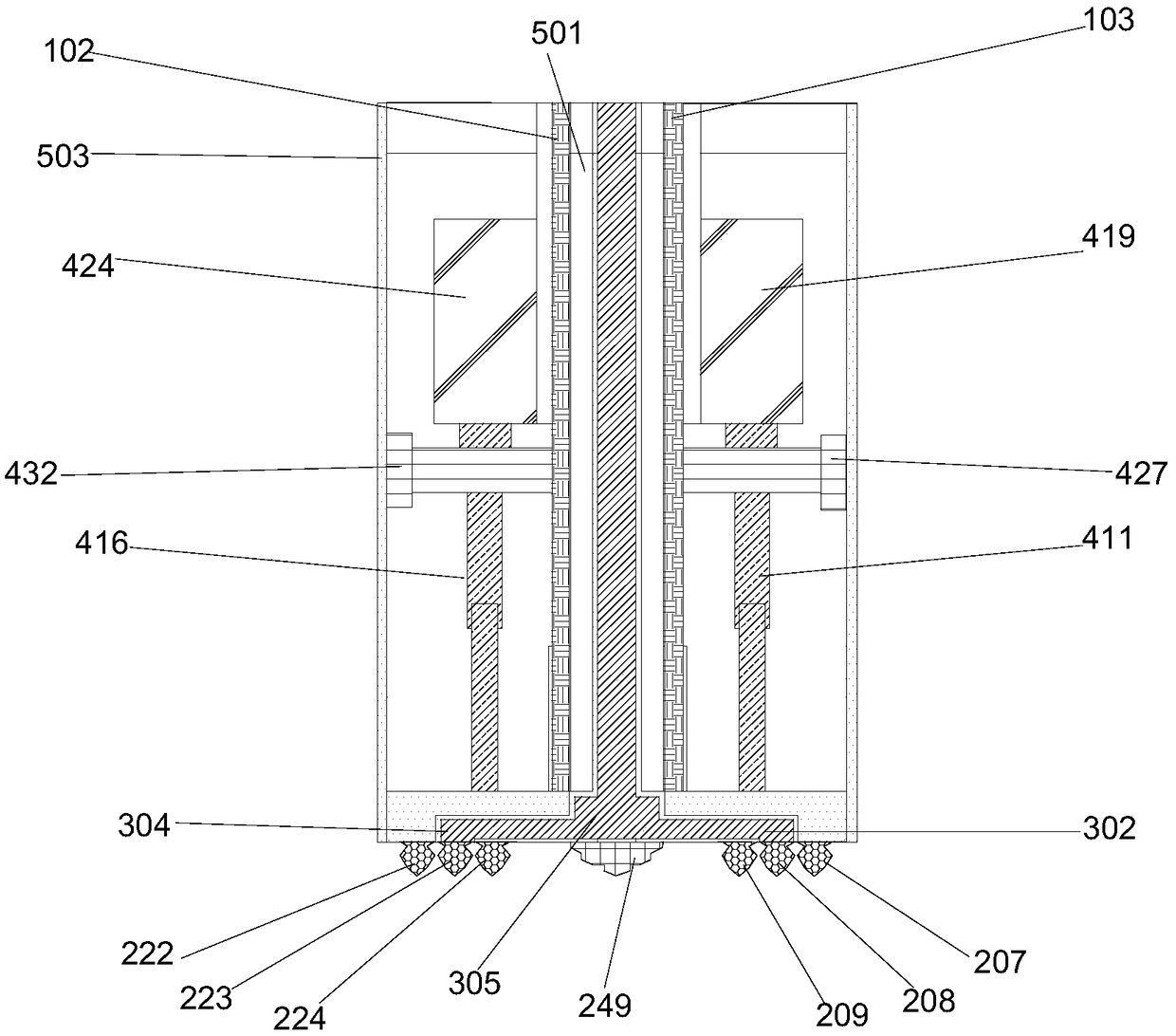

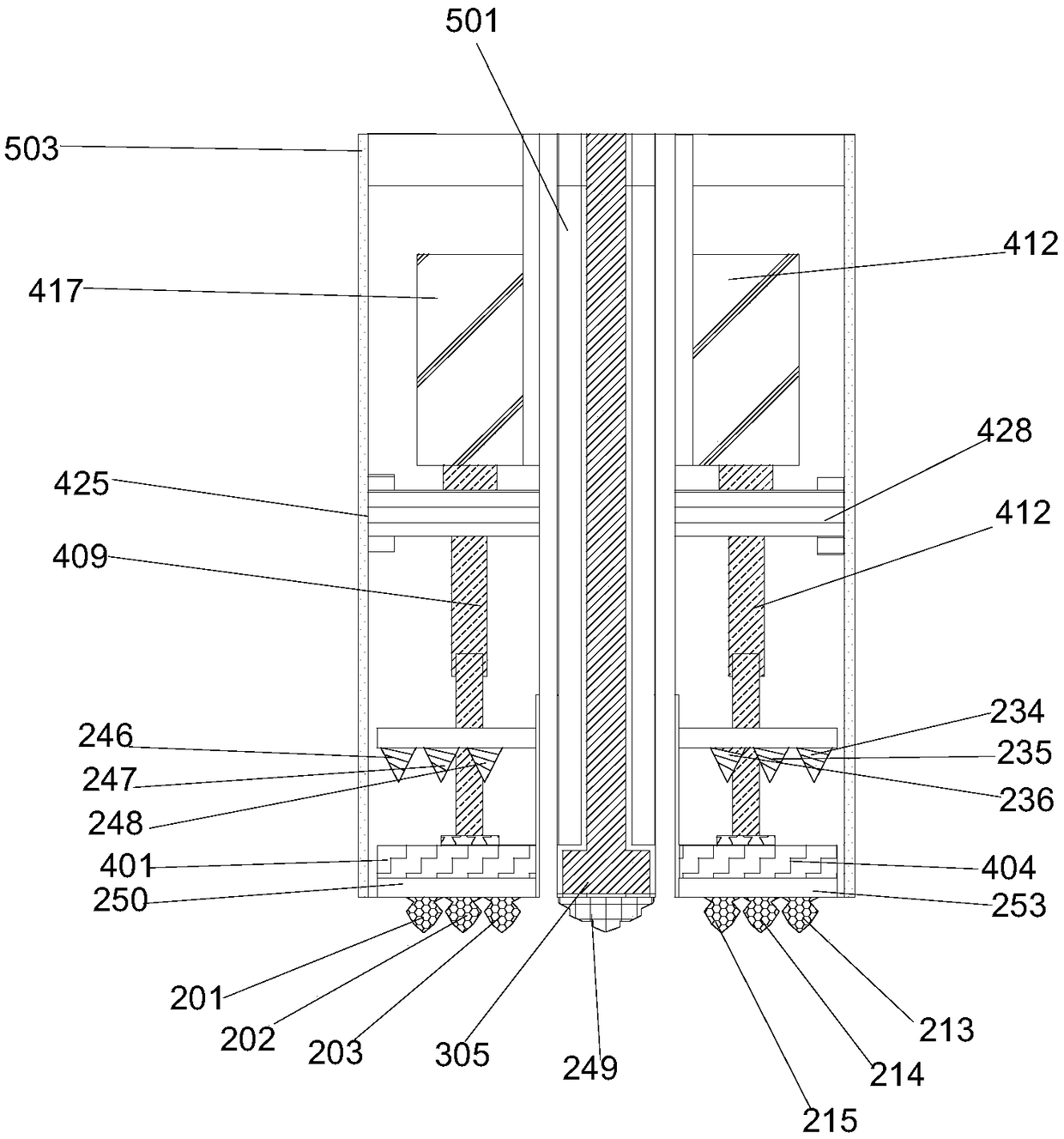

The invention provides a full-cutterhead lifting-type composite drilling and cutting device for soft and hard strata, and belongs to the technical field of underground engineering geotechnical drilling and cutting. The full-cutterhead lifting-type composite drilling and cutting device comprises a high-pressure mud pump mud-discharging system, a cutterhead lifting automatic control system, a watersupply system, a hydraulic pressurization system, a sensing system, a composite drilling and cutting system and a rotating shaft system. Full-cutterhead lifting-type control over drilling and cuttingforce of the drilling and cutting face is achieved, it is guaranteed that a main structure does not tilt during underground engineering drilling and cutting construction, the construction quality is guaranteed, drilling and cutting integration of the soft and hard strata is achieved, the problem that a drilling and cutting head is prone to plugging a pipe during drilling and cutting construction is solved, and the full-cutterhead lifting-type composite drilling and cutting device has the advantages of being large in flexible range of a cutterhead, uniform in drilling and cutting force, high inhole forming precision, low in cost and high in drilling and cutting speed.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

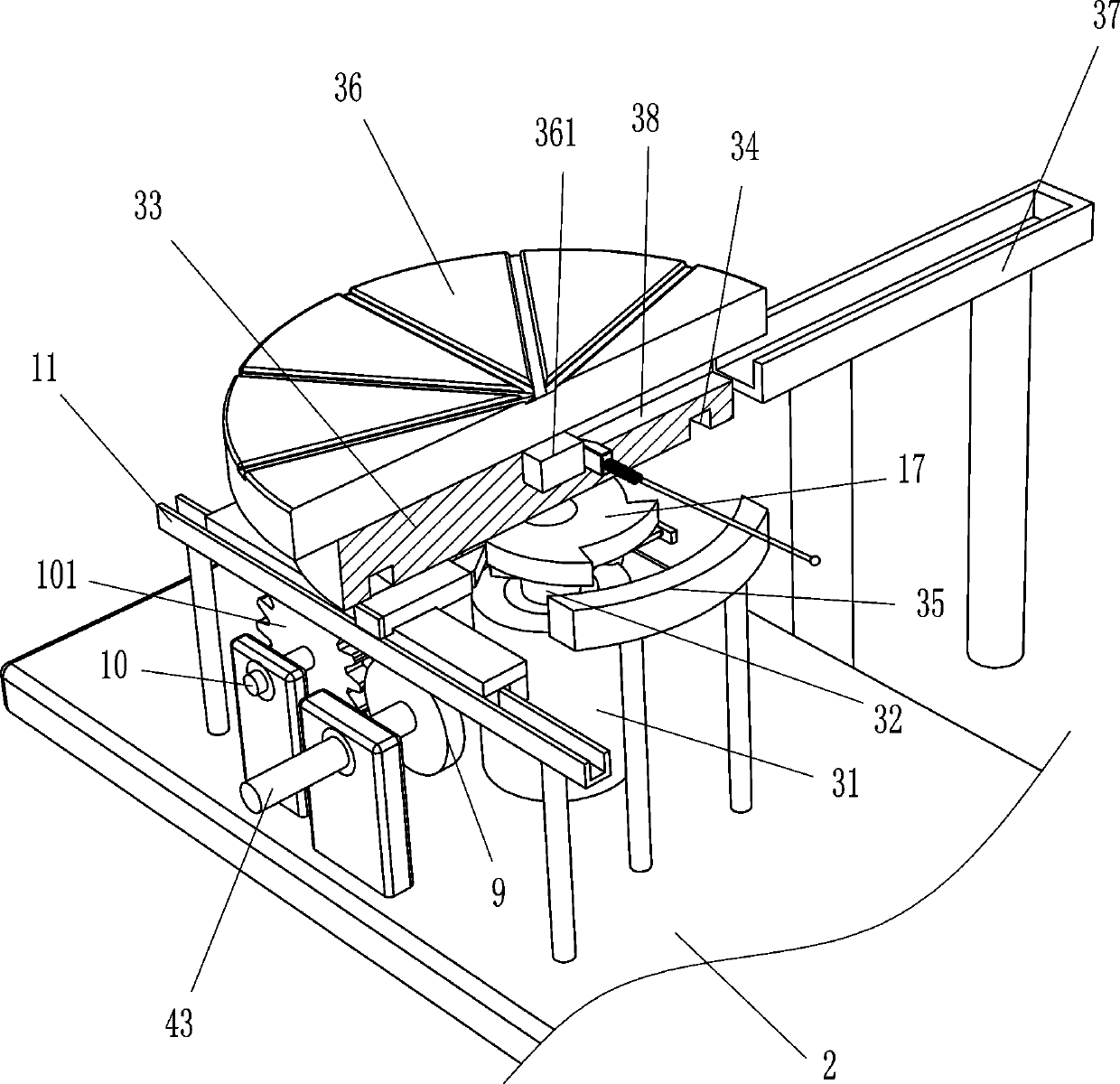

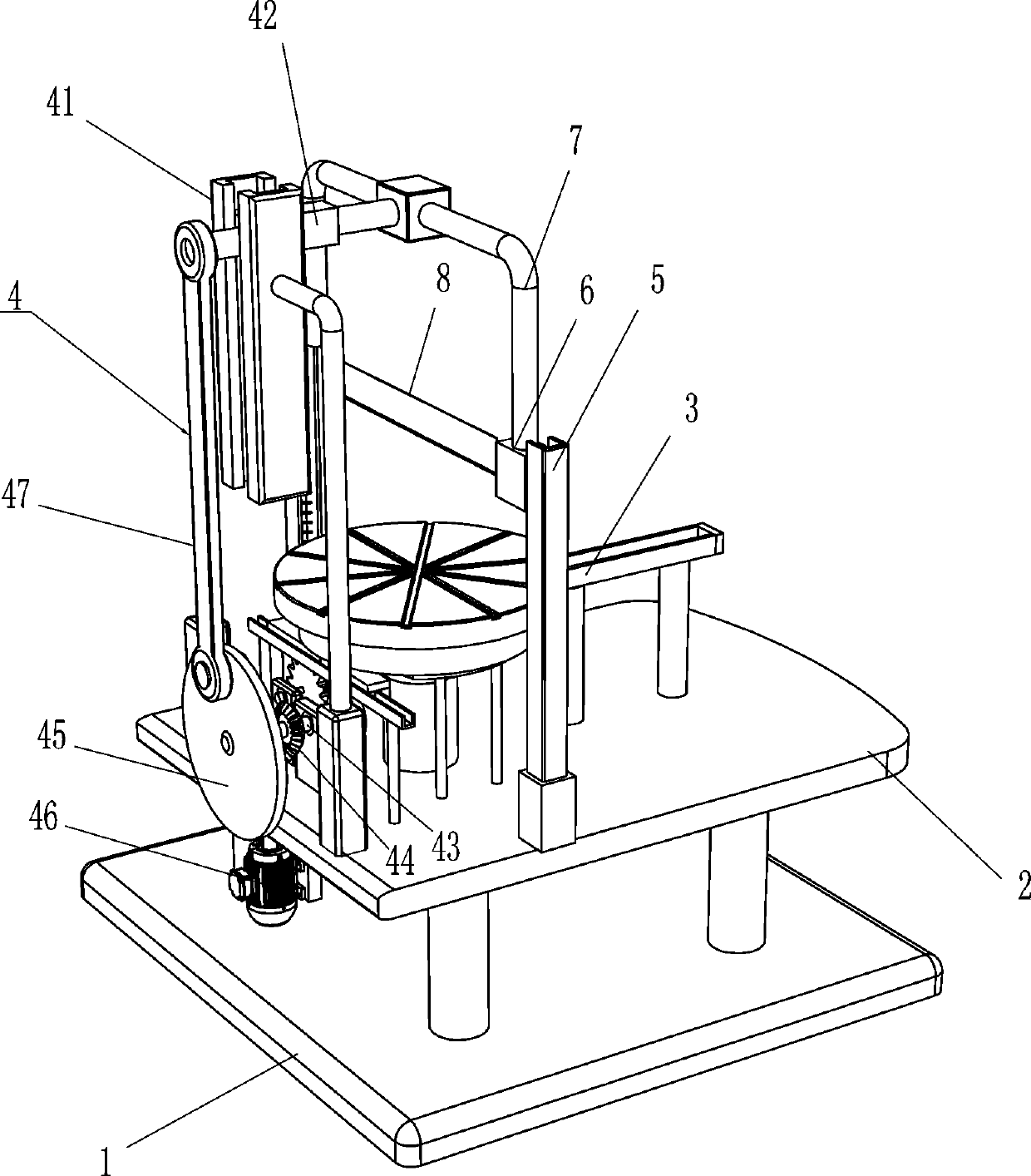

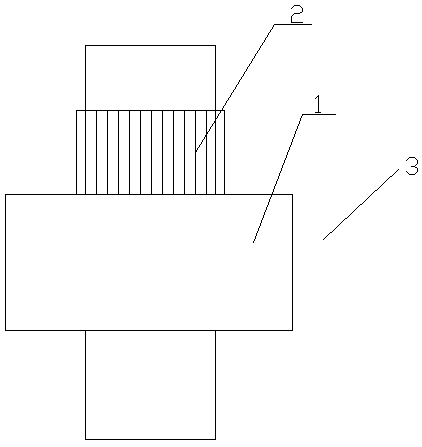

Equal dividing and cutting device for cake

InactiveCN111374163AEasy to operatePrecise cuttingBaked article cutting/slicingStructural engineeringKnife holder

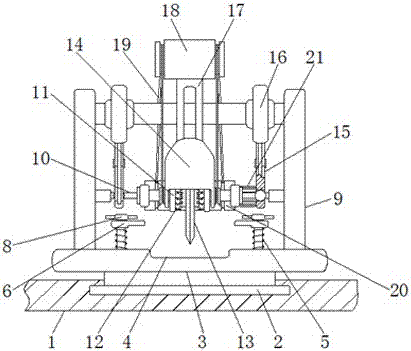

The invention relates to a cutting device, in particular to an equal dividing and cutting device for a cake. The technical problem of the invention is to provide the equal dividing and cutting devicefor the cake that is convenient to operate and accurate to cut. According to the technical scheme, the equal dividing and cutting device for the cake comprises a bottom plate, a holding device, a lifting device, guide plates, a knife rest and a cutting knife, wherein the top part of the bottom plate is provided with a worktable; the holding device used for holding the cake is arranged on the worktable; the lifting device is arranged on the worktable; the guide plates are symmetrically arranged on the worktable with respect to the holding device, and the two guide plates are each glidingly provided with a second sliding block; the knife rest is arranged at upper parts of the two second sliding blocks, and the knife rest is connected with the lifting device; and the cutting knife is detachably provided on the two second sliding blocks. The equal dividing and cutting device achieves the effects of convenient operation and precise cutting.

Owner:丘三贱

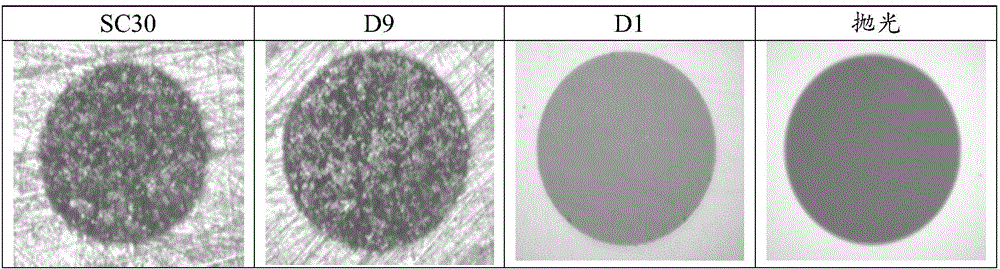

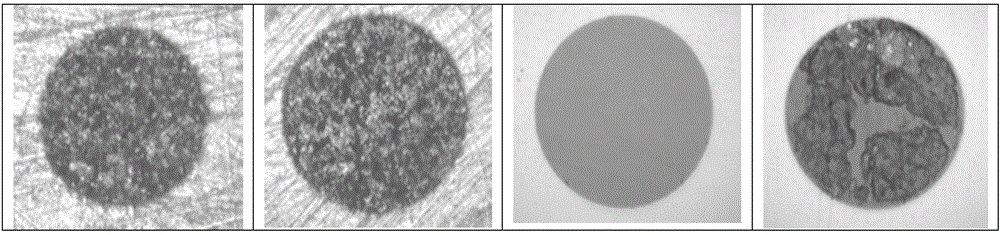

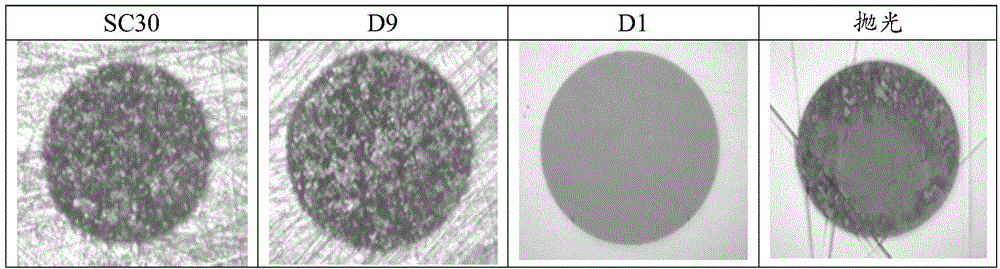

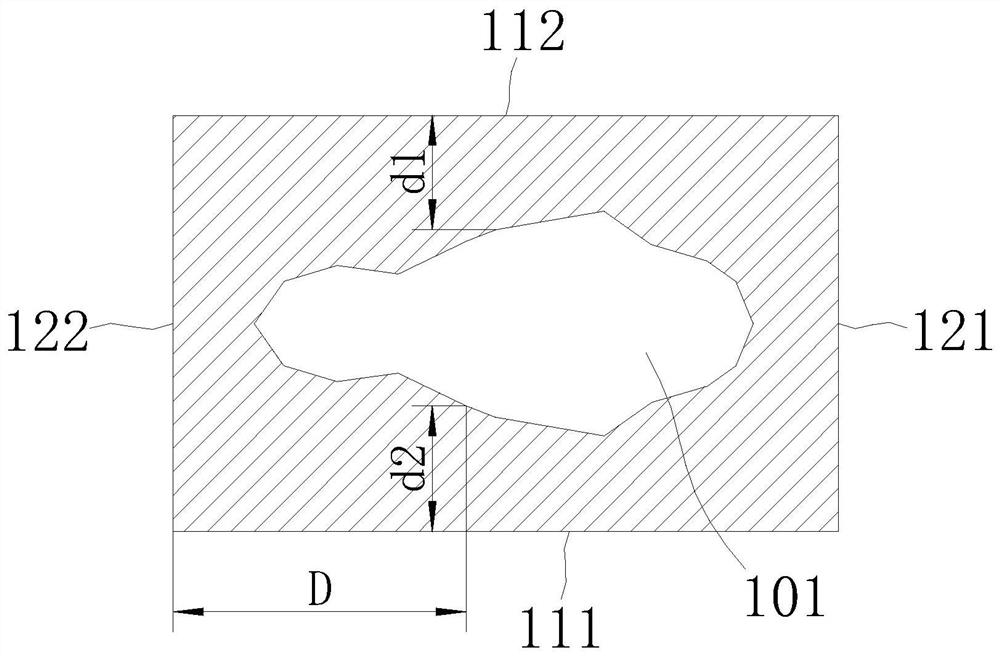

Nanometer silicon dioxide thin film base polished section and preparation method thereof

ActiveCN104128896AUniform particle size distributionUniform polishing effectAbrasion apparatusGrinding devicesWork in processCutting force

The invention discloses a nanometer silicon dioxide thin film base polished section and a preparation method of the nanometer silicon dioxide thin film base polished section. The preparation method includes the following steps that (1) nanometer silicone sol is prepared; (2) a precoating is coated on a PET tape base and a processed base material is obtained; (3) the nanometer silicone sol, soluble resin, and a soluble curing agent are mixed and then abrasive coating liquid is obtained; (4) the abrasive coating liquid is evenly coated on the base material processed in the step (2), a semi-finished product is obtained and is solidified under 80 DEG C to 100 DEG C for 40 hours to 60 hours, and the nanometer silicon dioxide thin film base polished section is obtained. The nanometer silicon dioxide thin film base polished section is even in cutting force, and good in polishing effect when the polished section is applied to an optical fiber connector.

