Efficient electrochemical polishing device and method for outer surface of tungsten pipe

A polishing device and outer surface technology, applied in the field of electrochemical polishing, can solve the problems of large difference in polishing degree, low polishing efficiency, different polishing effect and efficiency, etc., achieve consistent polishing effect, ensure polishing quality, and shorten polishing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

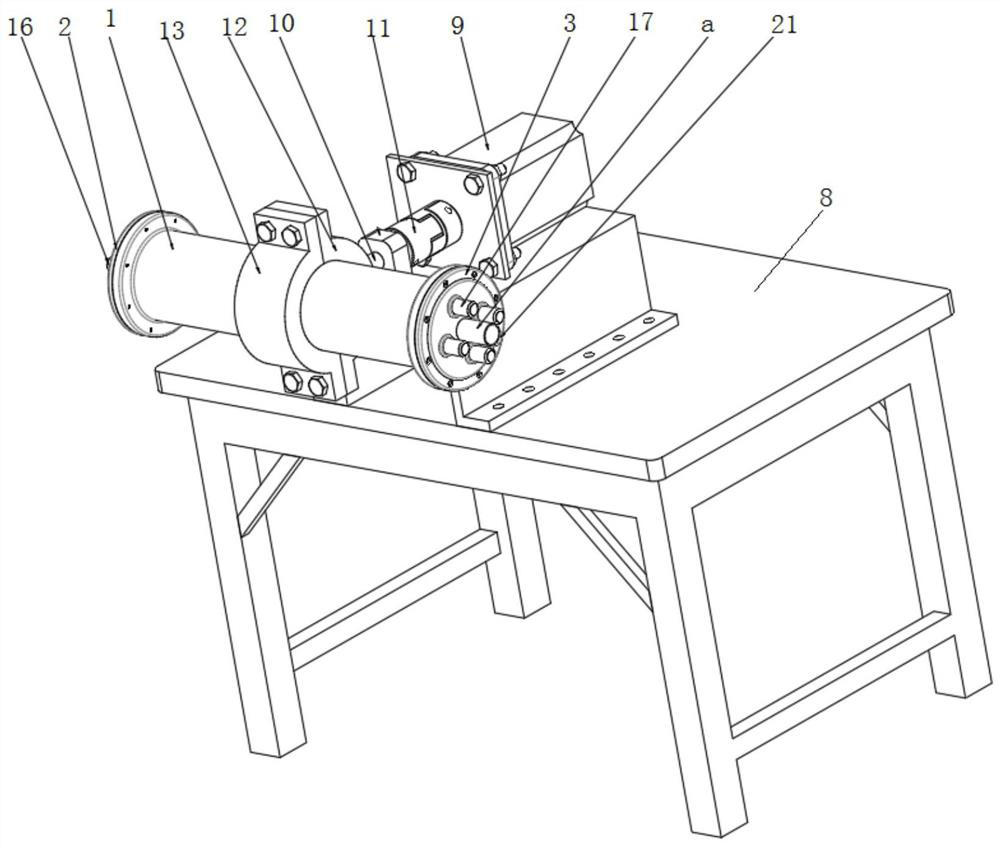

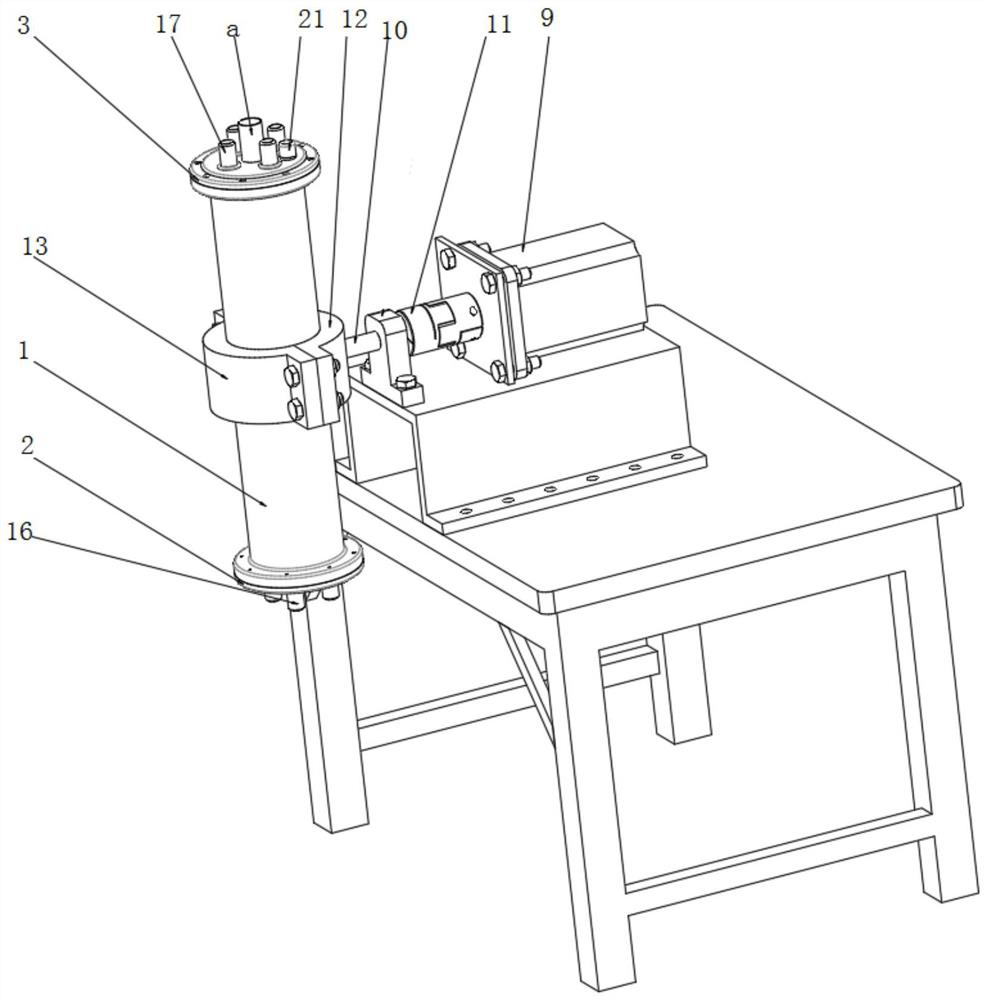

[0032] refer to Figure 1-Figure 6 , the present invention proposes a high-efficiency electrochemical polishing device for the outer surface of a tungsten tube, including a cathode conductive cylinder 1, a conductive part and a fixture; wherein:

