Patents

Literature

47results about How to "Uniform polishing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

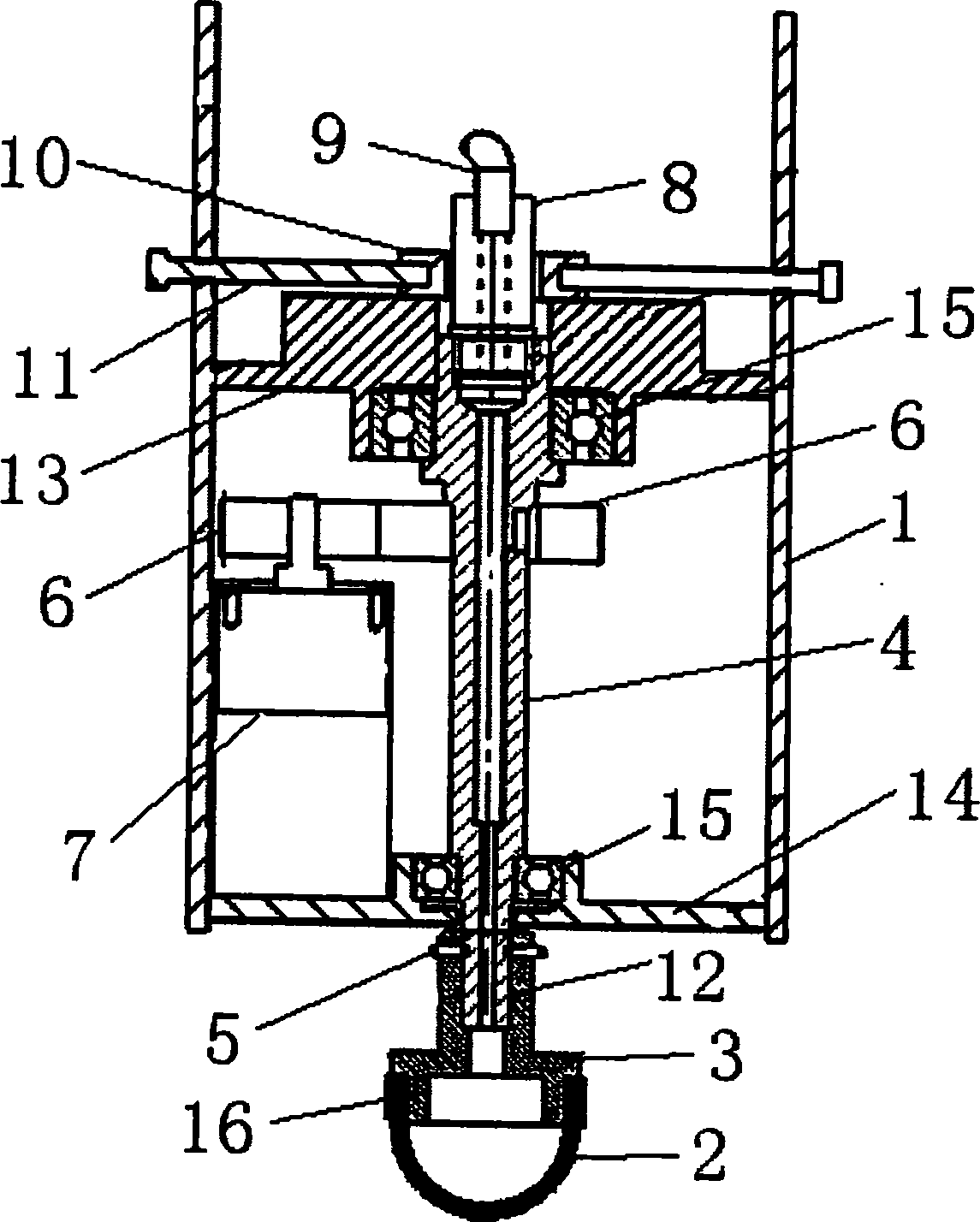

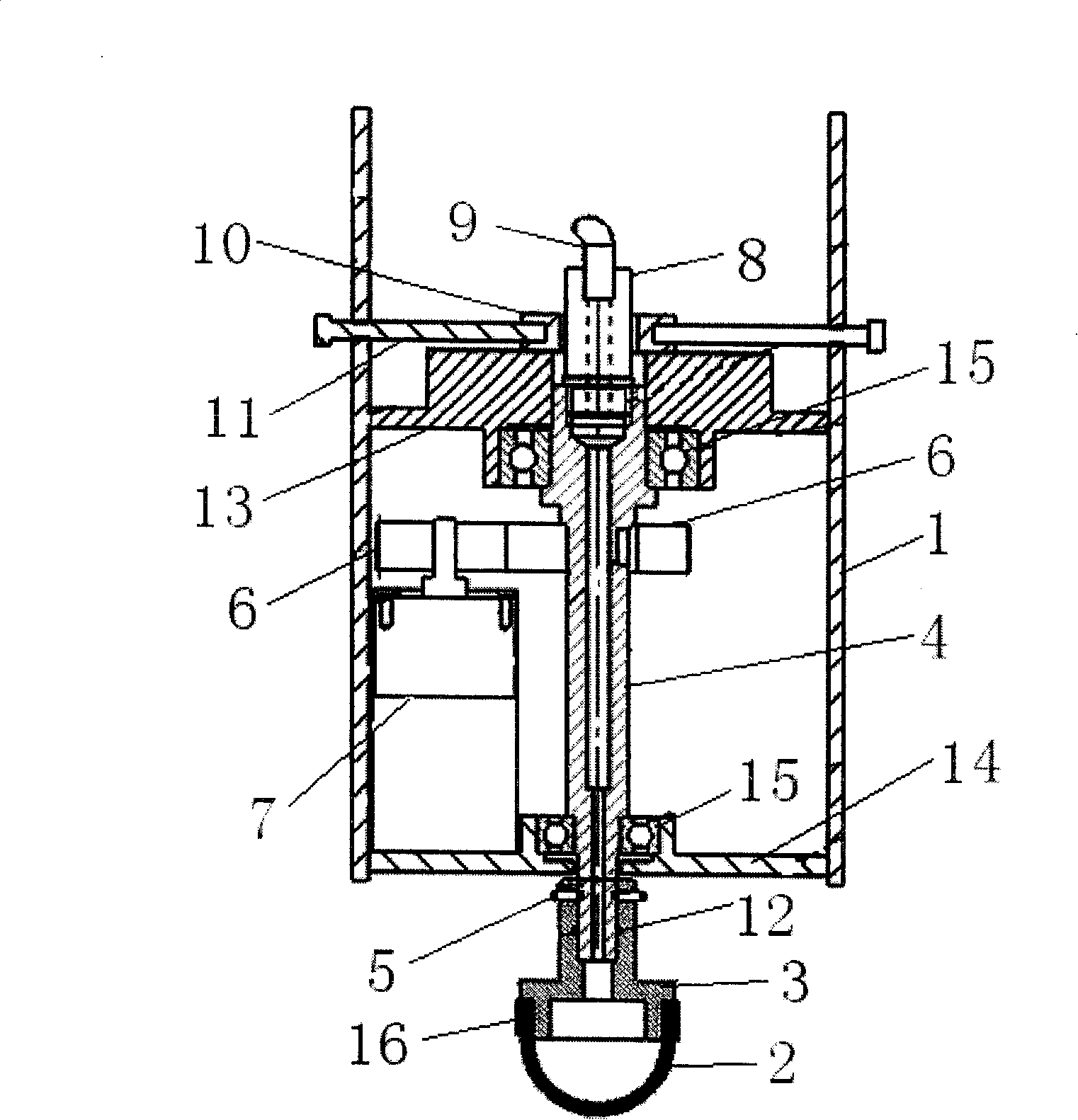

Electric pneumatic adjustable flexible polishing tool

InactiveCN1880017AAdapt to face widthEliminate external driversFlexible-parts wheelsBurnishing machinesAir cellElectric machinery

The invention relates to an electric pressure adjustable flexible furnish device, which comprises: a support and an air cell, wherein the front end of air cell has furnish cloth as working surface; said air cell is mounted on the air cell holding support which is mounted on the front part of one rotation axle; said rotation axle via transmission axle is connected to the output axle of motor; the back end of rotation axle is connected to the rotation air connector; the connector and the air feeding tube are connected and fixed on the support; the connector, rotation axle, and air cell holding support are all hollow; the connector, rotation axle and the chamber of holding support form the airflow channel. The invention has high furnishing efficiency and high furnishing quality, with online control.

Owner:ZHEJIANG UNIV OF TECH

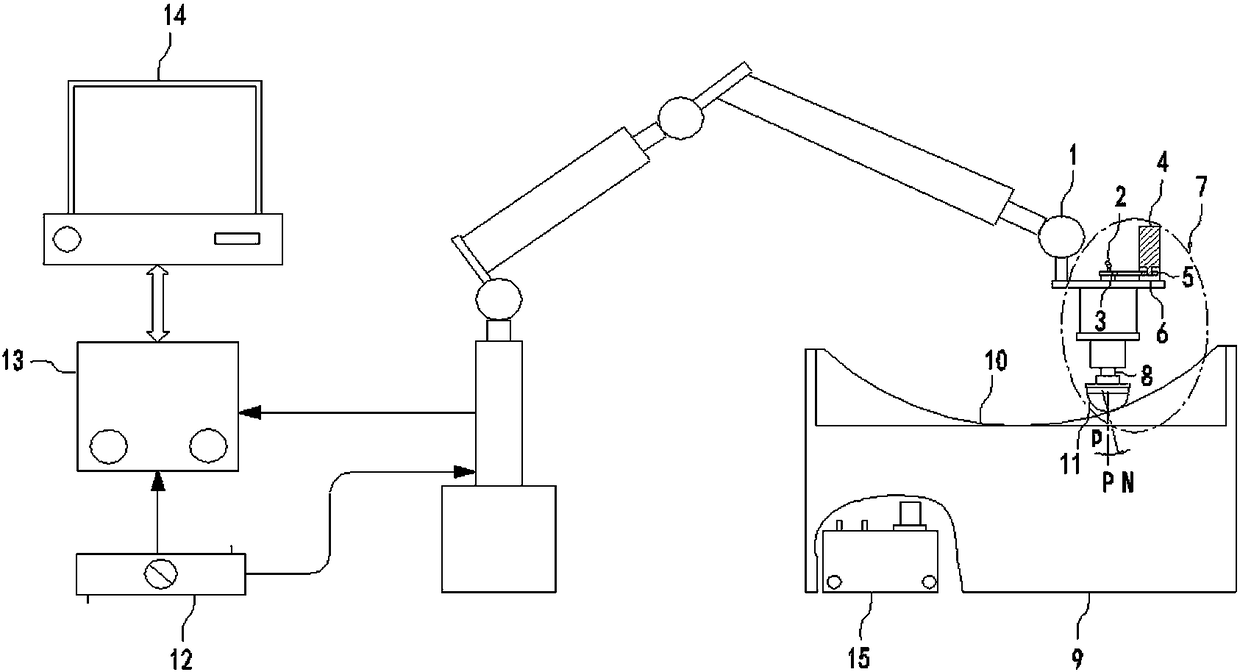

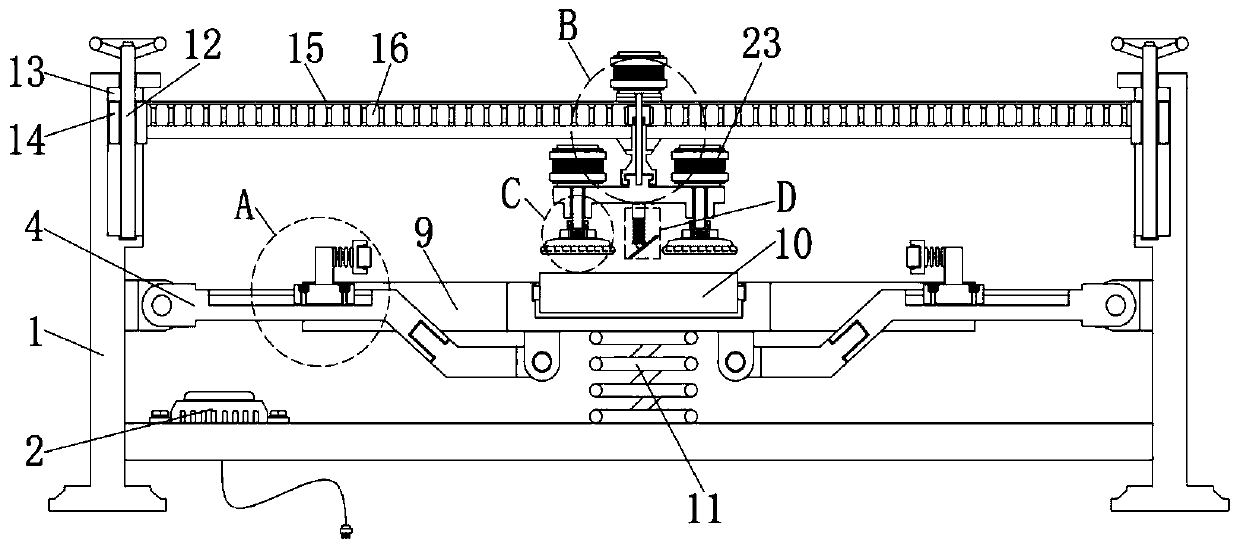

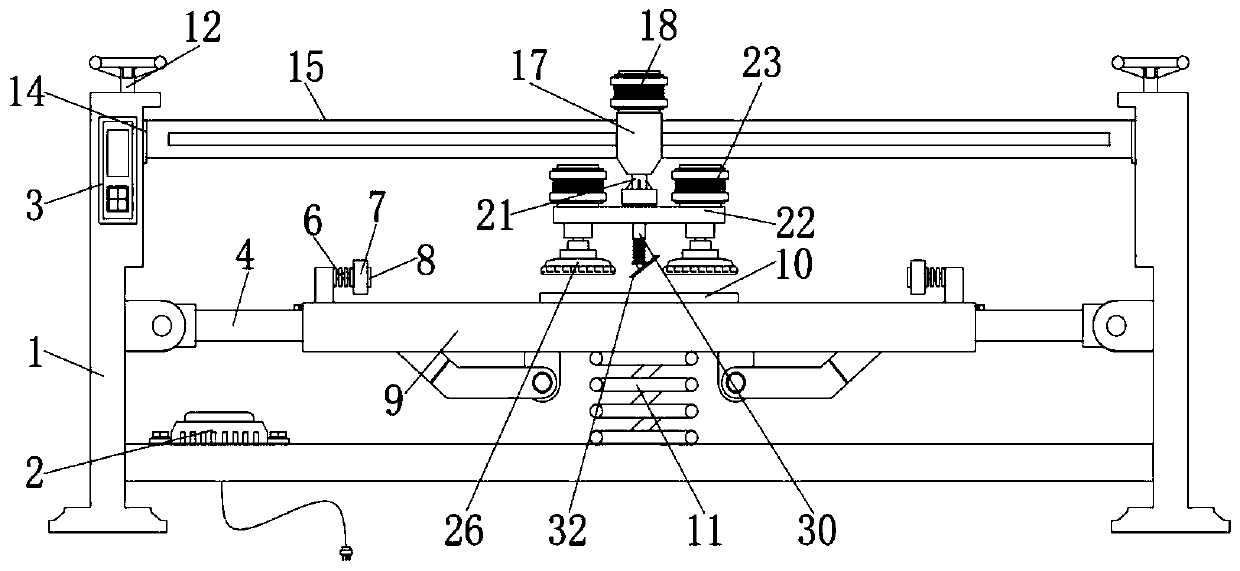

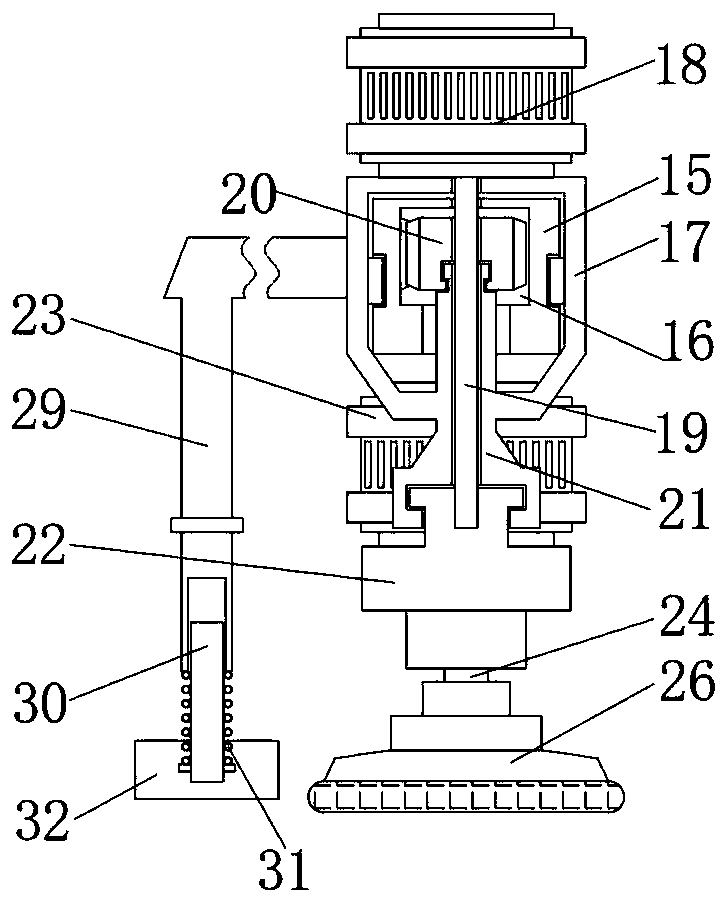

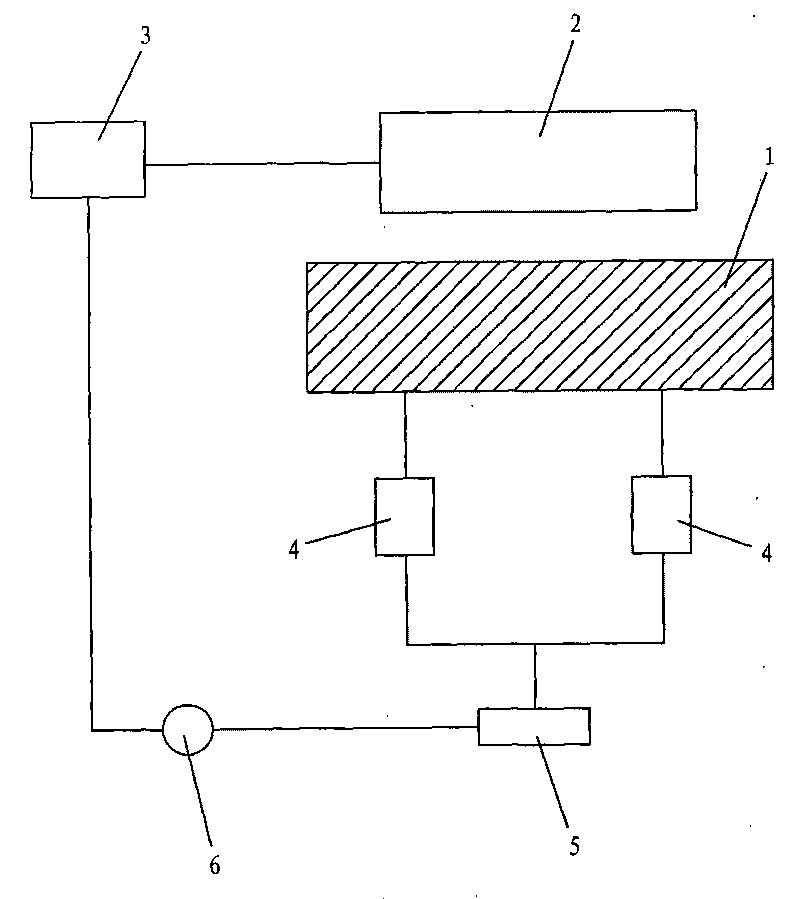

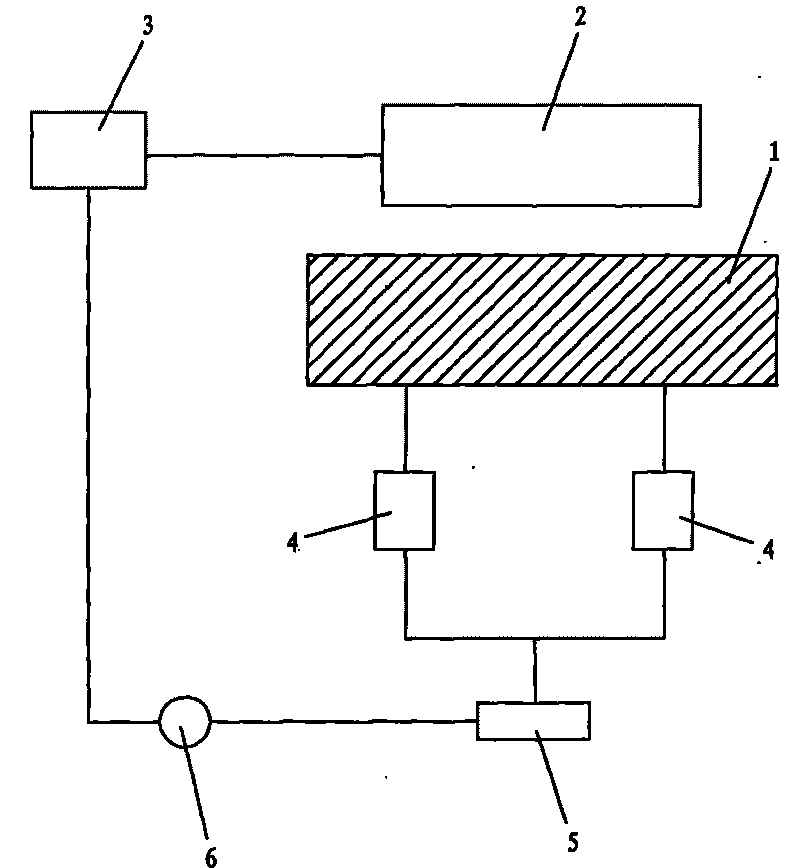

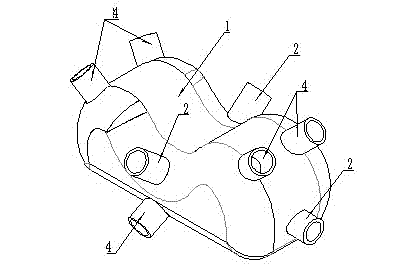

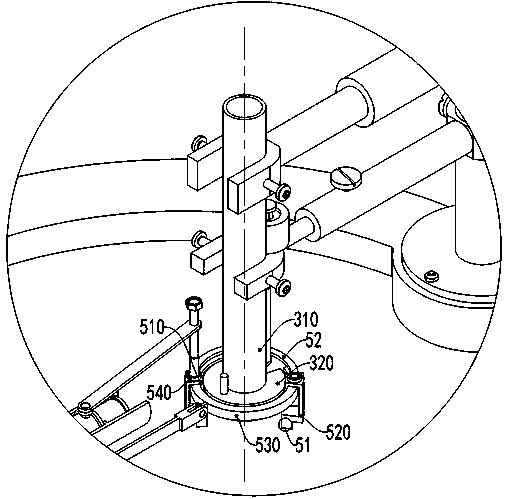

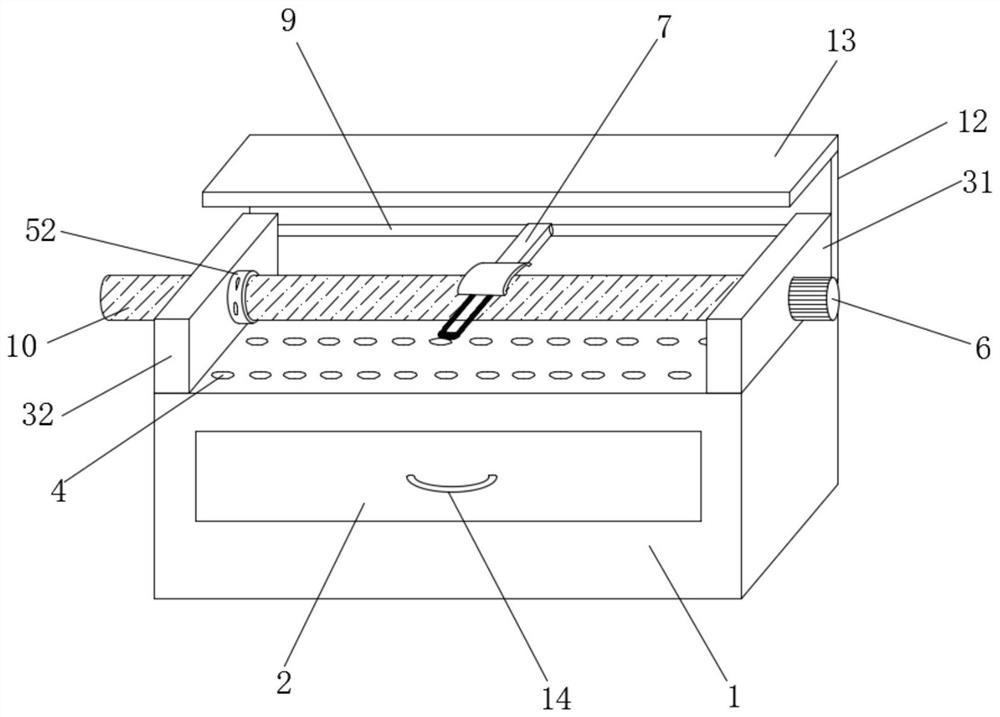

Intelligent flexible polishing method for non-spherical optical element and intelligent flexible polishing device adopted for intelligent flexible polishing method