Owner:绍兴自远磨具有限公司

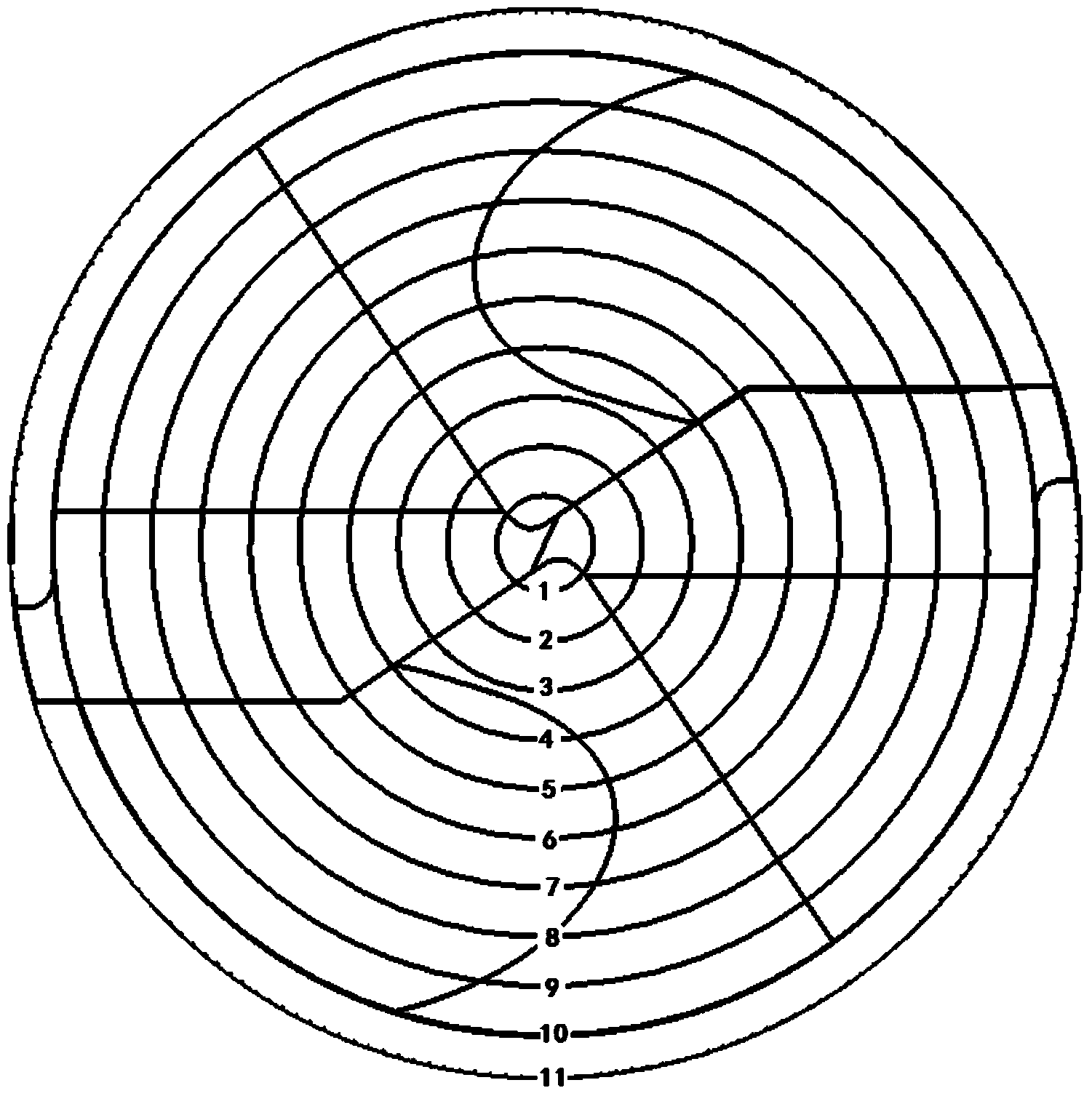

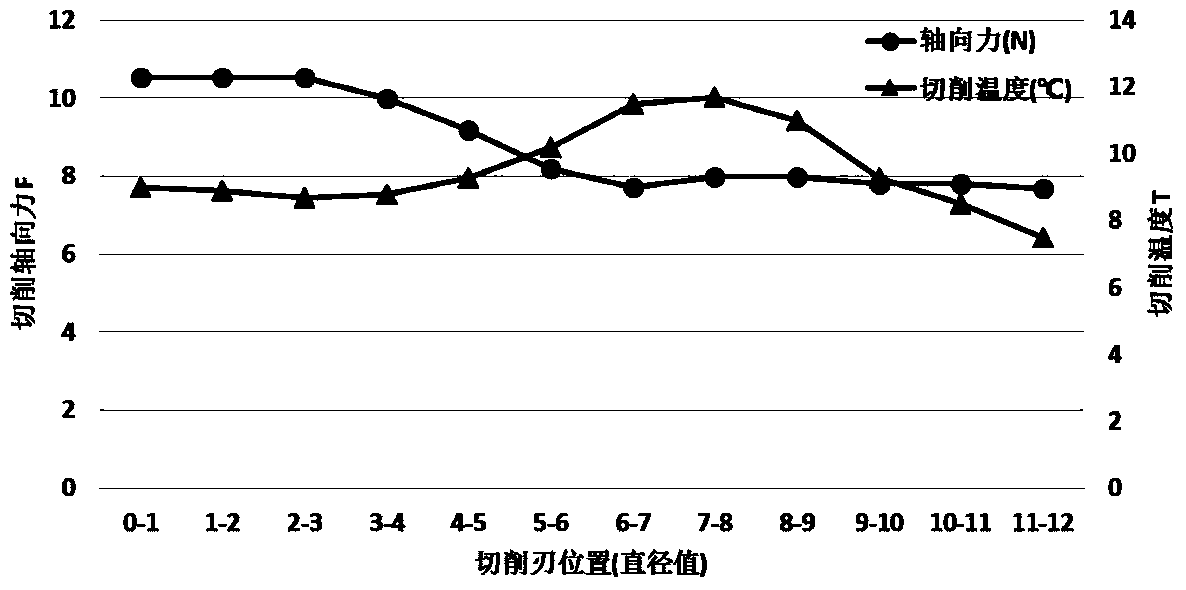

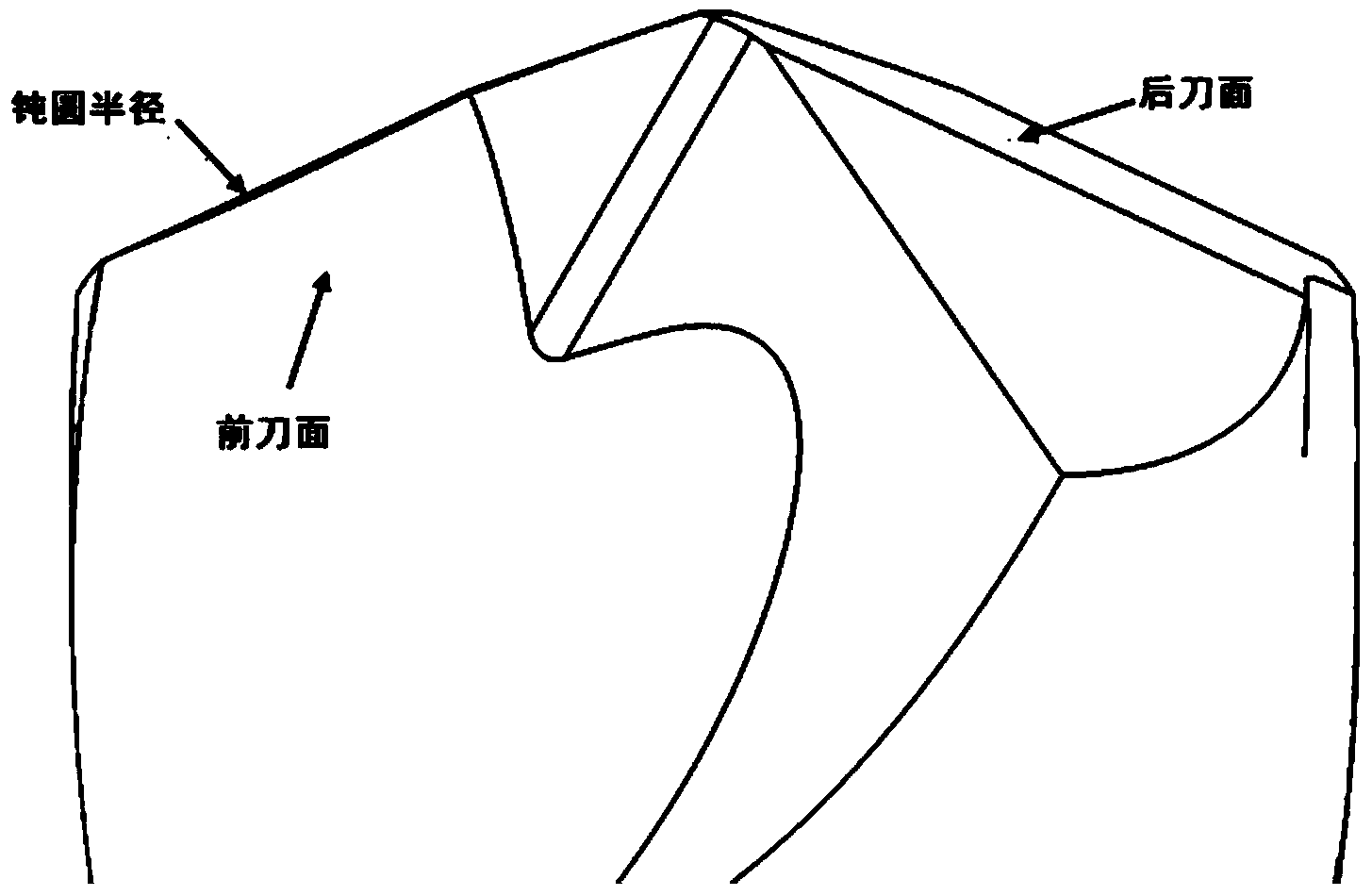

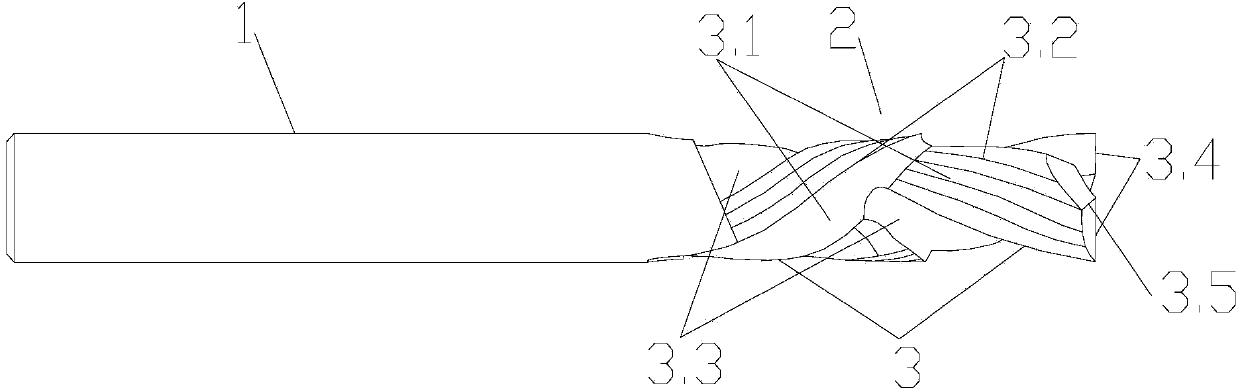

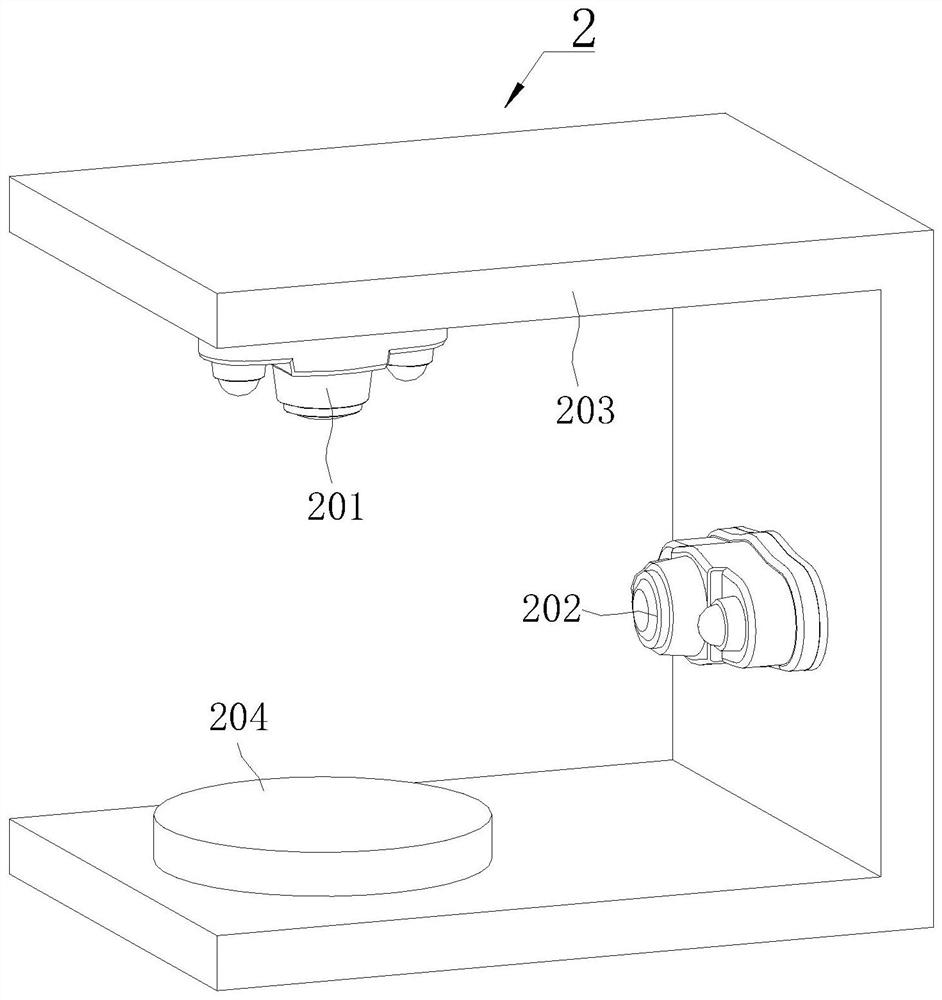

Drill bit for CFRP machining and experimental determining method for structural parameters of drill bit

ActiveCN103970995AUniform cutting forceReduced drilling defectsMetal working apparatusSpecial data processing applicationsEngineeringCutting force

The invention discloses an experimental determining method for structural parameters of a drill bit for CFRP machining. The method includes the steps of obtaining the distribution of cutting force and cutting temperature on a main cutting edge of the drill bit through a cutting experiment of prefabricated holes of different diameters, obtaining the function relationship between the cutting force, the cutting temperature and the structural parameters of the drill bit through an orthogonal free cutting experiment of CFRP, determining distribution parameter values of the angle of the rear corner of the drill bit and the radius of a blunt circle along the main cutting edge by the utilization of the known angle of a front corner of the drill bit according to the principle of the even distribution of the cutting force and the cutting temperature, and manufacturing the drill bit according to the determined parameter values. According to the drill bit for CFRP machining, in the actual production process of the CFRP, the cutting force and cutting temperature on the main cutting edge are evenly distributed, and drilling defects are reduced.

