Polishing device and polishing method of aspheric optical element

A technology of optical components and polishing devices, which is applied in the direction of optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems that aspheric optical components are difficult to process, polishing tools cannot match the workpiece, etc., and achieve uniform surface of the workpiece to be processed. Improved material removal rate and high surface shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

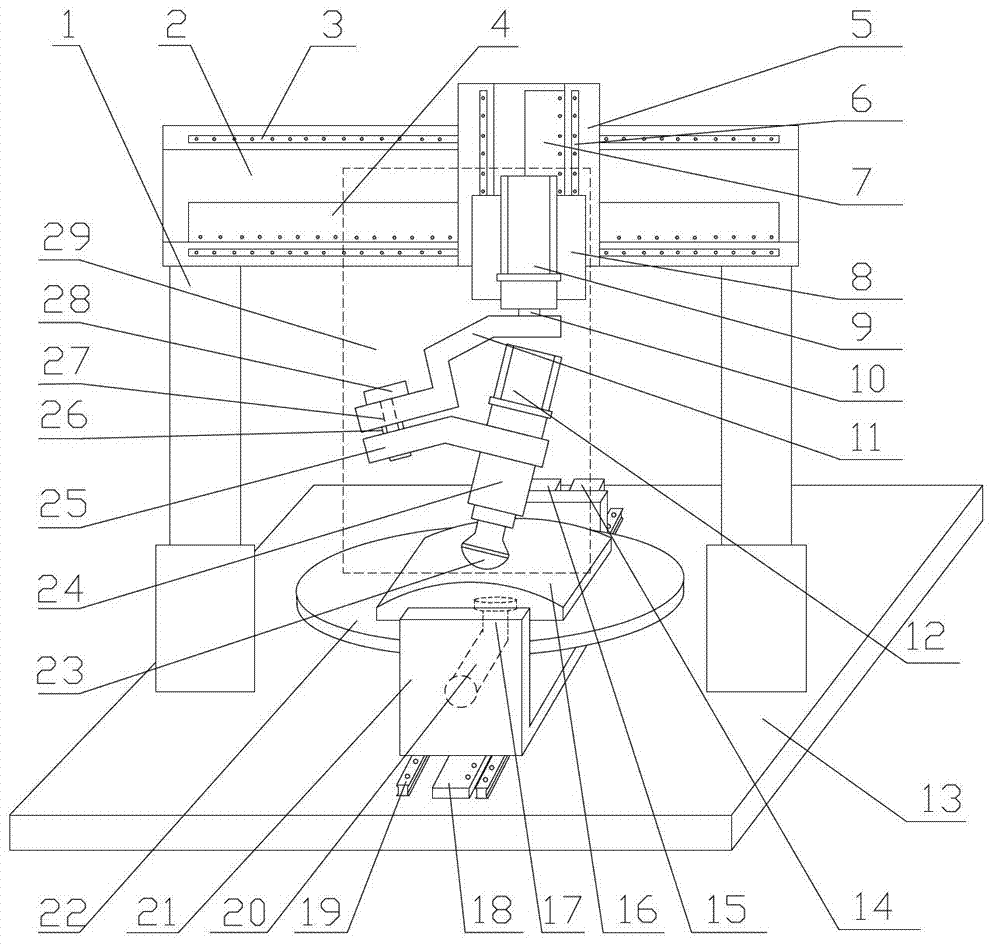

[0028] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0029] The technical solution of the present invention is described below by taking the polishing of an axisymmetric aspheric surface as an example. Of course, the present invention is not limited to the polishing of an axisymmetric aspheric optical element, and can be extended according to the processing needs of different workpieces.