PendingCN108161646AGood face shape adaptabilityHigh precisionOptical surface grinding machinesAutomatic grinding controlMaterial removalOptical processing

The invention belongs to the technical field of optical machining and particularly relates to an intelligent flexible polishing method for a non-spherical optical element and an intelligent flexible polishing device adopted for the intelligent flexible polishing method. The intelligent flexible polishing method includes the steps that (1) a robot scans a workpiece through a sensor to collect characteristic information of the workpiece; (2) a robot control system determines a polishing theoretical track; (3) a polishing mechanism drives a polishing airbag to move on the surface of the workpiecealong the polishing theoretical track, and the material removal quantities of various points on the surface of the optical element are accurately controlled; and (4) the robot control system carriesout iterative operation repeatedly so as to control the surface shape error of the workpiece. The intelligent flexible polishing device comprises the robot (1), a rotating joint (2), a workbench (10),an air pressure adjusting device (12), the robot control system (13), the polishing mechanism (7) and a computer (14). A machine area is stable, surface shape adaptability is good, the operating conditions of a polishing system can be monitored in real time, and ultraprecise polishing of large-size high-curvature non-spherical surfaces is achieved.

Owner:SHENYANG ACAD OF INSTR SCI

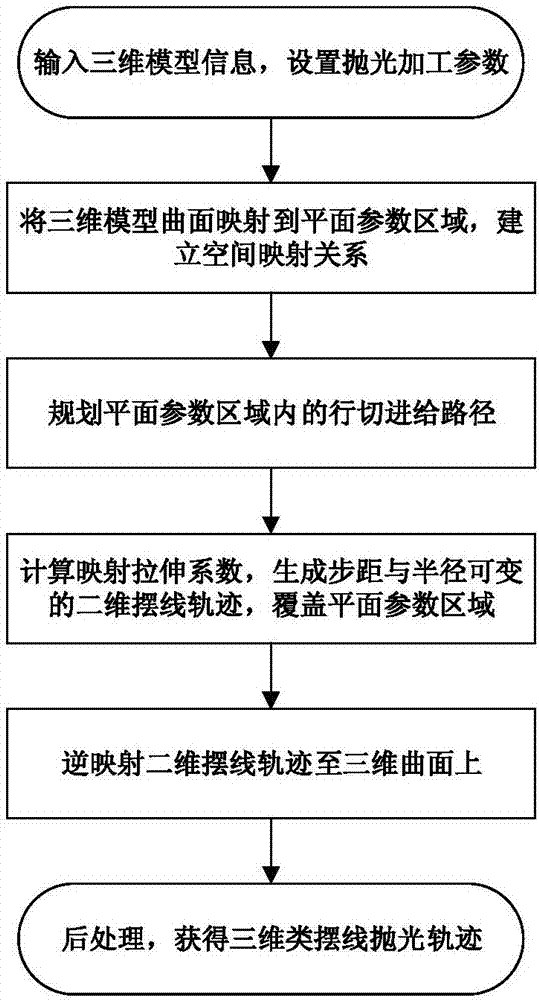

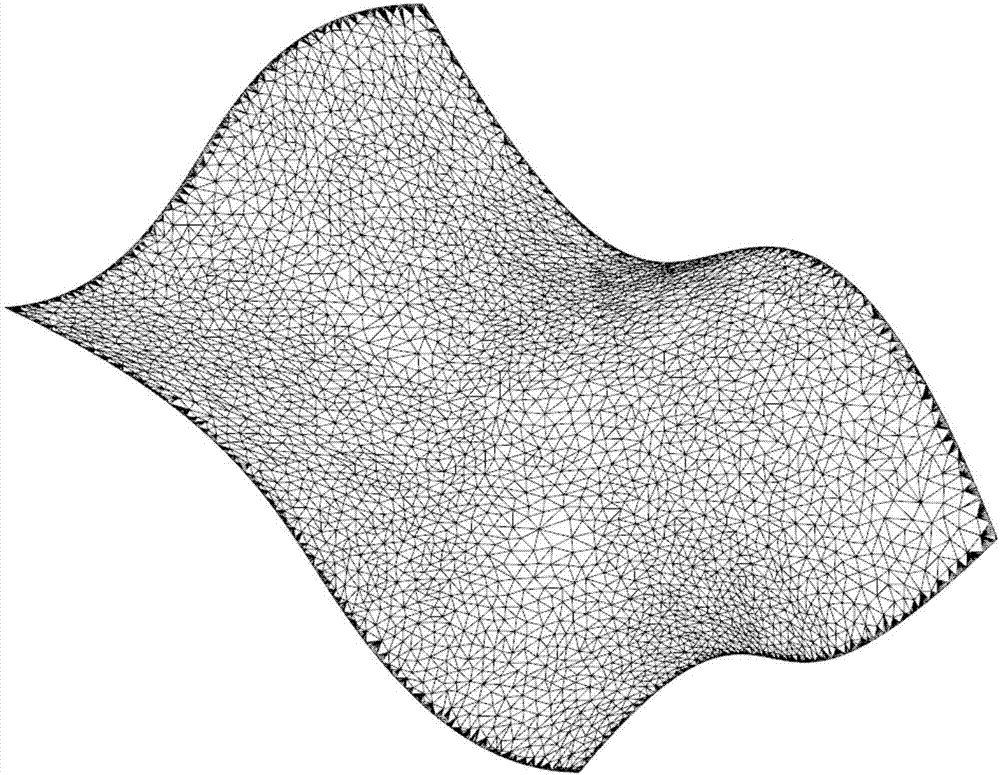

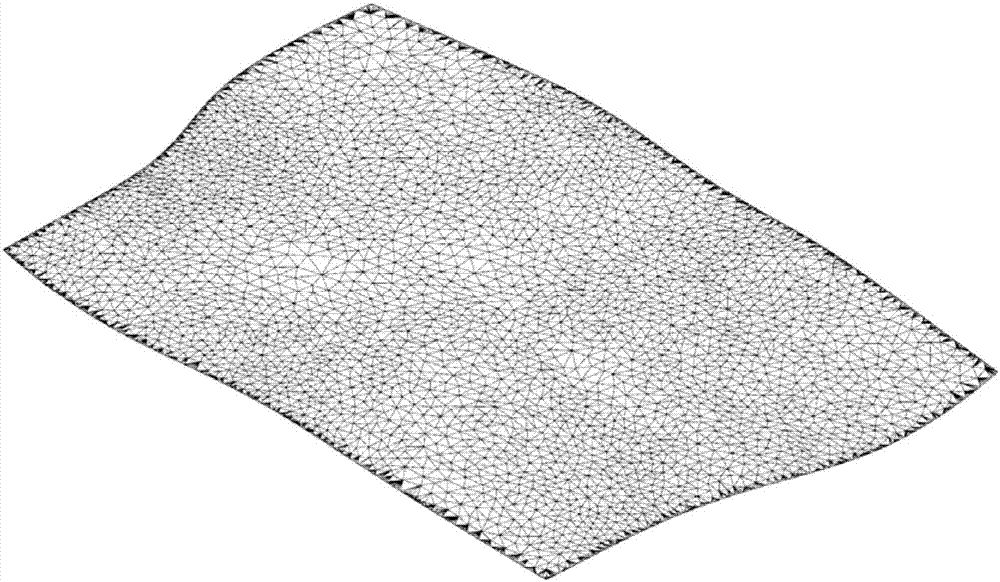

Three-dimensional cycloid-like polishing locus generation method for feeding along cutting path

ActiveCN107369127AReduce complexityImprove surface qualityGeometric image transformation3D-image renderingSpatial mappingEngineering

The invention discloses a three-dimensional cycloid-like polishing locus generation method for feeding along a cutting path, and the method comprises the steps: S1, obtaining and building a spatial mapping relation between a three-dimensional curved surface and a two-dimensional parameter region; S2, carrying out the planning of a cutting feeding path in a plane parameter region; S3, calculating the mapping stretching coefficients of the position of the cutting feeding path in two directions of a parameter domain, and adaptively adjusting the step value and radius value of a two-dimensional cycloid of the feeding along the cutting path; S4, taking the cutting feeding path as a lead line according to the step value and radius value of the adaptive two-dimensional cycloid, and generating the locus of the two-dimensional cycloid through continuous iteration, so as to cover the whole plane parameter region; S5, mapping the locus of the two-dimensional cycloid to the three-dimensional curved surface, and obtaining a three-dimensional cycloid-like polishing locus. The method provided by the invention can avoid the generation of a periodic polishing locus through the multiple directivity of the cycloid locus, can improve the polishing uniformity of a free curved surface, and improve the surface quality of the machined workpiece.

Owner:SOUTH CHINA UNIV OF TECH

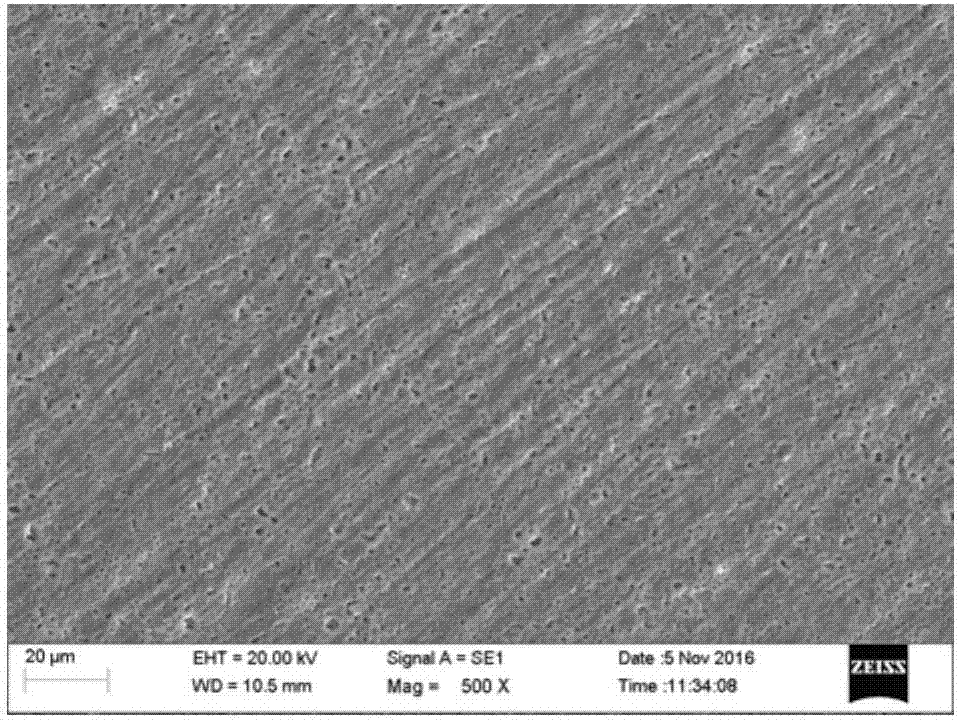

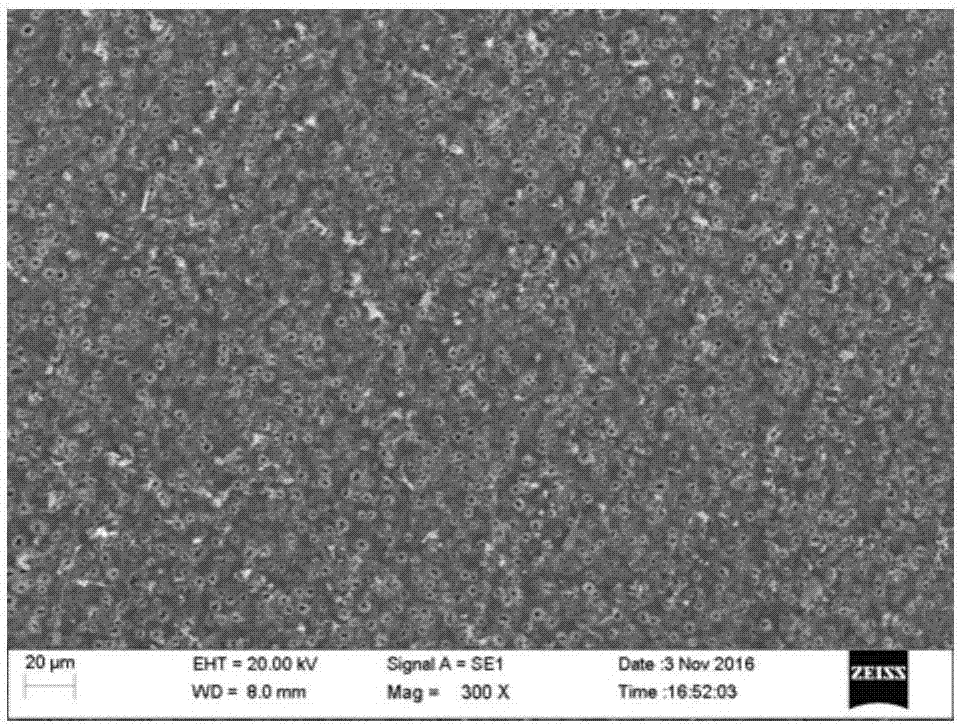

Nanometer silicon dioxide thin film base polished section and preparation method thereof

ActiveCN104128896AUniform particle size distributionUniform polishing effectAbrasion apparatusGrinding devicesWork in processCutting force

The invention discloses a nanometer silicon dioxide thin film base polished section and a preparation method of the nanometer silicon dioxide thin film base polished section. The preparation method includes the following steps that (1) nanometer silicone sol is prepared; (2) a precoating is coated on a PET tape base and a processed base material is obtained; (3) the nanometer silicone sol, soluble resin, and a soluble curing agent are mixed and then abrasive coating liquid is obtained; (4) the abrasive coating liquid is evenly coated on the base material processed in the step (2), a semi-finished product is obtained and is solidified under 80 DEG C to 100 DEG C for 40 hours to 60 hours, and the nanometer silicon dioxide thin film base polished section is obtained. The nanometer silicon dioxide thin film base polished section is even in cutting force, and good in polishing effect when the polished section is applied to an optical fiber connector.