Owner:上海工具厂有限公司 +1

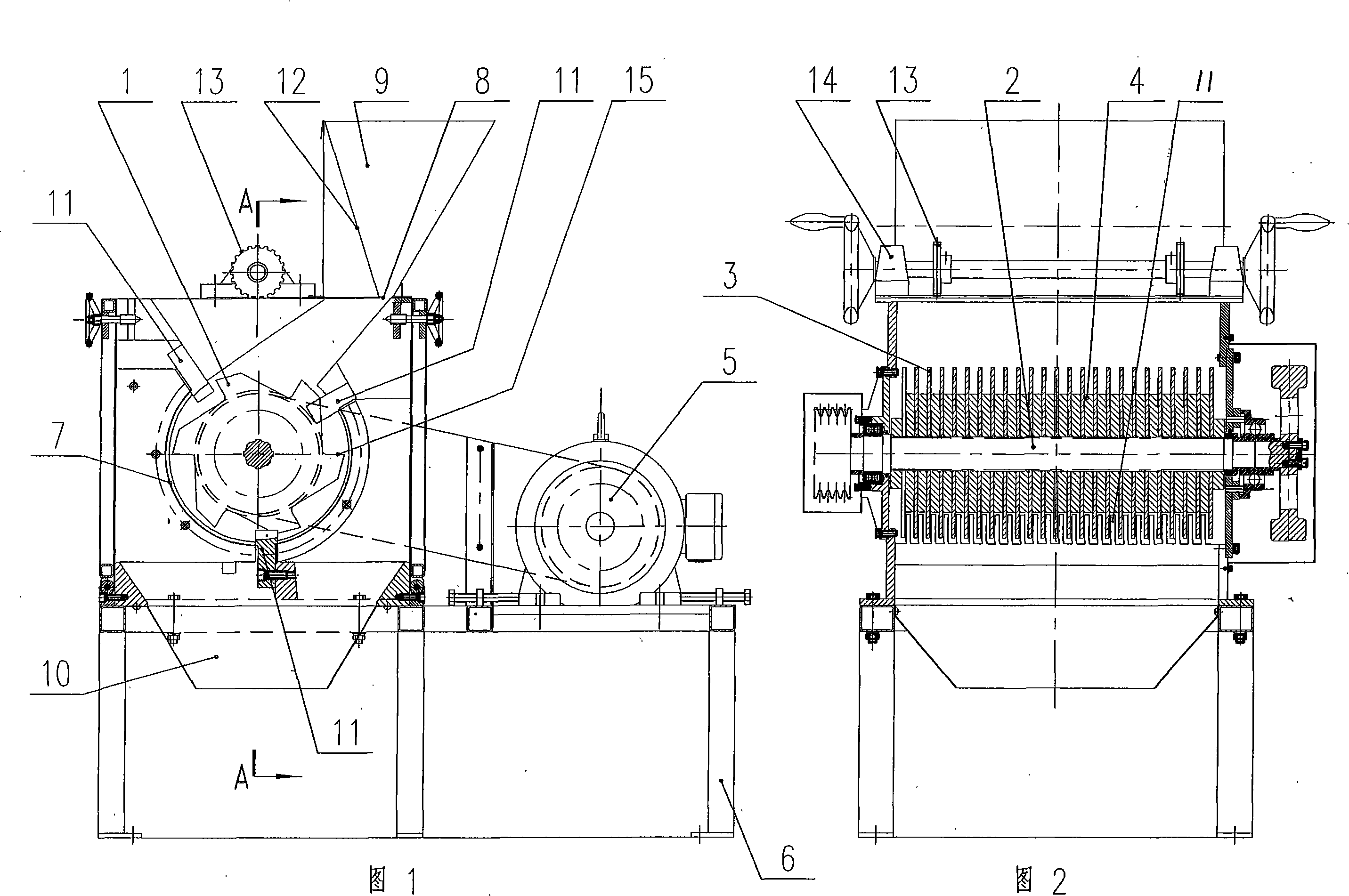

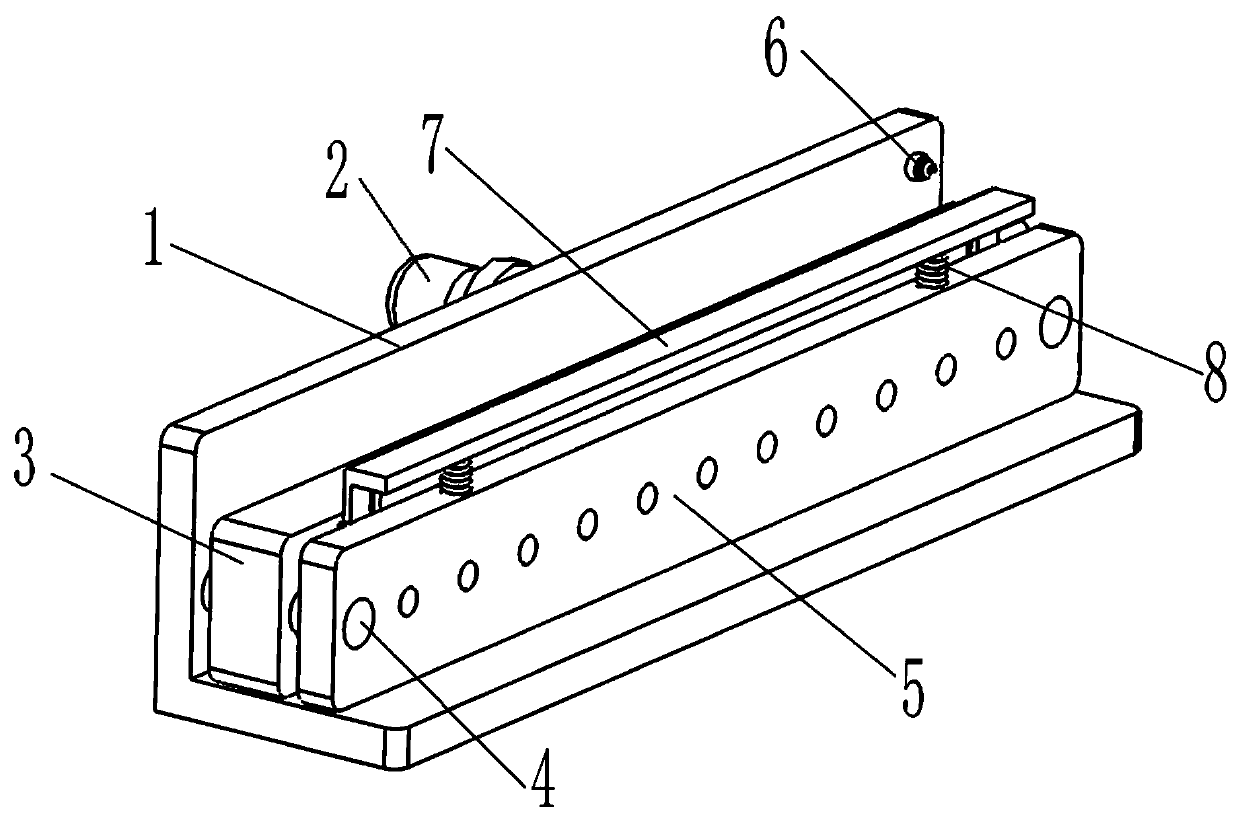

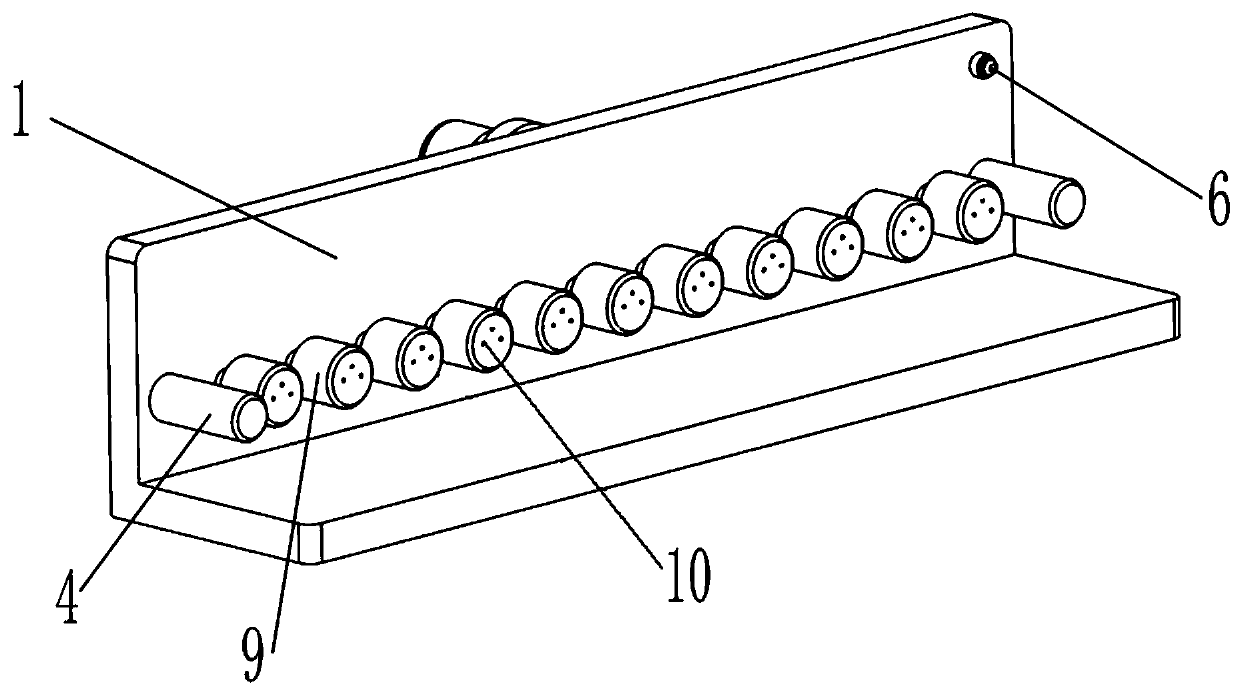

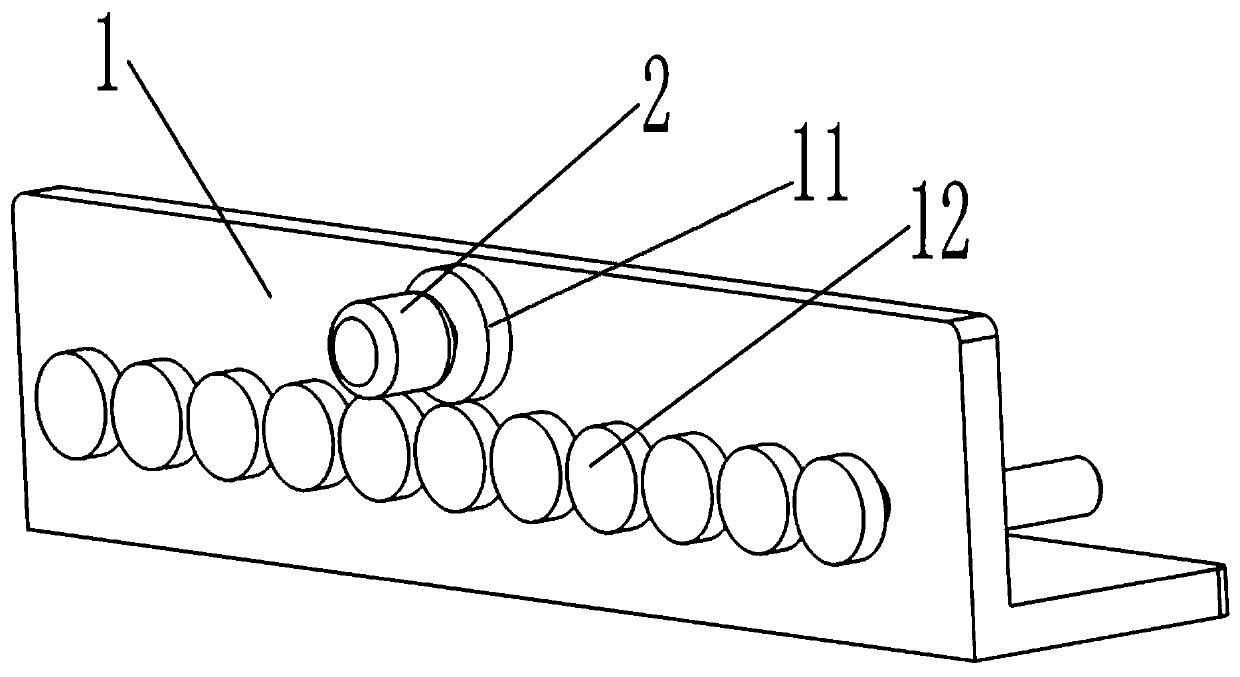

Rolling cutter grinder

InactiveCN101214458AEffective shreddingAvoid cloggingTobacco treatmentGrain treatmentsEngineeringKnife blades

A hob pulverizing machine comprises a stander (6) and a hob mounted on the stander. The hob comprises a horizontal rotating shaft (2) and a moveable knife tackle (1) installed on the rotating shaft. The moveable knife tackle has a subassembly of blades with cutting edge (15). The blades are separated by a range spacer (4). The rotating shaft of the moveable knife tackle is connected with a gear (5). A meshed cylinder (7) is arranged outside the moveable knife tackle. One or more than one comb-shape stationary knives (11) are arranged on the inner wall of the cylinder along the direction of circumference. The comb of the stationary knife and the blades of the moveable knife tackle alternate with each other and match. The top of the cylinder is provided with a feed opening (8). The bottom of the cylinder is provided with a discharge opening (10). The utility model provides the hob pulverizing machines that can pulverize wet and cellulosic materials. The particle size of the wet and cellulosic materials is consistent. The utility model has high efficiency and simple structure. And caulking materials do not stick easily and inlet amount can be adjusted.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

