Aluminum alloy cylinder body and ceramic treatment method thereof

A processing method and aluminum alloy technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of many casting defects, high manufacturing cost, failure to reach the cylinder body, etc., and achieve excellent lubricating performance and use The effect of long life and no discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

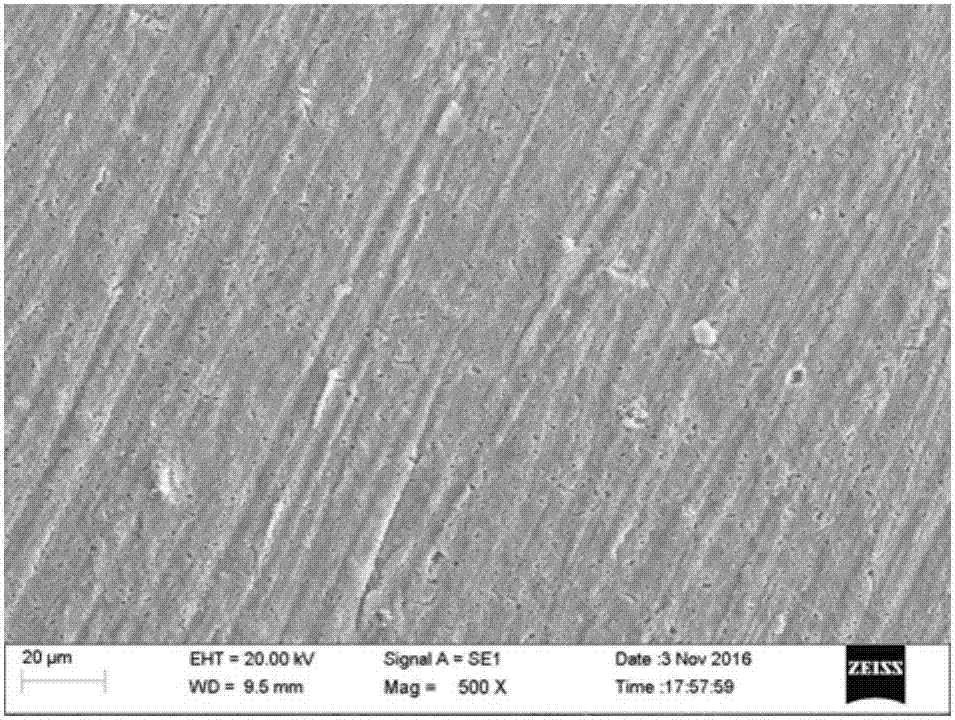

Embodiment 1

[0031] This embodiment provides an aluminum alloy cylinder body, which is mainly processed by the following methods:

[0032] The air intake hole and exhaust hole of the cylinder block are closed with corks, and the combined cathode is installed at the center of the cylinder block. Start the circulation pump, input the electrolyte in the electrolytic cell into the liquid storage tank, and then connect it to the cylinder. The electrolyte flows out through the spark plug hole on the upper part of the cylinder block, and then returns to the electrolytic tank through the overflow tank.

[0033] Wherein, the electrolyte includes: sodium hexametaphosphate, film forming agent and potassium carbonate. The dosage ratio of sodium hexametaphosphate and film forming agent is 8g / L:1g / L. The pH of the electrolyte is 8. The film-forming agent includes potassium titanium oxalate and sodium oxalate in a mass ratio of 8:1.

[0034] The positive pole of the micro-arc oxidation power supply i...