Owner:绍兴自远磨具有限公司

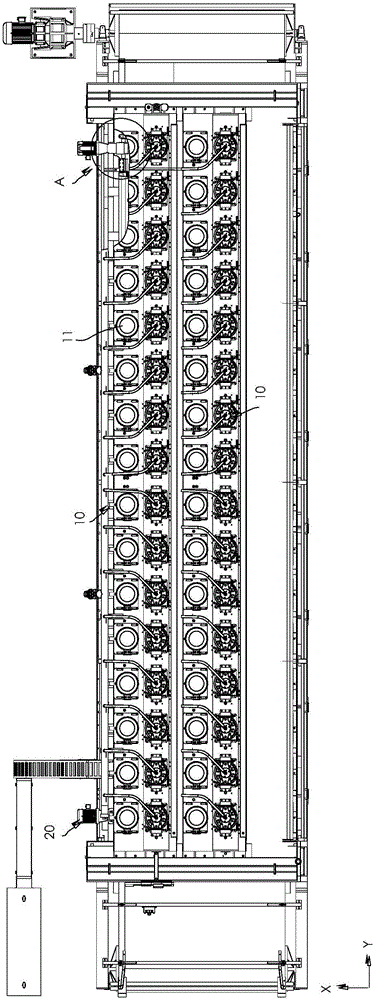

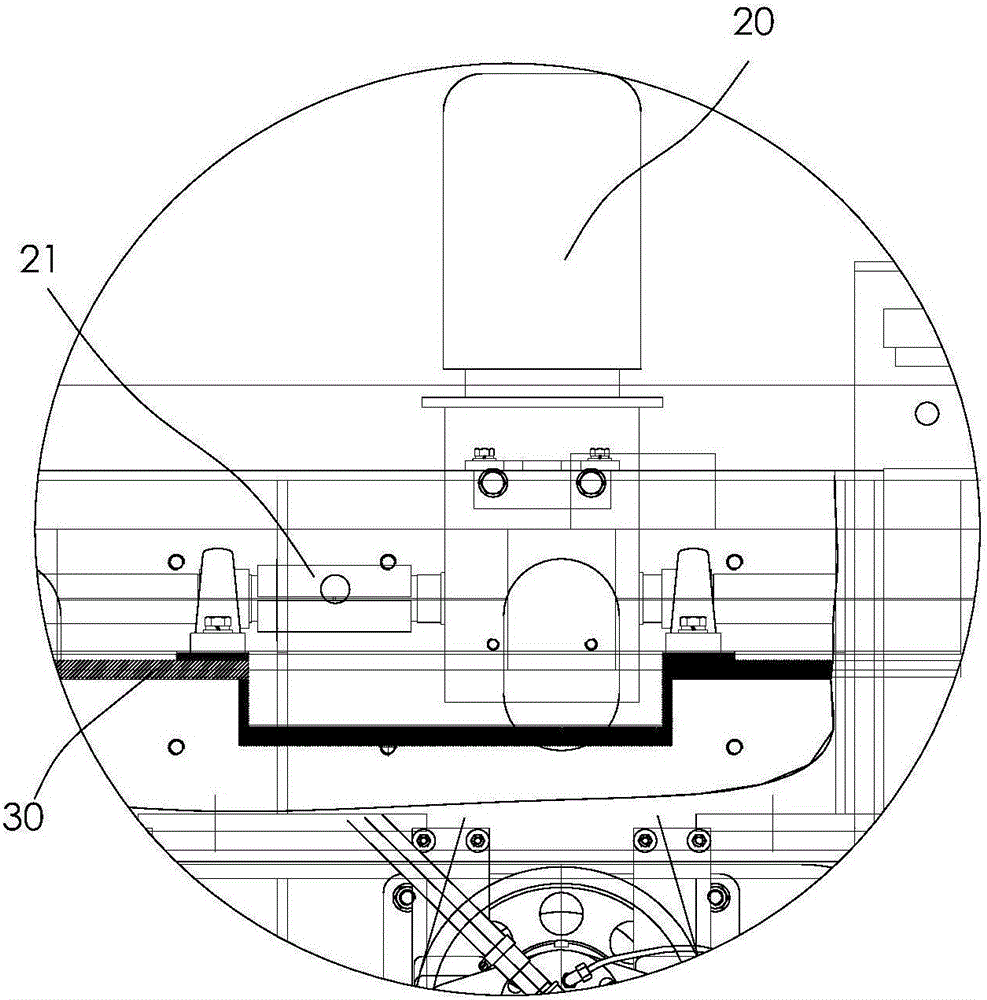

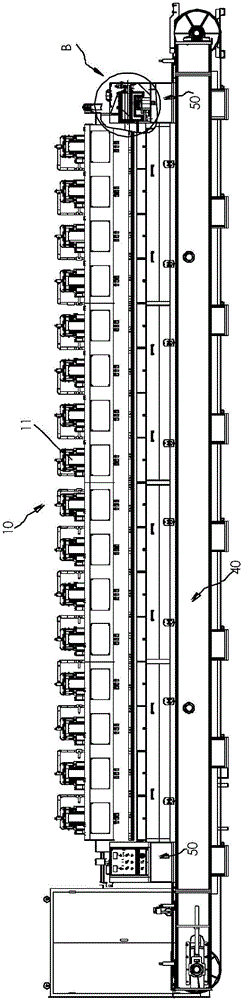

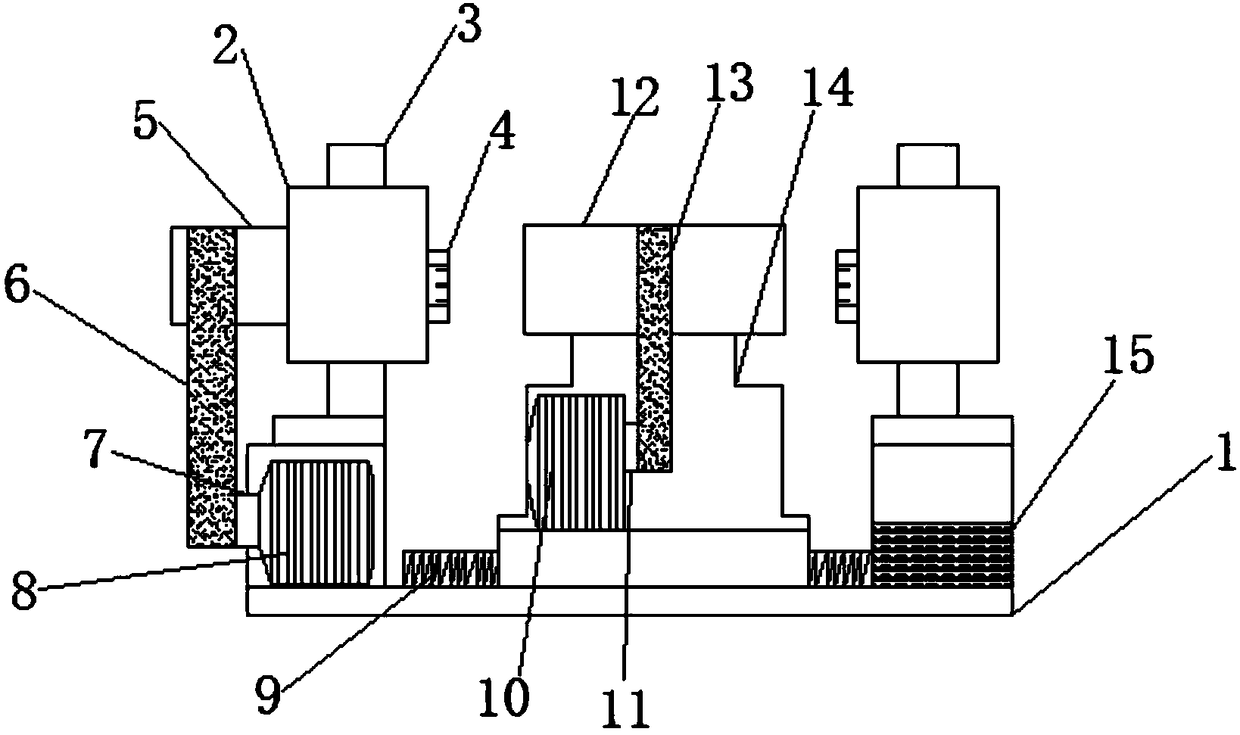

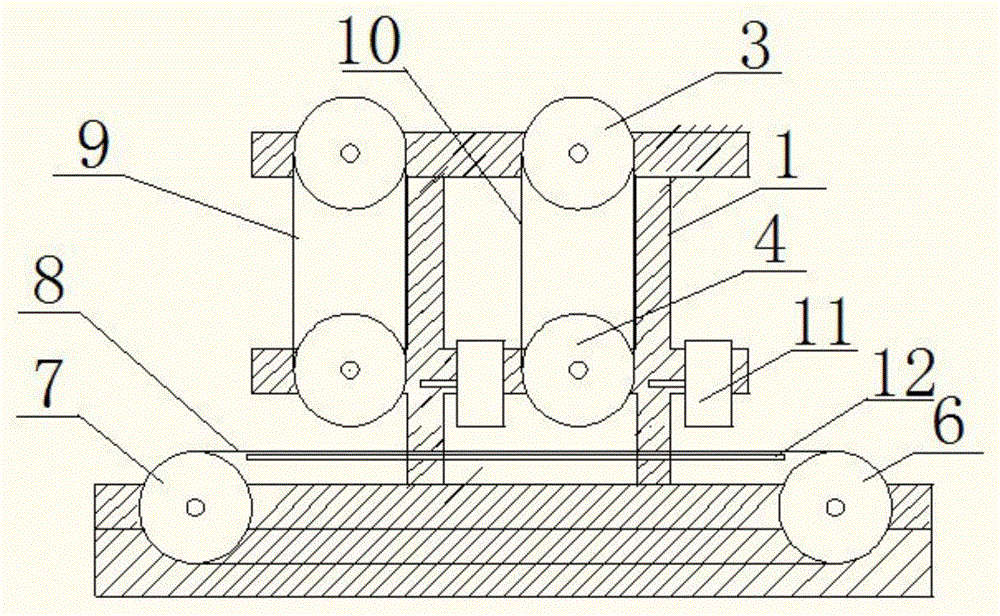

Efficient polishing machine

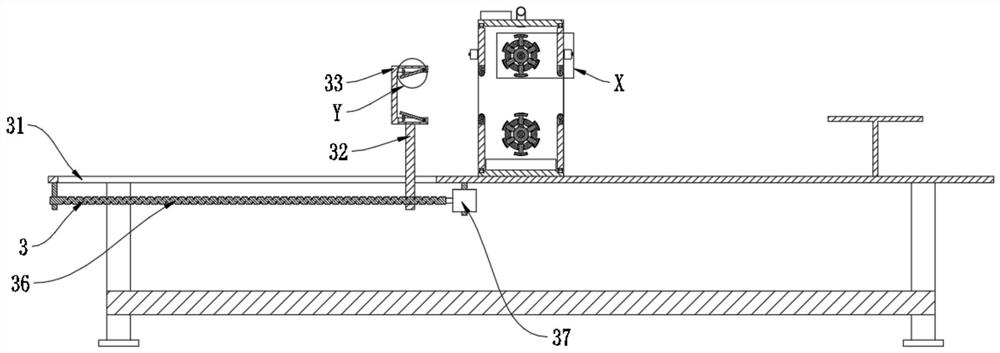

InactiveCN106514478ANo need to reduce conveying speedReduce swingGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention discloses an efficient polishing machine. The efficient polishing machine comprises a conveying mechanism, at least two sets of polishing assemblies and a first driving mechanism, wherein the conveying mechanism conveys outside workpieces to be machined in the first direction; the polishing assemblies are used for polishing to-be-machined faces of the workpieces to be machined and arranged in the second direction in a space mode; the second direction intersects with the first direction; and the first driving mechanism is used for driving the polishing assemblies to reciprocate in the second direction. According to the efficient polishing machine, the polishing swing amplitude can be effectively reduced; and meanwhile, higher workpiece feeding speed is met, and the polishing efficiency is improved.

Owner:GUANGDONG EDING IND

Novel polishing machine

InactiveCN104191341AUniform polishing effectImprove work efficiencyPolishing machinesMotor driveEngineering

The invention relates to a novel polishing machine which is suitable for polishing hinges, even in polishing effect and high in working efficiency. The novel polishing machine comprises a workbench, a conveying belt, a polishing mechanism, a feed mechanism and a discharge mechanism. The conveying belt moving relative to the workbench is arranged above the workbench and is a nonmagnetic metal conveying belt, containing grooves for containing workpieces are formed in the top face of the conveying belt at intervals, and the depth of the containing grooves is larger than 2 / 3 of the thickness of the workpieces and smaller than the thickness of the workpieces. The feed mechanism comprises a push oil cylinder, a push rod and a material push plate, wherein the push oil cylinder is used for pushing the material push plate to move towards the conveying belt. The polishing mechanism is arranged above the conveying belt. The discharge mechanism comprises a guide rail arranged above the workbench, a sliding block relatively sliding on the guide rail and a motor driving the sliding block to move. An air cylinder is arranged on the sliding block, an electromagnet is arranged at the output end of the air cylinder, and the air cylinder is used for pushing the electromagnet to move towards the top face of the conveying belt. A material receiving box is arranged at the bottom of the outer side of the guide rail.

Owner:SUZHOU AOLIN HARDWARE

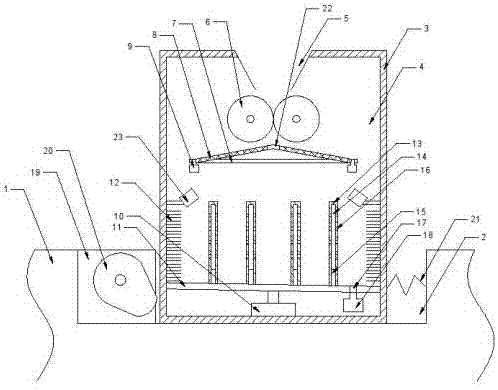

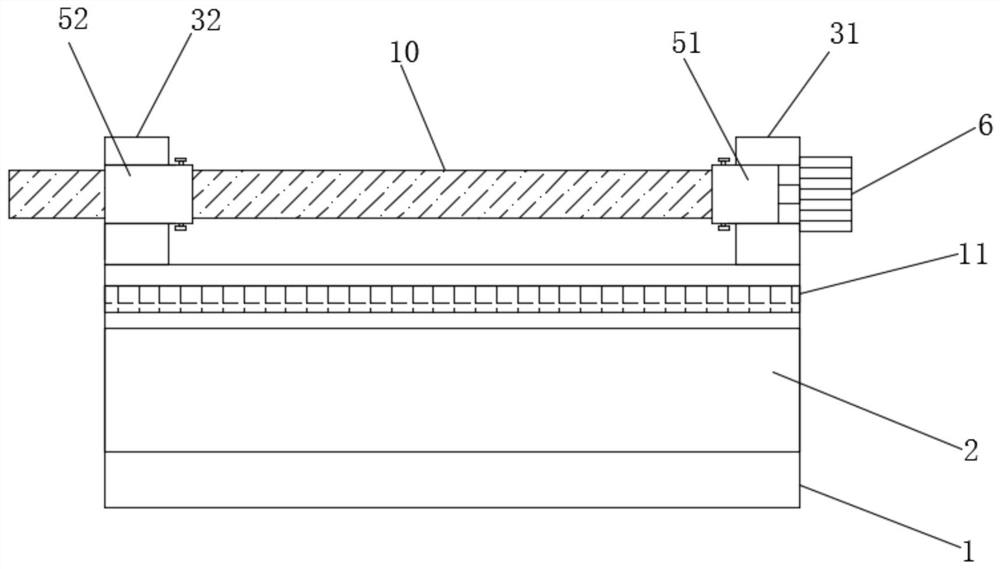

Surface layer polishing device for ecological board material production

ActiveCN110814987AAvoid offsetStable fore and aftPolishing machinesGrinding drivesElectric machineEngineering

The invention discloses a surface layer polishing device for ecological board material production. The device comprises device main outer frames, a motor controller, a shift knob, a first motor and asecond motor. The motor controller is fixedly mounted on the left sides of the bottoms of the device main outer frames, the shift knob is fixedly arranged on the front faces above the left sides of the device main outer frames, hinge rods are hinged to the middle positions of the inner walls of the device main outer frames correspondingly, movable blocks are inserted into the hinge rods, and firstsprings are fixedly mounted above the movable blocks. The bottoms of the left sides and the right sides of bearing boards are hinged to the hinge rods correspondingly, the hinge rods are hinged to the inner walls of the device main outer frames, when ecological boards are put on the bearing boards, the bearing boards sink due to the gravity influence, the hinge rods on the two sides are driven torotate and deflect, clamping blocks mounted above the hinge rods deflect, the ecological boards are clamped, and the situation that the ecological boards skew when bearing force in polishing operation is effectively avoided.

Owner:蒙城县国超生态板业有限公司

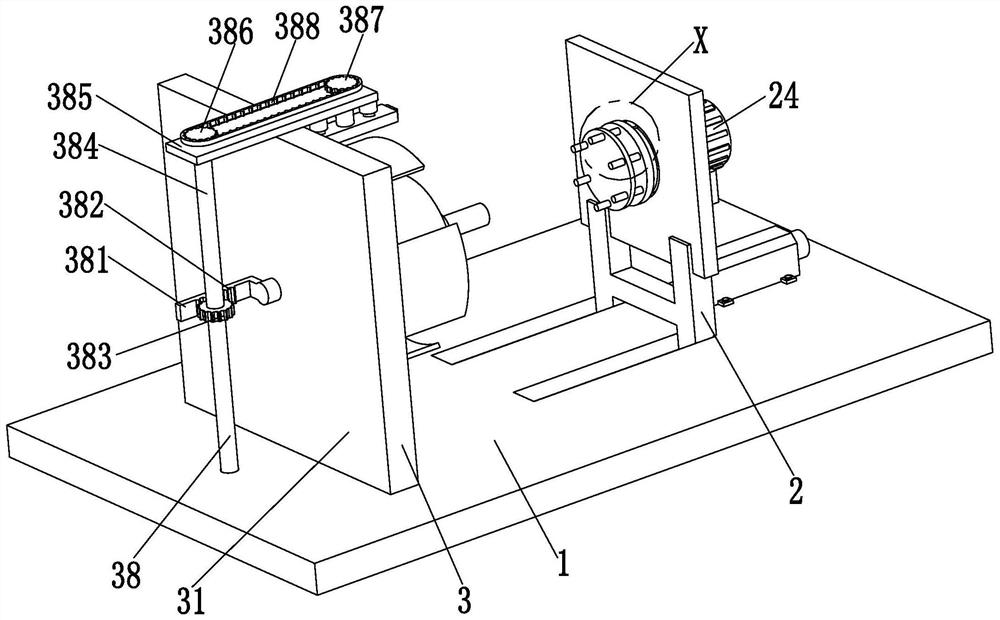

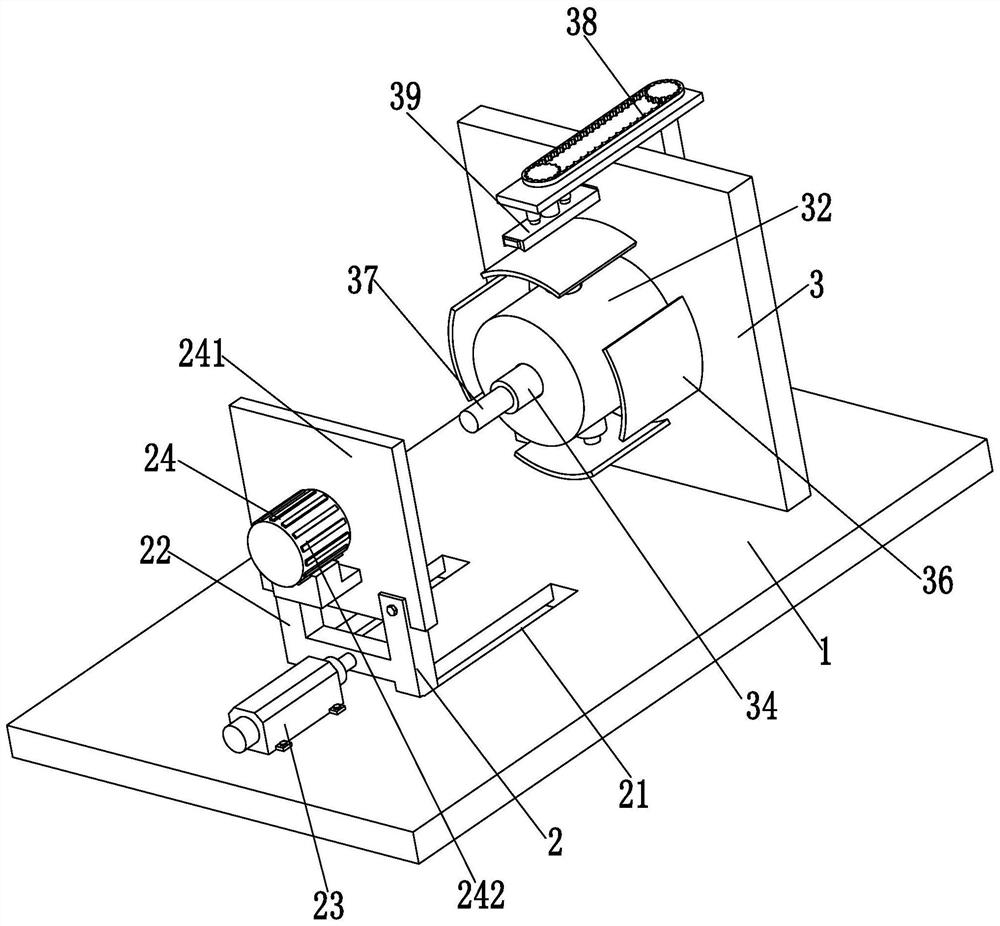

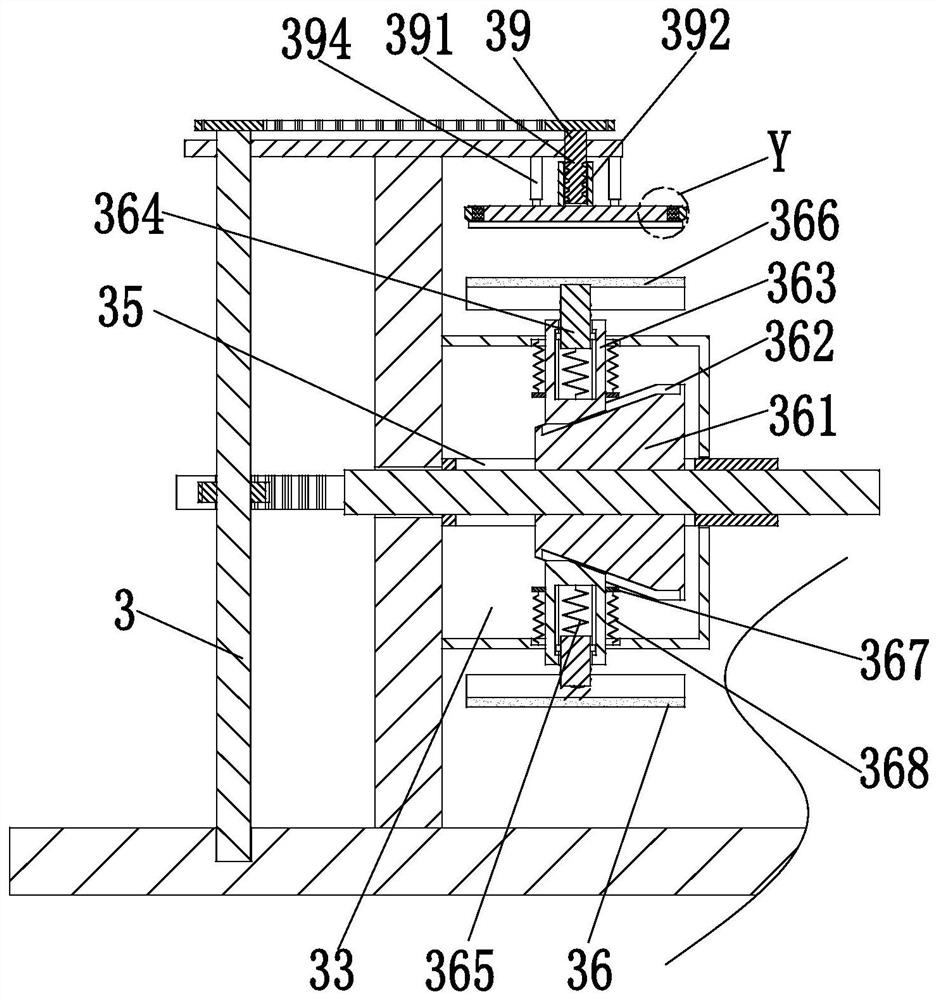

Aluminum alloy hub surface automatic machining system

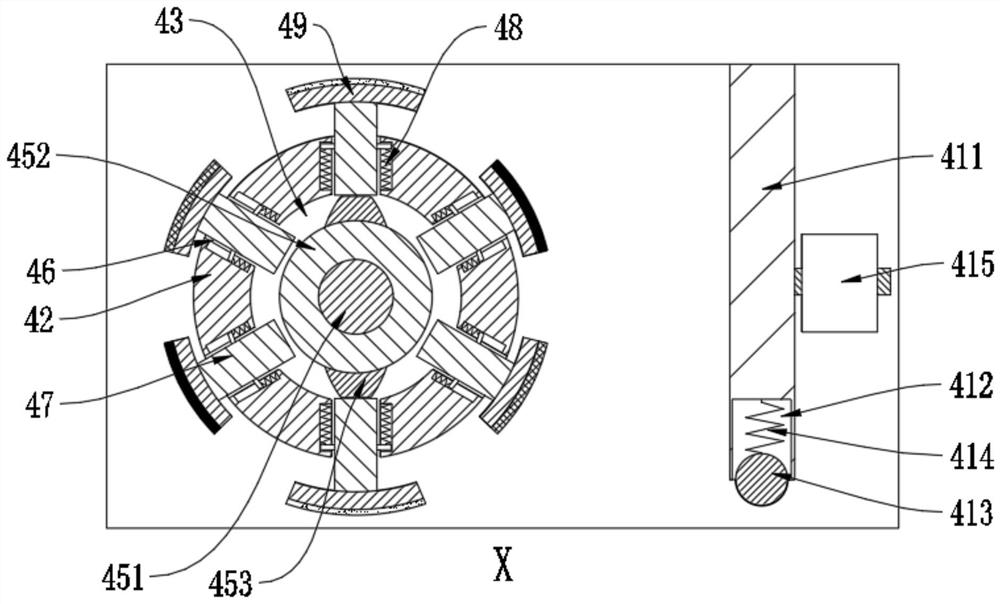

InactiveCN113118958AImprove polishing efficiencyImprove aestheticsPolishing machinesGrinding drivesPolishingStructural engineering

The invention relates to an aluminum alloy hub surface automatic machining system, which comprises a fixed base, a driving device and a polishing device, wherein the driving device is arranged on the right side of the upper end face of the fixed base, and the polishing device is arranged on the left side of the upper end face of the fixed base. The problems that when the surface of an aluminum alloy hub is polished, the inner surface and the outer surface of the aluminum alloy hub cannot be polished at the same time due to the fact that manual handheld polishing equipment is usually adopted for polishing treatment, the machining efficiency is low, the manual labor amount is large, and due to the fact that the outer surface of the aluminum alloy hub is in a curved surface shape and is irregular, therefore, during polishing, the attaching degree of the polishing equipment and the outer surface of the aluminum alloy hub is difficult to ensure, the polishing effect is poor, the overall polishing effect is inconsistent, and the attractive degree and the using effect of the aluminum alloy hub can be affected.