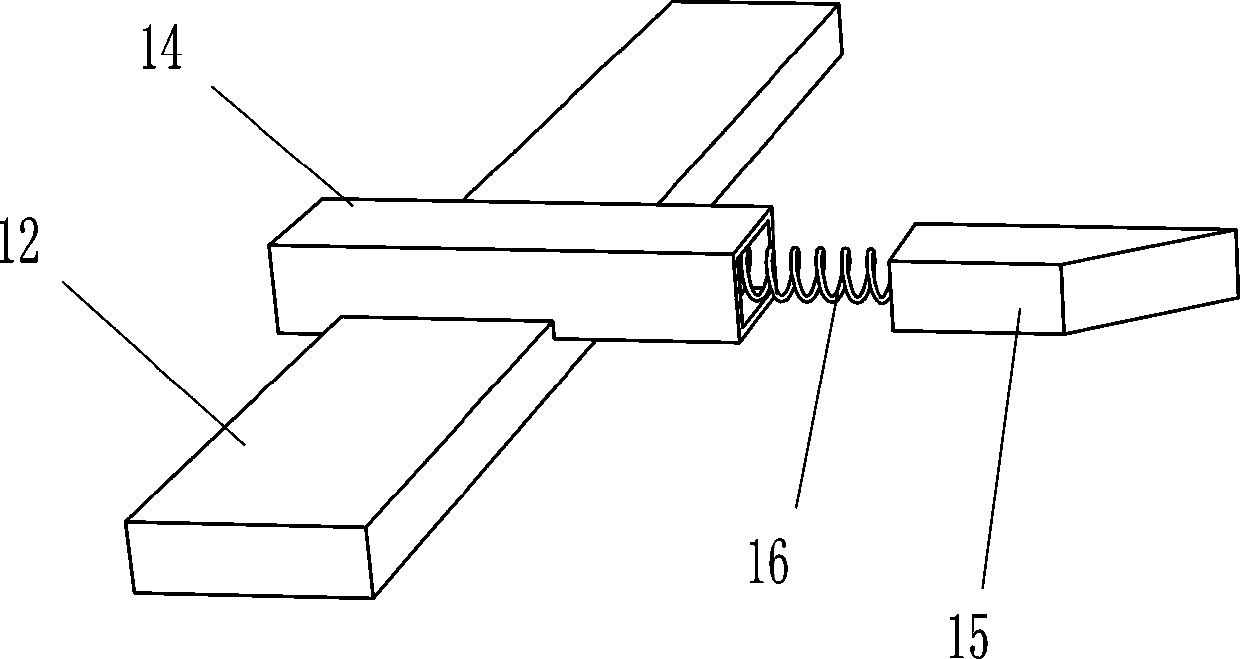

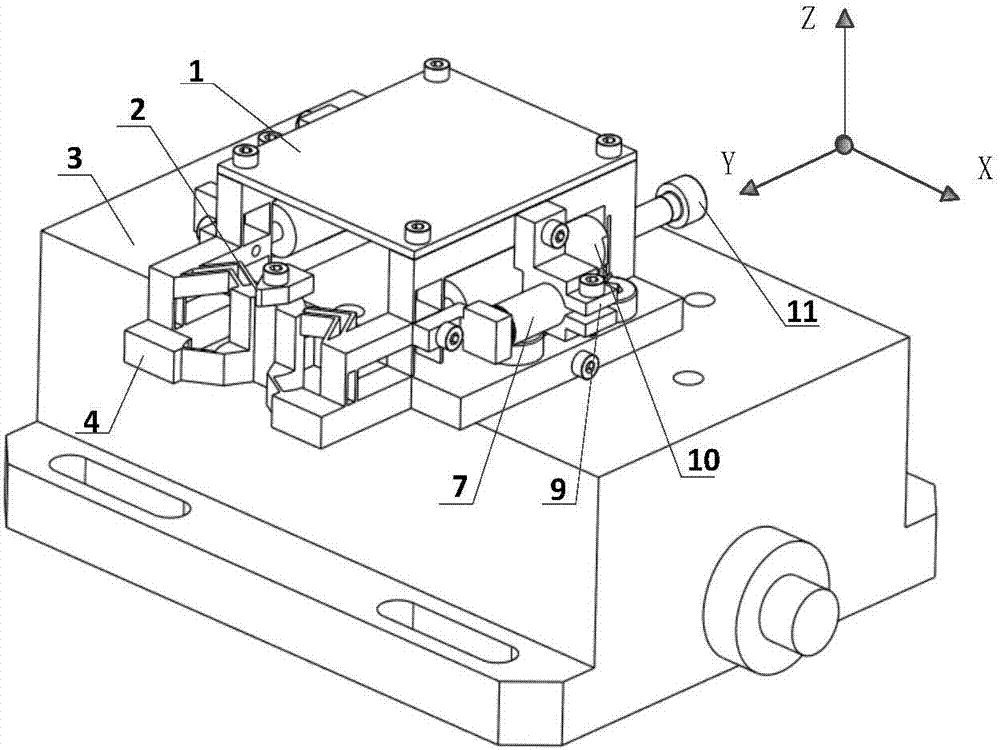

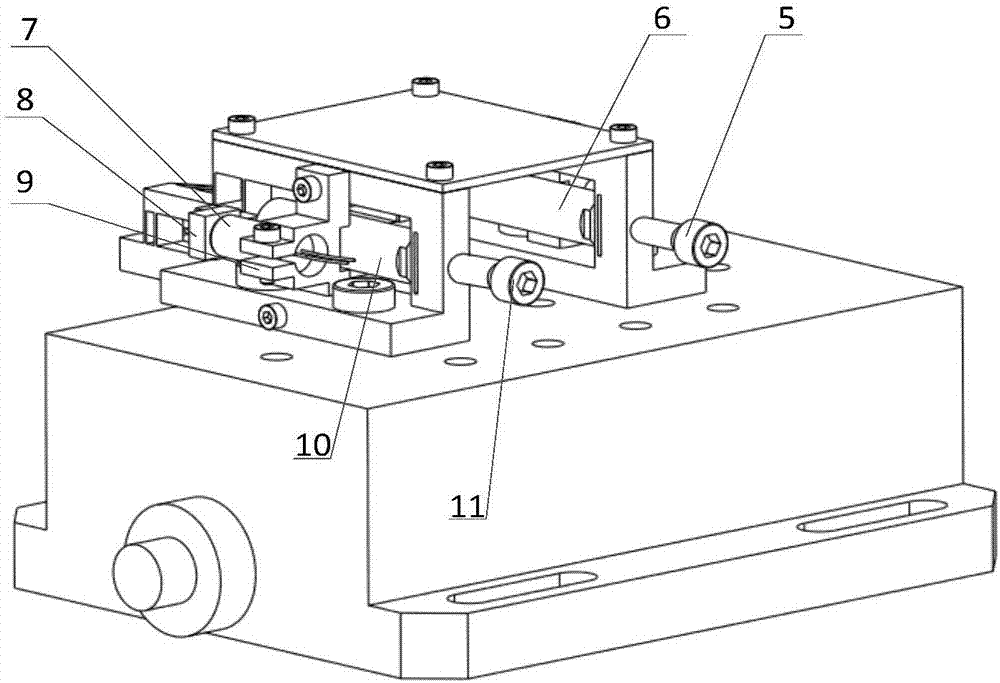

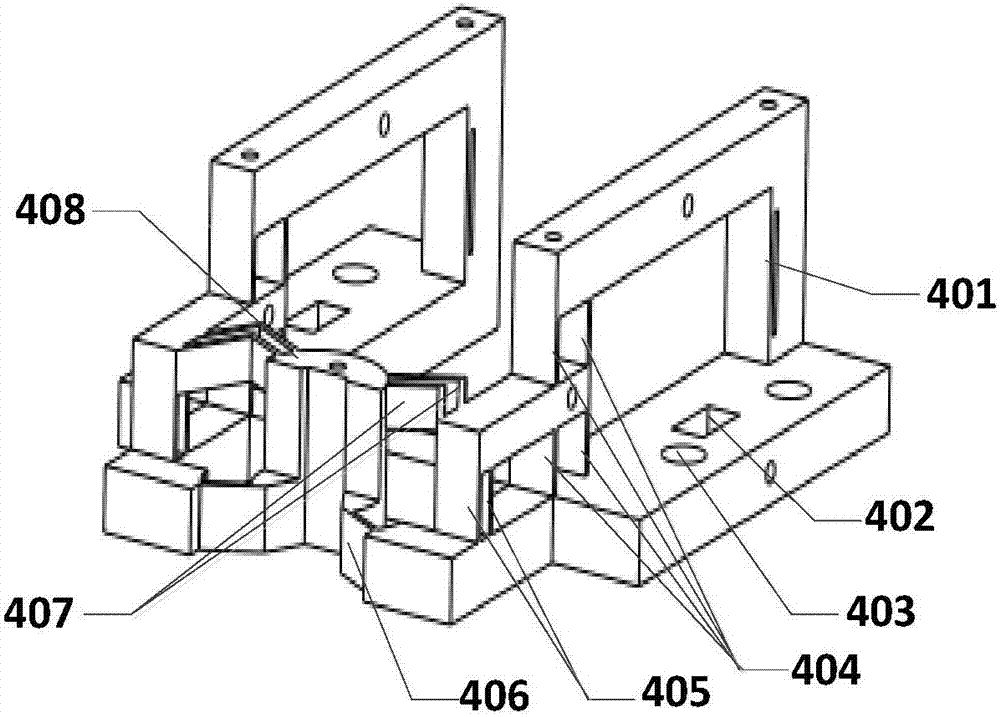

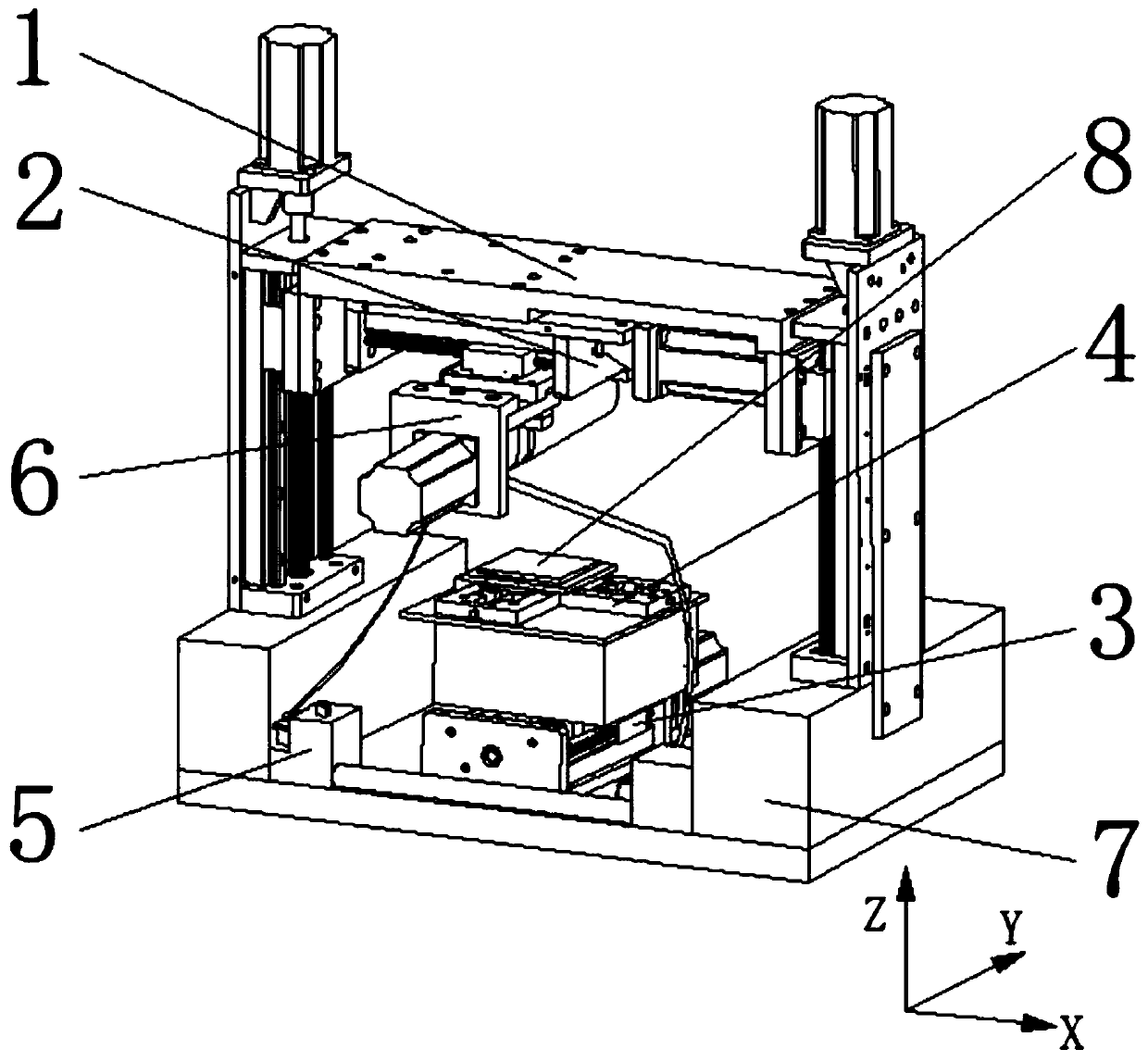

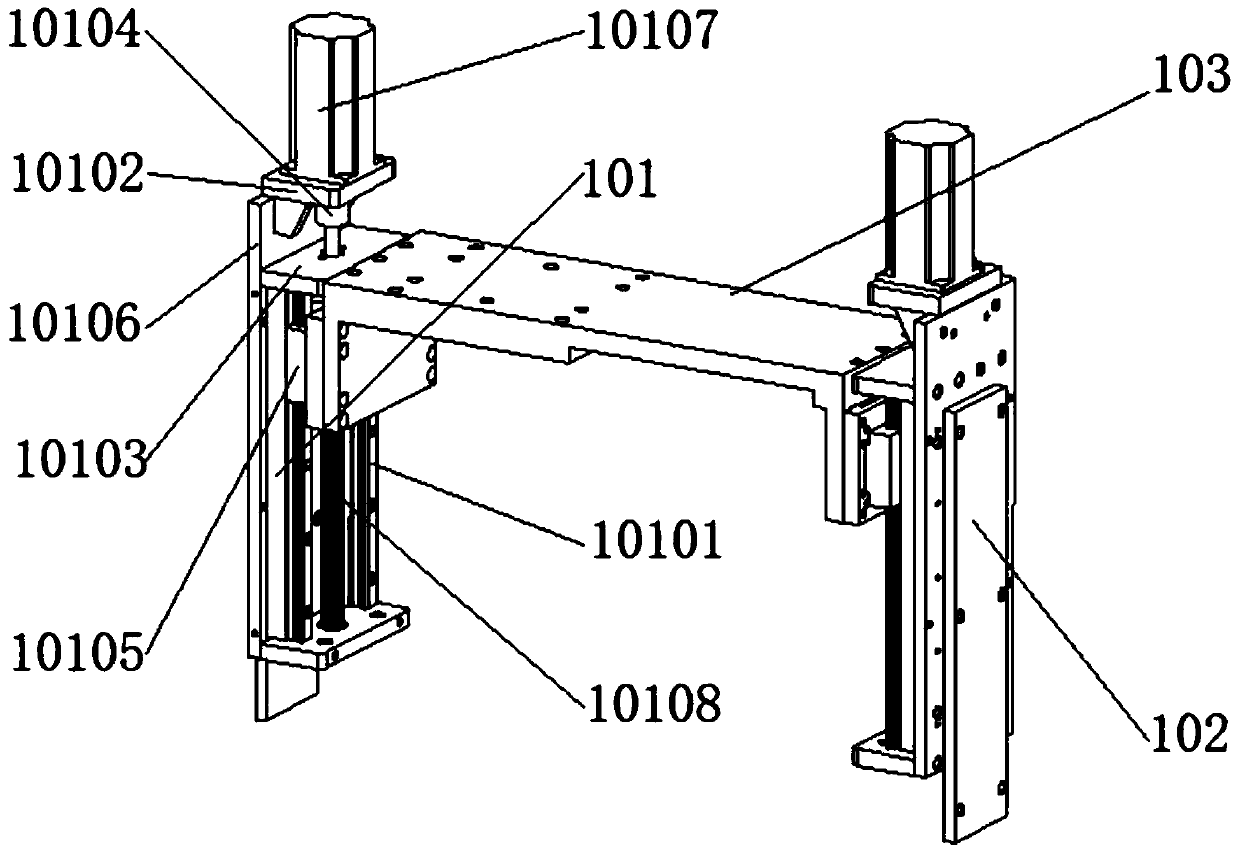

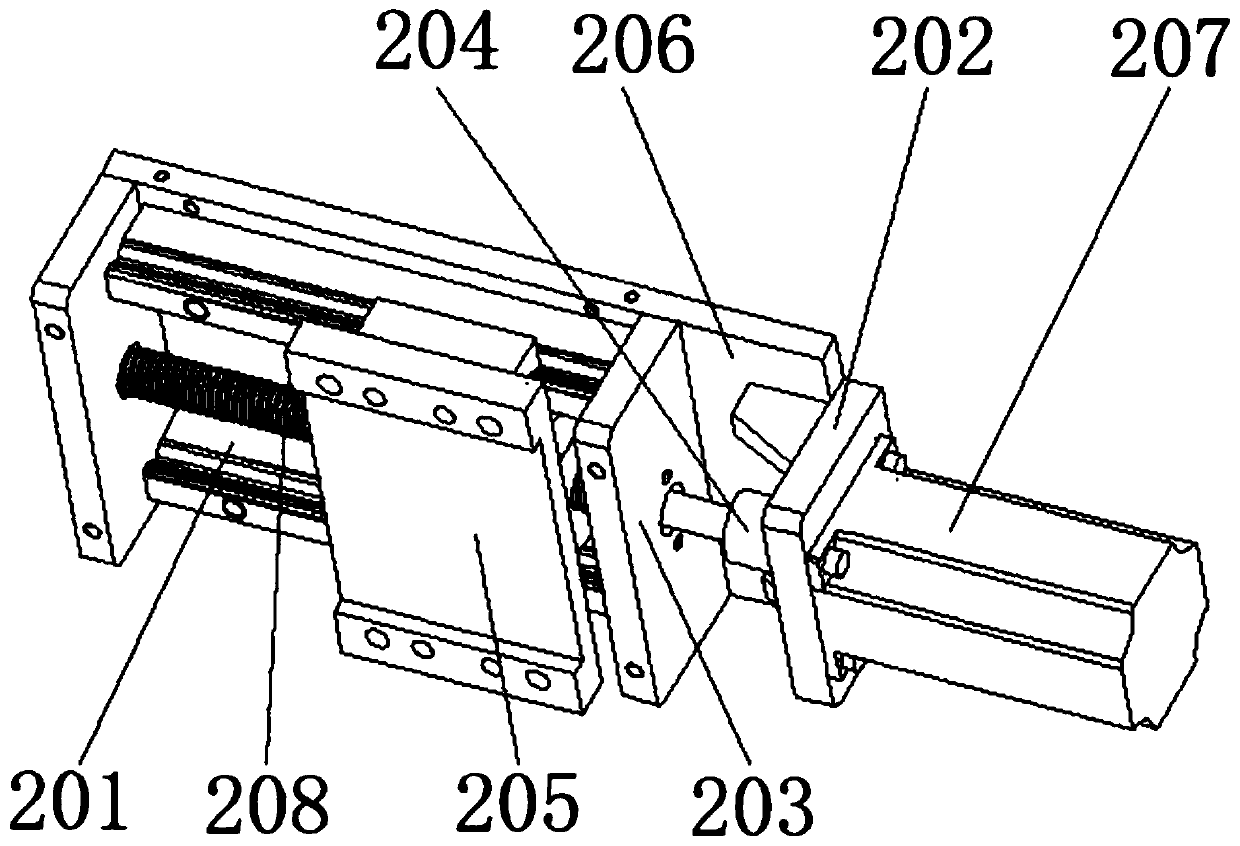

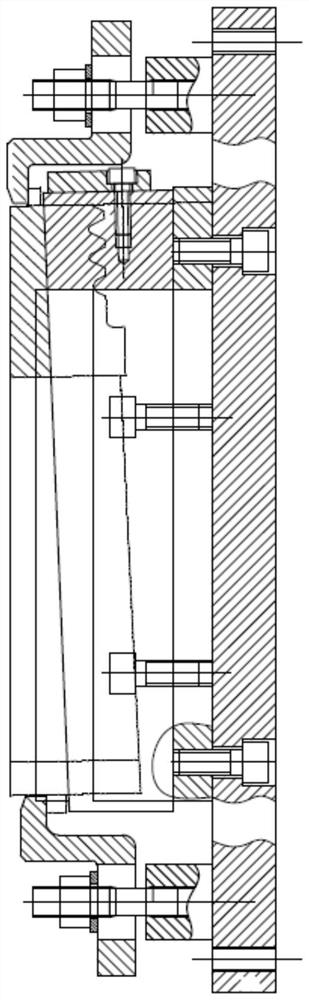

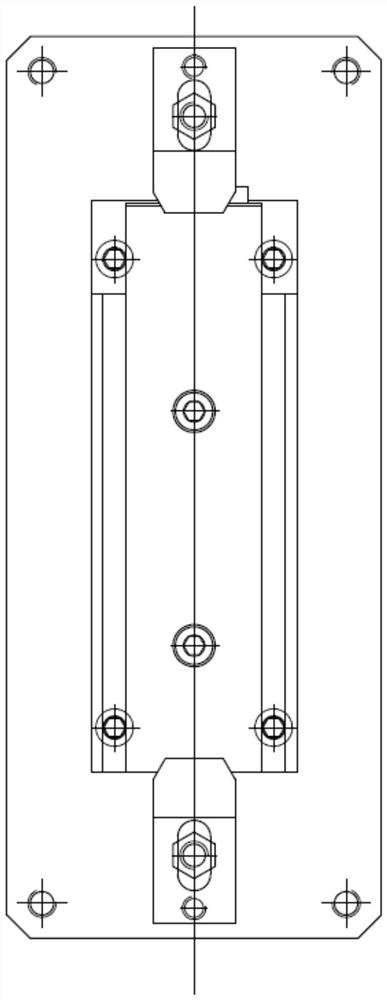

Parallel driving vibration-assisted rotary turning device and method

ActiveCN107414095AGood elasticityEffective exerciseAuxillary equipmentTurning machinesCapacitanceElectricity

The invention discloses a parallel driving vibration-assisted rotary turning device and method. The device comprises a flexible device platform, a first piezoelectric stack and a second piezoelectric stack. The first piezoelectric stack is installed on the flexible device platform through a first piezoelectric stack pre-tightening screw, and the second piezoelectric stack is installed on the flexible device platform through a second piezoelectric stack pre-tightening screw. A first capacitance displacement measurement baffle and a second capacitance displacement measurement baffle are connected with the flexible device platform through fastening screws correspondingly. A first capacitance displacement sensor and a second capacitance displacement sensor are correspondingly installed on a first capacitance displacement sensor clamping seat and a second capacitance displacement sensor clamping seat. By means of the parallel driving vibration-assisted auxiliary turning device and method, L-shaped straight panel flexible hinges are adopted, and therefore the beneficial effects that the structure is novel, flexibility is good, symmetric distribution is formed, the precision of micro-displacement movement is easy to control, and the rotation track in a tool movement platform space of the device is easy to control are achieved.

Owner:CHANGCHUN UNIV OF TECH

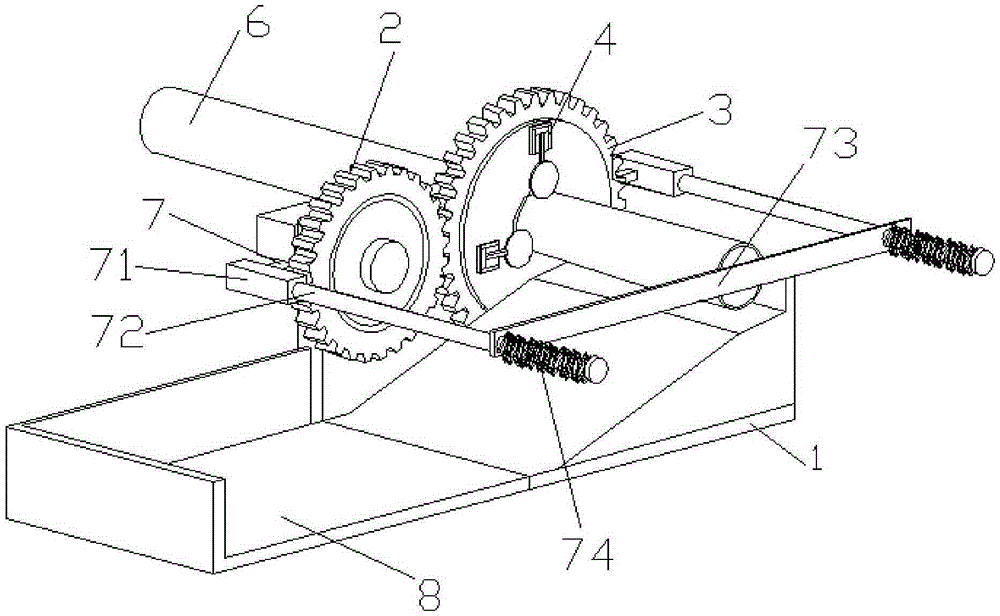

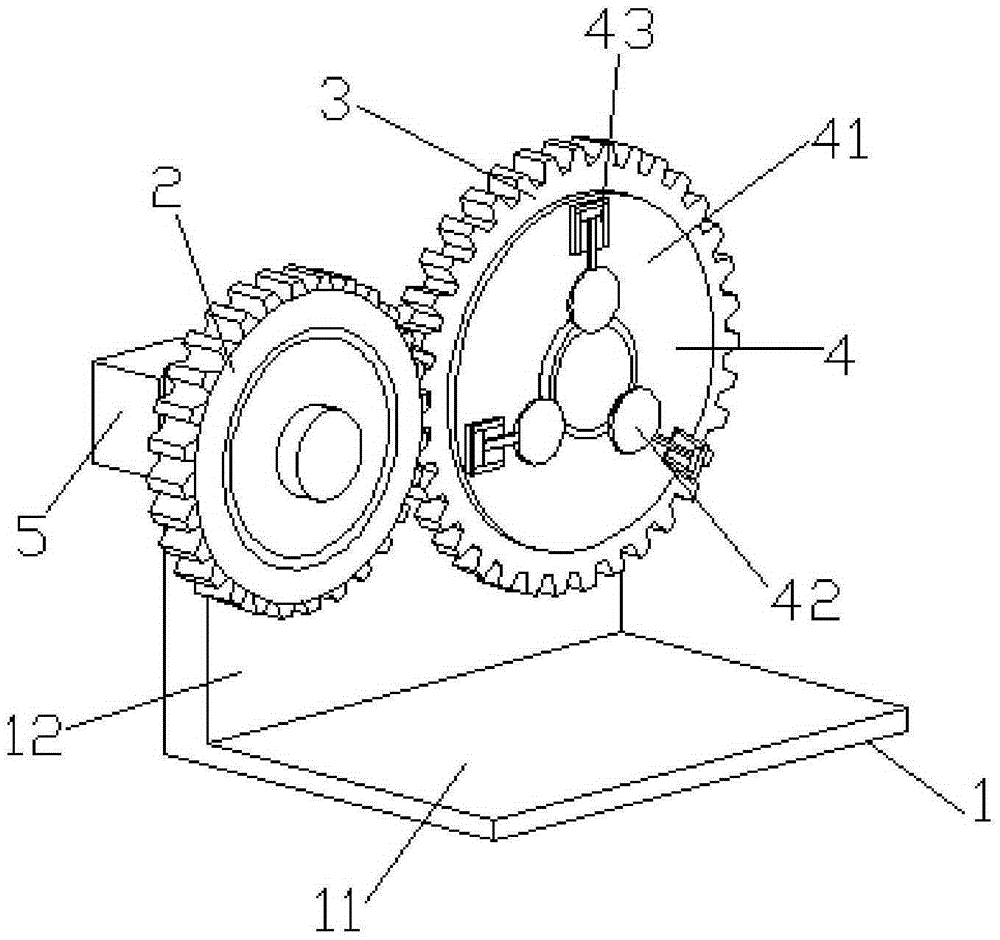

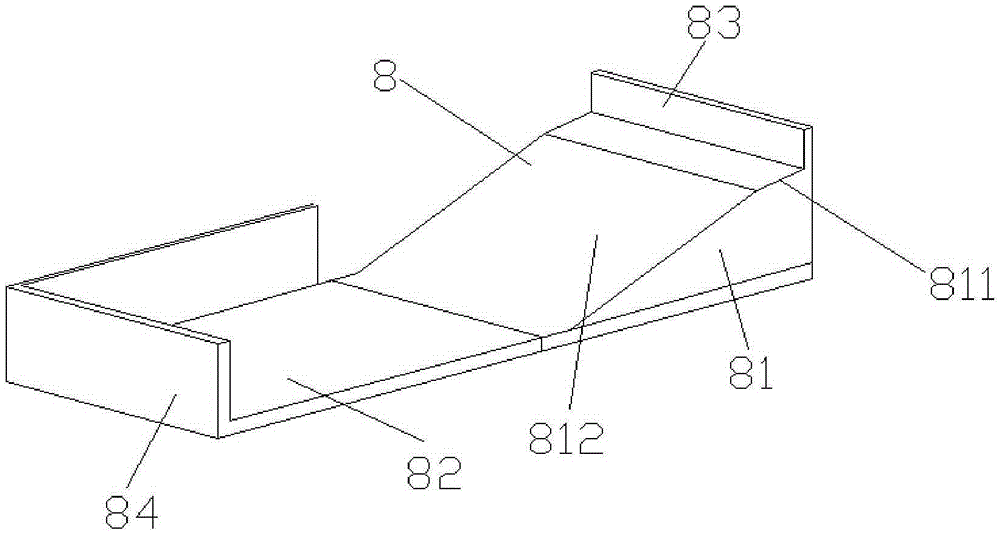

Pipe machining equipment

InactiveCN105414648AShorten the timeIncrease production capacityTube shearing machinesShearing machine accessoriesCutting forceEngineering

The invention provides pipe machining equipment. The pipe machining equipment comprises a fixing seat, a small gear, a big gear, a cutting assembly, a motor, measuring components and a collecting table, wherein the fixing seat comprises a baseplate and a side plate which are perpendicular to each other; the small gear is connected with one end of the side plate; the big gear is connected with the other end of the side plate; the cutting assembly is fixedly connected onto the gear in a parallel manner, coaxially arranged with the big gear, and comprises a plurality of cutters; the cutters are uniformly distributed on the outer circumference of a to-be-machined steel pipe, and in contact with the to-be-machined steel pipe; the measuring components are respectively arranged on two sides of the to-be-machined steel pipe; the collecting table is arranged below the to-be-machined steel pipe. The pipe machining equipment has the benefits that through arrangement of the cutters, the steel pipe cutting efficiency can be further improved when the uniform cutting force is guaranteed, so as to save time, improve the production efficiency, and achieve a more ideal cutting effect.

Owner:TIANJIN HUAYOU PETRO CHEM ENG CO LTD

Two-edge pressure-type end mill

ActiveCN104191020AUniform distribution of cutting edgesEvenly distributedMilling cuttersMilling cutterSinistral and dextral

The invention relates to the technical field of a cutter for cutting machining, in particular to a two-edge pressure-type end mill. The two-edge pressure-type end mill comprises a cutter handle and an edge part which is arranged on the front end of the cutter handle, wherein the edge part is formed by a plurality of sections of spiral structures which are identical in structure and are connected with one another from front to rear, each spiral structure is formed by screwing a left-handed edge body and a right-handed edge body relative to the same axis for half circle, a plurality of spiral scale backs are uniformly arranged on the back surface of each spiral cutter body, a seamed edge of each spiral cutter body and a seamed edge of each scale back are respectively provided with a cutting edge, a spiral cutter withdrawing groove is formed between the two spiral cutter bodies, the seamed-edge side edges of all the spiral cutter bodies form a spiral cutting edge of the two-edge pressure-type end mill, and the front end edges, on the front end of the edge part, of the spiral cutter bodies are intersected to form a mill end edge. The two-edge pressure-type end mill is specially used for cutting a composite material, is free of layering, burrs and the like in the machining process, and is high in machining quality.