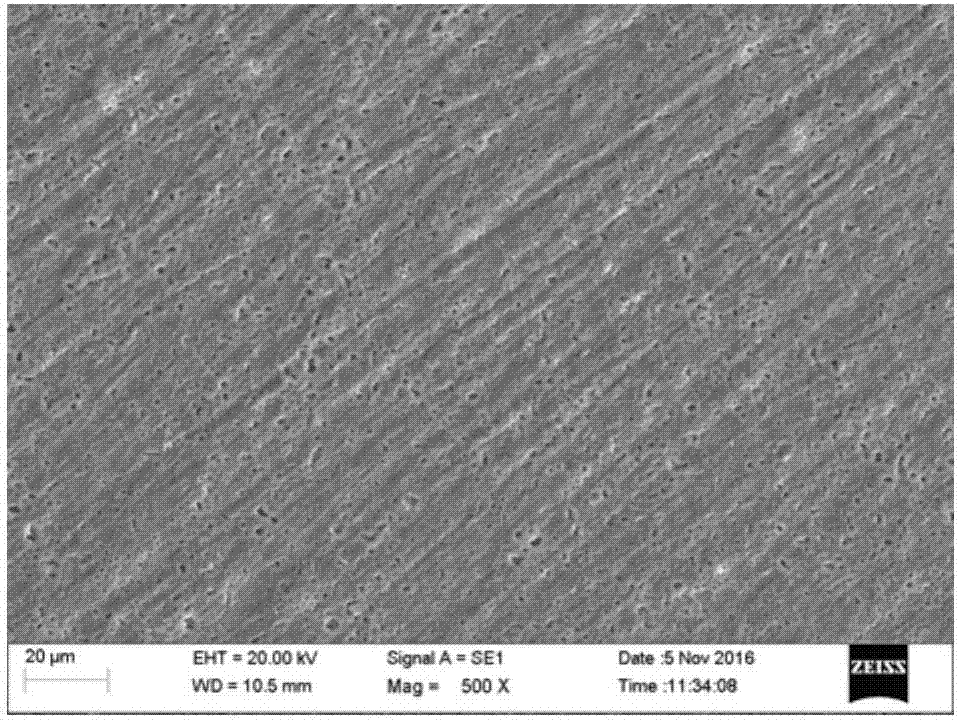

Embodiment 2

[0036] This embodiment provides an aluminum alloy cylinder body, which is mainly processed by the following methods:

[0037] The air intake hole and exhaust hole of the cylinder block are closed with corks, and the combined cathode is installed at the center of the cylinder block. Start the circulation pump, input the electrolyte in the electrolytic cell into the liquid storage tank, and then connect it to the cylinder. The electrolyte flows out through the spark plug hole on the upper part of the cylinder block, and then returns to the electrolytic tank through the overflow tank.

[0038] Wherein, the electrolyte includes: sodium hexametaphosphate, film forming agent and sodium carbonate. The dosage ratio of sodium hexametaphosphate and film forming agent is 50g / L:7g / L. The pH of the electrolyte was 9. The film-forming agent includes potassium titanium oxalate and sodium oxalate in a mass ratio of 12:1.

[0039]The positive pole of the micro-arc oxidation power supply is...

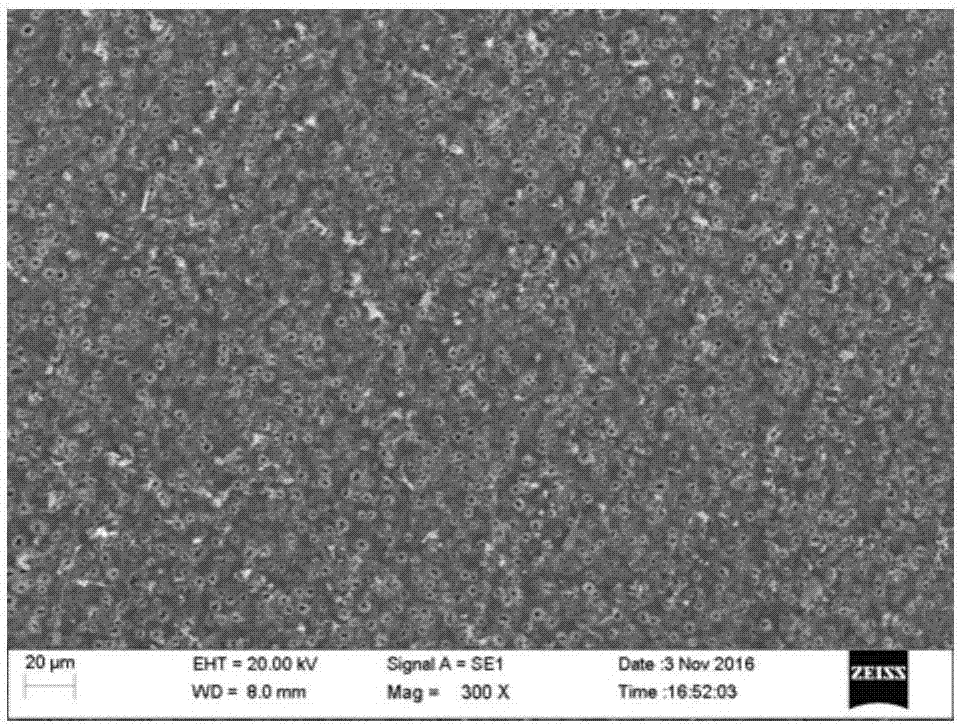

Embodiment 3

[0042] This embodiment provides an aluminum alloy cylinder body, which is mainly processed by the following methods:

[0043] The air intake hole and exhaust hole of the cylinder block are closed with corks, and the combined cathode is installed at the center of the cylinder block. Start the circulation pump, input the electrolyte in the electrolytic cell into the liquid storage tank, and then connect it to the cylinder. The electrolyte flows out through the spark plug hole on the upper part of the cylinder block, and then returns to the electrolytic tank through the overflow tank.

[0044] Wherein, the electrolyte includes: sodium hexametaphosphate, film forming agent, sodium carbonate, potassium carbonate and sodium hydroxide. The dosage ratio of sodium hexametaphosphate and film forming agent is 40g / L:7g / L. The pH of the electrolyte is 8. The film-forming agent includes potassium titanium oxalate and sodium oxalate at a mass ratio of 9:1.

[0045] The positive pole of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com