Owner:苏军旗

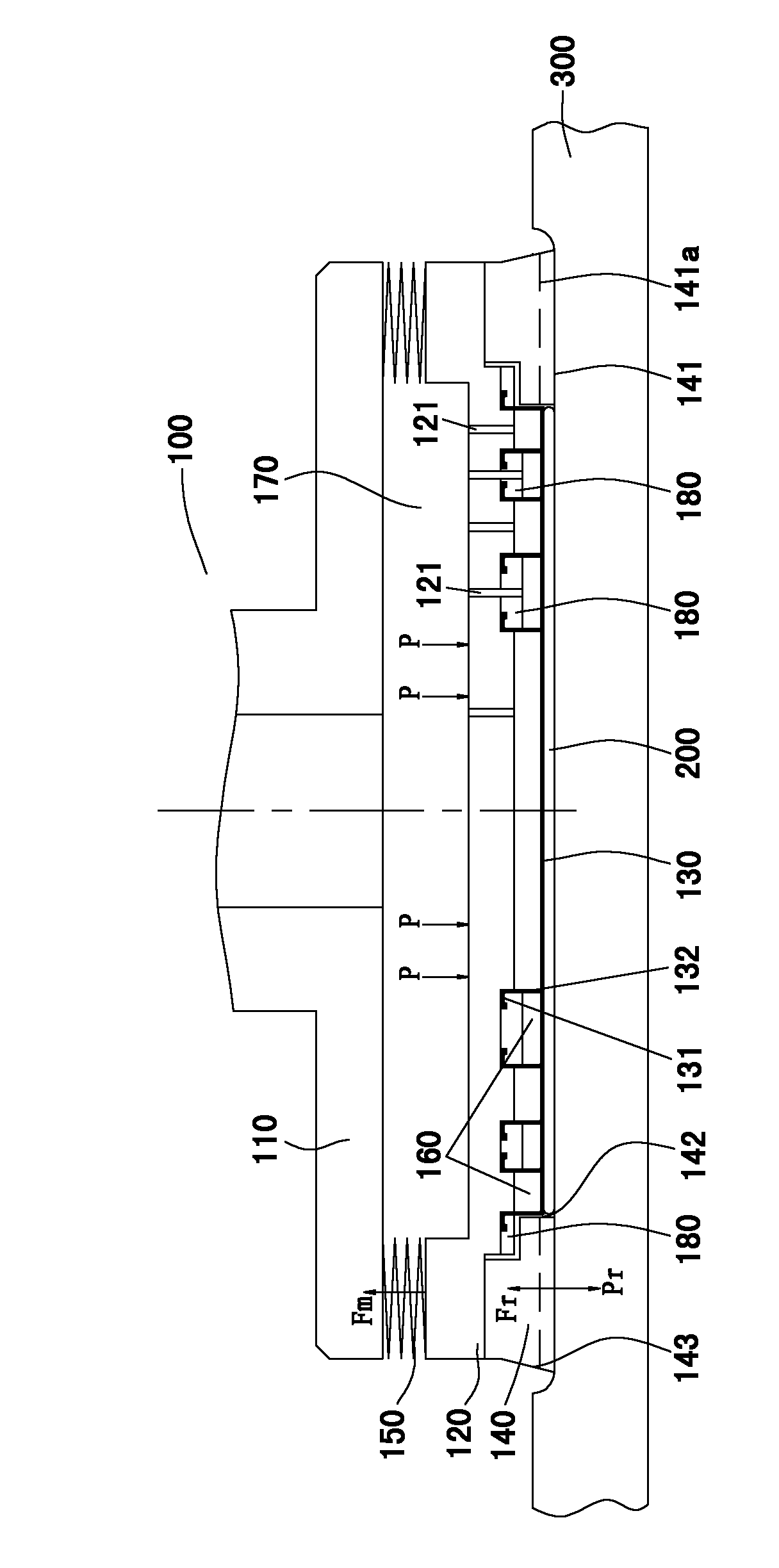

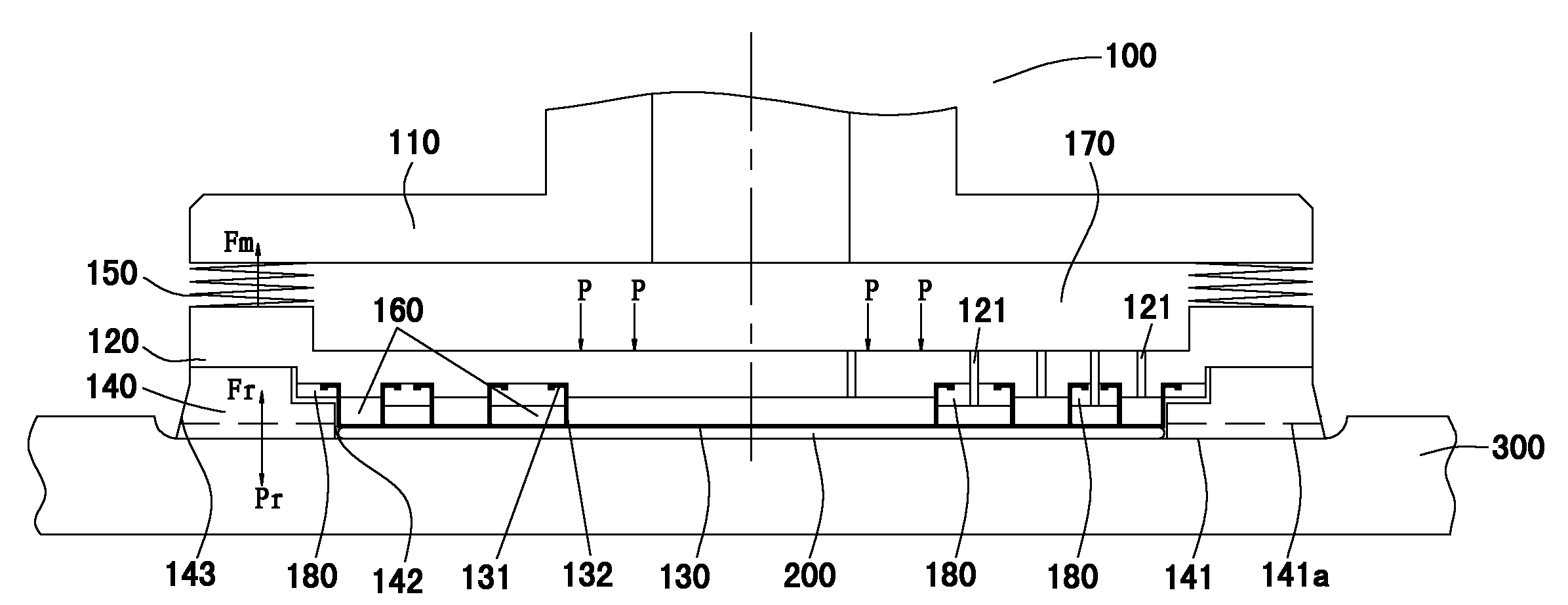

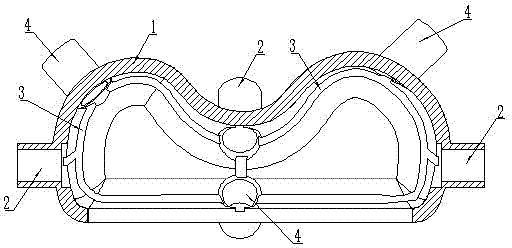

Polishing head

The invention discloses a polishing head comprising a cover plate, a main diaphragm, a substrate, a flexible membrane and a retaining ring, wherein the main diaphragm is annular, has elasticity and is fixed on the lower surface of the cover plate; the substrate is fixed on the lower surface of the main diaphragm; the flexible membrane is fixed on the lower surface of the substrate, and the flexible membrane and the substrate limit a lower cavity communicated with the outside; the retaining ring is fixed on the lower surface of the substrate; and the area of the radial cross section of the retaining ring is gradually decreased from bottom to top. According to the polishing head of the embodiment disclosed by the invention, a wafer can be prevented from throwing in the chemical mechanical polishing process, and even and consistent effect can be obtained. In addition, the abrasion of the retaining ring can not lower polishing effect, and thus the retaining ring has longer service life soas to lower polishing cost.

Owner:HWATSING TECH

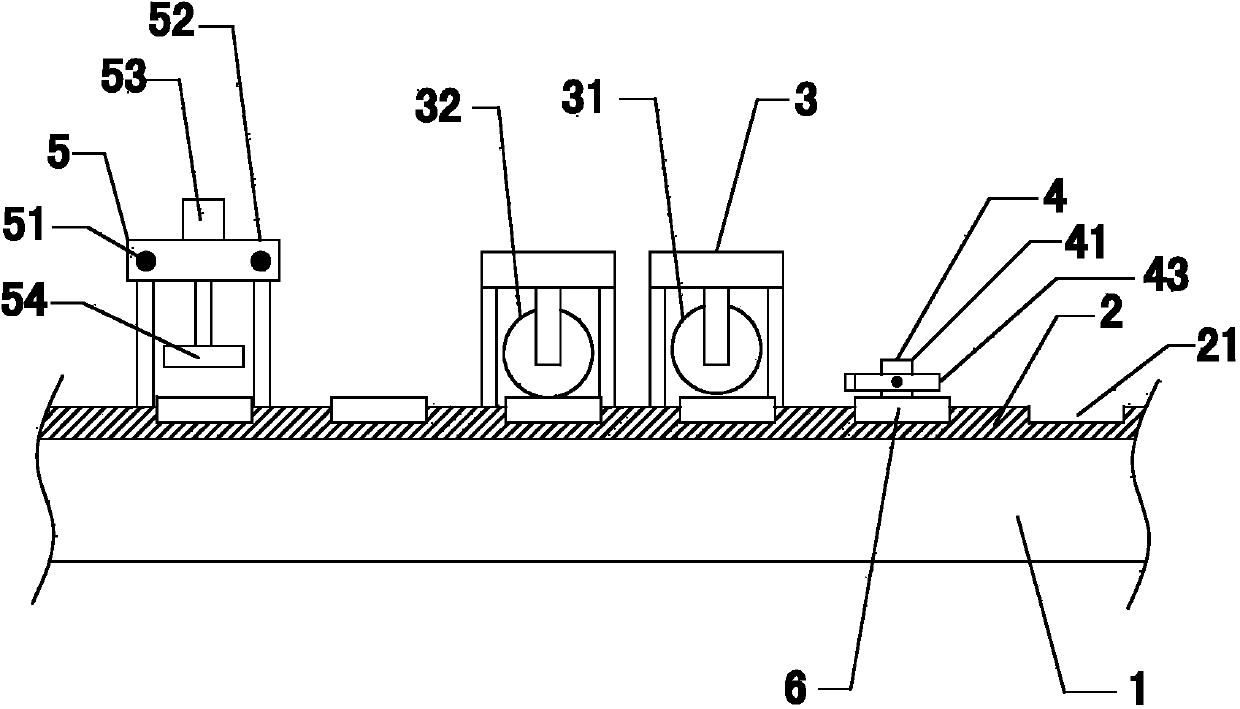

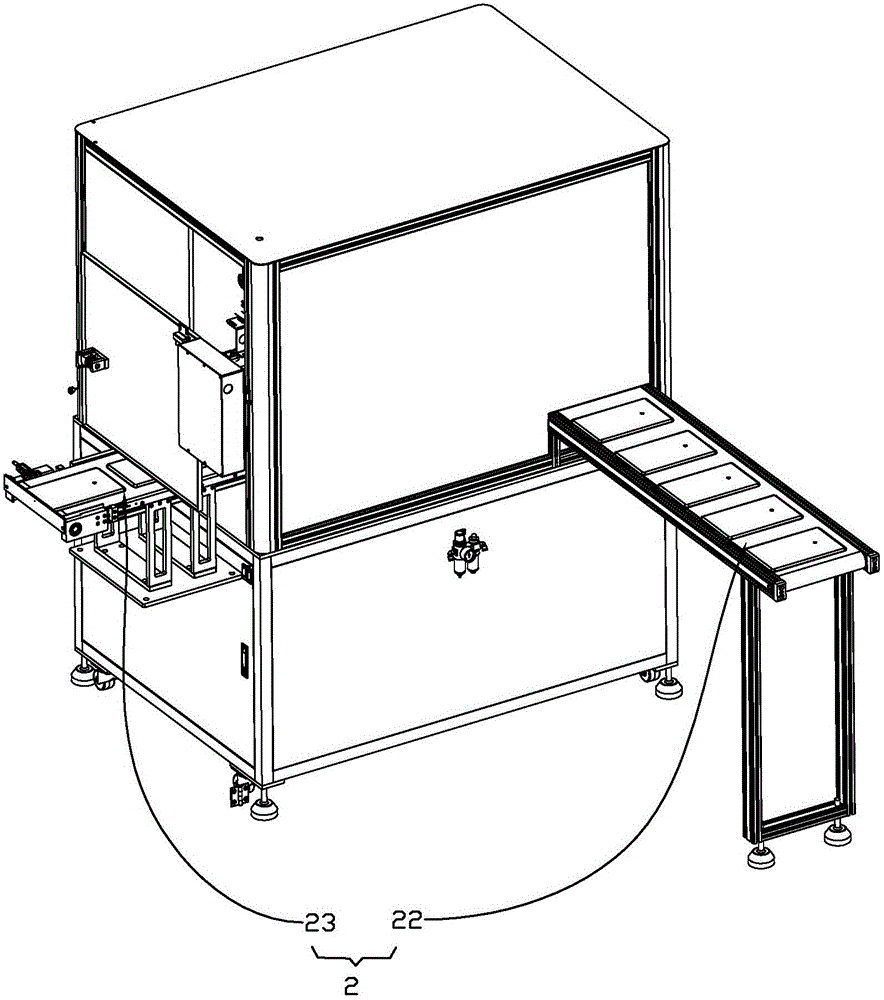

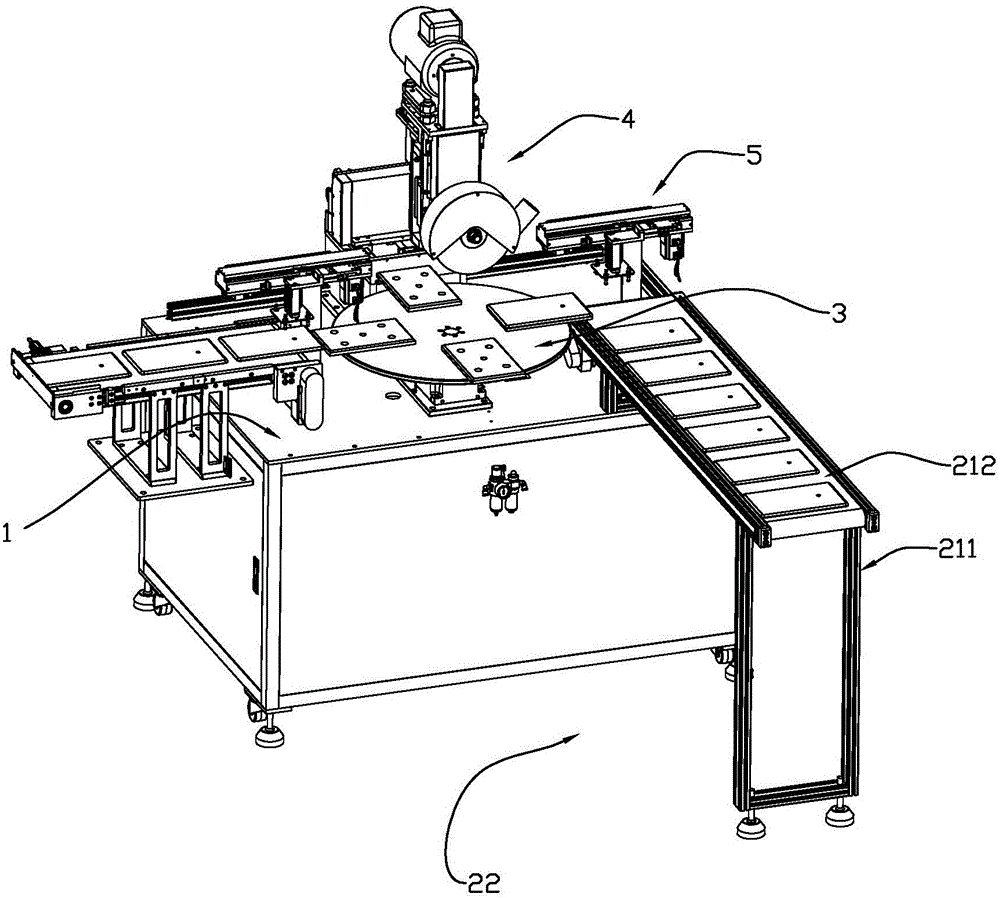

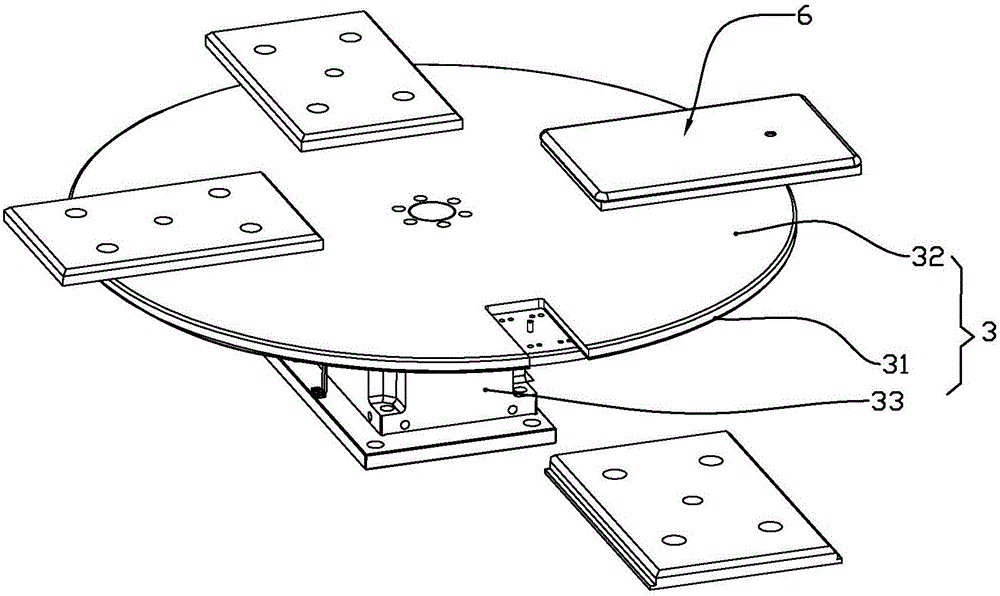

Polishing equipment aiming at metal shell edge

InactiveCN105751050AHigh degree of automationReasonable space designEdge grinding machinesPolishing machinesEngineeringConveyor belt

The invention discloses polishing equipment aiming at a metal shell edge. The polishing equipment comprises a worktable, a conveying assembly, a storage table and a polishing assembly, wherein the storage table is driven to intermittently rotate by a stepping motor; a metal shell is conveyed to a position close to a rotating table by the conveying assembly; an adsorption seat in a manipulator assembly moves outwards along a slide block so as to reach a position above the metal shell and descends along an upright post to be close to a conveyor belt by virtue of a horizontal guide rail; the metal shell is sucked up by a suction nozzle of an adsorption disc; after the metal shell is sucked by the adsorption seat and the adsorption disc, the horizontal guide rail ascends along the upright post, then the slide block drives the adsorption seat to move in place towards the direction of the rotating table along the horizontal guide rail so as to lay down the metal shell; the rotating table rotates to rotate the metal shell to the polishing assembly; the polishing assembly performs polishing on the metal shell edge. The polishing equipment disclosed by the invention is high in degree of automation, reasonable in space design, uniform in polishing effect on the metal shell edge and unified in polishing quality.

Owner:周胡琴

Wear compensation device for buffing wheel of buffing machine

InactiveCN101691025AUniform polishing effectAvoid uncertaintyPolishing machinesElectric machineryEngineering

The invention discloses a wear compensation device for a buffing wheel of a buffing machine. The device comprises a buffing platform, the buffing wheel positioned above the buffing platform and a motor for driving the buffing wheel to rotate, wherein a lifting mechanism for lifting the buffing platform is arranged under the buffing platform; the lifting mechanism is connected with a drive motor; the motor is connected with a current detecting signal control device; the current detecting signal control device is connected with the drive motor; and the buffing wheel is a cloth wheel or other polishing wheels. The device can automatically detect the wear condition of the buffing wheel, and automatically compensate missing stroke after the buffing wheel is worn so as to ensure accordant polishing effect of the surface of a work piece.