Owner:CHANGZHOU CHUANGWEI TOOL MFG

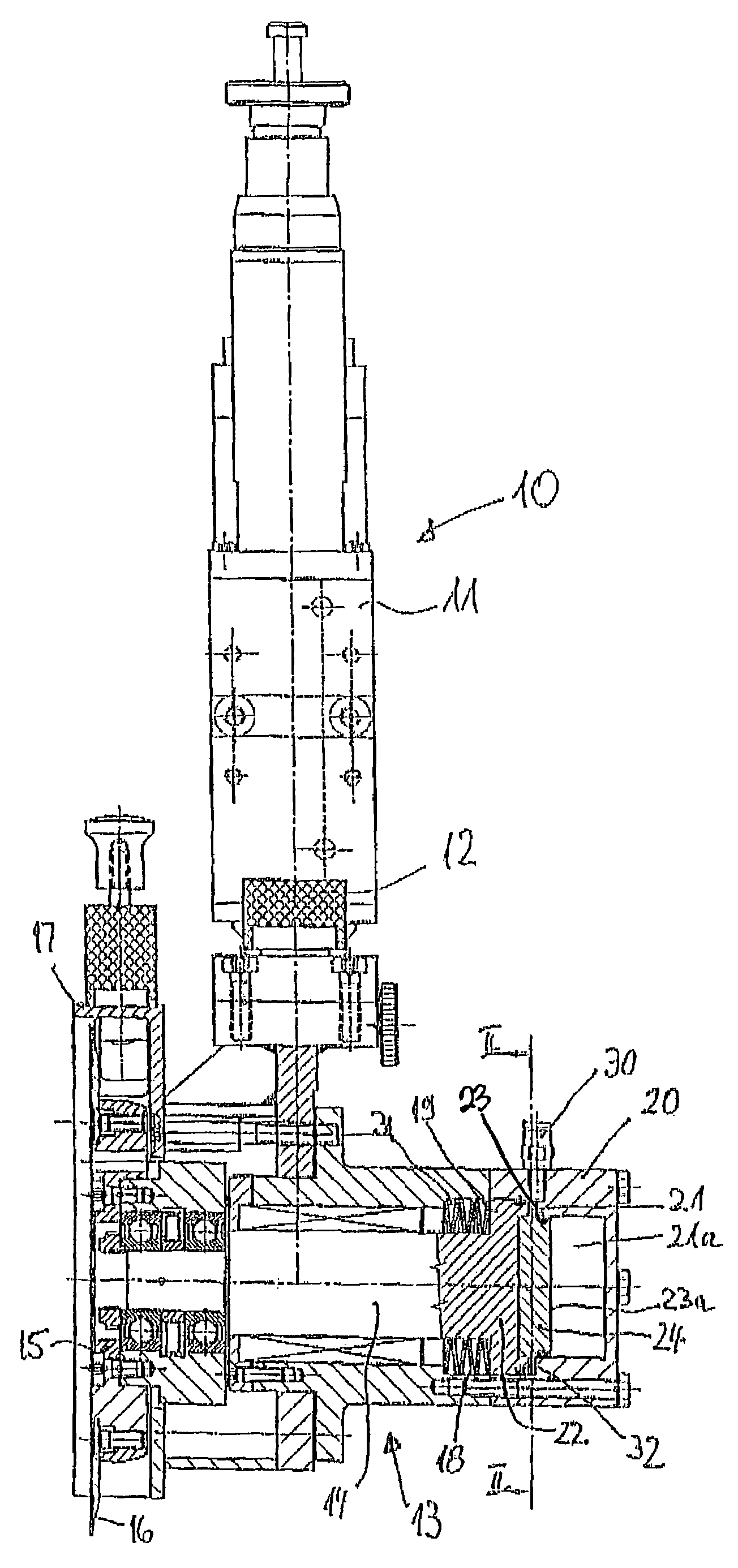

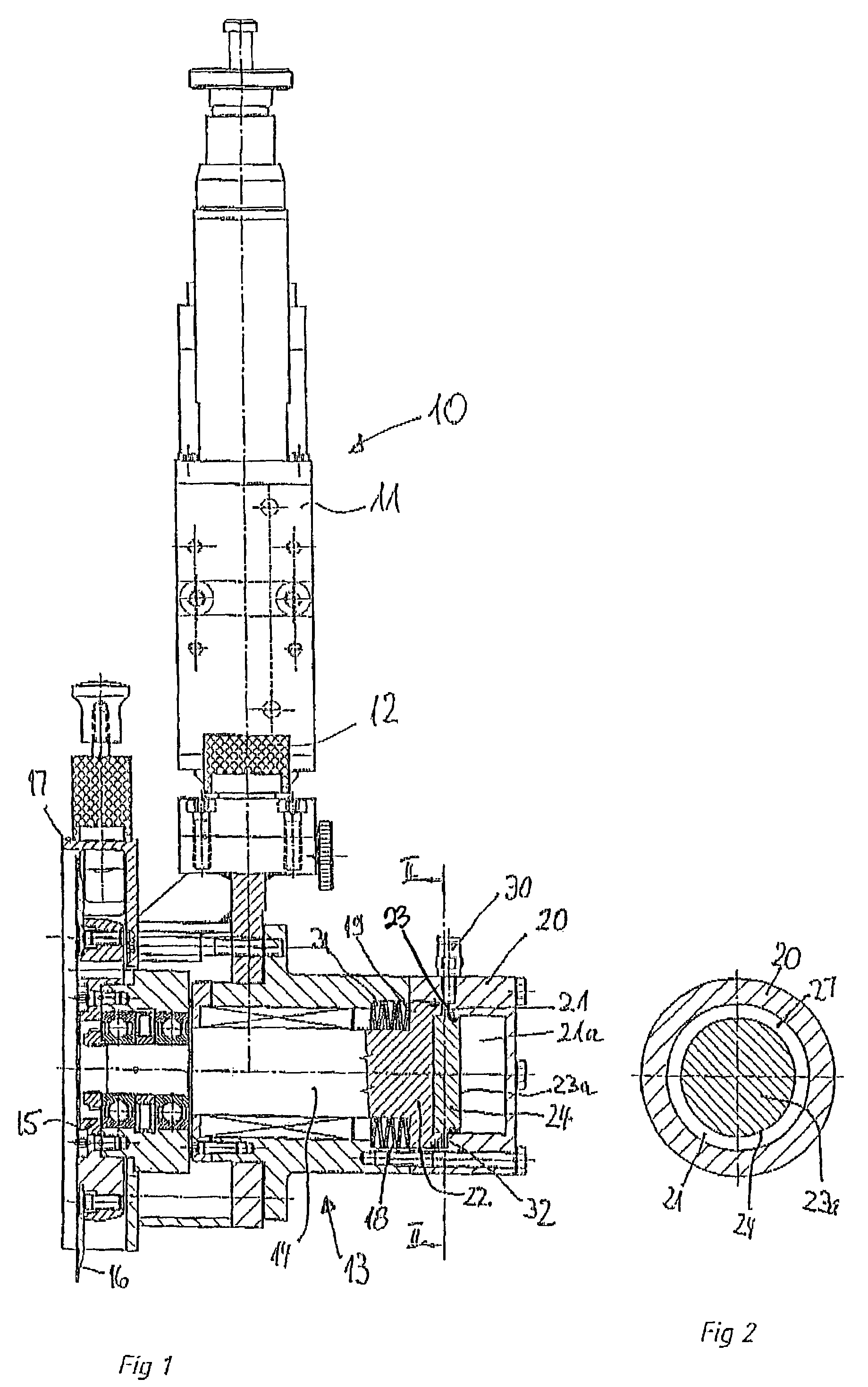

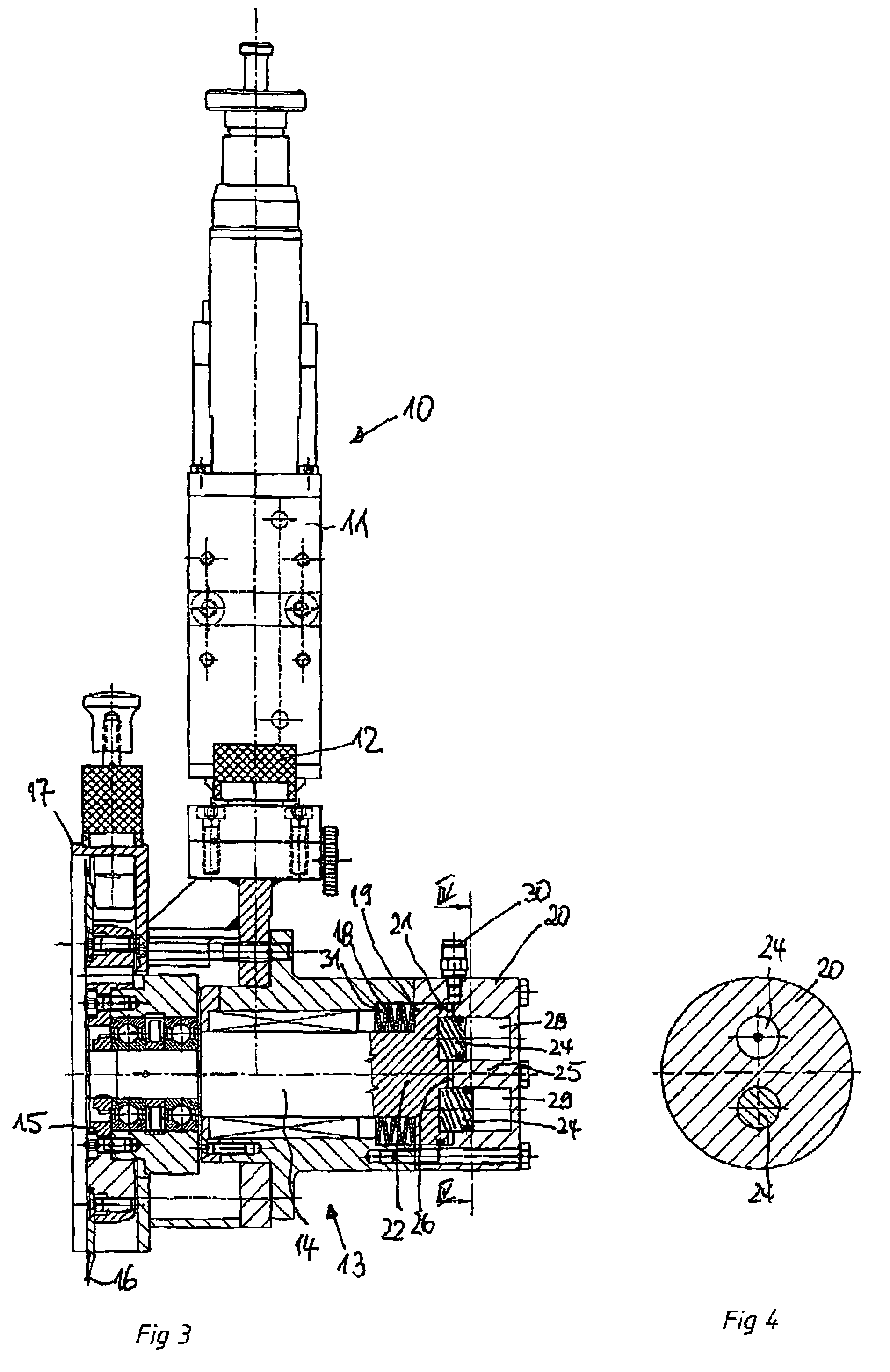

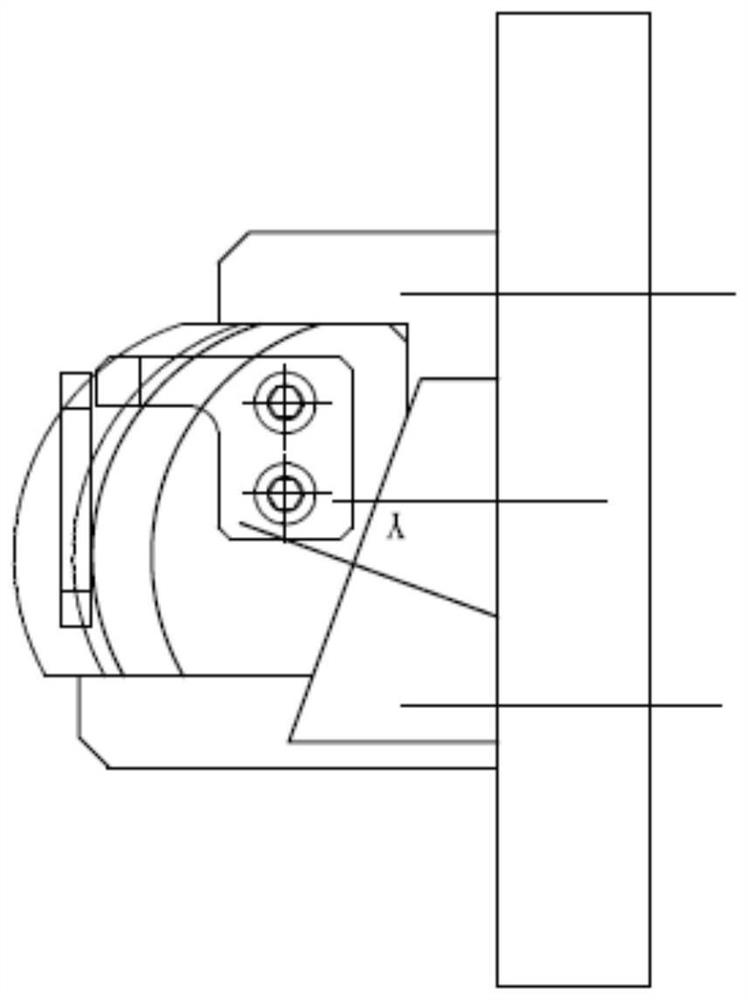

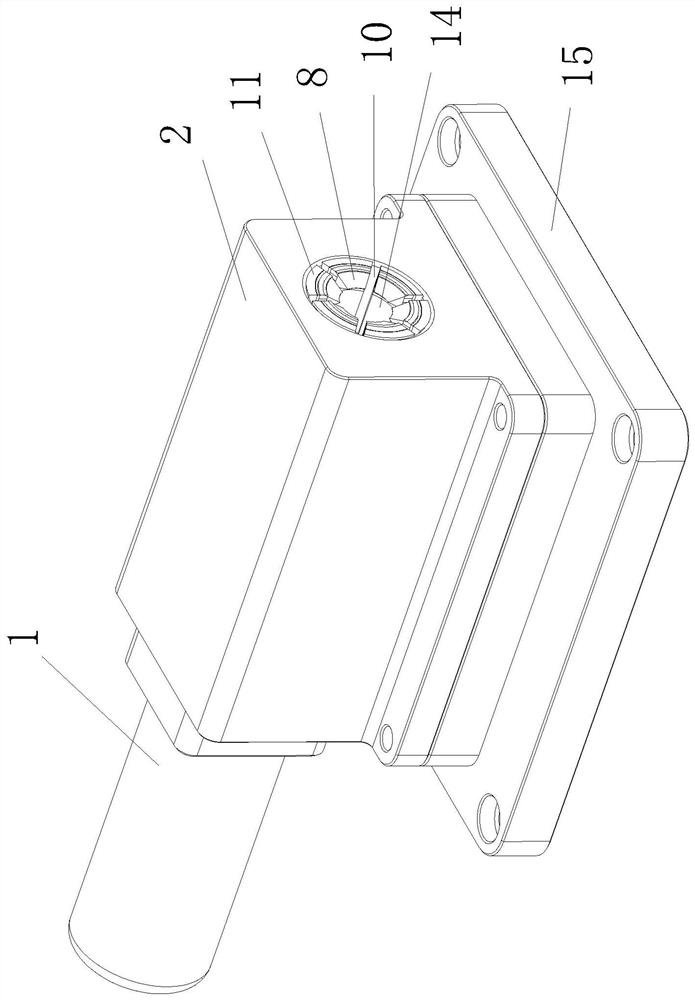

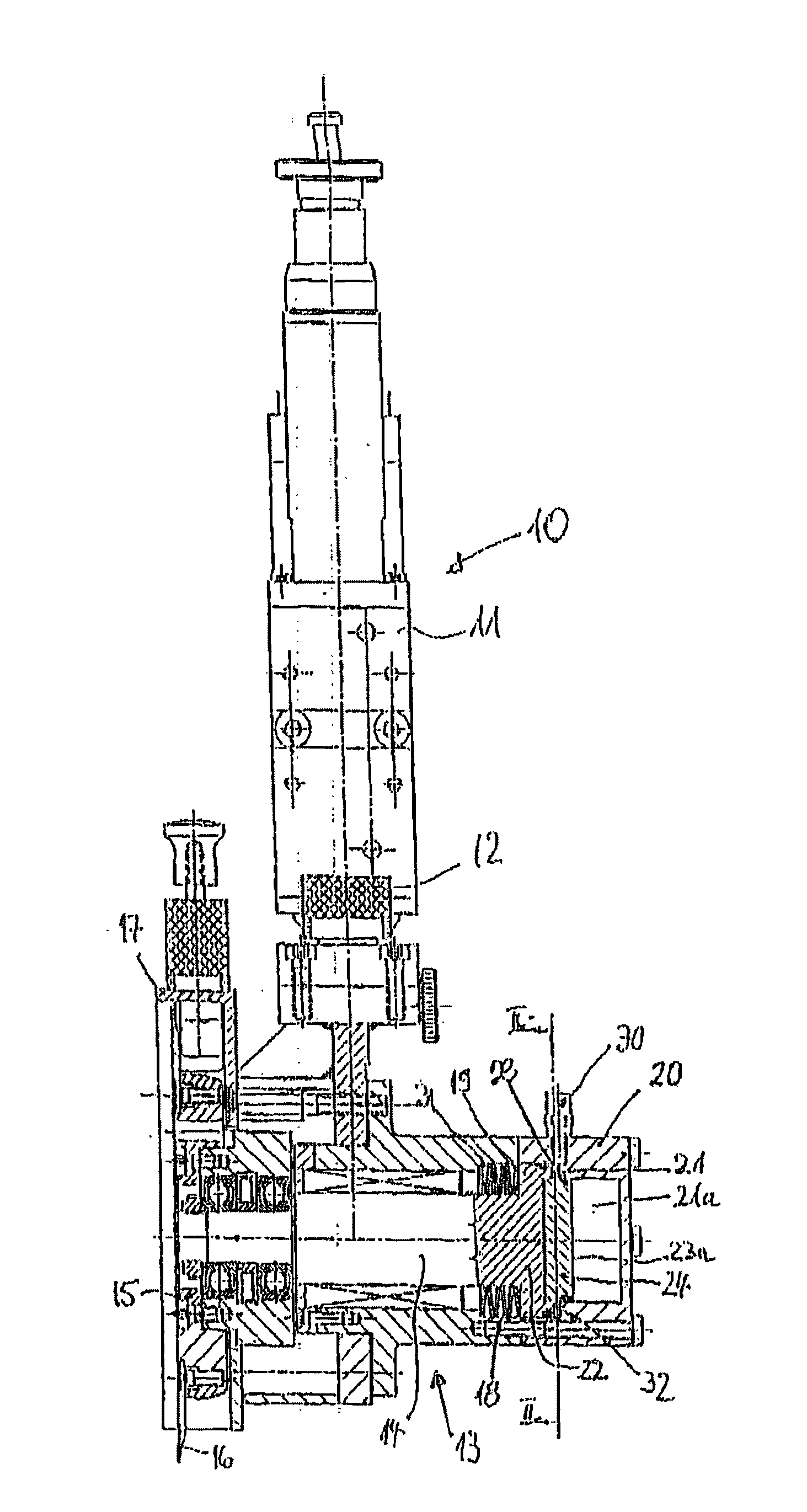

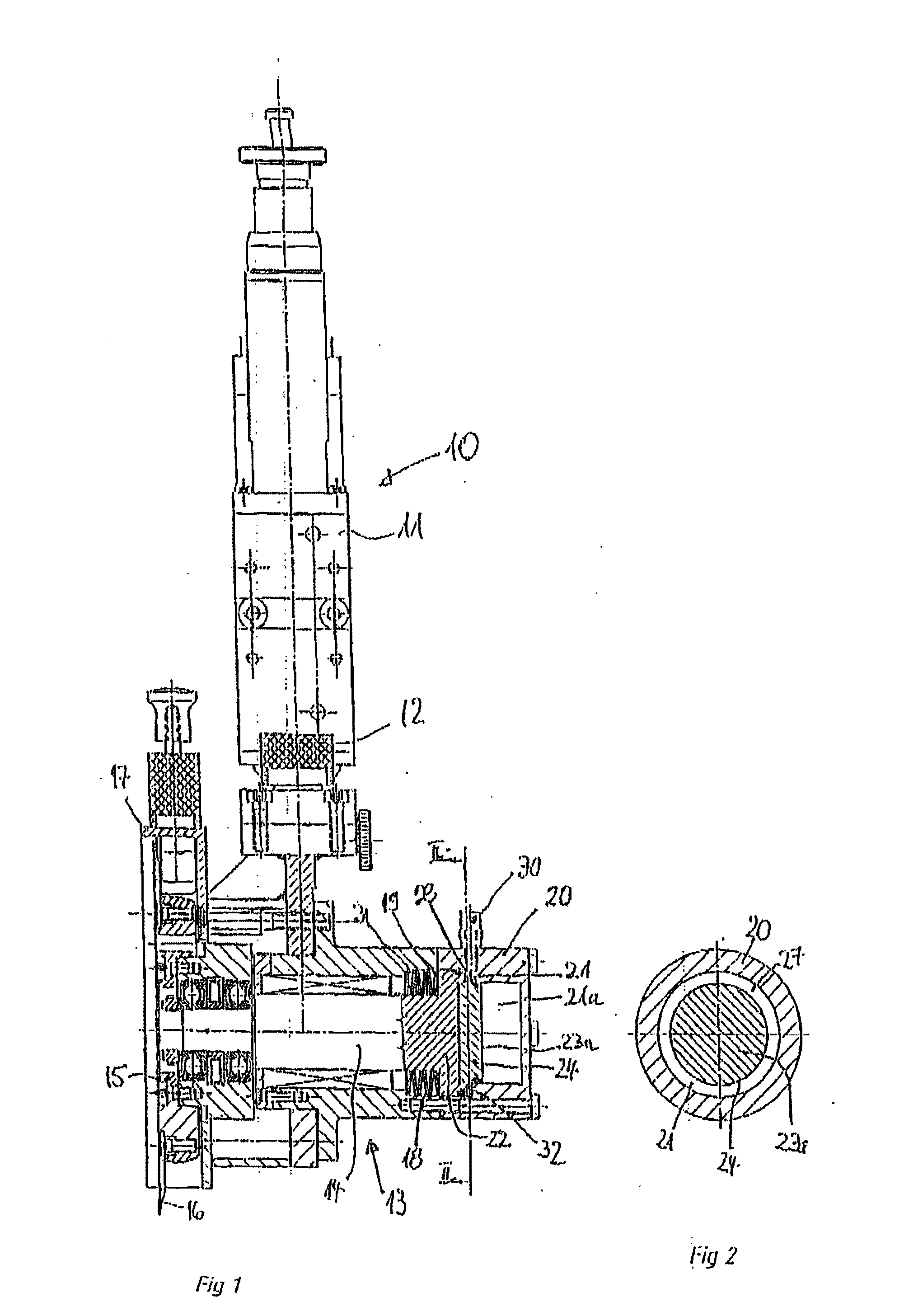

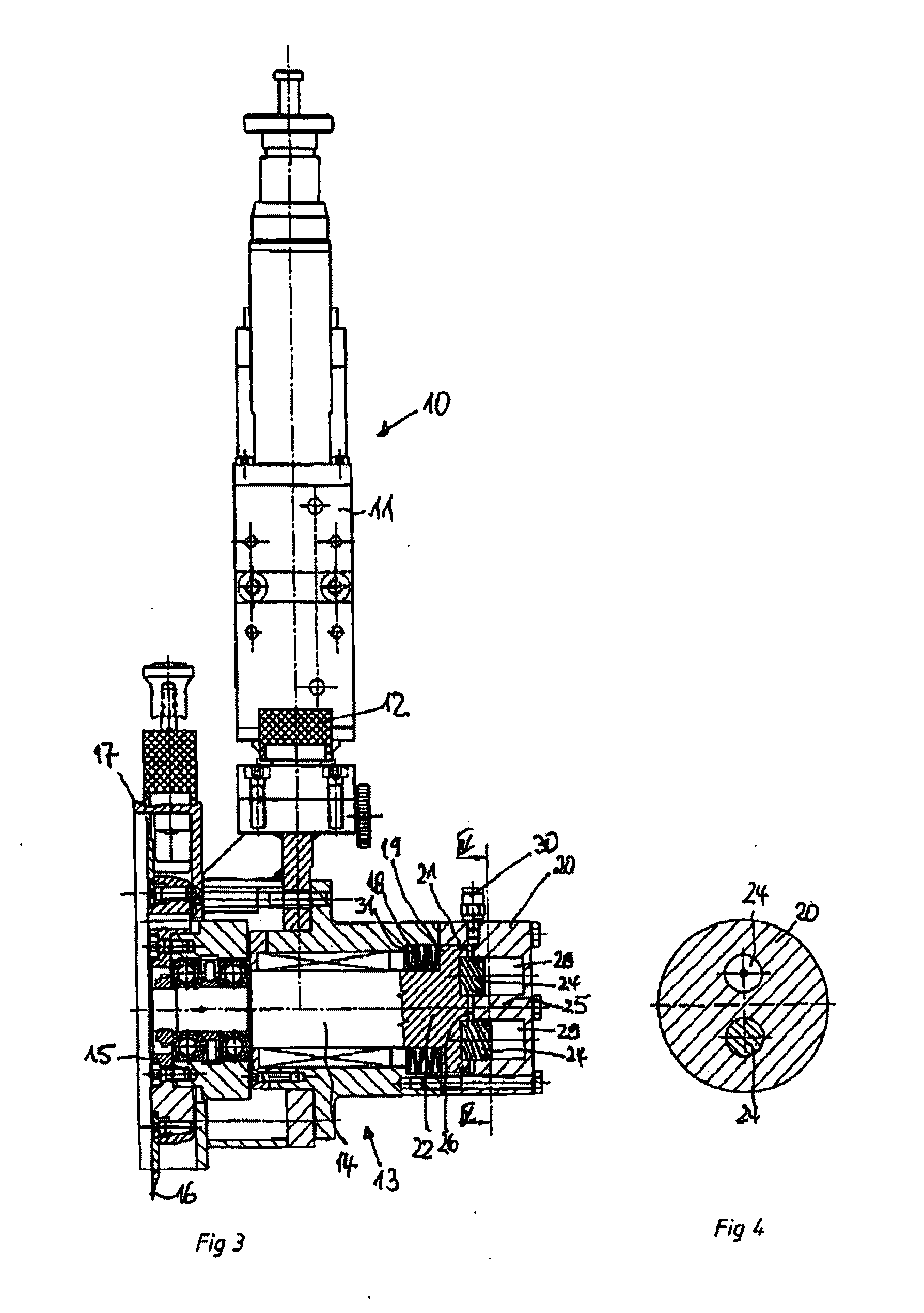

Blade holder having displacement-dependent spring force compensation

ActiveUS7284468B2Fine surfaceGreat spring forceServomotor componentsServomotorsSpring forceEngineering

A blade holder for cutting machines includes a blade head held on a raising and lowering device and an adjustment mechanism for a circular blade that is held on the blade head. The adjustment mechanism, for the movement of the circular blade between a cutting position and a ready position, is provided with an adjustment piston rod having an adjustment piston that is guided in a chamber of the blade head housing and can be moved by compressed air. The adjustment piston rod is biased by a compression spring into the ready position of the circular blade. The piston surface of the adjustment piston has a cross-sectional area that is configured such that as the path of the adjustment piston in the direction of adjustment increases, the piston surface that is acted upon by compressed air increases.

