Self-driving air sac pressure controlled flexible furbisher

A flexible polishing and self-driving technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low polishing efficiency, inability to perform online control, and low polishing quality of polishing tools, and achieve automatic polishing. Stable polishing force and high polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

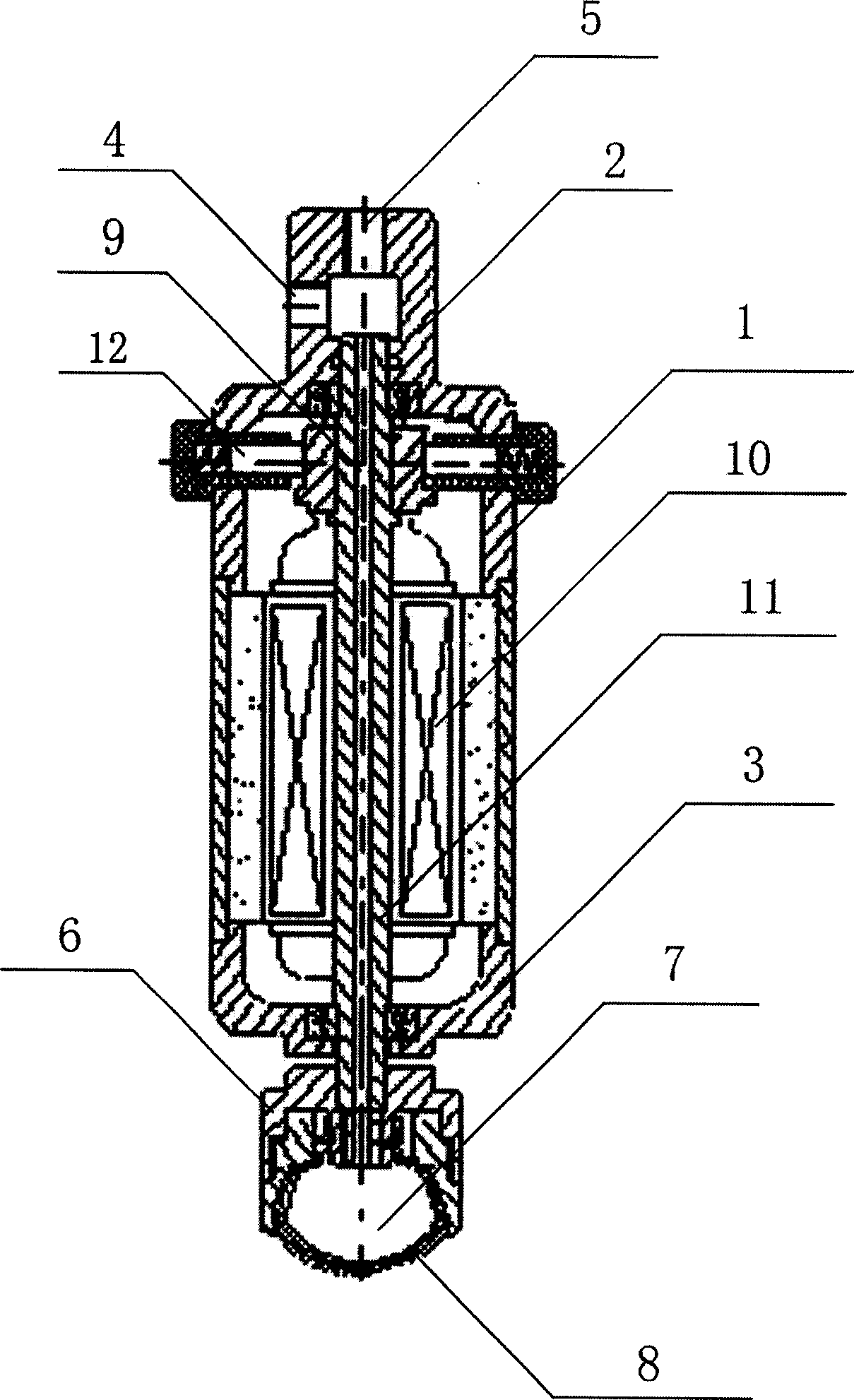

[0020] refer to figure 1 , a self-driven airbag pressure-controlled flexible polishing tool, the polishing tool includes an airbag 7, the front end of the airbag 7 has a polishing cloth 8 as a working surface, and the airbag 7 is installed in a cage 6; It also includes a rotary drive mechanism to rotate the cage. The rotary drive mechanism 10 is an electric motor. The motor includes a casing 1, a rear end cover 2, a front end cover 3, and a lead-in terminal 12. The rear end cover 2 is sealed and connected to the casing 1, the front end cover 2 is sealingly connected to the other end of the housing 1; the cage 6 is connected to the output shaft 11 of the motor, and the air bag 7 is connected to the inlet 4 of the external air source. The output shaft 11 of the motor is a hollow tube, which is used as the airflow channel connecting the air bag 7 to the inlet 4 of the external air source; the inlet 4 of the external air source and the overflow valve 5 are installed on the rear en...

Embodiment 2

[0023] refer to figure 1 , a self-driven airbag pressure-controlled flexible polishing tool, the polishing tool includes an airbag 7, the front end of the airbag 7 has a polishing cloth 8 as a working surface, and the airbag 7 is installed in a cage 6; It also includes a rotary drive mechanism that rotates the cage. The rotary drive mechanism 10 is an air motor. The air motor includes a housing 1, a rear end cover 2, a front end cover 3, and a lead-in terminal 12. The rear end cover 2 is sealed and connected At one end of the housing 1 , the front end cover 2 is hermetically connected to the other end of the housing 1 ; the cage 6 is connected to the output shaft 11 of the air motor, and the air bag 7 is connected to the inlet 4 of the external air source. The output shaft 11 of the air motor is a hollow tube, which is used as the air flow channel connecting the air bag 7 to the inlet 4 of the external air source; the inlet 4 of the external air source and the overflow valve 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com