Owner:文林

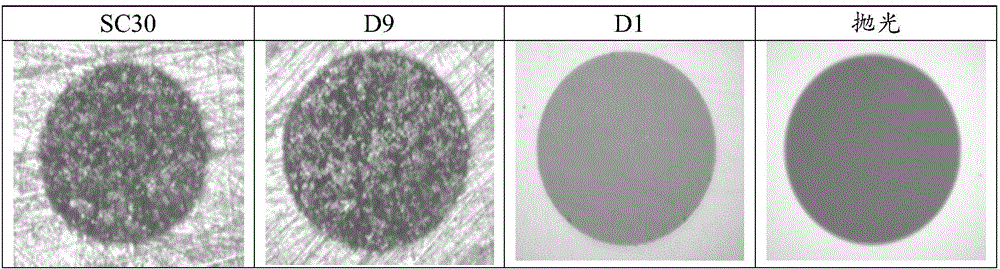

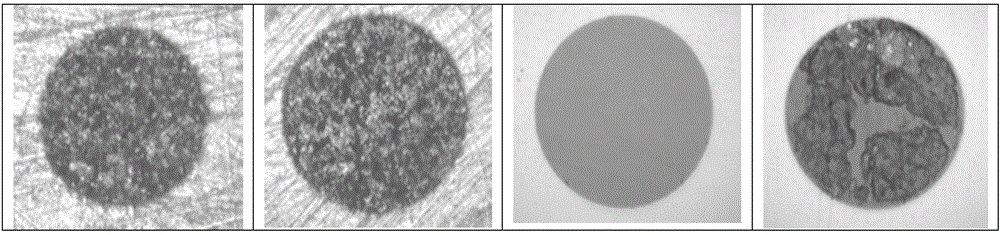

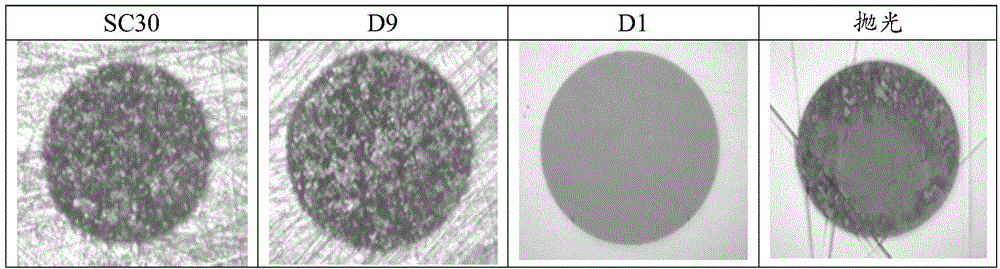

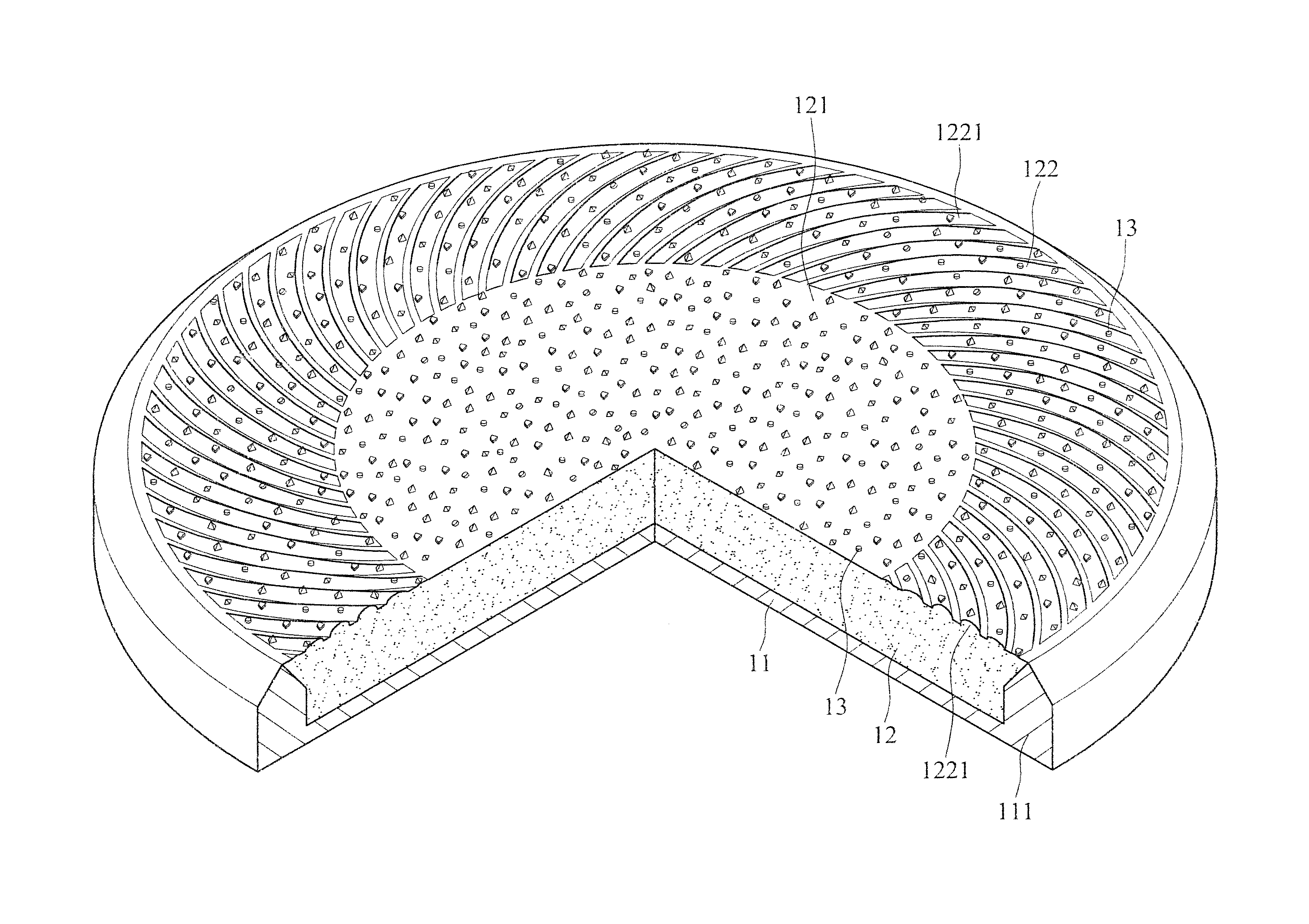

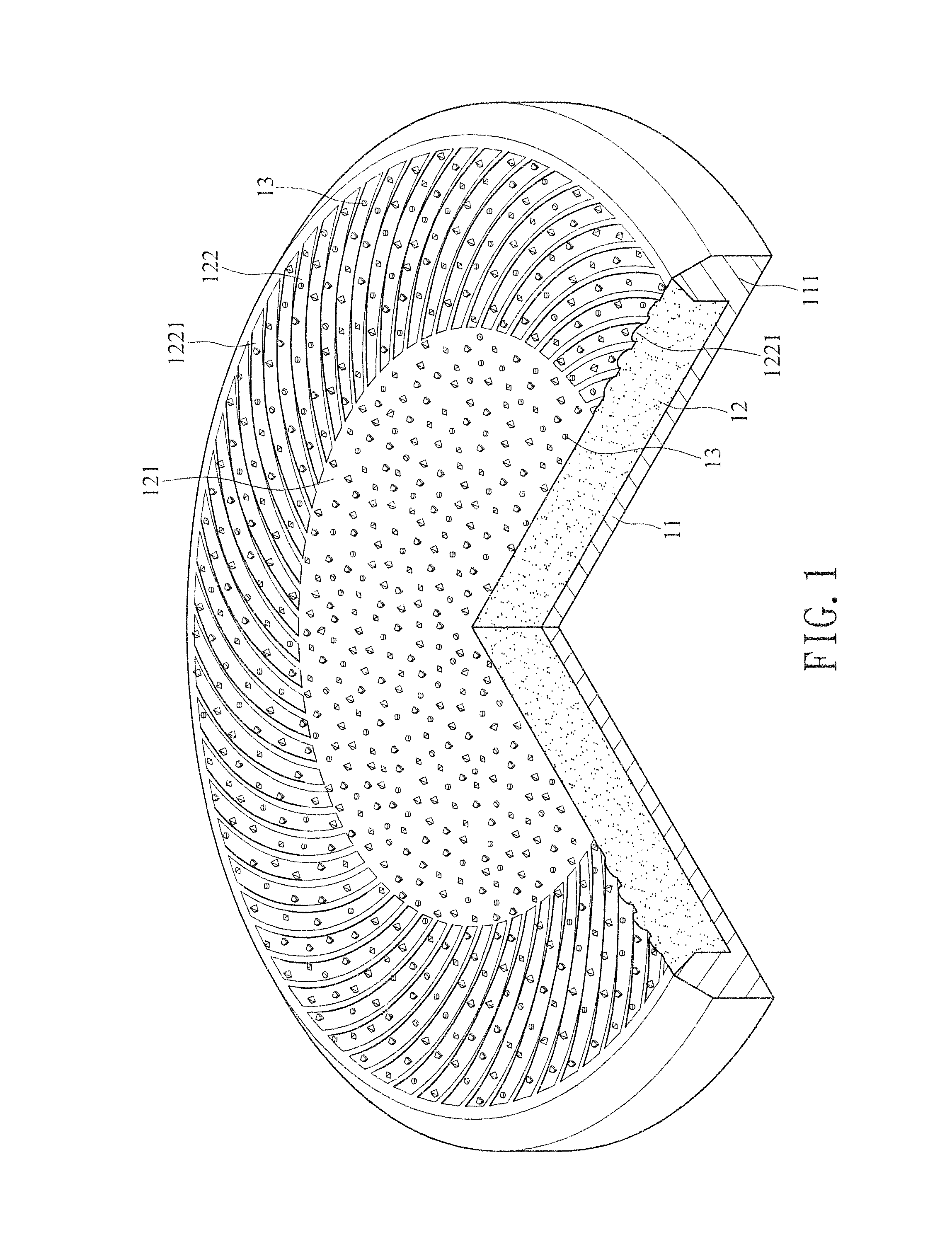

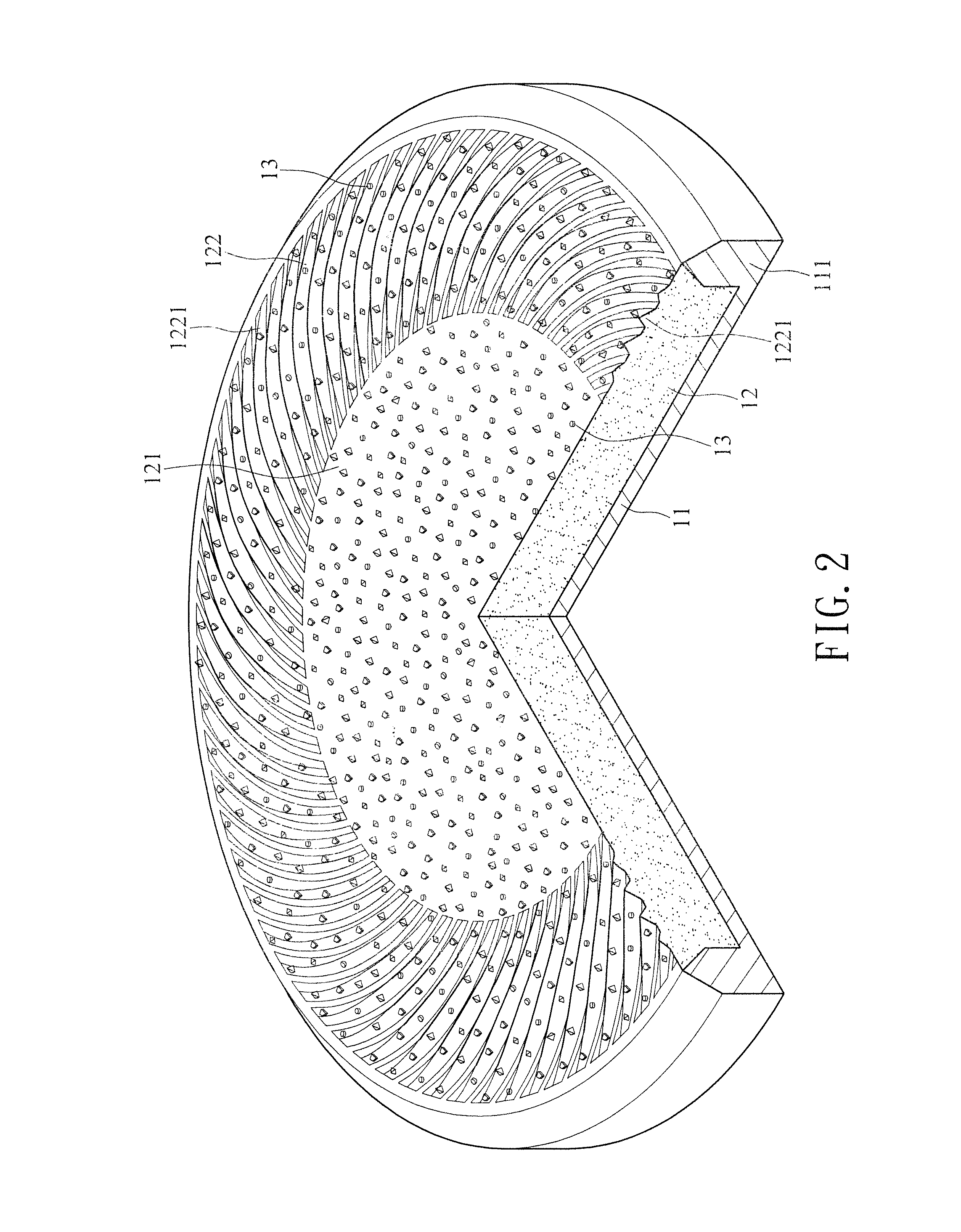

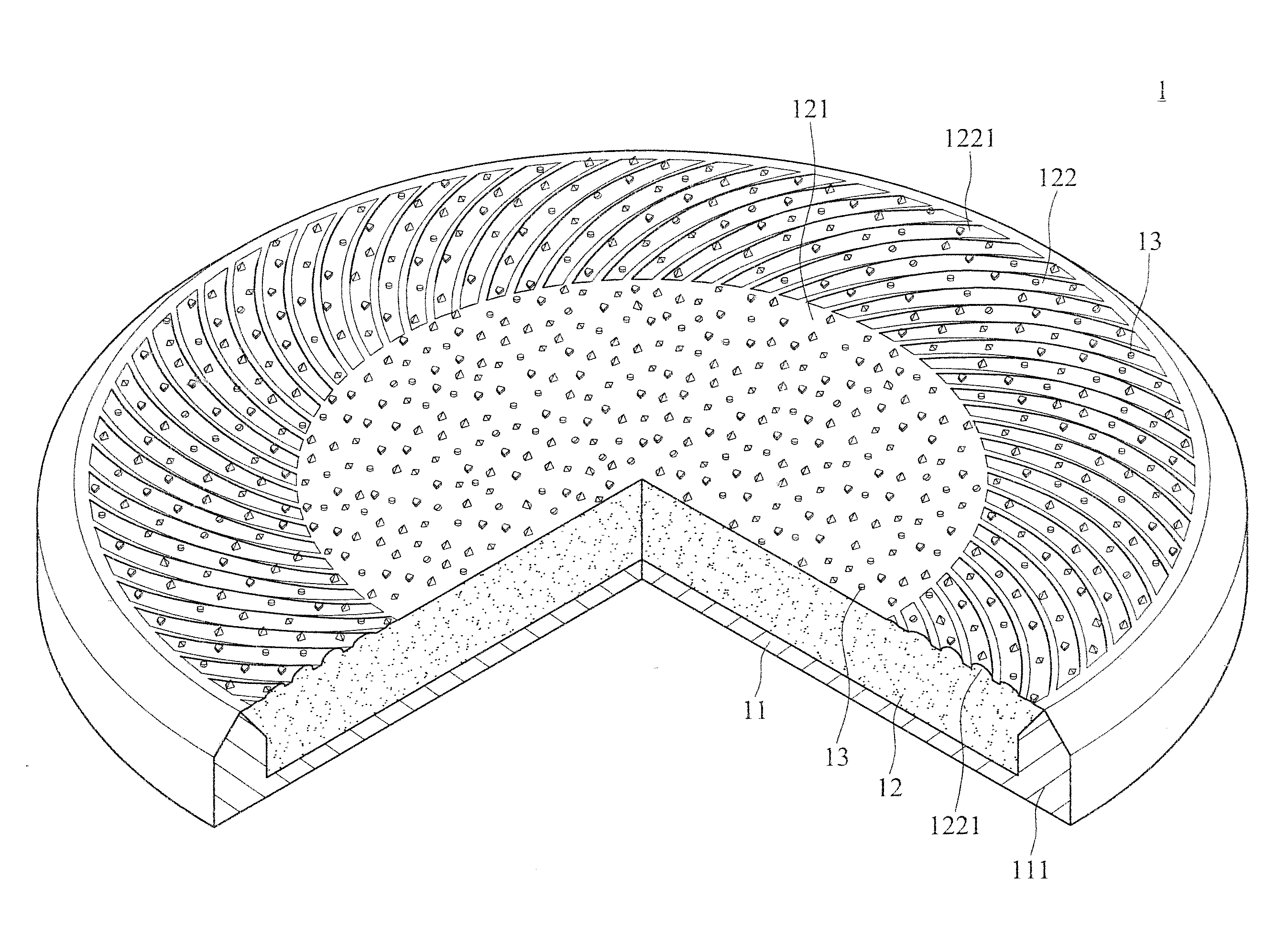

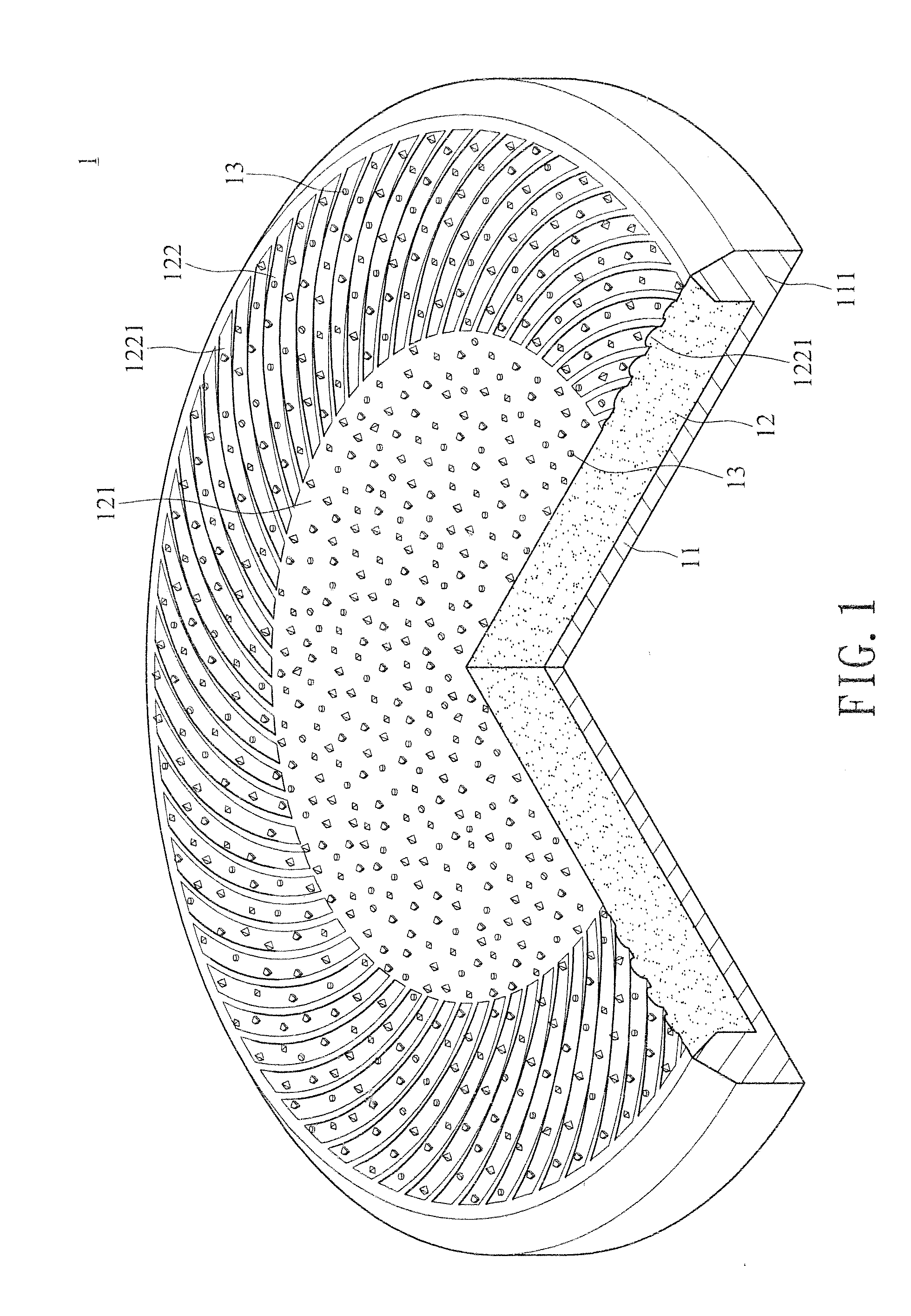

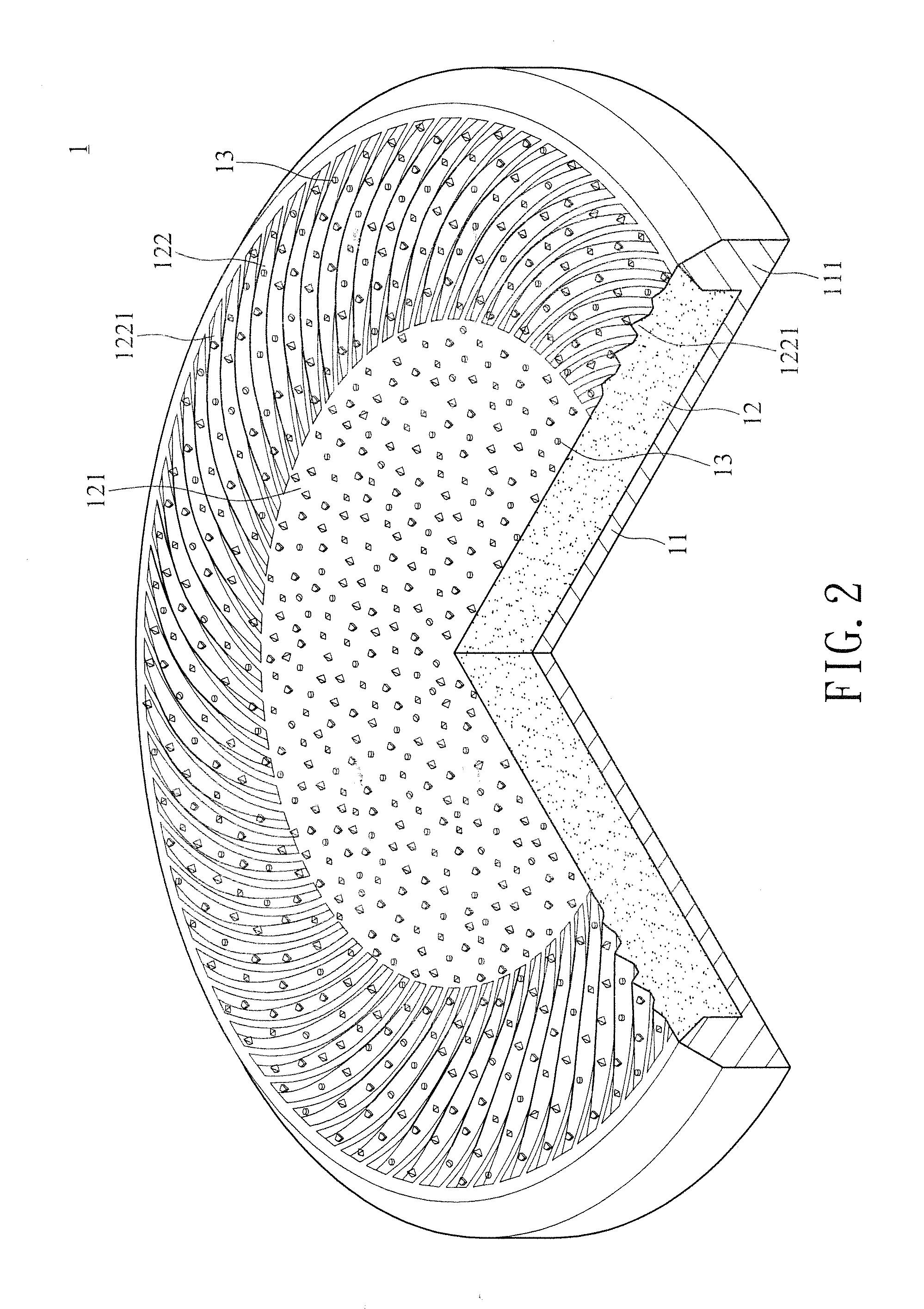

Arc blade-shaped processing surface structure of pad conditioner and manufacturing mold structure thereof

InactiveUS9017060B2Improve polishing efficiencyUniform polishing effectGrinding drivesConfectionerySurface structureBiomedical engineering

An arc blade-shaped processing surface structure of a pad conditioner includes an outer frame, a combining layer and a plurality of polishing particles. The polishing particles are disposed on a surface of the combining layer, and the combining layer has a first region and a second region sequentially arrange from the center to the outside of the combining layer, and the second region has a plurality of arc-shaped protrusions arranged separately from one another and disposed around the external periphery of the first region, and the protrusions arranged in order and separated with an interval apart from each other can be used to provide an appropriate space for extension and rebound for a polished surface material to obtain a definite and uniform polishing effect.

