Intelligent flexible polishing method for non-spherical optical element and intelligent flexible polishing device adopted for intelligent flexible polishing method

A technology of intelligent flexible and optical components, applied in grinding/polishing safety devices, optical surface grinders, grinding/polishing equipment, etc., can solve the problems of precision machining and processing efficiency restricting the wide development and application of aspheric surfaces, and achieve structural Compact, precisely polished influence function, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

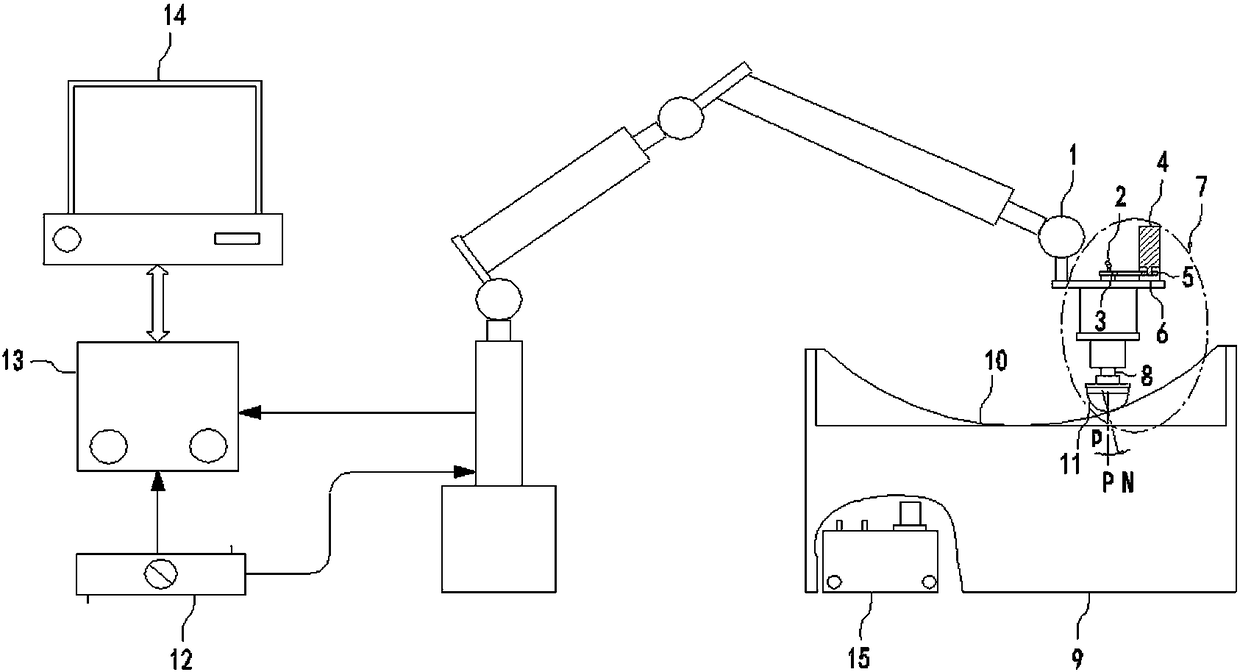

[0028] As shown in the figure, the intelligent flexible polishing method for aspheric optical elements can be implemented as follows:

[0029] (1) The robot scans the workpiece through the sensor to collect the feature information of the workpiece;

[0030] (2) The robot control system determines the theoretical polishing trajectory according to the data collected in step (1);

[0031] (3) The polishing mechanism drives the polishing airbag to move on the surface of the workpiece along the theoretical polishing track described in step (2). By controlling the corresponding process parameters on the surface of the workpiece, the amount of material removal at each point on the surface of the optical element is accurately controlled;

[0032] (4) The robot control system controls the surface error of the workpiece through multiple iterations, and finally completes the polishing operation.

[0033] According to the requirements of the surface shape and roughness of the polished curved surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com