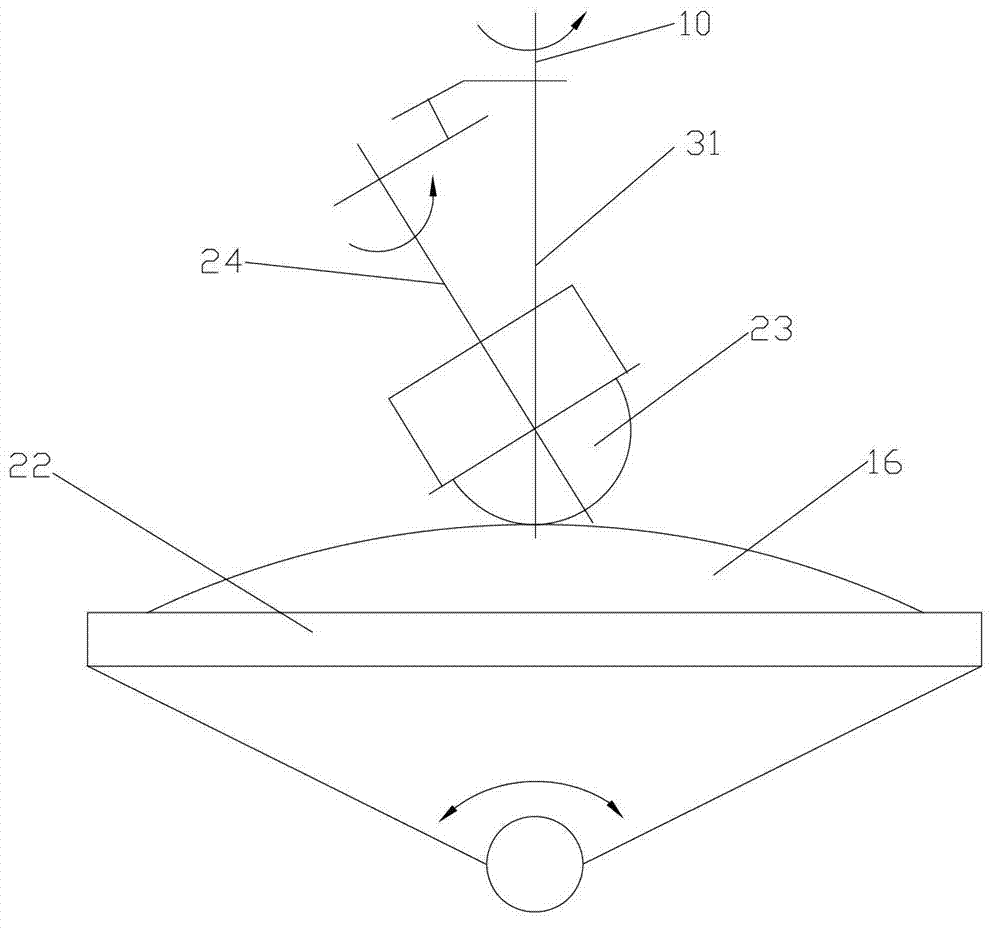

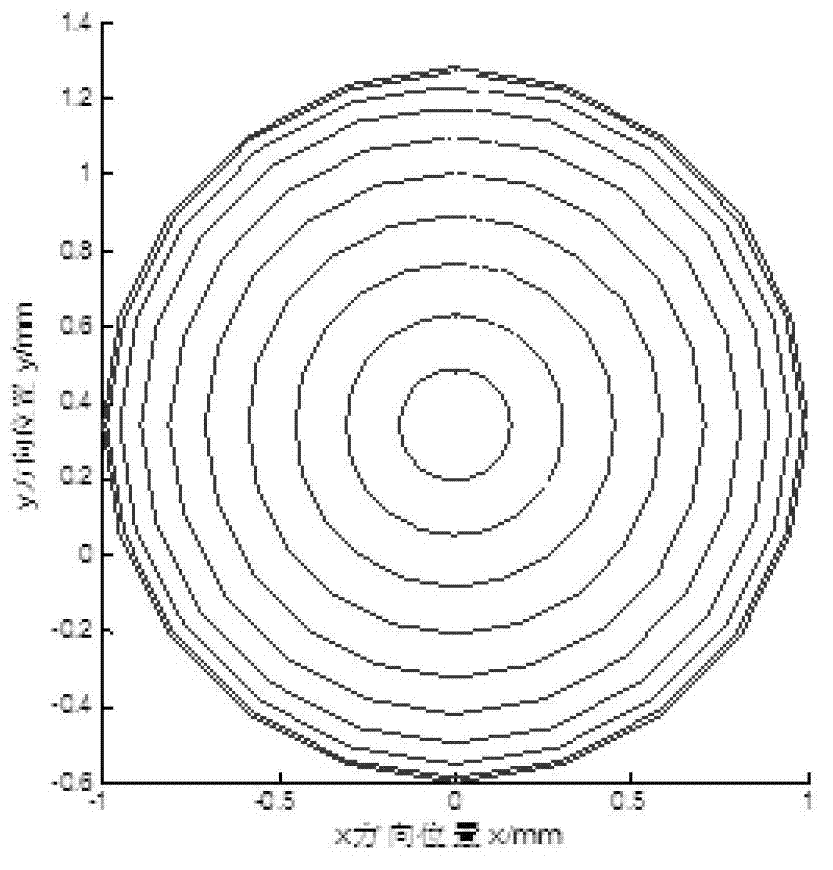

[0030] Due to the rotational symmetry of the axisymmetric aspheric optical element and the rotatable workbench of the polishing device of the present invention, the airbag tool only needs to walk half of a generatrix of the axisymmetric aspheric optical element to process the workpiece.

[0031] see figure 1 with 2 , the embodiment of the present invention is provided with a base 13, a workbench rotation drive motor 14, a workbench turning drive motor 15, a workbench rotation shaft 17, a Y-axis linear motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com