Owner:HUANG HUANG NAN +1

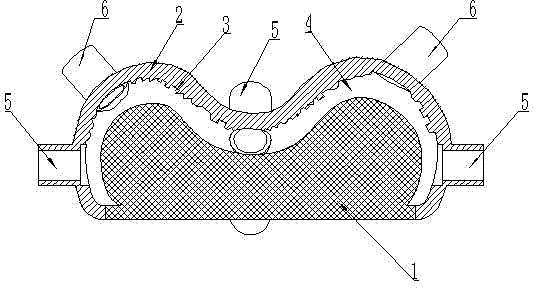

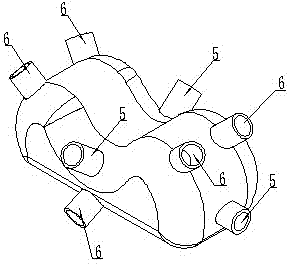

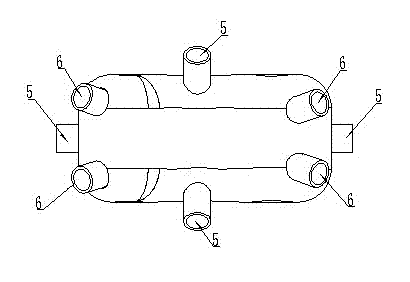

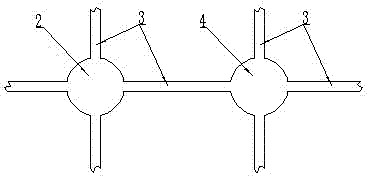

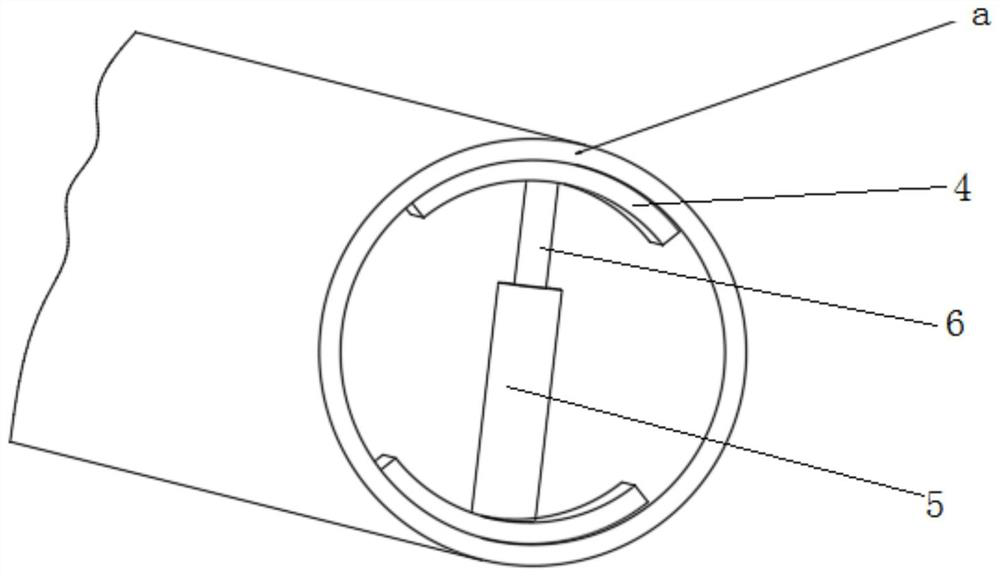

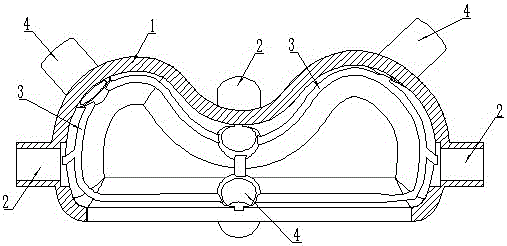

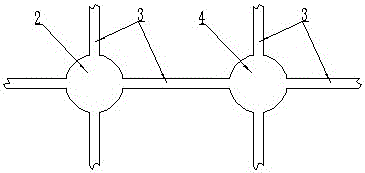

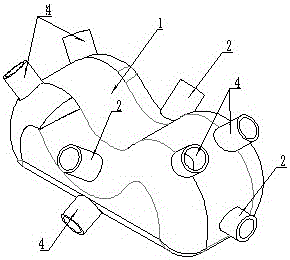

Curved surface turbulence polishing device with multiple outlets and inlets

ActiveCN103612165AImprove processing efficiencyImprove polishing effectPolishing machinesParticle flowEngineering

The invention relates to the field of abrasive particle flow polishing machining, in particular to a turbulence precise machining device for a titanium alloy joint prosthesis. The curved surface turbulence polishing device comprises a constraint component which is installed outside the joint prosthesis in a sleeved mode. The inner surface of the constraint component is the same as the outer surface of the joint prosthesis in shape. A copying flow channel is formed by the inner surface of the constraint component and the outer surface of the joint prosthesis, small grooves are formed in the inner surface of the constraint component, at least two sets of outlets and inlets of abrasive particle flows are formed in the constraint component, and the outlets and inlets of the abrasive particle flows are communicated with the copying flow channel. The copying flow channel where the abrasive particle flows are controlled is constructed through the constraint component, the small grooves are evenly distributed in the inner surface of the constraint component, so that the abrasive particle flows form a turbulence state more sufficiently, the multiple sets of outlets and inlets of the abrasive particle flows are formed in the constraint component, the complex curved surface is machined in a segmenting mode, therefore, it is avoided that polishing is not even because the abrasive particle flows are resisted at curved surface inflection points or singular points, machining efficiency is improved, the polishing effect is optimized, and polishing precision is high.

Owner:NANTONG YUANZHENG FREEZING EQUIP LTD

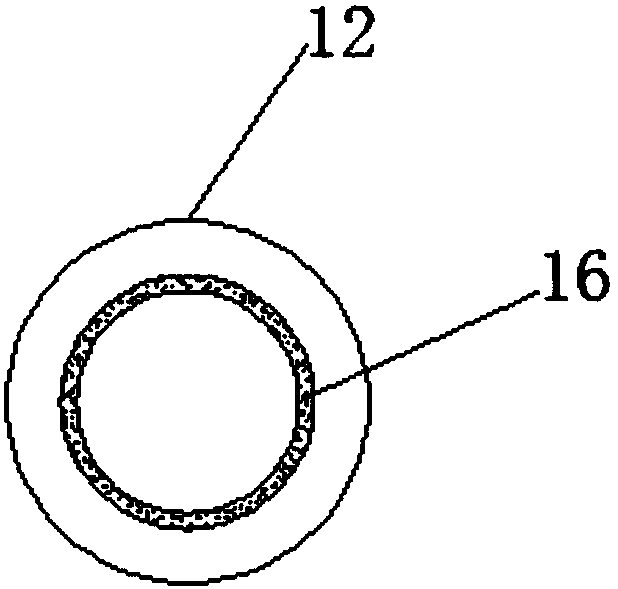

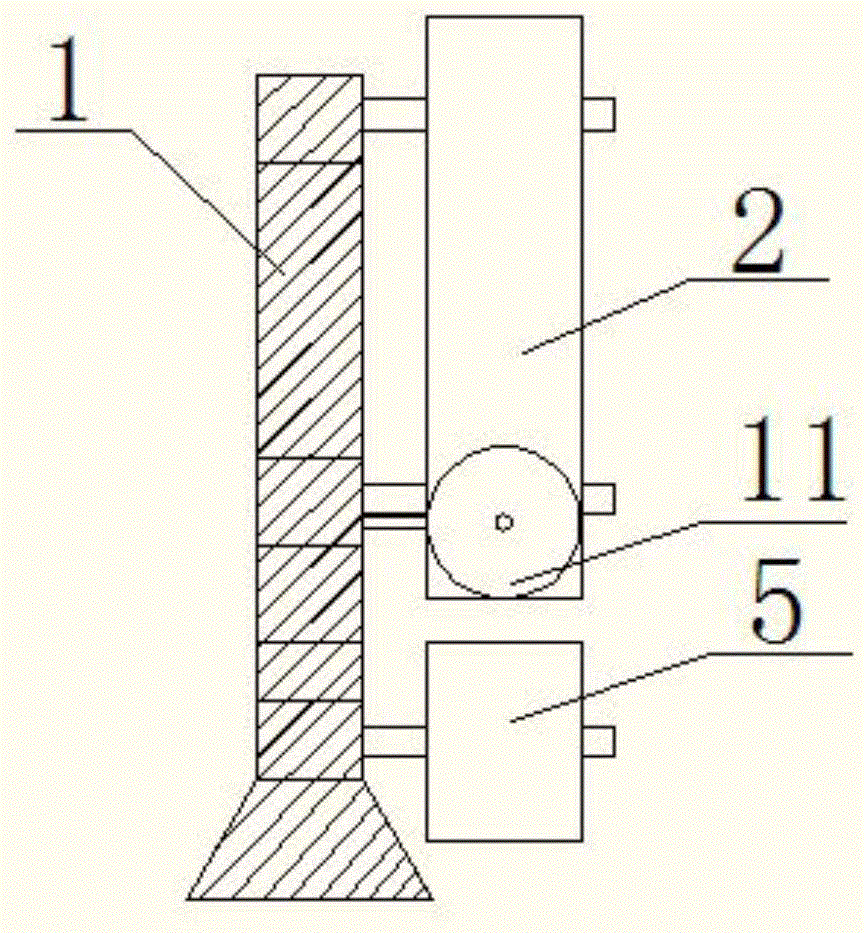

Outer wall polishing device for composite steel pipe

InactiveCN108068002ASimple structurePlay the role of fixing the steel pipePolishing machinesGrinding drivesMechanical engineeringEngineering

The invention discloses an outer wall polishing device for a composite steel pipe. The outer wall polishing device comprises a worktable, a clamp and a polishing device body; a fixed seat is mounted on the worktable; the clamp is rotatably connected with the fixed seat; a chuck is arranged at one end of the clamp, and the other end of the clamp is fixedly connected with a rotating shaft; a motor is mounted in an inner cavity of the fixed seat; an output shaft of the motor is rotatably connected with the rotating shaft through a conveyor belt; a ball screw is arranged at one end of the fixed seat, and one end of the ball screw is provided with a servo motor; the ball screw is slidably connected with a connecting piece, and the polishing device body is rotatably connected with the connectingpiece; a polishing layer is arranged on the inner wall of the polishing device body; and a polishing motor is fixedly mounted in an inner cavity of the connecting piece, and a spindle of the polishing motor is rotatably connected with the polishing device body through a belt. The outer wall polishing device for the composite steel pipe is simple in structure, convenient and practical, so that thepolishing effect is more uniform, and the polishing efficiency is higher.

Owner:TIANJIN HAOHANG COMPOSITE PIPE

Rice polishing machine

Disclosed is a rice polishing machine. The rice polishing machine comprises a base. A sliding groove is formed in the base, a box body is connected with the interior of the sliding groove in a sliding mode, and an intermittent mechanism is further arranged in the sliding groove. A cylindrical processing chamber is arranged in the box body, and a feeding opening is formed in the top of the box body. A hull removing mechanism, a filtering mechanism and a polishing mechanism are arranged in the processing chamber in sequence from top to bottom. The hull removing mechanism is located exactly below the feeding opening, and comprises two driving motors, wherein gears are fixedly connected to rotating shafts of the driving motors. The filtering mechanism comprises a sliding rail and a screen mesh, wherein collecting boxes are arranged at the two ends of the screen mesh. The polishing mechanism comprises a rotating motor, a disc and a plurality of brush bristles. A plurality of supporting rods are arranged on the disc at equal intervals in the circumferential direction, an air chamber is arranged in each supporting rod, and fans are arranged in the air chambers. A plurality of exhaust holes which are communicated with the air chambers are formed in the supporting rods. A through hole is formed in the disc, and a rice box is connected to the through hole. By the adoption of the scheme, the rice polishing machine mainly solves the problem that according to a conventional rice polishing mode, rice is not uniformly polished.

Owner:NINGXIA XINGTANG RICE GRP

Curved turbulence polishing device with pressure equalizing grooves

ActiveCN103612166ACauses uneven polishingSpeed up the flowPolishing machinesParticle flowArtificial joints

The invention provides a cambered turbulence polishing device with pressure equalizing grooves. The cambered turbulence polishing device comprises a constraint component which is arranged outside an artificial joint in a sleeved mode. The inner surface of the constraint component and the outer surface of the artificial joint are identical in shape. A profiling runner is arranged between the inner surface of the constraint component and the outer surface of the artificial joint. At least two sets of abrasive particle flow inlets and outlets are arranged in the constraint component. Grooves are arranged in the peripheries of the abrasive particle flow inlets and outlets to form the pressure equalizing grooves. The pressure equalizing grooves are distributed in the inner surface of the constraint component. The pressure equalizing grooves in the two adjacent abrasive particle flow inlets and outlets are mutually communicated. According to the cambered turbulence polishing device, the profiling runner for controlling abrasive particle flow is arranged through the constraint component, multiple sets of abrasive particle flow inlets and outlets are arranged in the constraint component, and a complex cambered surface is machined in a segmented mode, so the condition that the abrasive particle flow encounters resistance at inflection points or singular points of the cambered surface to cause uneven polishing is avoided. The pressure equalizing grooves are arranged in the peripheries of the abrasive particle flow inlets and outlets, so that pressure is evenly distributed on the inner surface of the constraint component, and the problem of high-pressure interference at the abrasive particle flow inlets is solved to some extent. Therefore, the cambered turbulence polishing device with the pressure equalizing grooves is good in polishing effect and high in precision.

Owner:NANTONG EXPEDITIONICESOURCE REFRIGERATION EQUIP

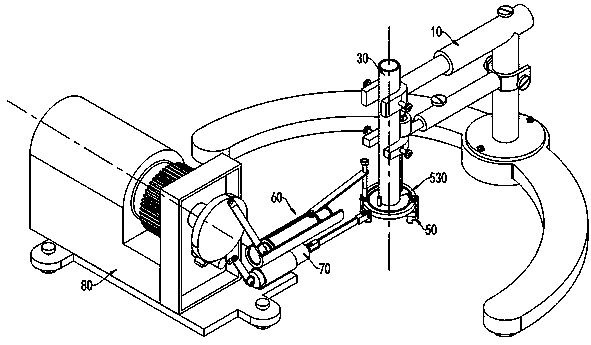

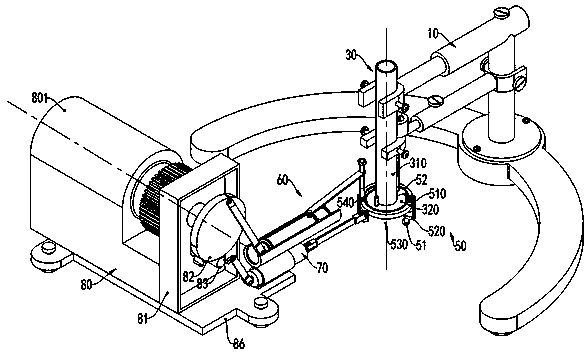

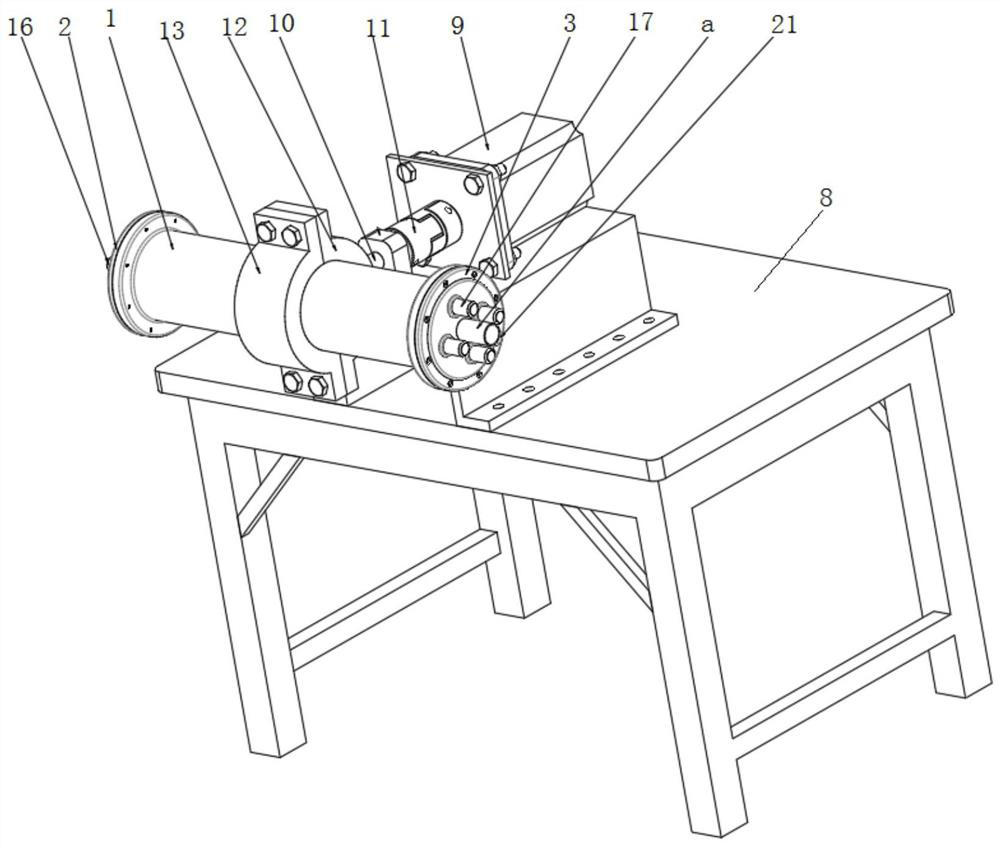

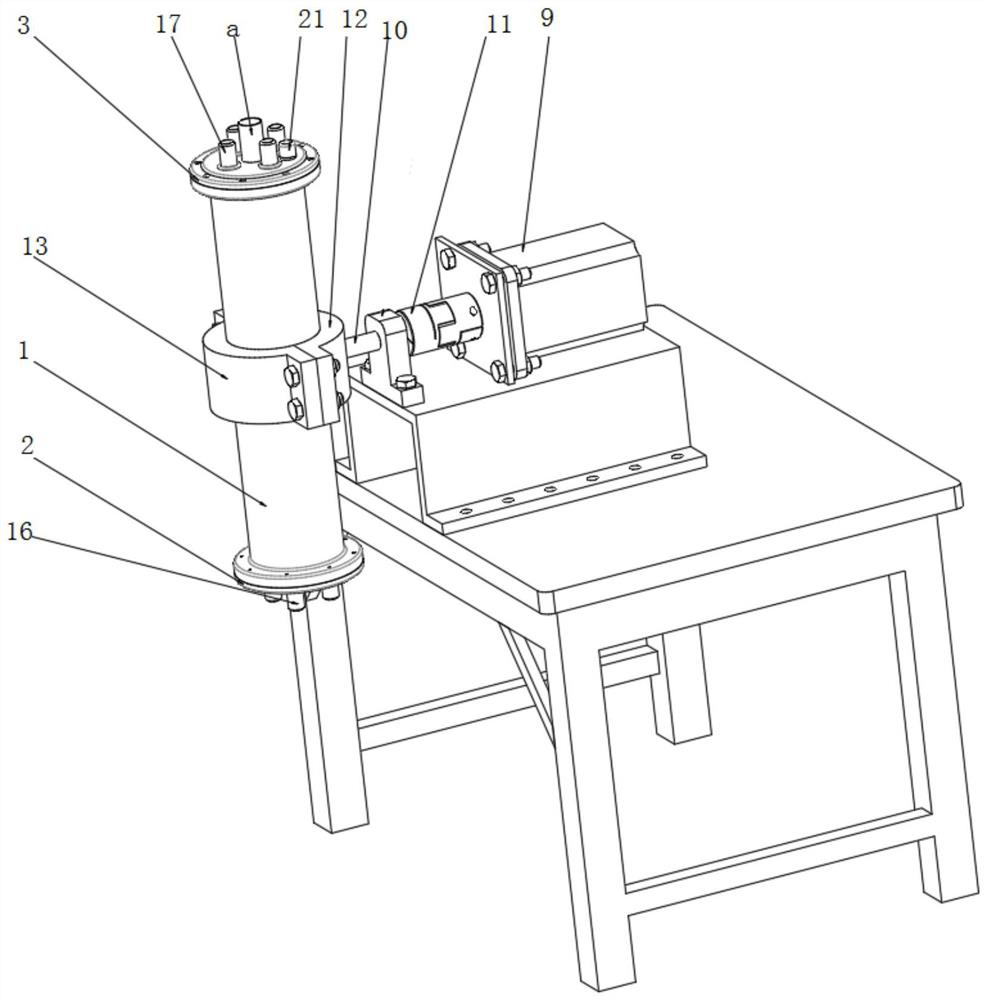

Clamping device for polishing metal material

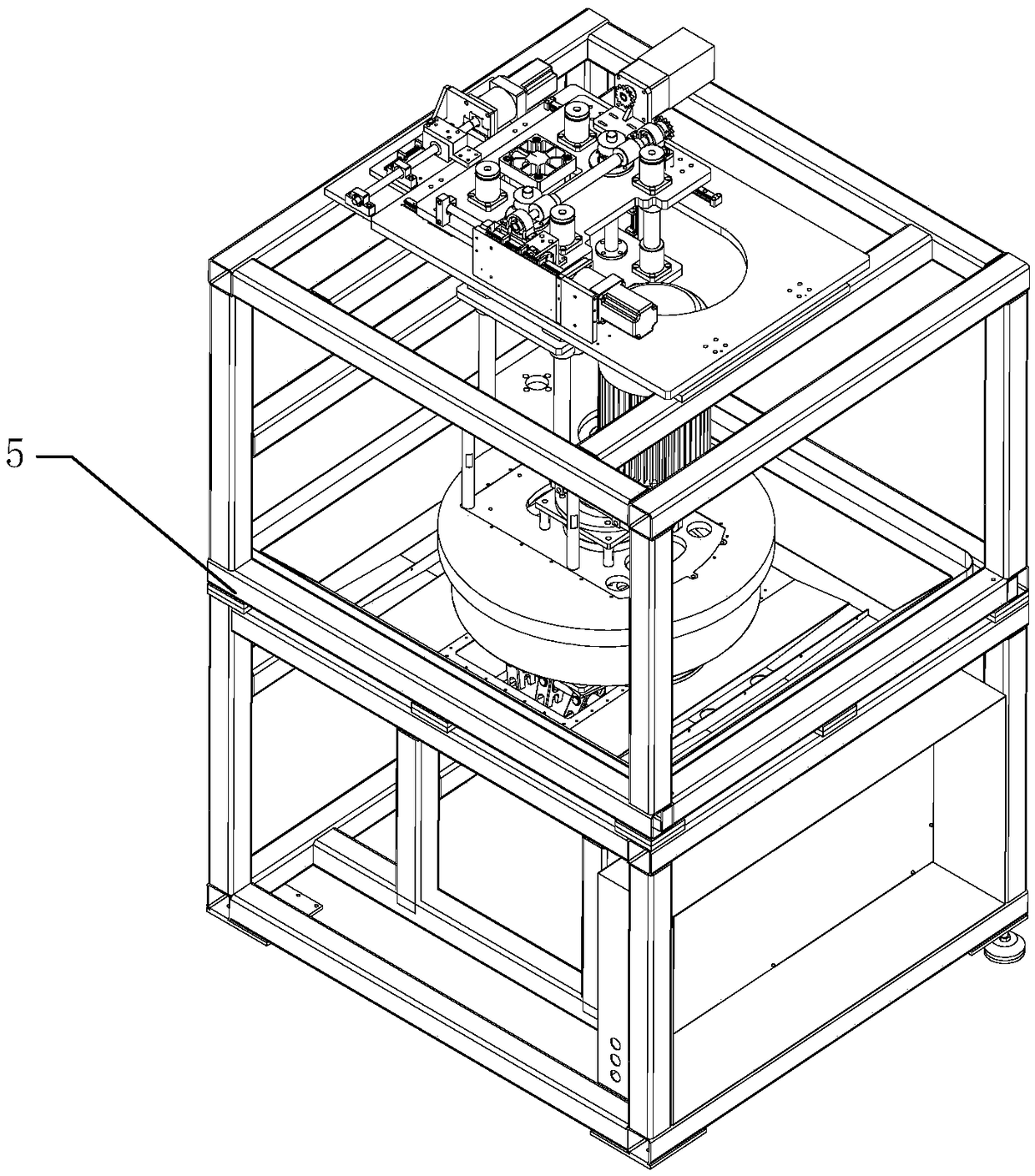

ActiveCN111438622AShorten the timeReduce manual operationsGrinding carriagesPolishing machinesPolishingMetallic materials

The invention relates to the technical field of metal material processing, in particular to a clamping device for polishing a metal material, which solves the problem that no devices that can guarantee the application of a controllable loading force to the polishing metal material and can periodically switch the polishing direction of the metal material are existed in the prior art. The clamping device for polishing the metal material specifically includes a bracket assembly; a force applying mechanism is detachably fixed on the working end of the bracket assembly; a clamping assembly can slide along a track and is also used for clamping the circumferential direction of the metal material to be processed; a first transmission mechanism drives and controls the clamping assembly to slide along the track within a preset sliding track scope; a driving mechanism is used for driving the first transmission mechanism to drive and control the clamping assembly to slide along a preset rotation track; a second end can be detachably connected to the driving mechanism or can be maintained in transmission connection with the driving mechanism; and the driving mechanism can intermittently drive asecond transmission mechanism. The clamping device for polishing the metal material can provide a controllable loading force and can prevent partial polishing; and the polishing process does not require manual contact with the polishing material, and is safe and reliable.