Owner:DIENES WERKE FUER MASCHTEILE

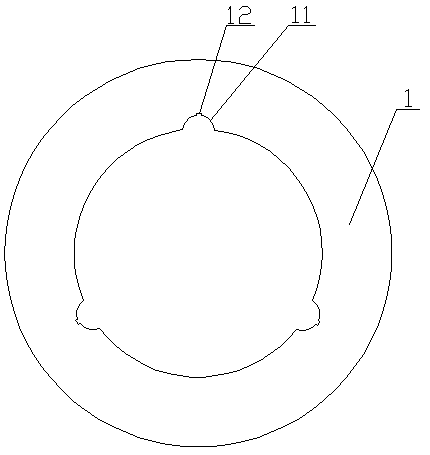

Machining technology of nylon gear

ActiveCN111231342AAvoid internal heat stressAffects internal structural strengthGear wheelsHobbingEngineering

The invention relates to a machining technology of a nylon gear. The nylon gear comprises a metal shaft and a nylon ring arranged on the outer portion of the metal shaft in a sleeving manner. The machining technology comprises the specific steps of A manufacturing the nylon ring, B conducting press fitting, C locating a dedicated hobbing device, D conducting hobbing on the nylon ring and E removing burrs. The machining technology of the nylon gear has the following advantages that a traditional process of conducting hobbing on the nylon ring firstly and then conducting press fitting is changed, and it is avoided that pressure stress and cutting force generated during hobbing cause deformation in the nylon ring and then influence follow-up press fitting; by the adoption of the process of conducting press fitting firstly and then conduct hobbing, press fitting is facilitated, and the internal strength of the nylon gear is guaranteed at the same time; during press fitting, a heating pressfitting manner is changed, so that it is avoided that thermal stress is generated in the nylon ring; and by forming a stress release groove, when the metal shaft vertically penetrates through the nylon ring, the stress in the nylon ring is effectively released, and it is avoided that stress concentration influences the internal structural strength of the nylon gear.

Owner:NANTONG ZHONGLV GEAR CO LTD

Vibration auxiliary roller type magnetorheological polishing device and method

PendingCN110238712AImprove distributionEvenly distributedGrinding drivesGrinding work supportsMagnetic currentMagnetorheological fluid

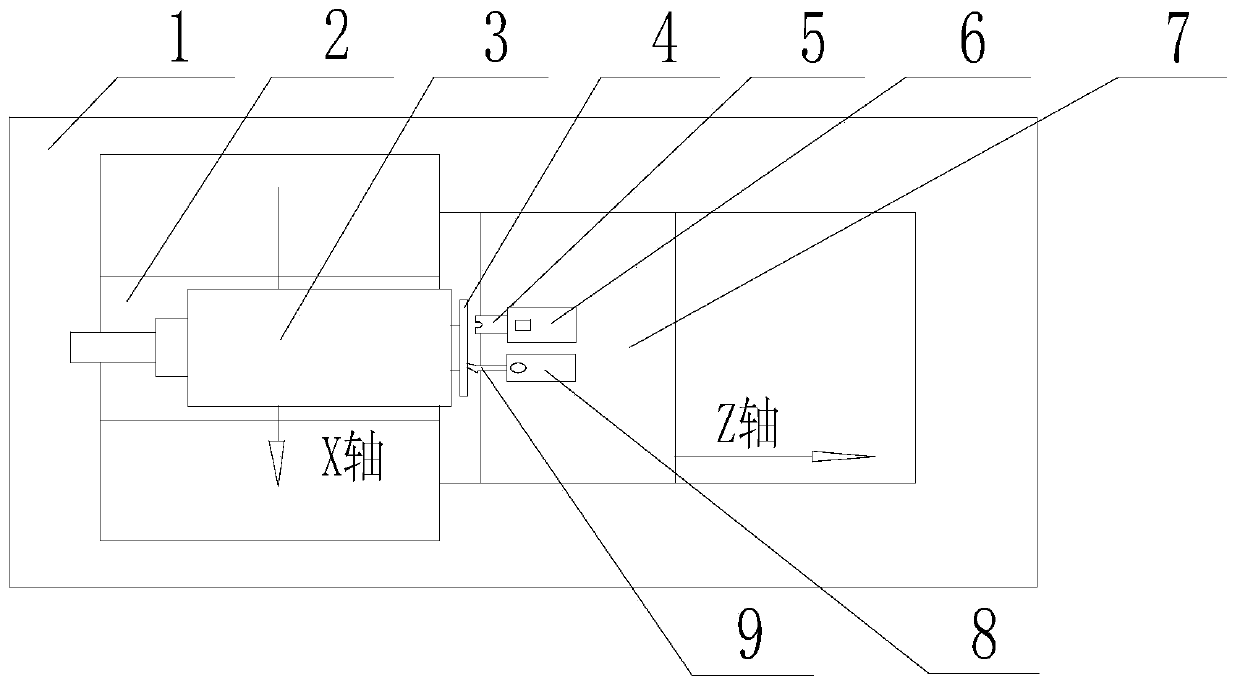

The invention relates to a vibration auxiliary roller type magnetorheological polishing device and method, and belongs to the field of ultra-precision machining. A Z-axis motion system is connected with a base platform by screws, and an X-axis motion mechanism is connected with the Z-axis motion system by screws; a Y-axis motion mechanism is connected with the base platform by screws, and an XY-axis vibration device is connected with a cushion block of the Y-axis motion mechanism by screws; and a polishing mechanism is connected with the X-axis motion mechanism by screws, and a magnetorheological fluid circulation system is connected with the polishing mechanism by screws. The magnetorheological polishing device has the advantages that the distribution of abrasive particles is more uniform, and the direction of polishing force can be changed through vibration, so that the distribution of the polishing force is more uniform; new scratches are avoided while scratches of the last working procedure are removed, so that the polishing accuracy is improved; the utilization rate of magnetorheological polishing fluid is improved, and the cost is saved; and heat dissipation is benefited.

Owner:CHANGCHUN UNIV OF TECH

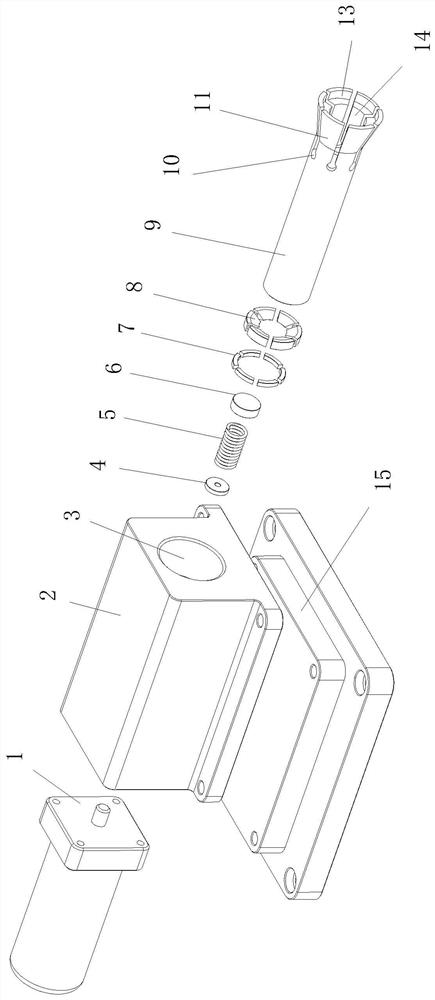

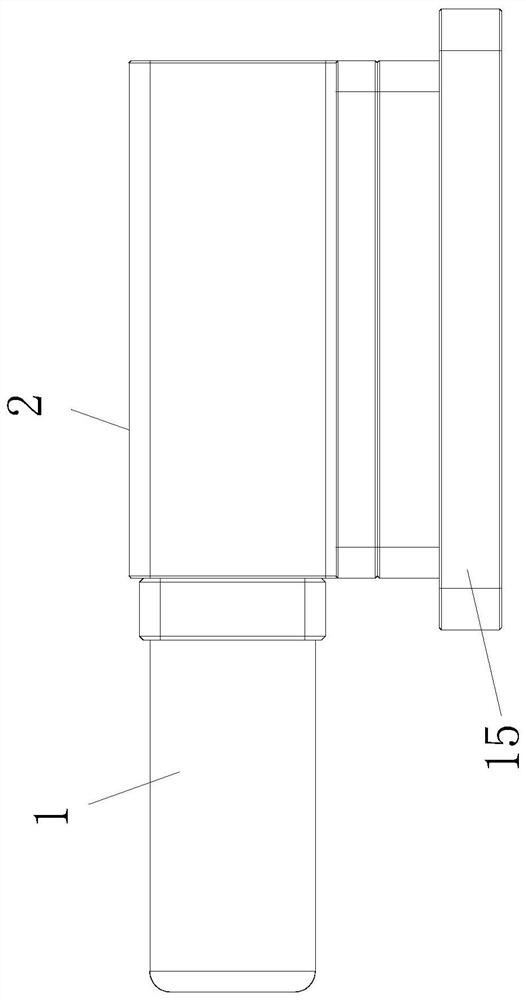

Rapid cap cutting device and method for semiconductor laser tube cap

ActiveCN111195750AEffective protectionWill not cause bending and closing phenomenonPositioning apparatusMetal-working holdersEngineeringErbium lasers

A rapid cap cutting device for a semiconductor laser tube cap comprises a base, N fixing seats, a fixing seat driving mechanism, a laser fixing plate and a cutting knife. The laser fixing plate can beinstalled in place after being inserted on a guide rod through a guide hole I, tube legs of lasers are inserted into corresponding insertion holes in the fixing seats, the fixing seat driving mechanism drives each fixing seat to rotate, rotation of each laser is achieved, the cutting knife is pressed downwards, a cutting edge below the cutting knife is in contact with the corresponding tube cap,and the rotating tube cap is cut off by the cutting edge. The tube legs are inserted into the insertion holes, so that the tube legs can be effectively protected, and the tube legs cannot be bent andfolded. When the tube cap is cut, the cutting force on the tube cap is uniform, the end face of the cut tube cap is tidy, deformation of the tube cap during cutting can not occur, damage to the insides of the lasers can not occur, and the product quality of cap cutting is improved.

Owner:潍坊华光光电子有限公司

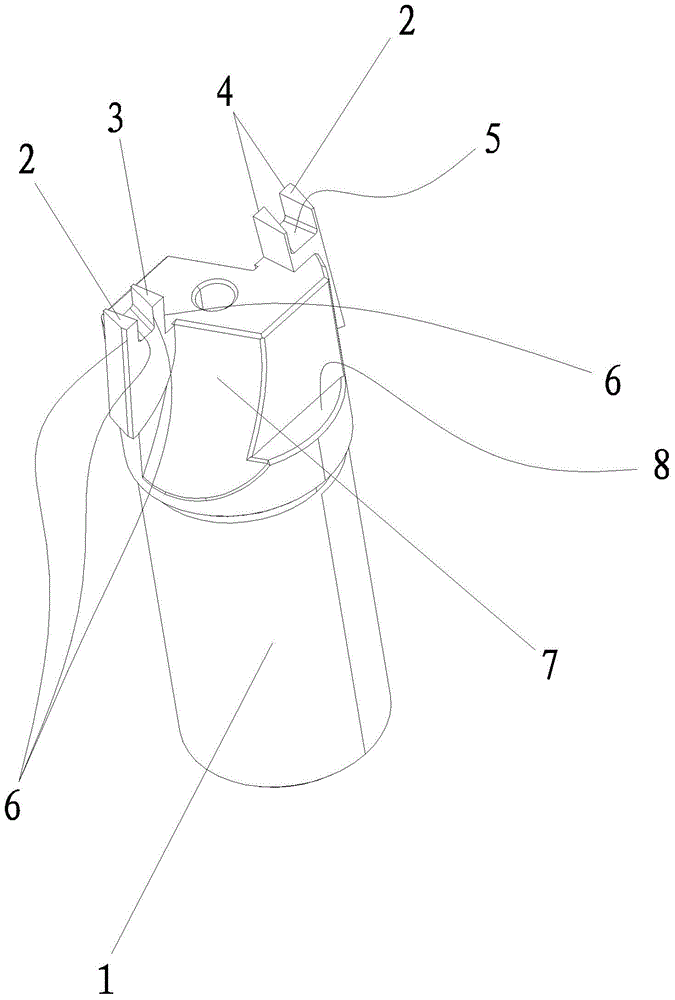

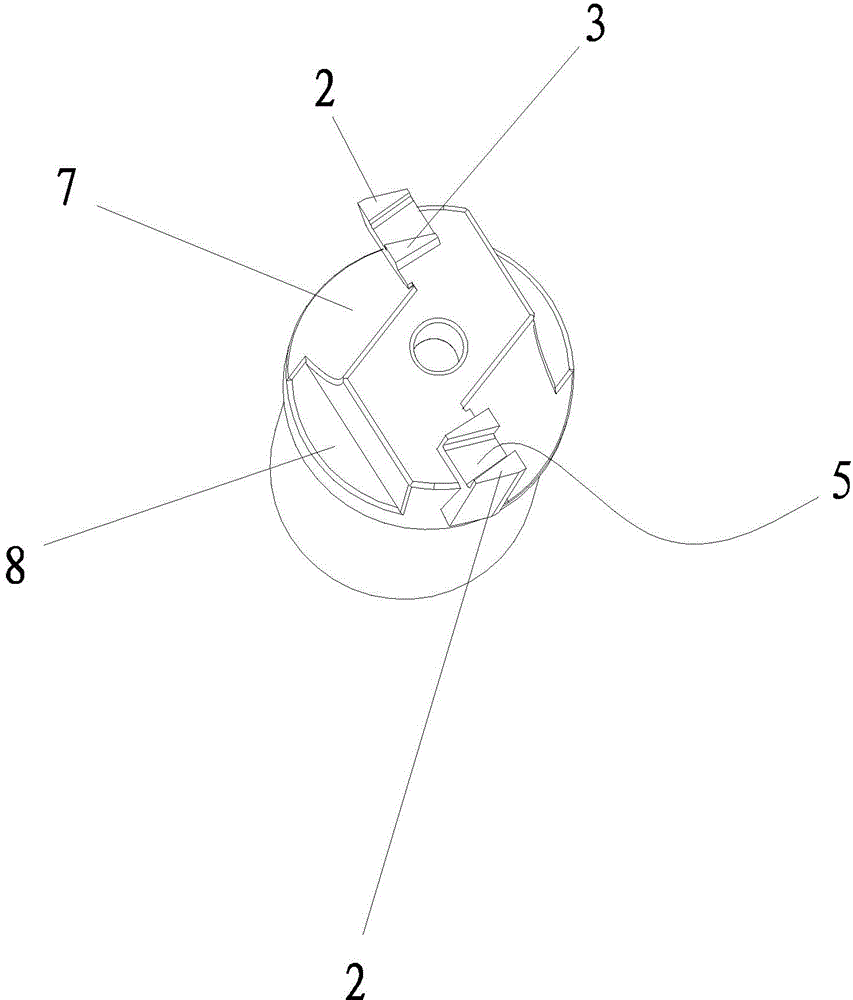

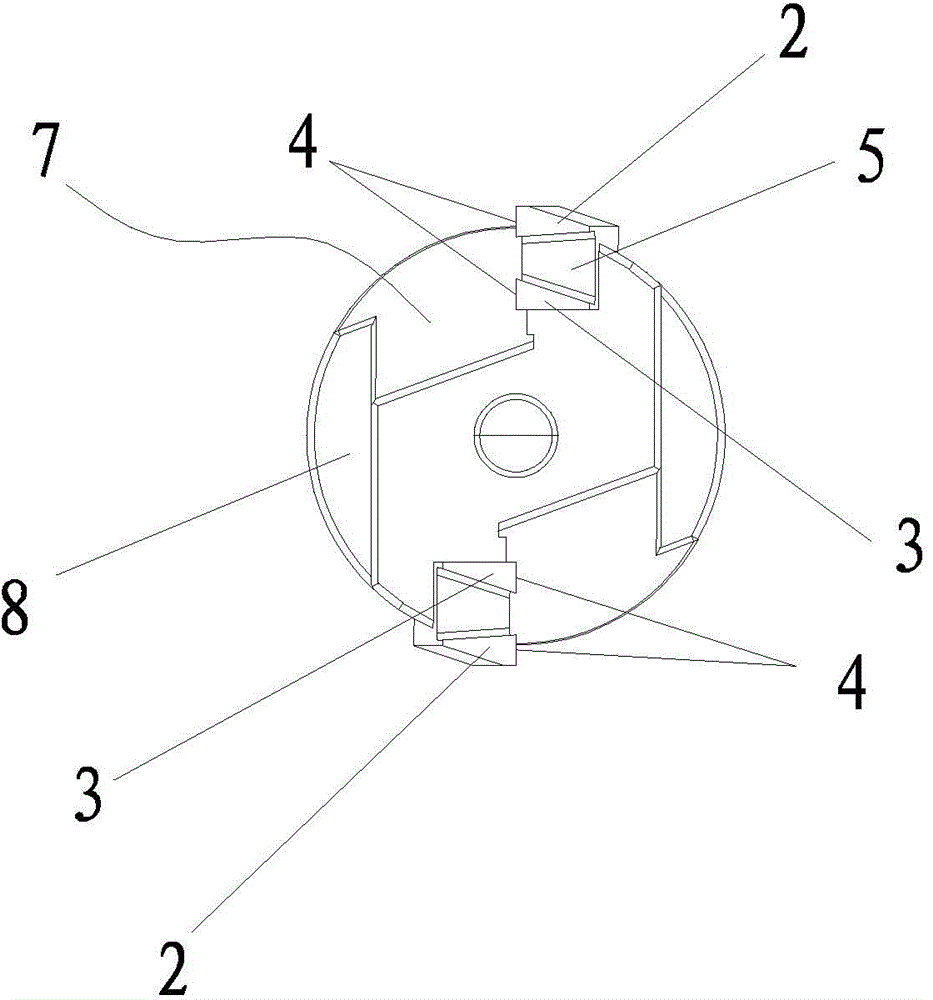

Cutter for razor nets of razors

InactiveCN104096870AImprove cutting accuracyGuaranteed synchronicityTurning toolsEngineeringMachining

The invention discloses a cutter for razor nets of razors. The cutter comprises a cutter bit holder, outer cutter bits and inner cutter bits. The outer cutter bits are used for cutting outer circular grooves, the inner cutter bits are used for cutting inner circular grooves, the outer cutter bits and the inner cutter bits are positioned at the same end of the cutter bit holder, main cutting edges are arranged on the outer cutter bits and the inner cutter bits, radial gaps are formed among the outer cutter bits and the inner cutter bits, and lateral blades are further arranged on the outer cutter bits and the inner cutter bits. The cutter has the advantages that the razor nets can be machined by the aid of the cutter and a machining and lathe turning method, and two circular grooves in each razor net can be simultaneously machined; the synchronism of each two corresponding cutter bits can be guaranteed owing to the fact that the two cutter bits are positioned on the same cutter bit holder; the lateral blades are used for scraping the side walls of the grooves while the grooves are cut, accordingly, follow-up machining can be omitted after the grooves are completely cut, the cutter is favorable for improving the groove cutting precision, and the machining efficiency can be obviously improved.