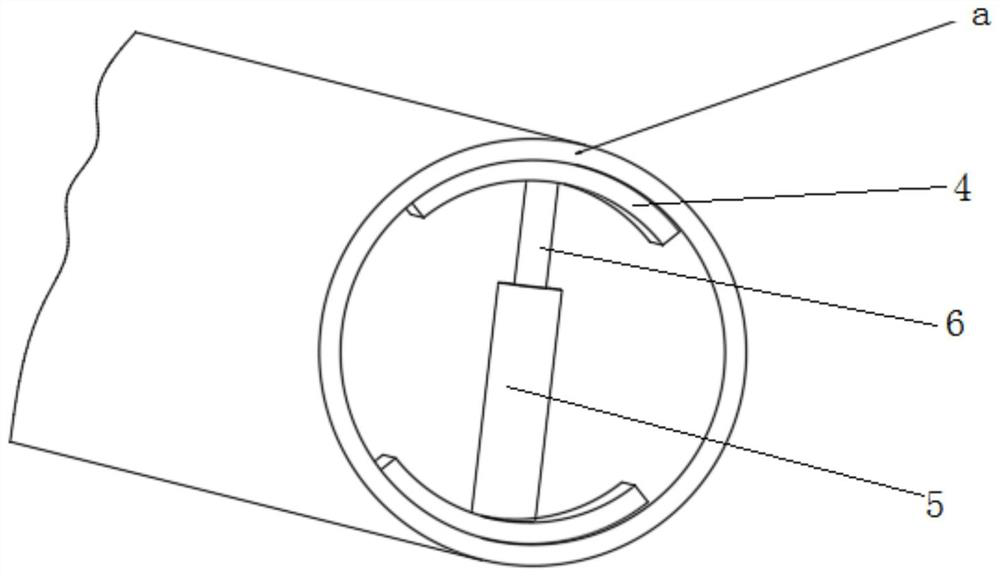

[0033] The interior of the cathode conductive cylinder 1 is hollow and its two ends are open. The openings at both ends of the cathode conductive cylinder 1 are respectively equipped with a liquid inlet end cover 2 and a liquid outlet end cover 3 for sealing it. The liquid inlet pipe 16 connected to the conductive cylinder 1 and the first jack is provided on the liquid inlet end cap 2, and the liquid outlet pipe 17 connected to the cathode conductive cylinder 1 is installed on the liquid outlet end cap 3, and the liquid outlet end cap 3 is provided with a There is a second socket, the central axis of the first socket coincides with the central axis of the second socket, the pipe to be polished a is set in the cathode conductive cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com