Owner:JILIN UNIV

Efficient electrochemical polishing device and method for outer surface of tungsten pipe

ActiveCN113832532AIncrease roughnessGood removal effectElectrolysis componentsElectrolytic agentMetallurgy

The invention provides an efficient electrochemical polishing device and method for the outer surface of a tungsten pipe. The method comprises the following steps that S1, pretreatment is conducted, specifically, the to-be-polished tungsten pipe is cleaned to remove impurities on the surface of the tungsten pipe, and the to-be-polished tungsten pipe is dried; S2, electrochemical polishing is conducted, specifically, a barrel is provided, the to-be-polished tungsten pipe is inserted into the barrel, the central axis of the to-be-polished tungsten pipe is made to coincide with or be parallel to the central axis of the barrel, the central axis of the to-be-polished tungsten pipe is made to be vertically arranged, electrolyte is introduced into the barrel till the barrel is full of the electrolyte, the central axis of the to-be-polished tungsten pipe is horizontally arranged, the to-be-polished tungsten pipe and the barrel are connected to an positive electrode and an negative electrode of a power source correspondingly, meanwhile, the electrolyte is circularly guided into the barrel, the electrolyte is left to stand, the central axis of the to-be-polished tungsten pipe is vertically arranged, introduction of the electrolyte is stopped, the barrel is opened for exhausting and left to stand, the power source is disconnected after polishing is finished, and the tungsten pipe is taken out; and S3, post-treatment is conducted, specifically, the tungsten pipe is cleaned and dried. According to the efficient electrochemical polishing device and method, efficient polishing of the tungsten pipe is achieved, the polishing efficiency is effectively improved, and the polishing quality is excellent.

Owner:HEFEI UNIV OF TECH

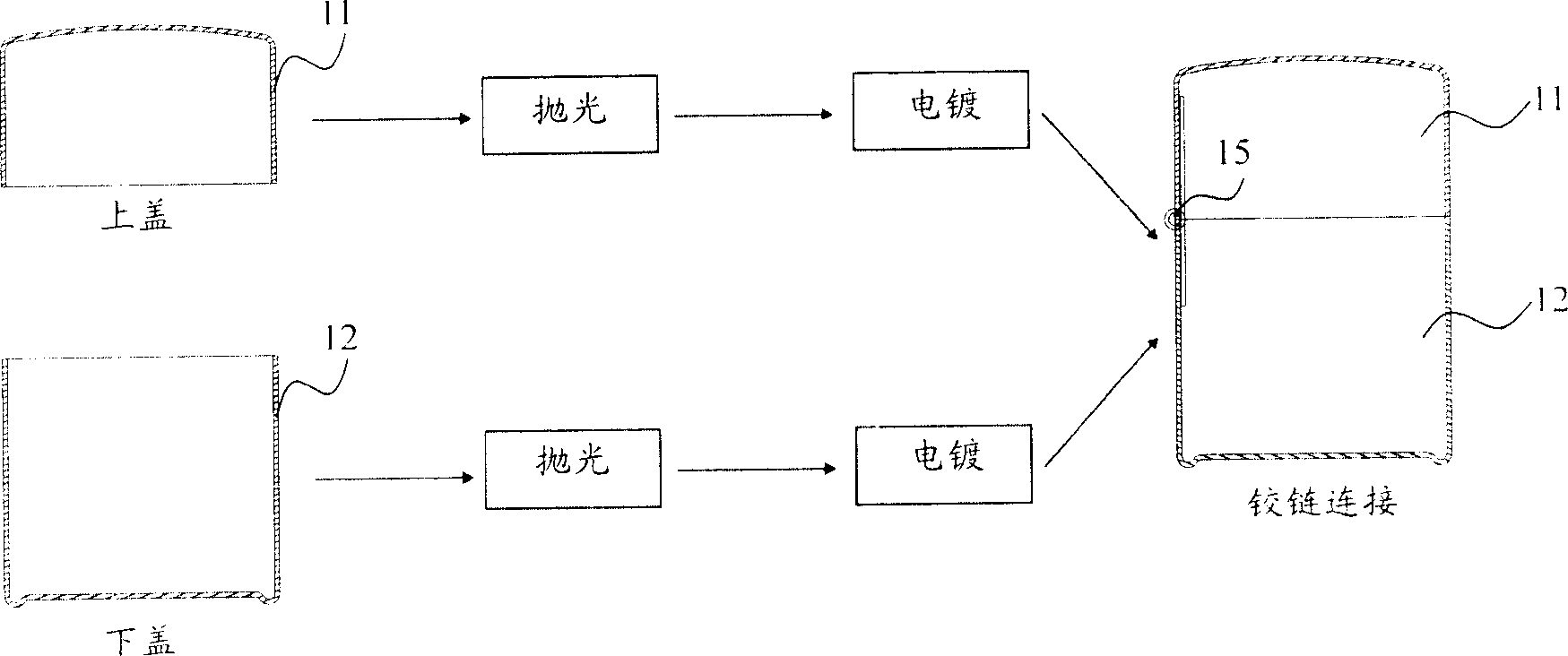

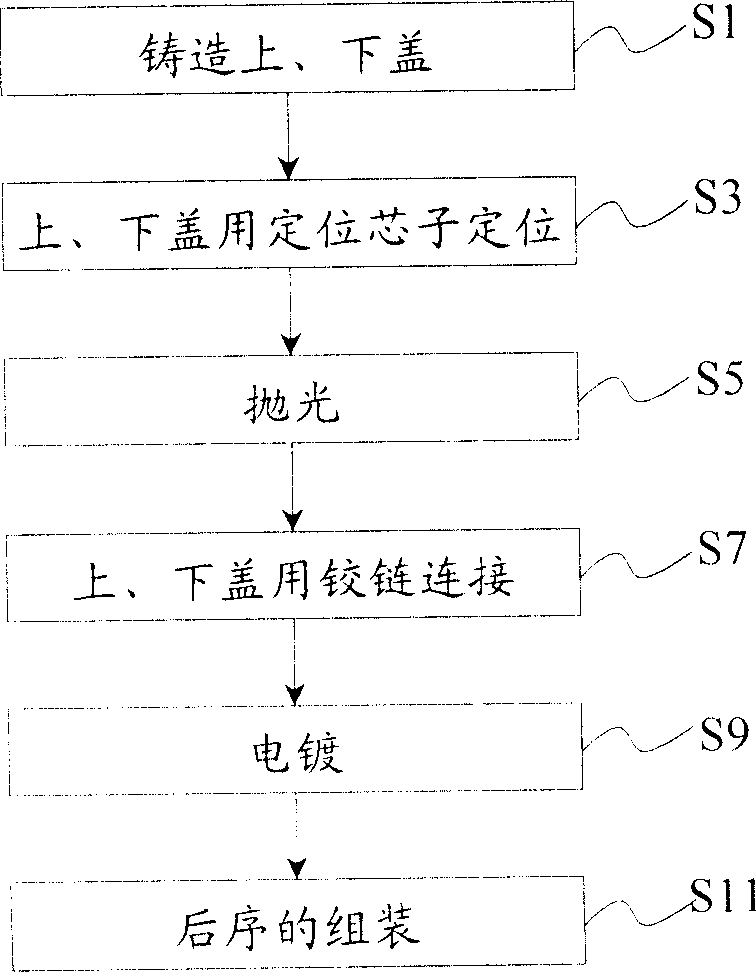

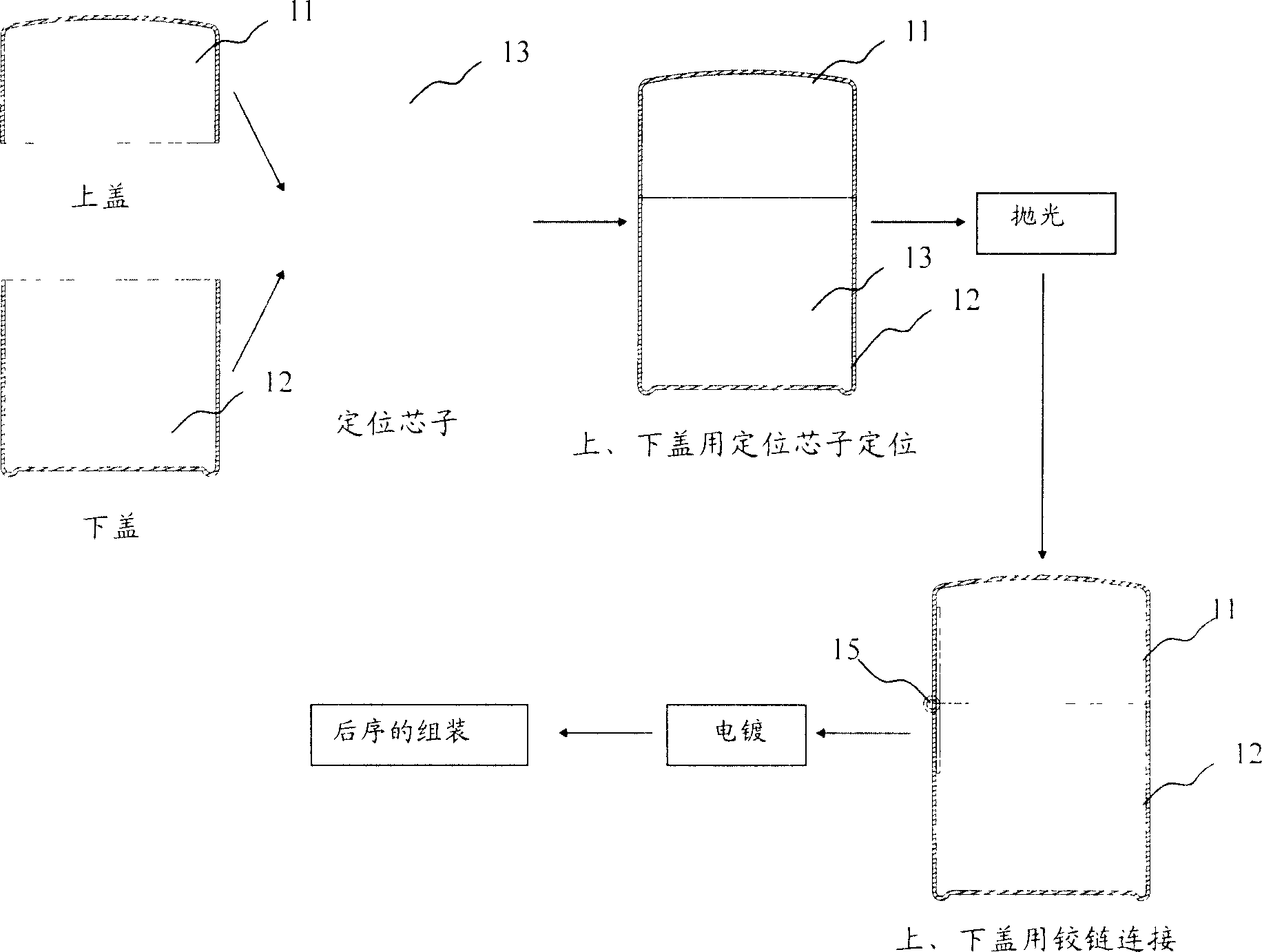

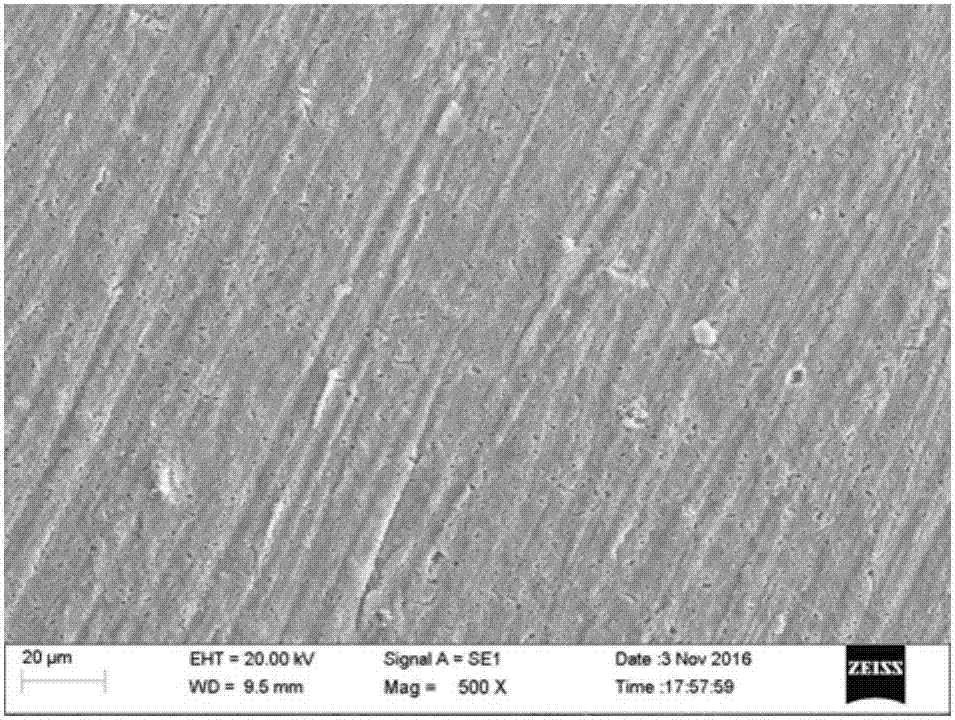

Process for treating lighter cast shell surface and sticking sheet for lighter shell

InactiveCN1900597AThe electroplating wire path is neat and consistentPlating color difference is consistentFuel lightersSurface finishingHinge angle

The body case of lighter unit includes ascast up cover and low cover. Processing steps are included as following: up cover and low cover are positioned by marking core so as to combine up cover with low cover tightly; polishing positioned up cover and low cover integrally; then, taking out marking core, and connecting up cover and low cover through hinge; finally, plating connected up cover and low cover. The up cover and low cover also include up and low skim sheets. The invention also includes following processing steps: connecting back faces of ascast up skim sheet, and low skim sheet through connection set; then plating them integrally; removing the connection set after plating; finally, pasting up and low skim sheets to up and low covers correspondingly. The invention also discloses skim sheet for body case of lighter including up and low skim sheets, which are formed integrally. The invention solves issues of plating chromatic aberration and floss in wire drawing plating.

Owner:陈建华

Aluminum alloy cylinder body and ceramic treatment method thereof

InactiveCN107447244AExtended service lifeImprove mechanical propertiesAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides an aluminum alloy cylinder body and a ceramic treatment method thereof, and relates to the technical field of light metal surface treatment. The ceramic treatment method of the aluminum alloy cylinder body comprises the steps that an electrolytic solution which comprises sodium hexametaphosphate, a film-forming agent and a pH regulator is fed into a cylinder body, and microarc oxidation treatment is carried out. The ceramic treatment method is simple in preparation technological process, high in controllability, low in preparation cost, and high in environmental-friendly degree, and is suitable for mass production. The aluminum alloy cylinder body is prepared through the treatment of the ceramic treatment method of the aluminum alloy cylinder body. The aluminum alloy cylinder body is provided with a ceramic oxidation film layer, so that the density and the intensity are high, the uniformity is good, and the aluminum alloy cylinder body is good in abrasive resistance, high in hardness, long in service life and excellent in lubricating property.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

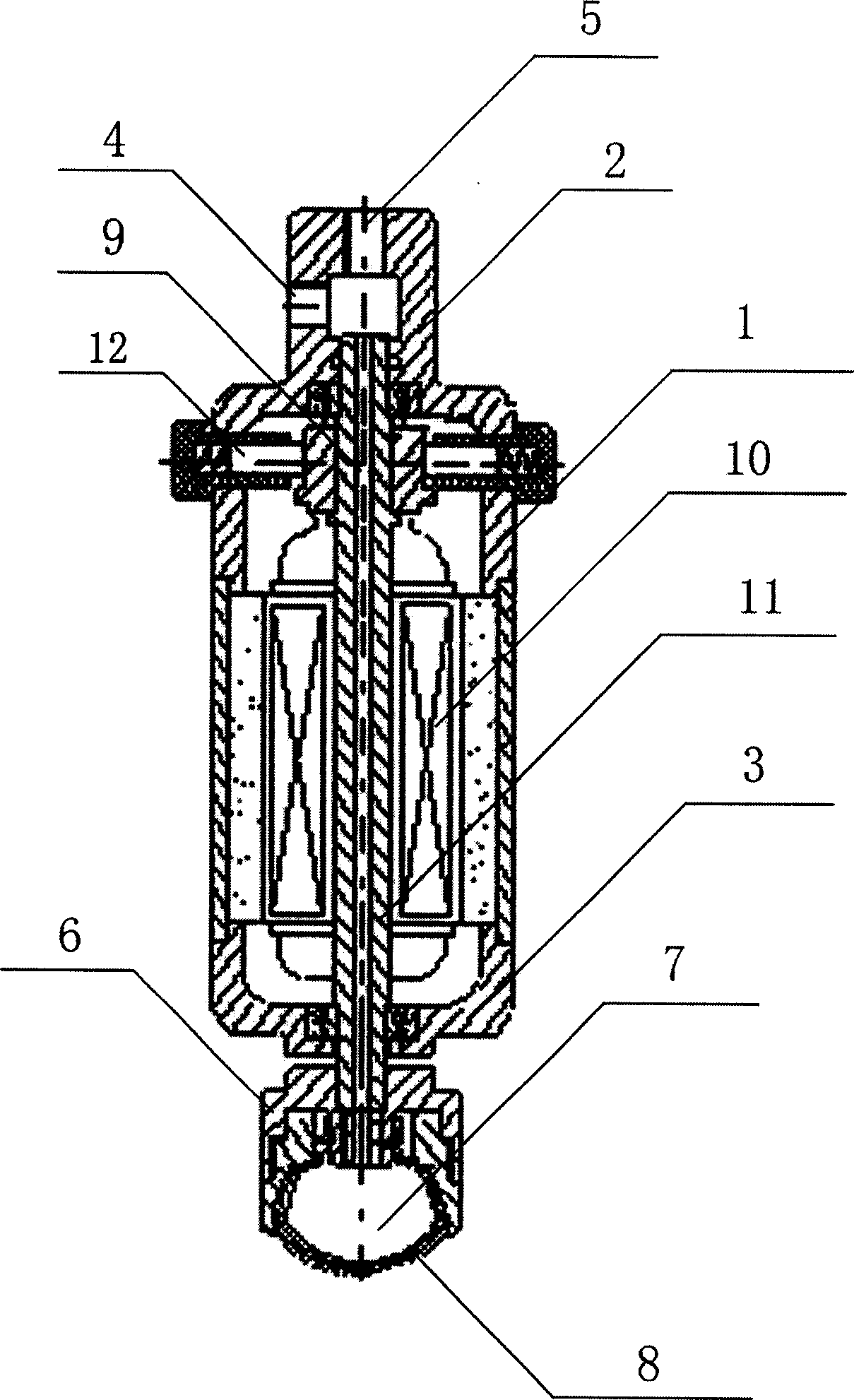

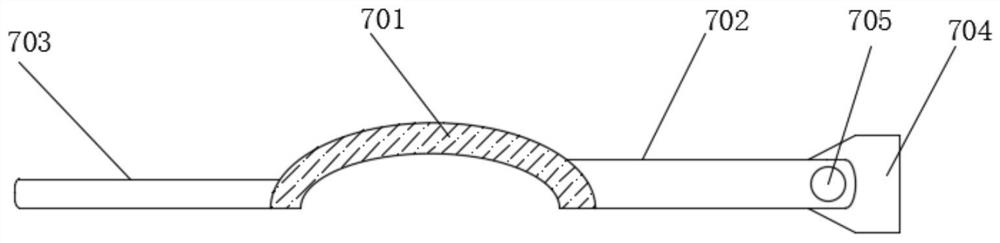

Self-driving air sac pressure controlled flexible furbisher

InactiveCN1754660AFlexible adjustment of removal volumeImprove polishing efficiencyMetal working apparatusEngineeringGas chamber

This invention relates to automatic gas pressure control flexible polishing tool, which comprises the following parts: one gas chamber with polishing cloth as work surface in front end installed in one sustaining rack; one rotation drive structure connected to the sustaining rack; the said gas chamber is connected to the outer gas source entrance through gas channel with overflow valve. The invention provides one mode curve polishing tool with high efficiency and quality.