Owner:NINGBO ZHENHE ELECTRICAL EQUIP

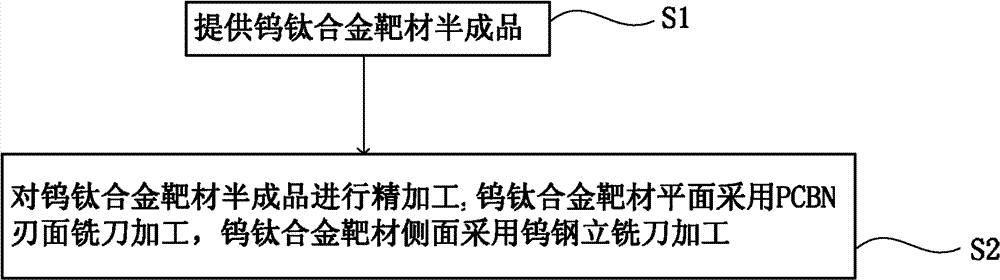

Machining method for milling tungsten alloy target material

ActiveCN102145403BUniform cutting forceAvoid cornersMilling equipment detailsMilling cutterBoron nitride

The invention discloses a machining method for a tungsten alloy target material, which comprises the steps of providing a semi-finished product of the tungsten alloy target material and carrying out finish machining on the semi-finished product of the tungsten alloy target material, wherein in the finish machining step, the plane of the tungsten alloy target material is machined by a PCBN (Polycrystalline Cubic Boron Nitride) face mill, and the side face of the tungsten alloy target material is machined by a tungsten steel end mill. By adopting the machining method for the tungsten alloy target material provided by the invention, the arris defect in the machining process is avoided, the machining of the tungsten alloy target material with complex curved surface can be realized, and the problems of long machining cycle and low production efficiency are solved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Ultra-precision machining method of cerium lanthanum alloy

The invention discloses an ultra-precision machining method of cerium-lanthanum alloy. The method comprises the following steps of, (1) Carrying out nanocrystallization treatment on the surface of thecerium lanthanum alloy : a nozzle is utilized to impact the surface of cerium-lanthanum alloy by cavitation jet bubbles, generating plastic deformation of the crystal, and realizing crystal pulverization on the surface of the material to nano-scale; and (2) Carrying out trace cutting on the surface of the cerium-lanthanum alloy subjected to nanocrystallization treatment on the surface by adoptinga single-point diamond machining tool and a machining process. According to the method disclosed by the invention, the processing stability of the cerium-lanthanum alloy can be improved; meanwhile, spontaneous combustion is inhibited, and the surface and sub-surface damage generated when the cerium-lanthanum alloy is subjected to traditional precise cutting is reduced; a compact layer is generated, the oxidation corrosion process is hindered, and the surface cleanness is improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Multi-angle dustproof cutting device used for metal processing

The invention discloses a multi-angle dustproof cutting device used for metal processing. The multi-angle dustproof cutting device includes a worktable, a bracket and a cutting disk. The interior of the worktable is provided with a round disk. The upper portion of the round disk is welded to a cutting table. The middle of the cutting table is provided with a cutting groove. The left side and the right side of the cutting groove are provided with screw rods. The upper portions of the screw rods are provided with pressing plates. The surfaces of the pressing plates are fixedly provided with frosted plates. The upper portions of the pressing plates are provided with rotating handles. The inner side of the bracket is provided with a connecting rod and the bracket is located above the cutting table. The inner side of the connecting rod is provided with an adjusting disk. The inner side of the adjusting disk is provided with a rotary rod. The upper portion of the cutting disk is provided with a dustproof cover. The cutting disk is located between the rotating rods. The left side and the right side of the connecting rod are provided with supporting rods. The upper portions of the supporting rods are welded to connecting blocks. The multi-angle dustproof cutting device used for metal processing can conduct multi-angle cutting, the cutting table can rotate freely, the cutting strength is average, and the service life of a cutter is long.

Owner:徐州尚航船舶配件有限公司

Automatic prepuce girdling device and prepuce girdling method thereof

PendingCN107007332AFree from painEliminate reactivityInstruments for stereotaxic surgeryAnimal scienceMedicine

The invention discloses an automatic prepuce girdling device and a prepuce girdling method thereof. According to the key points in the technical scheme, the automatic prepuce girdling device comprises a prepuce fixed base, a negative pressure adsorption device which is used for adsorbing and locating prepuce tissue on the outer wall of the prepuce fixed base and is connected with the prepuce fixed base, the outer part of the negative pressure adsorption device is connected with a girdling device which is used for girding the prepuce tissue which is located at the outer wall of the prepuce fixed base, and the negative pressure adsorption device comprises multiple air suction holes formed in the prepuce fixed base, a vent channel and an air suction device which is connected with the vent channel. According to the automatic prepuce girdling device and the prepuce girdling method thereof, negative pressure vacuum is adopted to adsorb and locate the prepuce tissue, and an untoward effect of pains and irritation brought by binding and location through a binding belt can be removed.

Owner:何利 +1

Magnetic conversion type tool change drilling method for soft and hard stratums

The invention belongs to the technical field of underground engineering rock and soil body drilling and cutting, and underground engineering disaster prevention and reduction, and provides a magneticconversion type tool change drilling method for soft and hard stratums. When the in-hole tool change operation is carried out, a telescopic controller is used for controlling the retraction of a telescopic rod to drive a magnetic block and a first set of drill bit fixing plates to retract together, when the height of the other set of drill bit fixing plates is reached, the magnetization function ends, and the magnetic block is separated from the first set of drill bit fixing plates; a lifting sliding rod set is controlled to rotate by a certain angle, so that the other set of drill bit fixingplates can be coincided with the axis of the magnetic block in the vertical direction; then the magnetic block is driven to descend; the magnetic block is controlled to be magnetically connected withthe other set of ferromagnetic drill bit fixing plates, and the in-hole replacement of the cutters is completed. Meanwhile, the rapid drilling and cutting construction of the soft and hard stratums can be achieved through variable drilling and cutting, and any stratum rock debris can be quickly discharged through a pump water washing system, the stratum adaptability of the drill holes is improved,and the problem that the hole deviation in drilling in soft and hard stratums is large is solved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Machining method for assembling surface of dehumidifying blade

ActiveCN111805187AGuaranteed finishGuaranteed machining accuracyStructural engineeringMachining process

The invention discloses a machining method for an assembling surface of a dehumidifying blade, belongs to the field of machining methods, and aims to solve the problems that the profile tolerance of ablade profile is poor, a bench worker is required to eliminate a gap during assembly, the gap is reproduced when the end surface of a blade crown is assembled again through a beveling procedure and the welding quality is affected due to high probability of bowing and deformation when two ends are clamped in the machining process of the conventional dehumidifying blade. According to the machiningmethod, the clamping mode of an existing machining method for the assembling face of the dehumidifying blade is changed, the machining technological process is correspondingly changed, the margins oftwo-end technological sections are reserved when a workblank is selected, the two-end technological sections are clamped and machined through a clamp during machining, and therefore the defects of anexisting workpiece two-end clamping mode are effectively overcome. The machining method is mainly used for machining and manufacturing the assembling face of the dehumidifying blade.

Owner:HARBIN TURBINE +1

Large-cutting-depth turning and milling composite rotary blade used under heavy-load condition

InactiveCN112024919AReduce processing costsHigh strengthMilling cuttersCutting insertsMilling cutterMechanical impact

The invention discloses a large-cutting-depth turning and milling composite rotary blade used under a heavy-load condition, belongs to the technical field of heavy machining, and can solve the problems that when a large special-shaped forge piece of a water chamber end cap is subjected to heavy cutting, due to relatively large cutting depth, a cutter is subjected to a dynamically-changed mechanical impact effect, consequently the cutter is stressed unevenly, and therefore phenomena such as abrasion, tipping and breakage are generated; and meanwhile, a large amount of cutting heat is accumulated in a cutting contact area in the cutting process, and the problems such as blade-chip adhesion between the cutter and the cutting chips caused by poor heat dissipation conditions are solved. The cutting edges of the blade are negative chamfered cutting edges; and every two adjacent negative chamfered cutting edges have arc edge transition there-between; cylindrical micro-pit textures arranged triangularly are arranged near an arc edge; the side surface of a square protruding platform at the upper surface of the blade and rake faces form arched chip breaking grooves; a trapezoid-like bump isarranged at the intersection position of the rake faces of the blade; each rake face is provided with a water drop-shaped bump; a major flank and a minor flank of the blade are each provided with a micro-groove texture; and the geometric center of the blade is provided with a fastening screw hole used for being connected with a turning tool bar or a facing cutter. The large-cutting-depth turning and milling composite rotary blade provided by the invention is suitable for turning and milling composite machining which adopts the water chamber end cap as a typical large-size forge piece.

Owner:HARBIN UNIV OF SCI & TECH

Multi-zone freezing type lifting drill-cutting method for soft and hard strata

The invention belongs to the technical field of underground engineering rock and soil drilling and cutting, and underground engineering disaster prevention and mitigation, and particularly relates toa multi-zone freezing type lifting drill-cutting method for soft and hard strata. A multi-zone independent-lifting type drill-cutting tool is adopted, so that drill-cutting tool discs of different areas are mutually combined to achieve independent up-and-down moving, and in-hole cutting tool selecting and in-hole quick cutting tool replacing in any stratum can be achieved. The construction progress is accelerated, and the construction cost is saved. A freezing type freeze-drill-cutting method is adopted meanwhile, a freezing controller is adopted to control a freezing salt water agent to discharge freezing salt water, and the freezing salt water is injected into a to-be-constructed stratum through freezing pipes with vertical extending of the cutting tool discs, so that quick freezing drill-cutting for complex strata in a multi-zone block mode is achieved. Quality accidents such as collapse due to water abundance in uneven-soft-and-hard in-hole strata can be avoided. The construction quality is reliable, and the cost is low. The method has the characteristics that the water-rich strata are fully frozen, the frozen areas are quickly selected, frozen area drilling and cutting are integrated, the drill-cutting force is uniform, the cost is low, hole-forming accuracy is high, and the drill-cutting speed is high.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Reaction force cone cutting device

ActiveCN112421349AAvoid deformationGuaranteed surface qualityLine/current collector detailsLarge fixed membersMilling cutterEngineering

The invention provides a reaction force cone cutting device which is used for solving the problem that in the prior art, a reaction force cone cutting device is low in cutting efficiency. The device comprises a workbench, a clamping assembly, a cutting assembly and an ejector rod assembly, wherein the clamping assembly, the cutting assembly and the ejector rod assembly are mounted on the workbench. The clamping assembly is of a three-jaw chuck structure and used for adjusting the axis of a cable and making the axis of the cable consistent with the axis of a hollow shaft I. The cutting assemblycomprises a sliding table, a swing mechanism and a milling cutter swing mechanism, cutting is conducted through three milling cutters which are evenly distributed, and a conical cutting area is formed when the milling cutters work; and the ejector rod assembly supports the end part of a cable conductor inner core. The chuck structure is matched with a lead screw to complete centering and pressingof the cable, and the ejector rod assembly is used for fixing the cable to prevent deformation of the cable in the cutting process. The cylindrical milling cutters are adopted, so that the surface quality of a cut reaction force cone can be ensured. Three milling cutters are used for cutting simultaneously, cutting force is balanced, and the situation that cutting quality is reduced due to unevencable stress is avoided.

Owner:UNIV OF JINAN

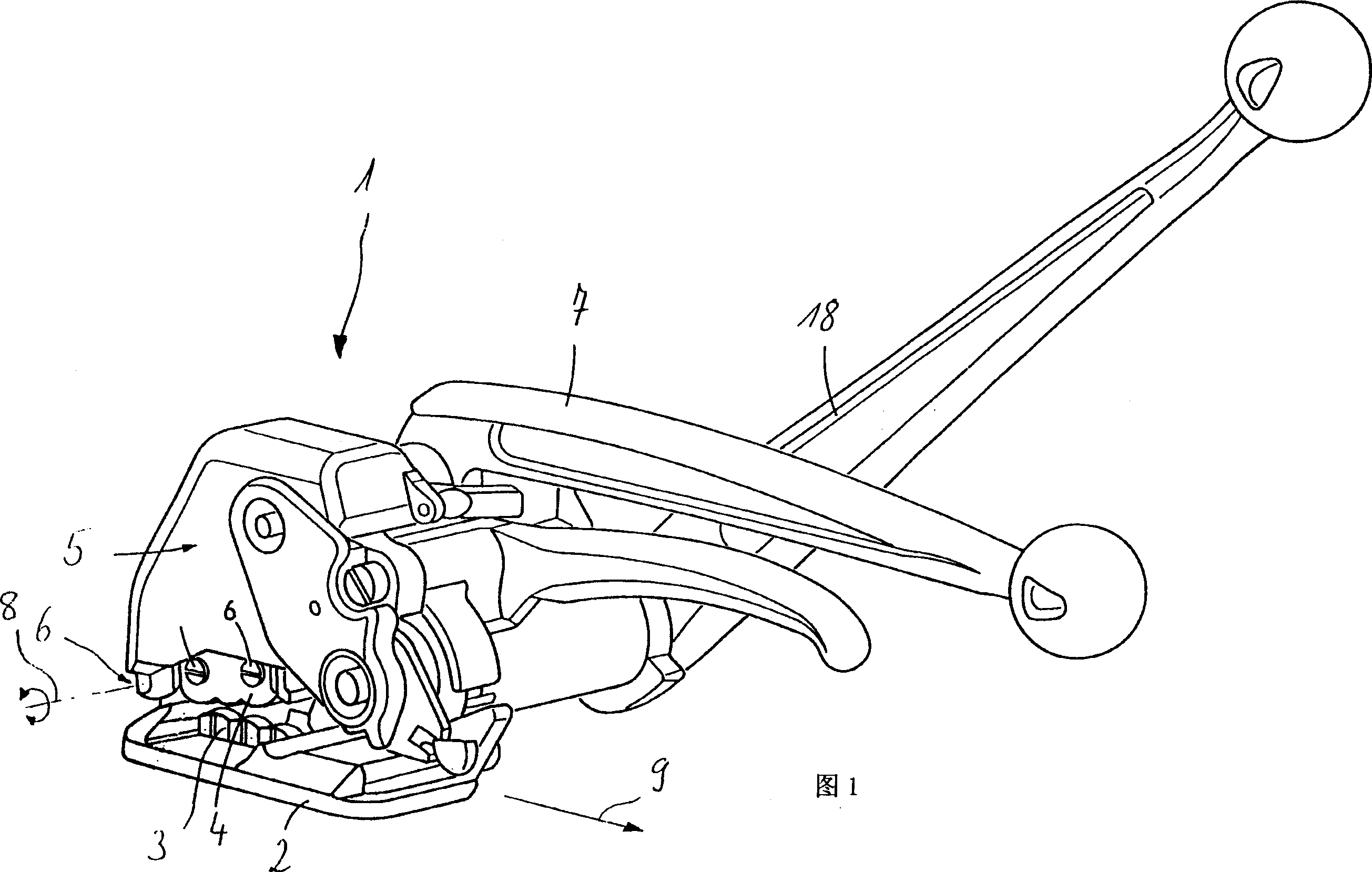

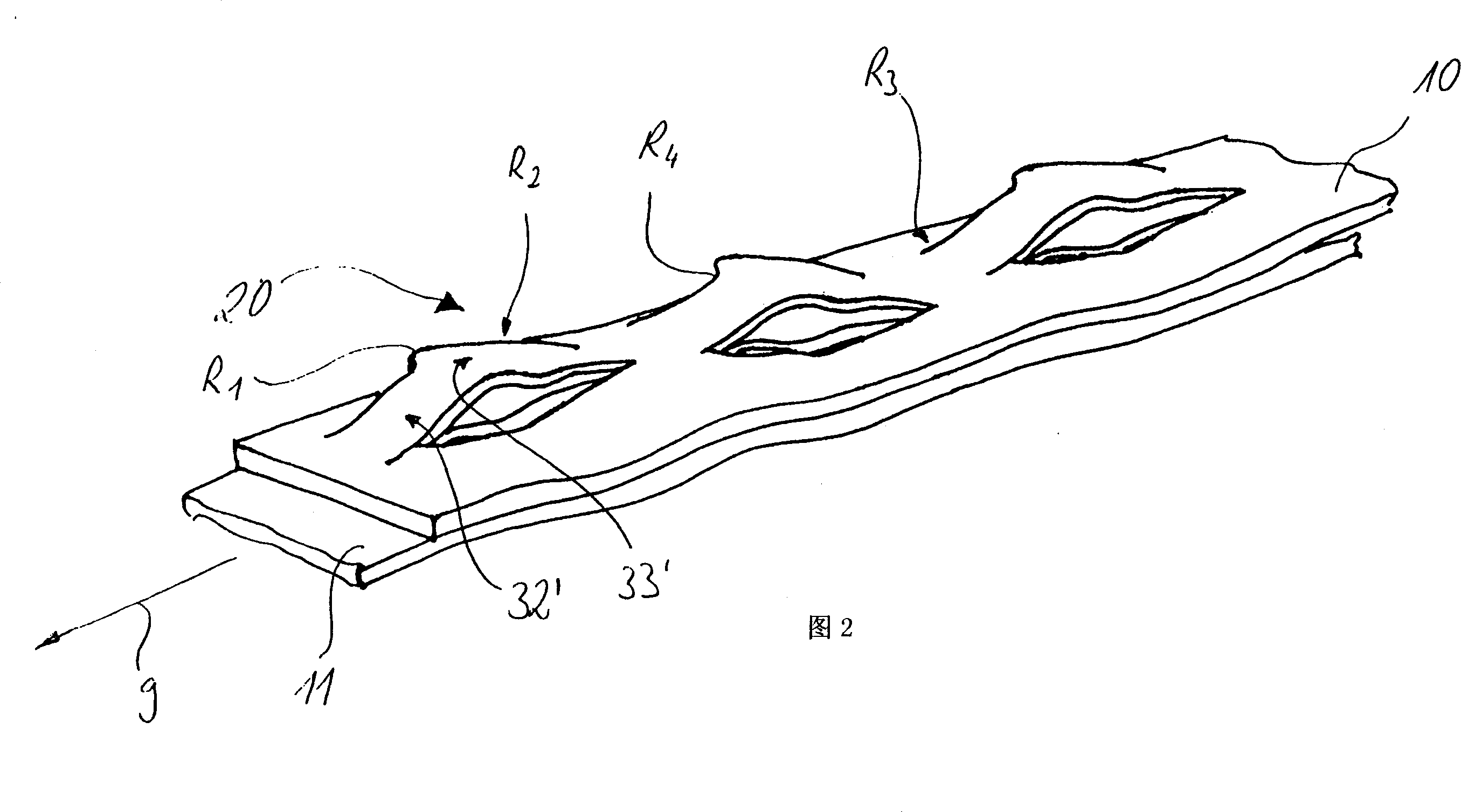

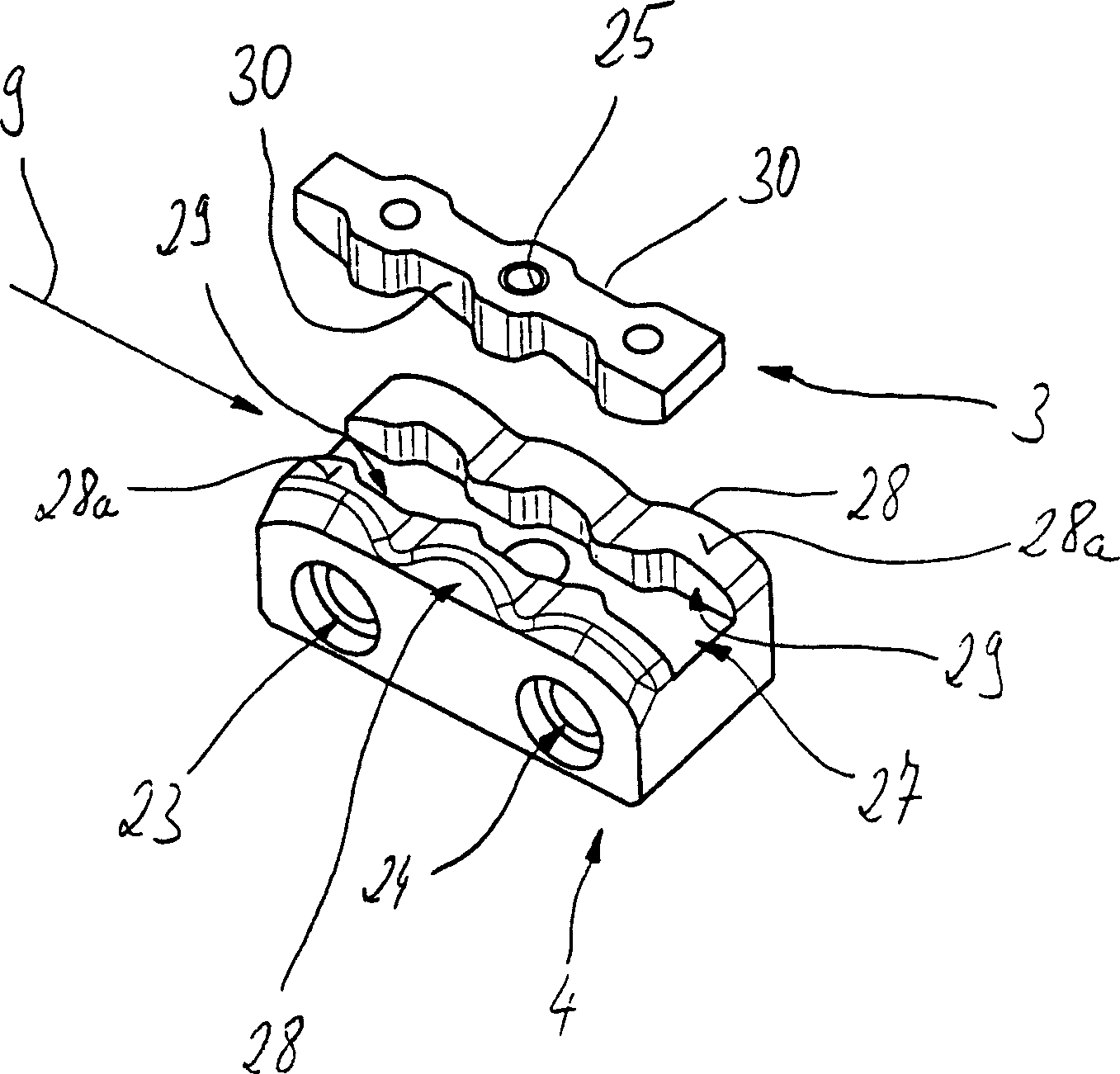

Punching/deforming tool for hundle-up device

Using a punching tool for a strapping unit for producing an auxiliary-free connection of ends of a strapping band, the tool having a recess of different widths, in the case of which at least one section of a recess-bounding wall is provided with a rounded portion in the region of at least one change in width, on the one hand, the intention is to make a fixed closure between the band ends possible. On the other hand, the intention is for this tool to be produced as easily and cost-effectively as possible and, in addition, for uniform cutting forces to be made possible. For this purpose, it is proposed that the rounded portion is of circle-arc shape with a certain radius, and that the largest width of the recess is equal to or less than four times the radius of the wall.