Owner:ZHEJIANG UNIV OF TECH

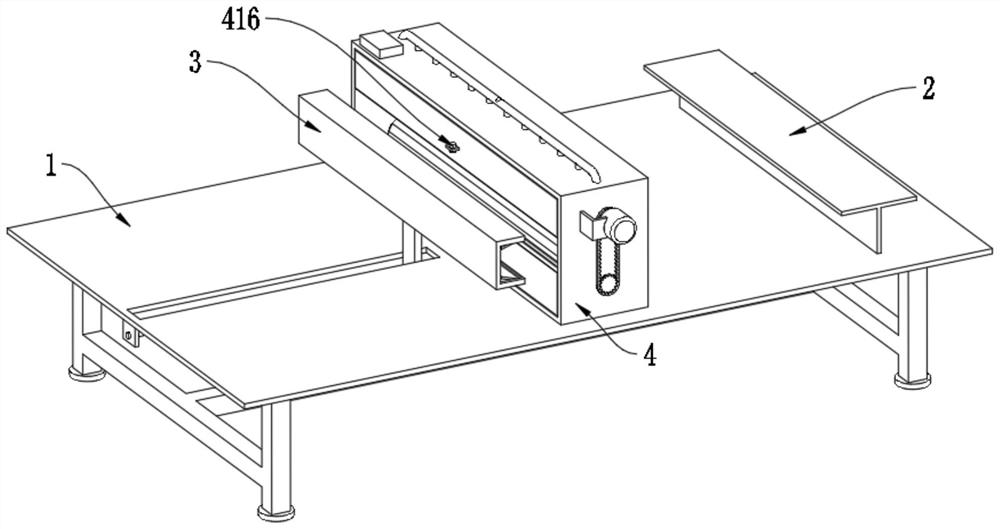

Grinding and polishing device and method for wood processing

ActiveCN114571332AImprove grinding and polishing efficiencyReduce workloadGrinding carriagesPolishing machinesPolishingIndustrial engineering

The invention relates to the technical field of plate processing, in particular to a grinding and polishing device and method for wood processing, the grinding and polishing device comprises a mounting bottom plate, supporting columns are evenly fixed to the positions, close to the four corners, of the lower end face of the mounting bottom plate, and a T-shaped containing frame is mounted on one side of the upper end face of the mounting bottom plate; an auxiliary propelling mechanism is arranged on the other side of the upper end face of the mounting bottom plate, and a polishing mechanism is mounted in the middle of the upper end face of the mounting bottom plate. Compared with the prior art, the device capable of conducting graded grinding and polishing on wood is high in mechanization degree, the workload of workers is reduced, meanwhile, the grinding and polishing efficiency of the wood is improved, the polishing effect of the surface of the wood can be stabilized, and the quality of the wood is improved. The situation that the wood surface polishing effect is not uniform during manual graded polishing is avoided, it is ensured that the wood plate face is even in polishing degree, and compared with one-time polishing, the graded polishing mode can further improve the precision of the wood plate face.

Owner:宿迁市浩远木业股份有限公司

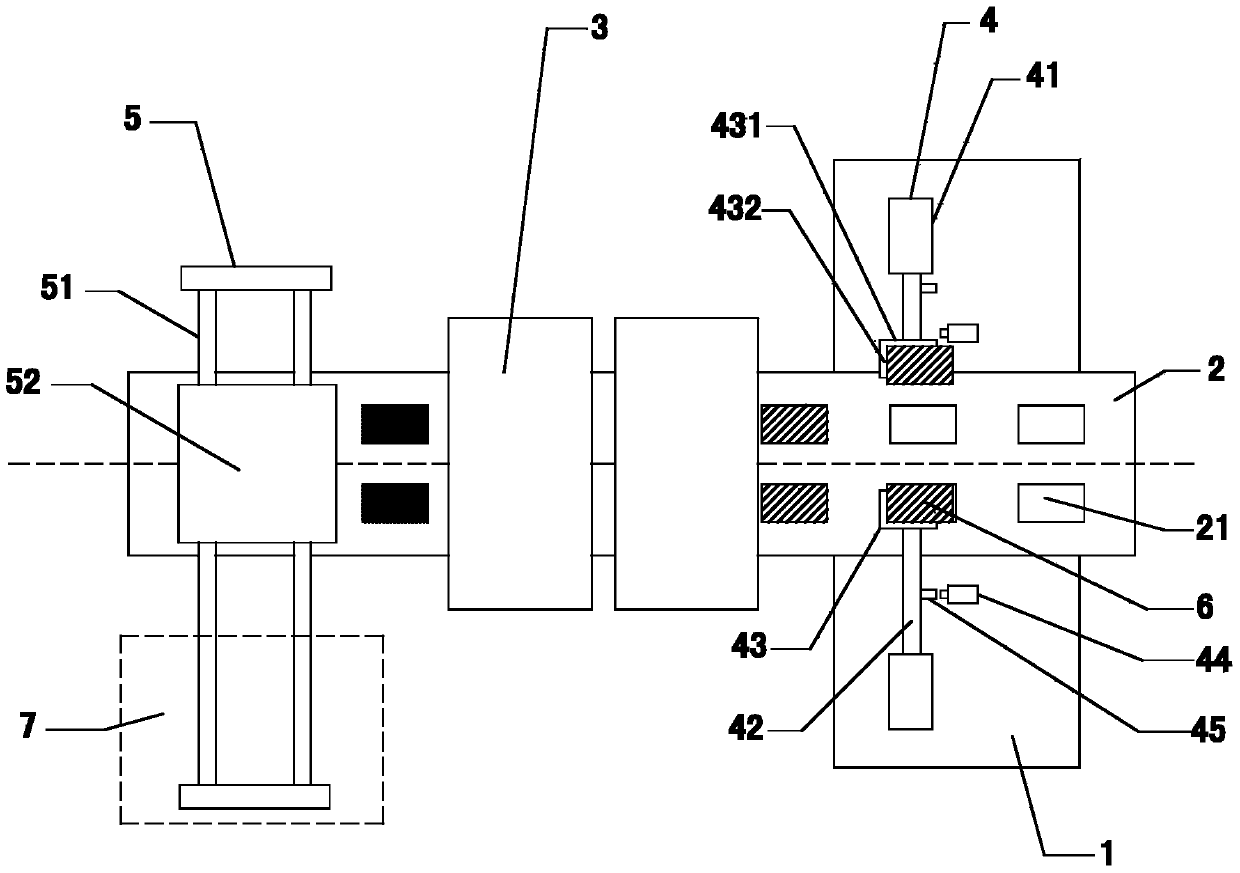

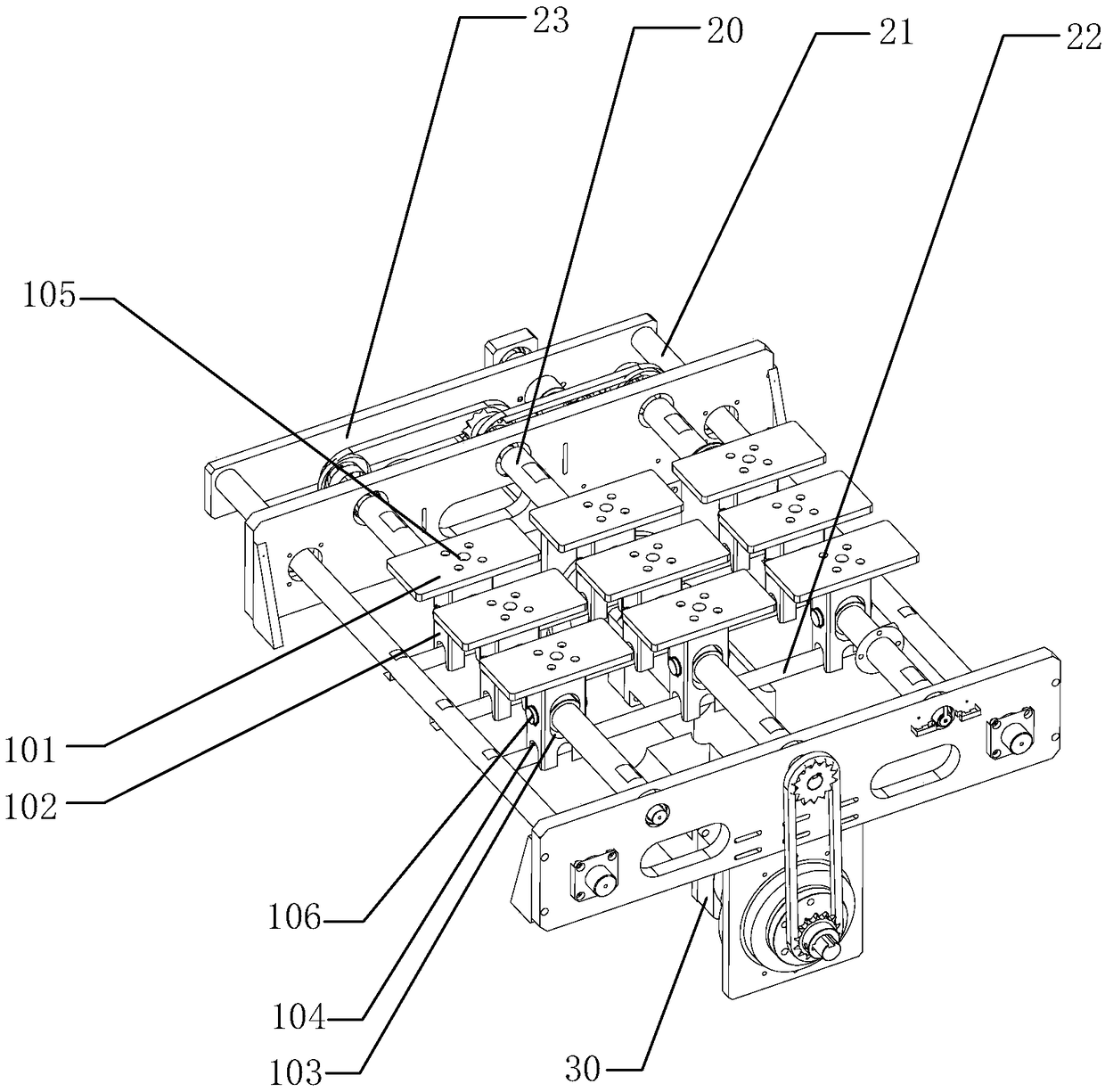

Automatic polishing machine

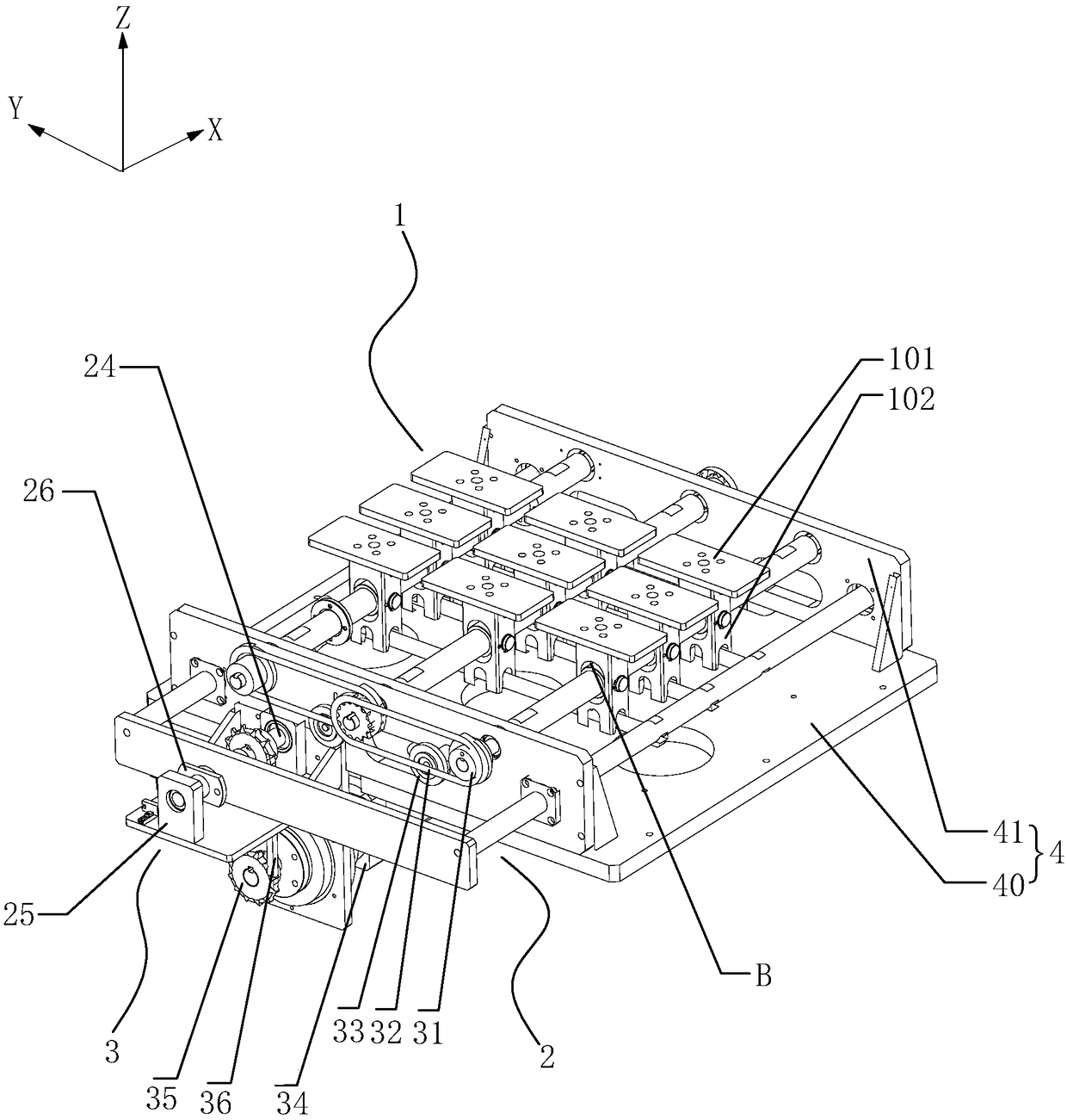

PendingCN108857843ASimple structureConsistent inclinationGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention relates to an automatic polishing machine. The automatic polishing machine comprises a jig mechanism, a polishing component and a machine frame. In a jig component, a link rod componentcomprises a plurality of rotating shafts and connecting rods installed along an X-direction, and a plurality of translation shafts installed along a Y-direction. A positioning piece support frame of aplurality of jigs is provided with first through holes in the X-direction and second through holes in the Y-direction. A plurality of the jigs is arranged in an opposite row and / or column. While therotating shafts pass through one column of the first through holes, and are rotated around an own center shaft through the action of a rotating driving component, the jigs are driven to be rotated andinclined around the rotating shaft. While the translation shafts pass through one row of the second through holes and are fixedly connected with the connecting rod, and the connecting rods are horizontally moved along the X-direction through the action of a translation driving component, the jigs are driven to be rotated and inclined around a hinging piece installed in the Y-direction, and a workpiece is polished by a polishing head component above the workpiece in an inclined process. The above automatic polishing machine is simple in structure, and capable of adjusting the multiple jigs andenabling the jigs to be simultaneously inclined, wherein an inclined degree is consistent, so an arc chamfering edge or a cambered surface with good quality is obtained.

Owner:深圳市五力波智能科技有限公司

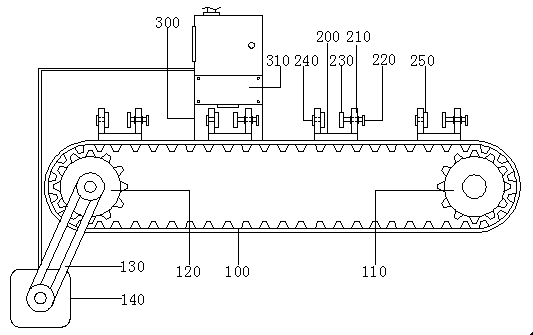

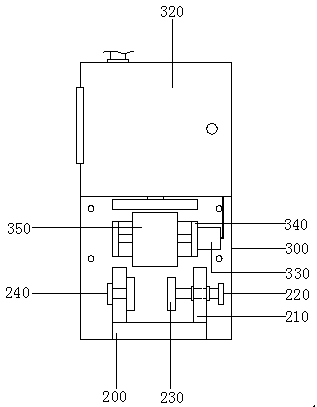

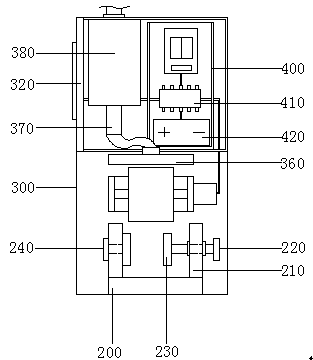

Hardware timed polishing device

InactiveCN110640583AUniform polishing effectEnsure safetyAutomatic grinding controlGrinding machinesFrequency conversionPolishing

The invention belongs to the technical field of processing devices and particularly relates to a hardware timed polishing device which comprises a conveyor belt, a polishing plate, a control box and an inner box, wherein the polishing plate is fixedly connected with the top of the conveyor belt through a screw; and the top of the polishing plate is in contact with the control box. According to thehardware timed polishing device, through combination utilization of components, the inner box comprising a frequency conversion controller can be utilized to control a primary motor to be started; after driving a primary wheel and a secondary wheel, the polishing plate on the conveyor belt can move step by step; the frequency conversion controller can carry out timed control on a secondary motorto enable a polishing wheel to realize the timed polishing purpose; the timed purpose is effectively realized while processing hardware on batches, so that the polishing effect of the hardware tends to be unified, and the labor intensity and the reworking probability are lowered; and a suction plate is cooperated with an interior sucking pump to filter and transfer powder and chippings generated during the polishing process, so that the safety of the polishing environment is ensured, and the life harm is reduced.

Owner:徐州恒永电子科技有限公司

Control arm polishing liquid material composite and preparing method and application of control arm polishing liquid

The invention discloses a control arm polishing liquid material composite and a preparing method and application of control arm polishing liquid. The composition comprises phosphoric acid, sulfuric acid, oxalic acid, glycerol, nanometer aluminum oxide, nanometer calcium oxide and zinc nitrate and includes, by weight, 10-30 parts of sulfuric acid, 5-20 parts of oxalic acid, 1-10 parts of glycerol, 1-5 parts of nanometer aluminum oxide, 1-5 parts of nanometer calcium oxide and 3-20 parts of zinc nitrate relative to 100 parts of phosphoric acid. By means of the design, after control arms are soaked, the glossiness of the surfaces of the control arms can be greatly and effectively improved, the control arms are well polished, manual labor is omitted, cost of manual operation is greatly reduced, the polishing effect of the control arms can be consistent through soaking, and the problem that the quality of the manufactured control arms is inconsistent is avoided.

Owner:ANHUI LUOSHI SHENGTAI AUTO PARTS

Arc blade-shaped processing surface structure of pad conditioner and manufacturing mold structure thereof

InactiveUS20130171917A1Improve polishing efficiencyUniform polishing effectGrinding drivesConfectioneryEngineeringSurface structure

An arc blade-shaped processing surface structure of a pad conditioner includes an outer frame, a combining layer and a plurality of polishing particles. The polishing particles are disposed on a surface of the combining layer, and the combining layer has a first region and a second region sequentially arrange from the center to the outside of the combining layer, and the second region has a plurality of arc-shaped protrusions arranged separately from one another and disposed around the external periphery of the first region, and the protrusions arranged in order and separated with an interval apart from each other can be used to provide an appropriate space for extension and rebound for a polished surface material to obtain a definite and uniform polishing effect.

Owner:HUANG HUANG NAN +1

Profile steel pipe body polishing device

InactiveCN112589659AAchieve polishing workPrevent exposure to hazardsGrinding carriagesPolishing machinesElectric machinePolishing

The invention discloses a profile steel pipe body polishing device. The device comprises a base, a first supporting column, a second supporting column, a first rotary fixing sleeve, a second rotary fixing sleeve, a driving motor and a polishing mechanism, wherein the first supporting column and the second supporting column are vertically arranged on the upper surface of the base in parallel, the first rotary fixing sleeve is rotatably arranged in the middle of the first supporting column, the second rotary fixing sleeve matching the first rotary fixing sleeve is arranged in the middle of the second supporting column, the driving motor is further arranged on the side face of the first supporting column, an output shaft on the driving motor is coaxially and fixedly connected with one end ofthe first rotary fixing sleeve so as to drive the first rotary fixing sleeve to rotate, and the polishing mechanism is arranged on a back plate on the upper surface of the base and can freely slide inthe horizontal direction. By means of the device, the problems that in the prior art, the safety of manual polishing cannot be guaranteed, polishing is uneven, and polishing missing is likely to happen are solved.

Owner:芜湖司毛特机械制造有限公司

Polishing machine

The invention provides a polishing machine which comprises a fixed support, a conveying system, polishing systems and cleaning systems, wherein the conveying system, the polishing systems and the cleaning systems are connected to the fixed support, the cleaning systems are behind the polishing systems, and the conveying system is positioned under the cleaning systems and the polishing systems; the conveying system comprises a conveying belt and a conveying driving component, and the conveying belt does step-by-step cycling movement; each polishing system comprises a polishing driving component, a driving wheel, a driven wheel and a polishing abrasive belt, and the polishing abrasive belt is tensioned to attach to the driving wheel and the driven wheel; each cleaning system comprises a circular brush and a cleaning driving component; the distance between the polishing systems and the cleaning systems is matched with the step distance of the conveying belt, and the cleaning systems and the polishing systems are the same in number. The polishing machine has the advantages of being simple in structure and convenient to use and can roughly polish, finely polish and clean polished pieces, secondary polishing and cleaning are avoided, and the working efficiency is improved.

Owner:TIANJIN LYVCHUAN TECH CO LTD

Electric pneumatic adjustable flexible polishing tool

InactiveCN100402235CPrecise control of removal volumeImprove polishing efficiencyFlexible-parts wheelsBurnishing machinesAir cellElectric machinery

The invention relates to an electric pressure adjustable flexible furnish device, which comprises: a support and an air cell, wherein the front end of air cell has furnish cloth as working surface; said air cell is mounted on the air cell holding support which is mounted on the front part of one rotation axle; said rotation axle via transmission axle is connected to the output axle of motor; the back end of rotation axle is connected to the rotation air connector; the connector and the air feeding tube are connected and fixed on the support; the connector, rotation axle, and air cell holding support are all hollow; the connector, rotation axle and the chamber of holding support form the airflow channel. The invention has high furnishing efficiency and high furnishing quality, with online control.

Owner:ZHEJIANG UNIV OF TECH

Curved surface turbulence polishing device with pressure equalization groove

ActiveCN103612166BCauses uneven polishingSpeed up the flowPolishing machinesParticle flowArtificial joints

The invention provides a cambered turbulence polishing device with pressure equalizing grooves. The cambered turbulence polishing device comprises a constraint component which is arranged outside an artificial joint in a sleeved mode. The inner surface of the constraint component and the outer surface of the artificial joint are identical in shape. A profiling runner is arranged between the inner surface of the constraint component and the outer surface of the artificial joint. At least two sets of abrasive particle flow inlets and outlets are arranged in the constraint component. Grooves are arranged in the peripheries of the abrasive particle flow inlets and outlets to form the pressure equalizing grooves. The pressure equalizing grooves are distributed in the inner surface of the constraint component. The pressure equalizing grooves in the two adjacent abrasive particle flow inlets and outlets are mutually communicated. According to the cambered turbulence polishing device, the profiling runner for controlling abrasive particle flow is arranged through the constraint component, multiple sets of abrasive particle flow inlets and outlets are arranged in the constraint component, and a complex cambered surface is machined in a segmented mode, so the condition that the abrasive particle flow encounters resistance at inflection points or singular points of the cambered surface to cause uneven polishing is avoided. The pressure equalizing grooves are arranged in the peripheries of the abrasive particle flow inlets and outlets, so that pressure is evenly distributed on the inner surface of the constraint component, and the problem of high-pressure interference at the abrasive particle flow inlets is solved to some extent. Therefore, the cambered turbulence polishing device with the pressure equalizing grooves is good in polishing effect and high in precision.

Owner:NANTONG EXPEDITIONICESOURCE REFRIGERATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com