Owner:ORGAPACK GMBH

PVC pipe cutting device for decoration construction

ActiveCN111702816AReduce distortionNo dentsMetal working apparatusHydraulic cylinderStructural engineering

The invention relates to the technical field of devices for decoration construction, and particularly relates to a PVC pipe cutting device for decoration construction. The PVC pipe cutting device fordecoration construction comprises a base, a cutting base, a collect, a conical groove, a hydraulic cylinder, cutter mounting grooves, a clearance groove, a positioning groove, a strip-shaped notch, arc-shaped cutters, a through groove, a semiconductor heating part and a material bouncing assembly, and the material bouncing assembly comprises a magnetic conductive block, an installation groove, anelectromagnet and an elastic piece. The PVC pipe cutting device has the beneficial effects that a PVC pipe is limited and clamped through the positioning groove of the elastic chuck, so that the PVC pipe does not deform, sink and the like during cutting, damage to the PVC pipe is avoided, the hydraulic cylinder is arranged to drive the elastic chuck to move in the cutting base, through elastic contraction of a circular truncated cone part, the cutters synchronously cut PVC pipe together, due to the fact that the cutters are used for cutting together, the cutting resistance during cutting is small, the cutting acting force borne by the PVC pipe acts on all positions of the surface of the PVC pipe evenly, deformation of the PVC pipe is further reduced, and the cutting blind area is small.

Owner:泉州台商投资区品新装潢设计工作室

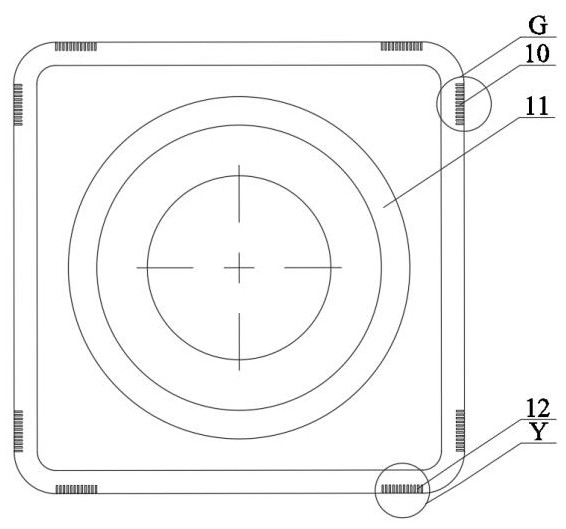

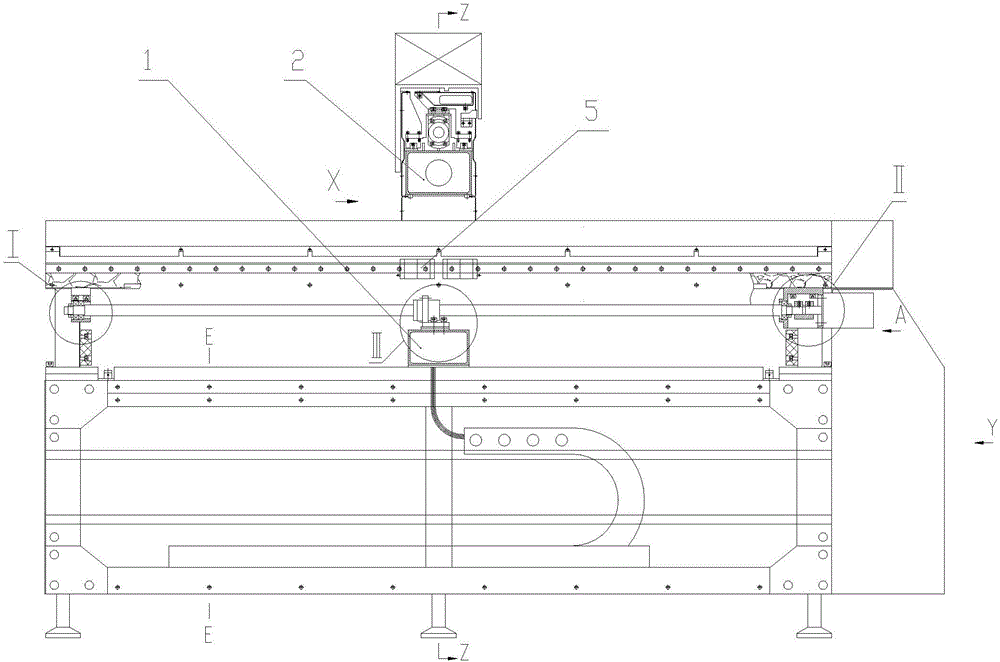

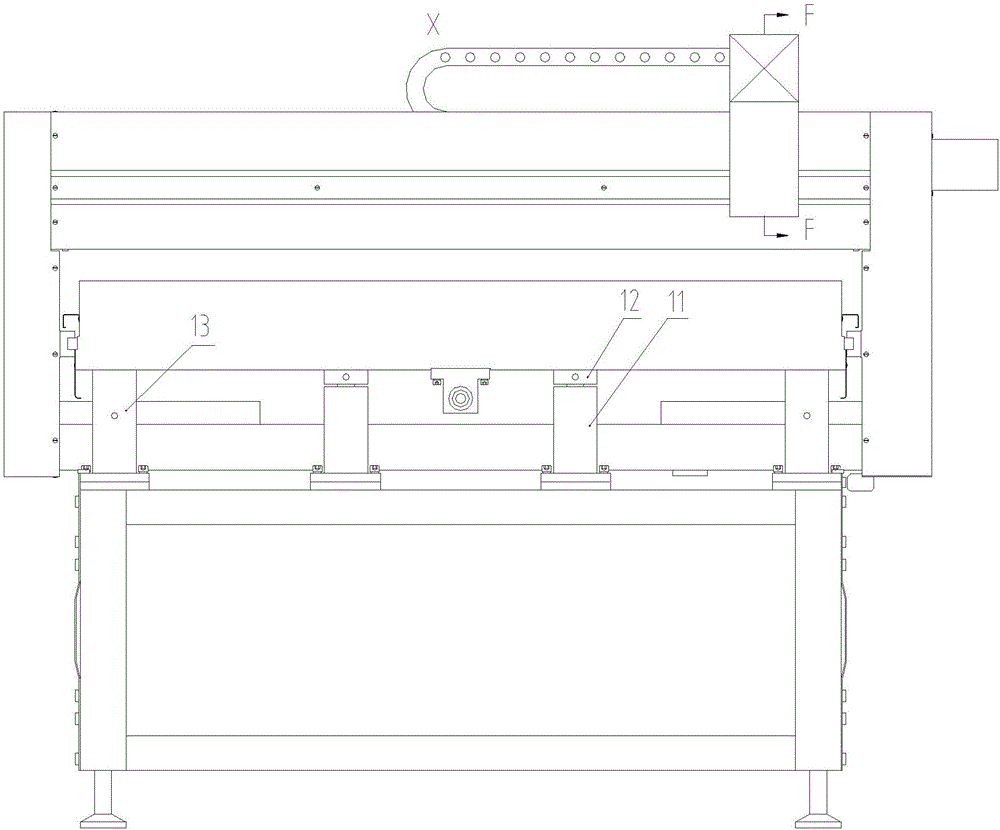

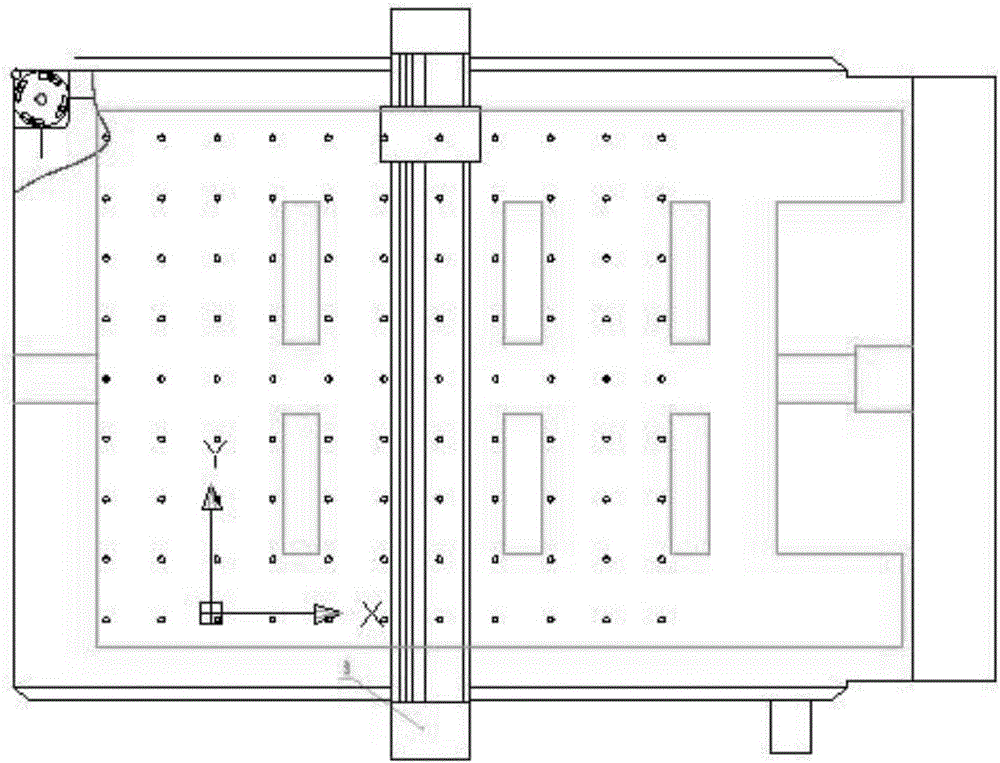

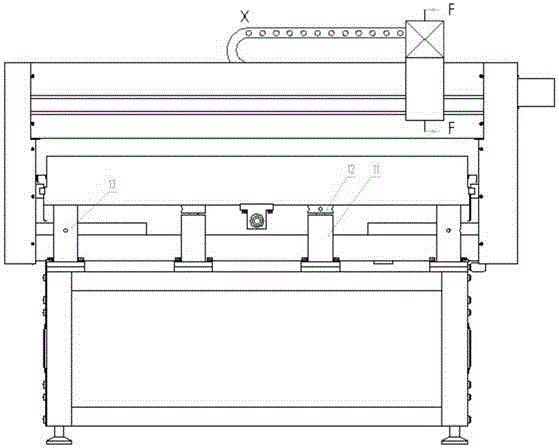

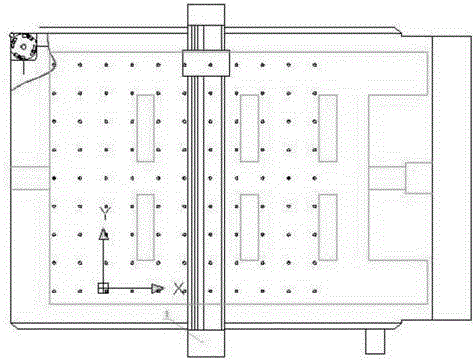

A photoelectric glass cutting machine

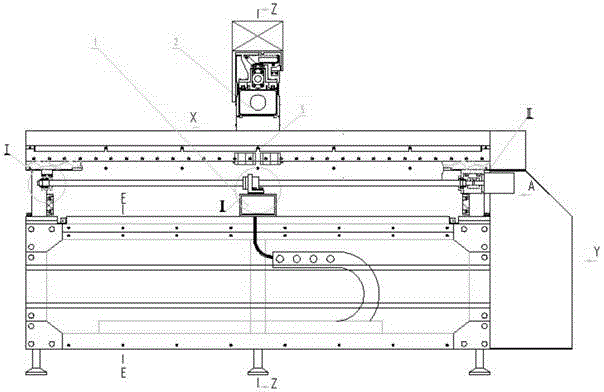

ActiveCN104609716BReduce consumptionImprove labor productivityGlass severing apparatusGlass productionAutomatic controlCutting glass

The invention discloses a photoelectric glass cutting machine, relates to the field of glass cutting machinery, overcomes the defects of low efficiency, high consumption and low precision in the prior art, and provides important equipment which can improve labor productivity, cut a plurality of glass different in specification and size, reduce raw material consumption, improve working efficiency and reduce production cost. A to-be-cut raw glass sheet is large in size and to-be-cut glass is required to be thinner and thinner. Through computer automation control and mutual cooperation of three shafts, cutting is uniform in force, stable, quick and small in noise, and a cutting effect cannot be replaced with that of all conventional glass cutting equipment. Especially for ultrathin glass cutting, any shape can be cut, so that the working efficiency is greatly improved.

Owner:ANHUI ZHICHENG NC TECH CO LTD

Pathological hard tissue slicing system

PendingCN113848085ASave time at workPosition judgment is accurateWithdrawing sample devicesPreparing sample for investigationControl cellKnife blades

The invention discloses a pathological hard tissue slicing system, and belongs to the field of pathological experiments, the pathological hard tissue slicing system is used for slicing a wax block embedded with pathological tissue, the pathological hard tissue slicing system comprises a distance fixing unit, a clamping unit, a monitoring camera, a cutting unit and a control unit; the distance fixing unit collects distance information of the wax block through a visual element; the clamping unit is used for clamping and fastening a wax block, the clamping unit can control the clamping length of the wax block, the cutting unit comprises a blade, the monitoring camera is used for collecting structural information of the wax block, and the distance fixing unit, the clamping unit, the monitoring camera and the cutting unit are all controlled by the control unit. The position of the maximum section of the diseased tissue can be pre-judged; the wax block is roughly cut to the maximum section of the diseased tissue rapidly and accurately, then precise slice cutting is conducted, meanwhile, factors of the voidage, the tissue continuity and the tissue hierarchical sequence of the wax block are monitored in real time, unqualified wax blocks are rapidly removed, invalid actions are reduced, and the cutting efficiency is improved.

Owner:澎立检测技术(上海)有限公司

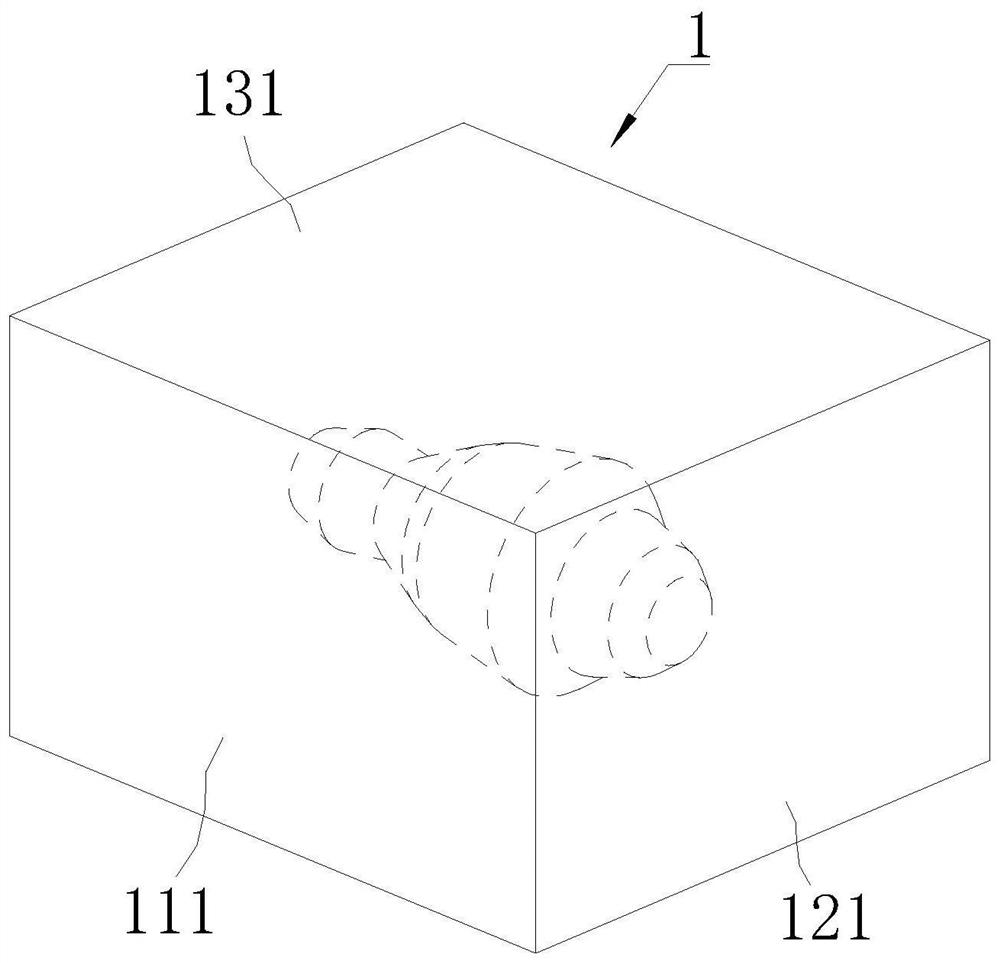

Magnetic force conversion type intelligent knife changing drilling and cutting device for soft and hard strata

The invention belongs to the technical field of underground engineering rock and soil body drilling, cutting and underground engineering disaster prevention and reduction, and provides a magnetic force conversion type intelligent knife changing drilling and cutting device for soft and hard strata. The device comprises a centrifugal mud discharging system, a variable drilling and cutting system, apump water flushing system, a magnetic force conversion system and a framework system. According to the device, the variable drilling and cutting system is utilized to realize rapid drilling and cutting construction of the soft and hard strata; a central drilling bit is arranged in the center of the device to realize ultra-hard soil cutting; a plurality of shell-shaped drilling bits and thread-shaped drilling bits are arranged at intervals around the device to realize drilling and cutting of soft soil, hard soil and homogeneous strata; and the pump water flushing system is utilized to realizerapid discharging of rock debris of any stratum, so that the stratum adaptability of drilling is improved, and the problem of large deviation of hole positions in the drilling construction of soft andhard strata is avoided.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Photoelectric glass cutting machine

ActiveCN104609716ASolve the defects of low efficiency, high consumption and low precisionLow efficiency and reduced consumptionGlass severing apparatusGlass productionAutomatic controlCutting glass

The invention discloses a photoelectric glass cutting machine, relates to the field of glass cutting machinery, overcomes the defects of low efficiency, high consumption and low precision in the prior art, and provides important equipment which can improve labor productivity, cut a plurality of glass different in specification and size, reduce raw material consumption, improve working efficiency and reduce production cost. A to-be-cut raw glass sheet is large in size and to-be-cut glass is required to be thinner and thinner. Through computer automation control and mutual cooperation of three shafts, cutting is uniform in force, stable, quick and small in noise, and a cutting effect cannot be replaced with that of all conventional glass cutting equipment. Especially for ultrathin glass cutting, any shape can be cut, so that the working efficiency is greatly improved.

Owner:ANHUI ZHICHENG NC TECH CO LTD

Blade holder having displacement-dependent spring force compensation

ActiveUS20080040933A1Uniform cutting forceShearing machinesMetal working apparatusSpring forceEngineering

A blade holder for cutting machines includes a blade head held on a raising and lowering device and having an adjustment mechanism for a circular blade that is held on the blade head. The adjustment mechanism for the movement of the circular blade between a cutting position and a ready position, is provided with an adjustment piston rod having an adjustment piston that is guided in a chamber of the blade head housing and can is adapted to be moved by compressed air. The adjustment piston rod is biased by a compression spring into the ready position of the circular blade. The piston surface of the adjustment piston has a cross-sectional area that is configured such that as the path of the adjustment piston in the direction of adjustment increases, the piston surface that is acted upon by compressed air increases.

Owner:DIENES WERKE FUER MASCHTEILE

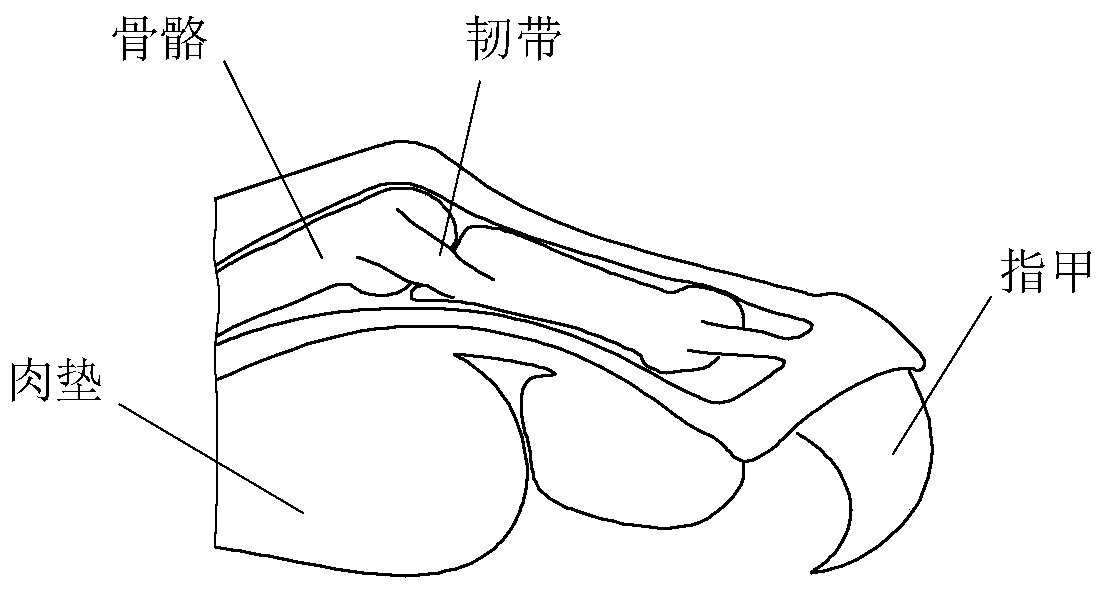

Bionic adaptive pressure equalization active vibration reduction pdc drill bit

ActiveCN109339711BUniform cutting forceAvoid regenerative cutting effectsEarth drilling toolsRotating vibration suppressionHydraulic cylinderThermodynamics

The invention discloses a bionic adaptive pressure-equalizing active vibration-damping PDC drill bit. A new type of active vibration-damping drill bit is designed using bionic technology. During the working process, the PDC blade automatically moves up and down according to changes in the hardness of the rock formation, pushing the hydraulic piston rod to move and compress. The gas in the high-pressure air chamber absorbs the vibration energy of the PDC blade and compresses it to dissipate heat. The hydraulic oil in the hydraulic cylinder absorbs the vibration energy of the PDC blade through damping and conducts it out in the form of heat to achieve the purpose of drilling. For the purpose of vibration reduction, the hydraulic cylinders are connected to each other to ensure that the cutting force of the PDC blade is equal, to avoid the occurrence of regenerative cutting effects, and to reduce the possibility of vibration.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com